机械合金化和真空热压烧结FeCoCrNiMn高熵合金的显微组织和力学性能

来源期刊:中国有色金属学报(英文版)2018年第7期

论文作者:程虎 谢炎崇 唐群华 饶聪 戴品强

文章页码:1360 - 1367

关键词:高熵合金;显微组织;力学性能;粉末冶金

Key words:high-entropy alloys; microstructure; mechanical properties; powder metallurgy

摘 要:采用机械合金化和热压烧结制备FeCoCrNiMn高熵合金。结果表明,采用机械合金化得到纳米晶合金粉末,粉末相结构由面心立方结构(FCC)相以及少量的体心立方结构(BCC)相和非晶相组成。热压烧结后,合金中BCC相基本消失,同时伴随着σ相和M23C6相的析出;烧结温度的升高导致析出相颗粒明显长大。随着热压烧结温度从700 °C升高到1000 °C,合金塑性应变从4.4%增加到38.2%,而屈服强度从1682 MPa下降到774 MPa。经800 °C和 900 °C烧结1 h的FeCoCrNiMn高熵合金具有较好的综合力学性能。

Abstract: FeCoCrNiMn high-entropy alloys were produced by mechanical alloying (MA) and vacuum hot pressing sintering (VHPS). Results showed that the nano-crystalline alloy powders were obtained by MA and the corresponding phase structures were composed of FCC matrices and low amounts of BCC and amorphous phases. After VHPS, the BCC phases almost disappeared, simultaneously with the precipitation of σ phases and M23C6 carbides. An increase of sintering temperature resulted in grain growth of the precipitated phases. As the sintering temperature was increased from 700 to 1000 °C, the strain-to-failure of the alloys rose from 4.4% to 38.2%, whereas the yield strength decreased from 1682 to 774 MPa. The bulk FeCoCrNiMn HEAs, consolidated by VHPS at 800 °C and 900 °C for 1 h, showed relatively good combination of strength and ductility.

Trans. Nonferrous Met. Soc. China 28(2018) 1360-1367

Hu CHENG1,2, Yan-chong XIE1, Qun-hua TANG3, Cong RAO4, Pin-qiang DAI1,4

1. School of Materials Science and Engineering, Fuzhou University, Fuzhou 350116, China;

2. School of Mechanical Engineering, Taizhou University, Taizhou 318000, China;

3. School of Mechanical & Electrical Engineering, Putian University, Putian 351100, China;

4. School of Materials Science and Engineering, Fujian University of Technology, Fuzhou 350118, China

Received 1 March 2017; accepted 28 May 2017

Abstract: FeCoCrNiMn high-entropy alloys were produced by mechanical alloying (MA) and vacuum hot pressing sintering (VHPS). Results showed that the nano-crystalline alloy powders were obtained by MA and the corresponding phase structures were composed of FCC matrices and low amounts of BCC and amorphous phases. After VHPS, the BCC phases almost disappeared, simultaneously with the precipitation of σ phases and M23C6 carbides. An increase of sintering temperature resulted in grain growth of the precipitated phases. As the sintering temperature was increased from 700 to 1000 °C, the strain-to-failure of the alloys rose from 4.4% to 38.2%, whereas the yield strength decreased from 1682 to 774 MPa. The bulk FeCoCrNiMn HEAs, consolidated by VHPS at 800 °C and 900 °C for 1 h, showed relatively good combination of strength and ductility.

Key words: high-entropy alloys; microstructure; mechanical properties; powder metallurgy

1 Introduction

The high-entropy alloys (HEA), composed of at least five principle components with nearly equiatomic concentrations, constitute a relatively new class in metallic materials. Compared with the traditional alloys, the HEAs exhibit the effects of multi-principal elements, which are proven to be mainly the high-entropy effects in thermodynamics, slow diffusion effects in kinetics, severe lattice distortion effects in structure and “cocktail effects” in performance [1]. Through rational component and technology design, HEA could demonstrate excellent comprehensive properties, such as high strength, hardness and distinct thermal stability [2,3].

Among HEA systems, the equiatomic FeCoCrNiMn HEA is a typical kind of solid solution alloy with the face centered cubic (FCC) structure. It has been commonly utilized as the ideal model for grain growth, diffusion, dislocation behavior, and texture evolution study of HEA with FCC structure [4-6]. The alloy demonstrates remarkable work hardening capacity at both room and cryogenic temperatures, and thus high ductility [7,8]. Moreover, the alloy has extremely high fracture toughness at room and cryogenic temperature, exceeding fracture toughness of the most other materials [5]. But, the alloy has relatively low yield strength.

Several approaches can be used to improve the yield strength of the FeCoCrNiMn alloy. One of them is the microstructure refinement through a thermomechanical treatment. Due to high Hall-Petch coefficient of this alloy [7,9], producing the fine recrystallized micro- structure by hot/warm working [10] or cold working with subsequent annealing [4,11-14] can effectively increase the yield strength of the alloy [7]. Another approach is to modify the chemical composition of the alloy by introducing additional alloying elements such as Al [15,16] or C [17,18]. These alloying elements also result in a significant strengthening of the alloy.

These FeCoCrNiMn HEAs as mentioned above have been produced mainly by arc melt/casting. But these fabrication routes are unsuitable for industrial manufacturing due to the disadvantages of diseconomy and limitations in shape and size of final products [19]. By contrast, powder metallurgy is a more convenient way. This process for preparing HEA includes two steps, that is, mechanical alloying (MA) and sintering. Nano-crystalline HEA powders with uniform components can be prepared by MA. Combined with the subsequent sintering, bulk HEAs with ultra-fine or nano grain sizes can be easily obtained from the as-milled powders [20-22].

JI et al [22] utilized MA and spark plasma sintering (SPS) technology to successfully prepare the nano- crystalline FeCoCrNiMn HEA. The compressive strength of the alloy is up to 1987 MPa, which is obviously higher than that of the alloys produced by arc melt/casting, but at the expense of dramatically reduced ductility (the strain-to-failure is only ~7%). In addition, the SPS equipment used to consolidate the alloy is expensive, thus resulting in high cost for preparing the alloy. Therefore, in this work, the relatively economic technology, vacuum hot pressing sintering (VHPS), is used to consolidate FeCoCrNiMn HEA. Since the rational selection of processing parameters, such as sintering temperature, is crucial for the regulation of microstructure and mechanical properties of the alloy, this work is focused mainly on the effect of VHPS temperatures on the microstructure and mechanical properties of the alloy, which is expected to provide the guide for technology optimization of the alloy synthesis.

2 Experimental

A high-energy planetary ball mill (QM-QX4L, Changsha Miqi Instrument Equipment Co., Ltd., China) was utilized for FeCoCrNiMn HEA powder preparation. Fe, Co, Cr, Ni and Mn metal powders of high purity (≥99.9%) were weighed in an equiatomic ratio and the average grain size of each metal powder was approximately 45 μm. Following grinding and uniform mixing, the powders were placed into a stainless steel vial for ball milling. The ball milling medium consisted of stainless steel balls (of 5, 10 and 15 mm in diameter) and the medium to material ratio was 15:1. The ball milling vial was sealed, evacuated and filled with high-pure argon, and the latter step was repeated 3 times for the air content to be removed as much as possible. The horizontal vial type was utilized for milling, the rotation speed was 250 r/min and the milling duration was 45 h. N-heptane was added during milling as a process controlling agent (PCA) for mechanical alloying in order for the cold welding effects to be reduced. The process was stopped every 5 h and little amount of powder samples was removed by a vial opening inside a vacuum glove box. The latter samples were for the following analytic tests to be conducted.

Differential thermal analysis of the 45 h milled alloy powders was conducted on a differential scanning calorimetry (DSC) analyzer (NETZSCH STA 449F3). The measurements were executed under a high-pure argon atmosphere with a heating rate of 10 °C/min, beginning from room temperature to 1200 °C, whereas a standard Al2O3 sample was utilized for the temperature and enthalpy calibration during heating. The 45 h-milled alloy powders were placed inside a tube furnace protected by an Ar atmosphere at temperatures between 500 and 700 °C with a heating rate of 8 °C/min and subsequently retained at the target temperature for 1 h.

VHPS was applied for these bulk alloys production. The alloy powders obtained from ball milling were firstly pretreated (100 °C for 10 h) for the PCA to be removed, consequently loaded into a graphite mold of 20 mm in diameter and the mold was placed inside a vacuum hot pressing furnace (ZT-40-20Y, Shanghai Chenhua Electric Furnace Co., Ltd., China) for sintering. According to DSC results of the alloy powders, the preselected sintering temperatures were 700, 800, 900 and 1000 °C, respectively. The heating rate was set to be 8 °C/min, the holding duration was 1 h, the pressure was retained at 50 MPa during sintering and the samples were cooled down inside the furnace.

The phase structures of the alloys were characterized by a X-ray diffractometer (Bruker D8, Germany) set at a scan rate of 2 (°)/min from 20° to 100°. The microstructure of the alloys were analyzed by a Hitachi S-200 type scanning electron microscope (SEM) with an accessory energy dispersive X-ray spectrometer (EDS) and a transmission electron microscope (TEM) with selected area electron diffraction (SAED), performed on a JEOL JEM-2100 (Tokyo, Japan) operated at 200 kV. The compressive properties at room temperature were measured by a MTS810 testing machine. The density of the bulk HEA was calculated with the Archimedes principle. The hardness of the bulk alloys was measured by a HXD-1000T micro-hardness tester. In order to ensure accuracy of the measurement results, each sample was tested 5 times and the mean values were calculated.

3 Results and discussion

3.1 Phases and microstructure

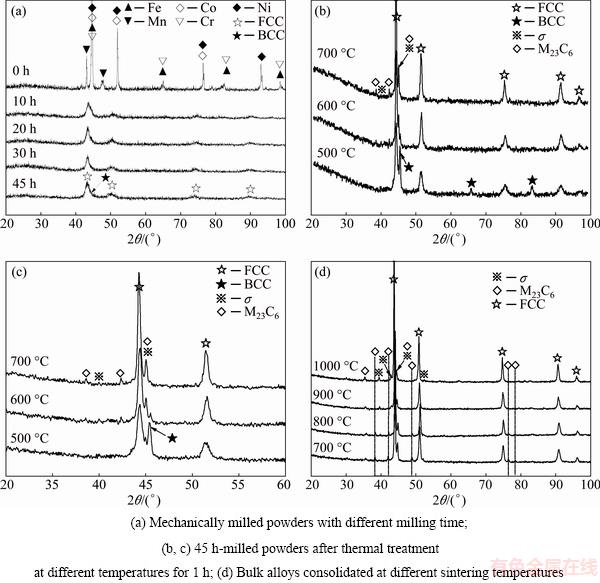

Fig. 1 XRD patterns

In Fig. 1(a), the XRD patterns of the alloys prepared with various ball milling durations are presented. Peaks corresponding to elemental Fe, Co, Cr, Ni and Mn were evident in the XRD pattern before milling. After 10 h of milling, the diffraction peak intensities decreased apparently with certain peaks having disappeared. As ball-milling duration reached 20 h, the diffraction peaks were broadened and the element peaks almost disappeared, indicating that the metal powder alloying was basically achieved. As the ball-milling duration was continuously extended to 45 h, the diffraction peaks were broadened further, the intensities of peaks became weaker further and a cellular morphology similar to non-crystalline structures was formed. Moreover, as the ball-milling duration increased, the crystalline size of alloy powders decreased gradually whereas the lattice parameters increased gradually (as presented in Table 1). After 45 h milling, the crystalline size and lattice parameter reached 11.4 nm and 3.616  , respectively. As linear broadening and linear asymmetry caused by crystal defects such as dislocation and twins were not considered during calculations, a deviation definitely existed between the calculated and the actual values; however, the variation trends of these parameters could still be reflected correctly. The XRD patterns of the 45 h-milled alloy powders following heat treatment are presented in Figs. 1(b) and (c). Regarding heat treatment at 500 °C, the diffraction peaks of BCC phases could be separated from FCC phase peaks with the highest intensity, whereas the weak precipitated phases (σ phase and Cr23C6 phase) diffraction peaks appeared. As the treatment temperature increased further, the BCC phase diffraction peaks disappeared gradually whereas the FCC phase peaks intensity increased gradually, accompanied by a gradual precipitation of the σ and Cr23C6 phases. Therefore, it could be inferred that the phase structure of the 45 h-milled alloy powders was the main FCC solid solution structures as matrices, in addition to low amounts of BCC sold solution structures and non-crystalline phases.

, respectively. As linear broadening and linear asymmetry caused by crystal defects such as dislocation and twins were not considered during calculations, a deviation definitely existed between the calculated and the actual values; however, the variation trends of these parameters could still be reflected correctly. The XRD patterns of the 45 h-milled alloy powders following heat treatment are presented in Figs. 1(b) and (c). Regarding heat treatment at 500 °C, the diffraction peaks of BCC phases could be separated from FCC phase peaks with the highest intensity, whereas the weak precipitated phases (σ phase and Cr23C6 phase) diffraction peaks appeared. As the treatment temperature increased further, the BCC phase diffraction peaks disappeared gradually whereas the FCC phase peaks intensity increased gradually, accompanied by a gradual precipitation of the σ and Cr23C6 phases. Therefore, it could be inferred that the phase structure of the 45 h-milled alloy powders was the main FCC solid solution structures as matrices, in addition to low amounts of BCC sold solution structures and non-crystalline phases.

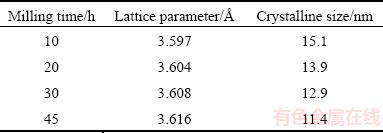

Table 1 Lattice parameter and crystalline size of FeCoCrNiMn alloy (FCC phase) with different milling time

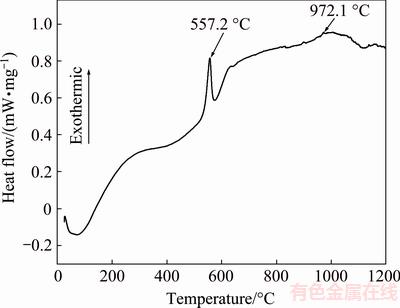

In Fig. 2, the thermal analysis curve of the 45 h-milled alloy is presented. A slow exothermic tendency appeared at lower temperatures. When the heating temperature was increased to 557 °C approximately, a strong exothermic peak (heat release of 0.815 mW/mg) was visible, and then the alloy exhibited a slow exothermic tendency again. The combination of thermal analysis and the afore-mentioned XRD analysis indicated the disappearance of BCC phases, precipitation of σ and Cr23C6 phases and the crystallization of non-crystalline phases in this stage [23]. As the temperature reached and exceeded 1000 °C, the alloys started to display a slow endothermic trend. In this stage, the metals with low melting points (such as Mn) began to absorb energy and the corresponding lattices collapsed until the alloys melt.

Fig. 2 DSC curve of 45 h mechanically-alloyed FeCoCrNiMn powders from room temperature to 1200 °C with heating rate of 10 °C/min

SEM morphology and EDS analysis result of the 45 h-milled alloy powders are presented in Fig. 3. During the milling, the alloy powders sustained repeated collisions, deformations, cold welding and smashing, finally reaching at a point of equilibrium between cold welding and smashing, with the formation of agglomeration structures presenting an irregular orientation [21,24,25]. After the 45 h milling, the alloy powders were composed of the aggregated particles of 20-50 μm in size (Fig. 3(a)). A particle was chosen randomly for EDS elemental analysis. The point scanning result indicated that the contents of the components in the alloys were approximately equiatomic, being basically consistent with the designed composition (Fig. 3(b)).

Fig. 3 SEM image (a) and EDS result (b) of 45 h-milled FeCoCrNiMn powders

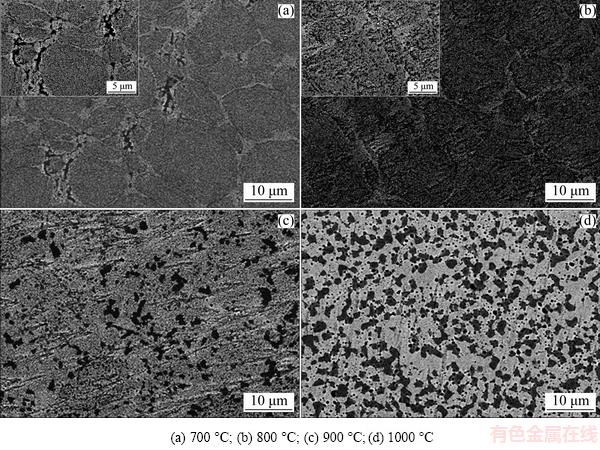

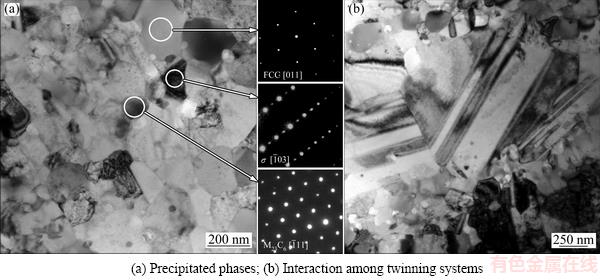

VHPS was utilized for bulk FeCoCrNiMn HEA preparation and the XRD pattern of the alloys sintered at various temperatures are presented in Fig. 1(d). It can be observed that, besides the formation of FCC solid solution phases, precipitated phases (such as σ and Cr23C6 phases) also existed apparently. However, JI et al [22] utilized SPS to prepare the bulk FeCoCrNiMn HEA, and the phase structure of the alloy was a single phase FCC, without precipitated phases. It was considered from the analysis that the short SPS sintering duration was probably not enough for the precipitation of σ phases or the precipitated amount was significantly low to be detected by regular methods such as X-ray diffractometry (XRD) and transmission electron microscopy (TEM). Compared with SPS, the long sintering duration of VHPS allowed the full diffusion of alloy elements during sintering, being favorable to precipitation of σ phases. As the sintering temperature was changed, there was an insignificant change in diffraction peak intensities of the alloy component phases. SEM morphology observations of the bulk alloy are presented in Fig. 4. The microstructure of alloy was composed of matrices, black bulk particles and fine pores. Combined with EDS and XRD analyses, it was proven that black bulk particles were the precipitated phases (as presented in EDS analysis, Cr 61.36, Mn 15.75, Fe 15.69, Co 7.04, Ni 0.16, molar fraction, %) and the matrices were FCC phases. Figure 5(a) shows a bright-field transmission electron microscope (TEM) image of the bulk FeCoCrNiMn HEA after VHPS at 800 °C for 1 h. It could be observed that there were two different sizes of grains, one was around 100-250 nm and the other one was approximately 50 nm. The selected-area electron diffraction (SAED) patterns of the precipitated phases are presented in Fig. 5(a), corresponding to a tetragonal structure along  and FCC structure along

and FCC structure along  , which confirmed again that the precipitated particles were σ phases and M23C6 carbides (where M=Cr, Mn, Fe), respectively. In addition, interaction among several twinning systems were also observed in some FCC solid solution grains, as shown in Fig. 5(b). Previous studies have shown that twins are readily formed in FCC phases of FeCoCrNiMn HEAs with low stacking fault energy [5,26]. As presented in Figs. 4(a)-(d), along with sintering temperature increasing, the particle sizes of precipitated phases increased gradually from the nano-scale (700 °C) to approximately 2 μm (1000 °C). The increase in sintering temperature enhanced the diffusion ability of alloying elements, leading to aggravated segregation. Interestingly, the re-dissolution of σ phases into FCC matrices during aging exceeding 800 °C, as reported [27,28], could not be observed in this work and high amounts of σ phases (Fig. 4(e)) were still distributed inside the bulk alloys after VHPS at 1000 °C for 1 h instead. Additionally, as sintering temperature increased, the sintered pores were gradually transformed from fine pores to larger ones, resulting in a gradual increase in the alloy densities (Table 2). At low sintering temperature (700 °C), the original aggregated particles by 45 h ball milling could be clearly observed. These particles could not aggregate completely and cracking phenomena occurred in large particles, indicating that the sintering temperature was significantly low and alloying elements did not diffuse completely.

, which confirmed again that the precipitated particles were σ phases and M23C6 carbides (where M=Cr, Mn, Fe), respectively. In addition, interaction among several twinning systems were also observed in some FCC solid solution grains, as shown in Fig. 5(b). Previous studies have shown that twins are readily formed in FCC phases of FeCoCrNiMn HEAs with low stacking fault energy [5,26]. As presented in Figs. 4(a)-(d), along with sintering temperature increasing, the particle sizes of precipitated phases increased gradually from the nano-scale (700 °C) to approximately 2 μm (1000 °C). The increase in sintering temperature enhanced the diffusion ability of alloying elements, leading to aggravated segregation. Interestingly, the re-dissolution of σ phases into FCC matrices during aging exceeding 800 °C, as reported [27,28], could not be observed in this work and high amounts of σ phases (Fig. 4(e)) were still distributed inside the bulk alloys after VHPS at 1000 °C for 1 h instead. Additionally, as sintering temperature increased, the sintered pores were gradually transformed from fine pores to larger ones, resulting in a gradual increase in the alloy densities (Table 2). At low sintering temperature (700 °C), the original aggregated particles by 45 h ball milling could be clearly observed. These particles could not aggregate completely and cracking phenomena occurred in large particles, indicating that the sintering temperature was significantly low and alloying elements did not diffuse completely.

The M23C6 carbides formed due to the presence of C originating from the N-heptane medium as well as from steel balls and vials used during the mechanical synthesis. This side effect is difficult to avoid when the blend includes Cr, which is highly prone to react with C. The phenomenon was also observed in Ref. [29]. The reasons for the precipitation of σ phases in the bulk HEAs after VHPS at 700-1000 °C could be explained by the following aspects. Firstly, following high energy ball-milling, although the elements in alloy powders distributed uniformly, the phases of the alloys were still thermodynamically unstable and various degrees of diffusion occurred among alloying elements during VHPS. Since the diffusion rates of Cr, Mn and Fe among the composition elements were higher than those of the other elements [30], the Cr-rich, Mn-rich and Fe-rich phases (such as σ phase) formed easily. Secondly, nano-crystalline HEAs could be obtained by high energy ball-milling, possibly leading to a distinct increase in the number of grain boundaries in the alloys. Because the activation energy required for grain boundary diffusion was lower than that of intracrystalline diffusion [31], the element diffusion ability of the nano-crystalline HEA with high amounts of grain boundaries was higher than that of the alloys with large crystal sizes. This also promoted the formation of σ phases to a certain extent. In addition, since the experiment of fabricating the FeCoCrNiMn HEA powders was conducted inside stainless steel vials with stainless steel balls as medium, low amounts of stainless steel component (especially Fe elements) entered the alloy during ball milling inevitably. This caused a deviation in actual alloy components from equiatomic components (Fig. 3) and probably led to σ phases formation during the following VHPS, in accordance with Ref. [28].

Fig. 4 SEM images of bulk FeCoCrNiMn alloys consolidated at different sintering temperatures

Fig. 5 TEM bright field images of bulk alloy consolidated by VHPS at 800 °C for 1 h with corresponding SAED patterns

3.2 Mechanical properties

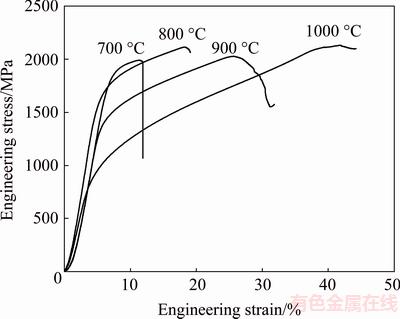

The engineering compressive stress-strain curves of the VHPSed FeCoCrNiMn HEAs sintered at different temperatures are shown in Fig. 6. Table 2 summarizes mechanical properties of the VHPSed HEAs in this work and the SPSed HEAs in Ref. [22]. The compressive stress-strain curve of the VHPSed alloys in this work obviously displayed strain-hardening phenomena and strain-hardening gradually increased as the sintering temperature increased from 700 to 1000 °C. The alloys sintered at the low temperature of 700 °C exhibited a higher yield strength (1682 MPa) than the alloys sintered at 800 °C, whereas the corresponding ultimate compressive strength (σmax), strain-to-failure (εf) and hardness (HV) were all lower than those of the alloy sintered at 800 °C. Especially, the strain-to-failure of the alloys sintered at 700 °C was only 4.4%. The element diffusion was insufficient at low temperatures and the alloys could not fully aggregate (Fig. 4), leading to a significantly low density (only 7.34 g/cm3) and poor mechanical properties. As the sintering temperature was increased from 800 to 1000 °C, the yield strength and hardness of the alloys exhibited an apparent descending trend, whereas strain-to-failure presented an apparent rising tendency. The yield strength, hardness and strain-to-failure of the alloys sintered at 1000 °C were 774 MPa, HV 332 and 38.2%, respectively. This occurred because the relatively high sintering temperature increased the diffusion ability of the elements, resulting in grain growth (such as the precipitated phases), softening in alloy matrices and further weakening in solid-solution strengthening effects. Therefore, the higher sintering temperature led to an apparent decrease in yield strength, hardness and an apparent increase in plasticity. As the sintering temperature was increased from 800 to 1000 °C, due to strain-hardening effect, the reduction in the ultimate compressive strengths was not apparent. Also, as the temperature was increased up to 1000 °C, the value of σmax for the alloy was slightly higher than that for the alloy sintered at 900 °C. In addition, it is noteworthy that the yield strength of the VHPSed FeCoCrNiMn HEAs (except 700 °C) in this work is lower than that of the SPSed alloy in Ref. [22]. The reasons may be the following two aspects. Firstly, hot pressing method for preparing the alloys needs longer time (such as 1 h for soaking at the sintering temperature) than SPS method (only 10 min at 800 °C in Ref. [22]). Longer sintering duration for the VHPSed alloys is beneficial to the full diffusion of alloy elements in the alloys, resulting in the coarser grains in the alloys. Secondly, the higher sintering temperature (at 900 and 1000 °C) for the VHPSed alloys also leads to the coarser grains in the alloys. Therefore, the contribution to the yield strength by grain-boundary strengthening in the VHPSed alloys is smaller than that of the SPSed alloy. Due to the strain-hardening effect, the VHPSed alloys exhibit higher ultimate compression strength in comparison with the SPSed alloy.

Fig. 6 Compressive engineering stress-strain curves of VHPSed FeCoCrNiMn HEAs sintered at different temperatures

Table 2 Mechanical properties and density of VHPSed and SPSed FeCoCrNiMn alloys

4 Conclusions

1) Mechanical alloying (MA) and vacuum hot pressing sintering (VHPS) were utilized for FeCoCrNiMn HEA production. The nano-crystalline high-entropy alloy powders were obtained by MA and the corresponding phase structures consisted of FCC matrix phases and low amounts of BCC and amorphous phases. As the heating treatment temperature was increased from 500 to 700 °C, the BCC phases disappeared with the precipitation of σ and M23C6 phases. After VHPS, the phase structure of the bulk alloys mainly included FCC matrix and precipitated phases. As the sintering temperature was increased within the range of 700-1000 °C, the amount of precipitated phases changed slightly whereas the corresponding sizes gradually increased from nanoscale to approximately 2 μm.

2) The sintering temperature had an apparent influence on the properties of prepared alloys. As the sintering temperature was increased, the density increased gradually from 7.34 g/cm3 (700 °C) to 7.75 g/cm3 (1000 °C), and the strain-to-failure rose from 4.4% to 38.2%; whereas the yield strength presented an apparent descending trend from 1682 MPa (700 °C) to 774 MPa (1000 °C). The hardness of the alloys firstly was improved from HV 413 (700 °C) to HV 472 (800 °C), and then declined to HV 332 (1000 °C). Due to the strain-hardening effects, the influence of sintering temperature on the ulimate compressive strength was not apparent. The bulk FeCoCrNiMn HEAs, consolidated by VHPS at 800 °C and 900 °C for 1 h, showed relatively good combination of strength and ductility.

References

[1] ZHANG Yong, ZUO Ting-ting, TANG Zhi, GAO M C, DAHMEN K A, LIAW P K, LU Zhao-ping. Microstructures and properties of high-entropy alloys [J]. Progress in Materials Science, 2014, 61: 1-93.

[2] CHUANG Ming-hao, TSAI Ming-huang, WANG Woei-ren, LIN Su-jien, YEH Jien-wei. Microstructure and wear behavior of AlxCo1.5CrFeNi1.5Tiy high-entropy alloys [J]. Acta Materialia, 2011, 59: 6308-6317.

[3] LU Z P, WANG H, CHEN M W, BAKER I, YEH J W, LIU C T, NIEH T G. An assessment on the future development of high-entropy alloys: Summary from a recent workshop [J]. Intermetallics, 2015, 66: 67-76.

[4] WU Z, BEI H, OTTO F, PHARR G M, GEOGE E P. Recovery, recrystallization, grain growth and phase stability of a family of FCC-structured multi-component equiatomic solid solution alloys [J]. Intermetallics, 2014, 46: 131-140.

[5] GLUDOVATZ B, HONHENWARTER A, CATOOR D, CHANG E H, GEORGE E P, RITCHIE R O. A fracture-resistant high-entropy alloy for cryogenic applications [J]. Science, 2014, 345: 1153-1158.

[6] ZHU C, LU Z, NIEH T. Incipient plasticity and dislocation nucleation of FeCoCrNiMn high-entropy alloy [J]. Acta Materialia, 2013, 61: 2993-3001.

[7] OTTO F, DLOUHY A, SOMSEN C, BEI H, EGGELER G, GEORGE E P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy [J]. Acta Materialia, 2013, 61: 5743-5755.

[8] GALI A, GEORGE E P. Tensile properties of high- and medium- entropy alloys [J]. Intermetallics, 2013, 39: 74-78.

[9] LIU W H, WU Y, HE J Y, NIEH T G, LU Z P. Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy [J]. Scripta Materialia, 2013, 68(7): 526-529.

[10] STEPANOV N D, SHAYSULTANOV D G, YURCHENKO N Y, ZHEREBTSOV S V, LADYGIN A N, SALISHCHEV G A, TIKHONOVSKY M A. High temperature deformation behavior and dynamic recrystallization in CoCRFeNiMn high entropy alloy [J]. Materials Science Engineering A, 2015, 636: 188-195.

[11] LAPLANCHE G, HORST O, OTTO F, EGGELER G, GEORGE E P. Microstructural evolution of a CoCrFeMnNi high-entropy alloy after swaging and annealing [J]. Journal of Alloys and Compounds, 2015, 647: 548-557.

[12] OTTO F, HANOLD N L, GEORGE E P. Microstructural evolution after thermomechanical processing in an equiatomic, single-phase CoCrFeMnNi high-entropy alloy with special focus on twin boundaries [J]. Intermetallics, 2014, 54: 39-48.

[13] BHATTACHARJEE P P, SATHIARAJ G D, ZAID M, GATTI J R, LEE C, TSAI C W, YEH J W. Microstructure and texture evolution during annealing of equiatomic CoCrFeMnNi high-entropy alloys [J]. Journal of Alloys and Compounds, 2014, 587: 544-552.

[14] CHEN B R, YEH A C, YEH J W. Effect of one-step recrystallization on the grain boundary evolution of CoCrFeMnNi high entropy alloy and its subsystems [J]. Scientific Reports, 2016, 6: 22306.

[15] WANG Woei-ren, WANG Wei-lin, WANG Shang-chih, TSAI Yi-chia, LAI Chun-hui, YEH Jien-wei. Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys [J]. Intermetallics, 2012, 26: 44-51.

[16] HE J Y, LIU W H, WANG H, WU Y, LIU X J, NIEH T G, LU Z P. Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system [J]. Acta Materialia, 2014, 62: 105-113.

[17] WU Z, PARISH C M, BEI H. J. Nano-twin mediated plasticity in carbon-containing FeNiCoCrMn high entropy alloys [J]. Journal of Alloys and Compounds, 2015, 647: 815-822.

[18] STEPANOV N D, SHAYSULTANOV D G, CHERNICHENKO R S, YU YURCHENKO N, ZHEREBTSOV S V, TIKHONOVSKY M A, SALISHCHEV G A. Effect of thermomechanical processing on microstructure and mechanical properties of the carbon-containing CoCrFeNiMn high entropy alloy [J]. Journal of Alloys and Compounds, 2017, 693: 394-405.

[19] SURYANARAYANA C, IVANOV E, BOLDYREV V V. The science and technology of mechanical alloying [J]. Materials Science and Engineering A, 2001, 304-306: 151-158.

[20] CHEN Wei-ping, FU Zhi-qiang, FANG Si-cong, XIAO Hua-qiang, ZHU De-zhi. Alloying behavior, microstructure and mechanical properties in a FeNiCrCo0.3Al0.7 high entropy alloy [J]. Materials Design, 2013, 51: 854-860.

[21] RAJABI M, SEDIGHI R M, RABIEE S M. Thermal stability of nanocrystalline Mg-based alloys prepared via mechanical alloying [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(2): 398-405.

[22] JI Wei, WANG Wei-min, WANG Hao, ZHANG Jin-yong, WANG Yu-cheng, ZHANG Fan, FU Zheng-yi. Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering [J]. Intermetallics, 2015, 56: 24-27.

[23] JI Wei, FU Zheng-yi, WANG Wei-min, WANG Hao, ZHANG Jin-yong, WANG Yu-cheng, ZHANG Fan. Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy [J]. Journal of Alloys and Compounds, 2014, 589: 61-66.

[24] YUAN Yan-bo, WANG Zhi-wei, ZHENG Rui-xiao, HAO Xiao-ning, AMEYAMA Kei, MA Chao-li. Effect of mechanical alloying and sintering process on microstructure and mechanical properties of Al-Ni-Y-Co-La alloy [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2251-2257.

[25] HAO Xiao-ning, ZHANG Hai-ping, ZHENG Rui-xiao, ZHANG Yi-tan, AMEYAMA Kei, MA Chao-li. Effect of mechanical alloying time and rotation speed on evolution of CNTs/Al-2024 composite powders [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(7): 2380-2386.

[26] ZADDACH A J, NIU C, KOCH C C, IRVING D L. Mechanical properties and stacking fault engergies of NiFeCrCoMn high-entropy alloy [J]. The Minerals, Metals & Materials Society, 2013, 65: 1780-1789.

[27] SCHUH B, MENDEZ-MARTIN F,  B, GEORGE E P, CLEMENS H, PIPPAN R, HOHENWARTER A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation [J]. Acta Materialia, 2015, 96: 258-268.

B, GEORGE E P, CLEMENS H, PIPPAN R, HOHENWARTER A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation [J]. Acta Materialia, 2015, 96: 258-268.

[28] STEPANOV N D, SHAYSULTANOV D G, OZEROV M S, ZHEREBTSOV S V, SALISHCHEV G A. Second phase formation in the CoCrFeNiMn high entropy alloy after recrystallization annealing [J]. Materials Letters, 2016, 185: 1-4.

[29] ROGAL  , KALITA D, TARASEK A, BOBROWSKI P, CZERWINSKI F. Effect of SiC nano-particles on microstructure and mechanical of the CoCrFeMnNi high entropy alloy [J]. Journal of Alloys and Compounds, 2017, 708: 344-352.

, KALITA D, TARASEK A, BOBROWSKI P, CZERWINSKI F. Effect of SiC nano-particles on microstructure and mechanical of the CoCrFeMnNi high entropy alloy [J]. Journal of Alloys and Compounds, 2017, 708: 344-352.

[30] TSAI K Y, TSAI M H, YEH J W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys [J]. Acta Materialia, 2013, 61: 4887-4897.

[31] HOHENWARTER A, FALLER M, RASHKOVA B, PIPPAN R. Influence of heat treatment on the microstructural evolution of Al- 3 wt.% Cu during high-pressure torsion [J]. Philosopphical Magazine Letters, 2014, 94: 342-350.

程 虎1,2,谢炎崇1,唐群华3,饶 聪4,戴品强1,4

1. 福州大学 材料科学与工程学院,福州 350116;2. 台州学院 机械工程学院,台州 318000;

3. 莆田学院 机电工程学院,莆田 351100;4. 福建工程学院 材料科学与工程学院,福州 350118

摘 要:采用机械合金化和热压烧结制备FeCoCrNiMn高熵合金。结果表明,采用机械合金化得到纳米晶合金粉末,粉末相结构由面心立方结构(FCC)相以及少量的体心立方结构(BCC)相和非晶相组成。热压烧结后,合金中BCC相基本消失,同时伴随着σ相和M23C6相的析出;烧结温度的升高导致析出相颗粒明显长大。随着热压烧结温度从700 °C升高到1000 °C,合金塑性应变从4.4%增加到38.2%,而屈服强度从1682 MPa下降到774 MPa。经800 °C和 900 °C烧结1 h的FeCoCrNiMn高熵合金具有较好的综合力学性能。

关键词:高熵合金;显微组织;力学性能;粉末冶金

(Edited by Bing YANG)

Foundation item: Project (2014H6005) supported by the Major Industry-Academy Cooperation Program of Fujian Province, China; Project (LY17E050003) supported by the Natural Science Foundation of Zhejiang Province, China; Project (2016PY015) supported by the Cultivation Foundation of Taizhou University, China

Corresponding author: Pin-qiang DAI; Tel: +86-18950330431; E-mail: pqdai@126.com

DOI: 10.1016/S1003-6326(18)64774-0