文章编号:1004-0609(2015)-03-0595-07

AA6082铝合金热变形损伤本构模型

马闻宇,王宝雨,周 靖,唐学峰

(北京科技大学 机械工程学院,北京 100083)

摘 要:利用Gleeble-1500热力模拟试验机在温度为425~525 ℃、应变速率为0.01~1 s-1条件下对AA6082铝合金进行热拉伸试验,研究该合金的热变形行为。结果表明:变形温度、应变速率和应变对AA6082铝合金的流变应力影响显著,流变应力随变形温度的升高而下降,随应变速率的提高而增加;材料热变形经历了应变硬化段、稳态变形段和由损伤引起的流变应力陡降段。建立AA6082铝合金热变形统一黏塑性损伤本构模型,该模型综合考虑位错、硬化、损伤、应变、应变速率和温度等因素,借助遗传算法工具箱确定模型中材料常数。该模型能够较好地预测AA6082铝合金热变形时的流变应力,同时可以较好地描述材料的损伤演化行为。

关键词:铝合金;损伤;本构模型;遗传算法

中图分类号:TG146.2 文献标志码:A

Damage constitutive model for thermal deformation of AA6082 aluminum alloy

MA Wen-yu, WANG Bao-yu, ZHOU Jing, TANG Xue-feng

(School of Mechanical Engineering, University of Science and Technology Beijing, Beijing 100083, China)

Abstract: Thermal deformation tests of AA6082 aluminum alloy were conducted by thermal-mechanical simulator Gleeble-1500 in the temperature range of 425-525 ℃ and strain rate of 0.01-1 s-1 to investigate the thermal deformation behavior. The results show that the flow stress of AA6082 aluminum alloy is significantly influenced by temperature, strain rate and strain. The flow stress increases with decreasing temperature and increasing strain rate. The thermal deformation goes through strain hardening, steady-state stage and steep-fall stage of flow stress. The unified viscoplastic damage model of AA6082 aluminum alloy was established, taking into account of many factors, such as dislocation, hardening, damage, strain, strain rate and temperature. Material constants in the model were determined by genetic algorithm tool. The model can accurately predict the flow stress of AA6082 aluminum alloy in thermal deformation and describe the damage evolution.

Key words: aluminum alloy; damage; constitutive model; genetic algorithm

节约资源和环境保护成为世界汽车生产制造领域高度关注的两个问题。近年来,用铝合金替代普通钢板来制造汽车零部件,成为实现汽车轻量化的主要途径之一[1-4]。AA6082铝合金属于Al-Mg-Si系,可以进行热处理强化,其强化相主要为Mg2Si。同时具有良好的耐腐蚀性和可回收再利用等优点[5]。但在室温下塑性差,通过热成形工艺可以提高材料的成形性能。在对铝合金热成形的工艺制备和热成形的数值模拟时,需要用到准确合理的材料本构模型。

材料的本构模型主要用来描述材料的流变应力与变形温度、应变速率和应变等因素之间的关系[6]。目前,许多学者对铝合金的热成形的本构模型进行了研究。李雪松等[5]采用含有Zener-Hollomon参数的双曲正弦函数对6082铝合金在热压缩变形时的流变应力进行了描述。陈学海等[7]建立了7085铝合金动态再结晶模型,该模型包括动态再结晶动力学方程和动态再结晶晶粒尺寸等方程。傅垒等[8]建立了耦合位错密度的热变形本构模型,用于描述6111铝合金的高温流变应力,该模型综合考虑了位错、变形温度、应变速率和应变速率等因素。考虑到损伤对铝合金热拉伸时流变行为的影响,可以在此模型基础上,耦合入损伤变量,用来描述和预测流变应力的上升段、平衡段和陡降段。同时,模型中的材料常数越少,模型越简洁,越有利于模型的推广和应用。

在此,本文作者利用热模拟试验对AA6082铝合金的高温力学性能进行了研究。同时,基于铝合金热成形过程中的损伤断裂机理,考虑了应变、应变速率和成形温度等因素,建立了损伤演化方程。并将损伤演化方程耦合到基于位错密度的统一黏塑性本构方程中,建立损伤本构模型。利用遗传算法工具箱确定模型中的材料常数,为该合金合理制定热冲压工艺及有限元仿真提供理论参考。

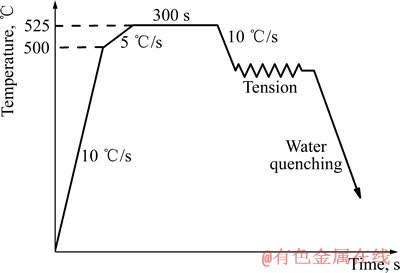

1 实验

本试验中材料为Alcoa公司提供的AA6082-T4铝板,其化学成分如表1所列。试样的几何形状及尺寸如图1所示。试样的厚度为1.5 mm,长度方向与轧制方向一致,由线切割制取,线切割后,试样两侧用砂纸打磨光滑。试验设备为Gleeble-1500热模拟试验机,该设备主要由加热系统、加力系统和计算机控制系统3部分组成。铝合金板热冲压试验时,首先将板料在固溶温度下固溶一段时间,然后转移到模具上进行热冲压试验。为使热模拟试验能够准确反映AA6082铝合金板在热冲压过程中的力学行为的变化,试验设计方案如图2所示。热模拟拉伸试验时,首先将试样以10 ℃/s加热到500 ℃,然后以5 ℃/s加热到525 ℃,以5 ℃/s加热为避免温升速度过快使得试样温度超过固溶温度(525 ℃)。保温5 min后,将试样以10 °C /s降至变形温度,在一定的应变速率下进行拉伸,试样拉断后进行水淬处理,用于保存其高温微观组织。变形温度为425~525 ℃, 应变速率分别为0.01、0.1和1 s-1。变形温度、位移和位移速度等变形条件由计算机的控制系统自动控制。系统自动记录时间、载荷和夹头位移等数据,通过一定的计算转换为真应力-真应变曲线。

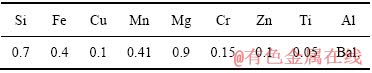

表1 AA6082 铝合金的化学成分

Table 1 Chemical composition of AA6082 aluminum alloy (mass fraction, %)

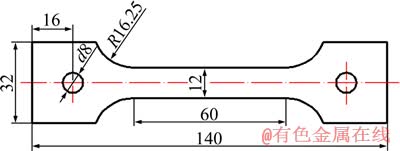

图1 高温拉伸试样几何形状及尺寸(单位:mm)

Fig. 1 Geometrical shape and specimen size of high temperature tensile sample (unit: mm)

图2 热拉伸试样温度变化曲线

Fig. 2 Temperature profile of sample for high temperature tensile test

2 结果与讨论

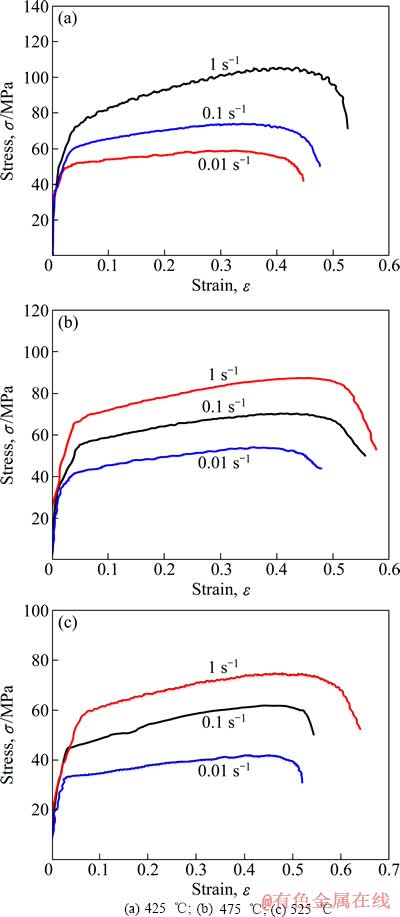

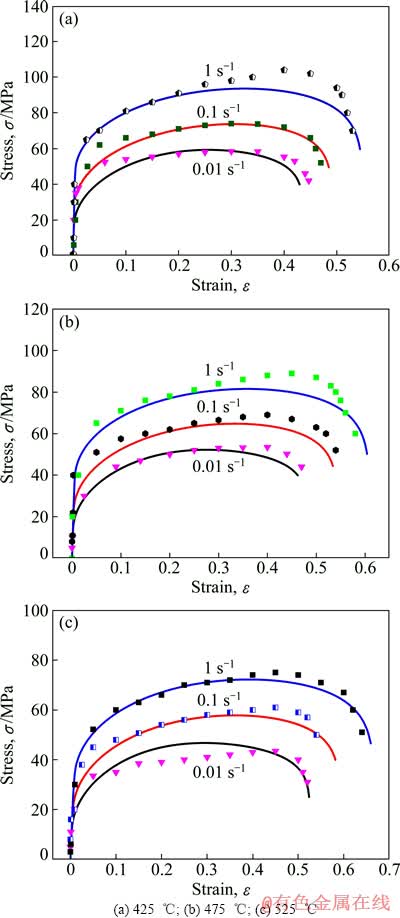

不同变形温度和应变速率下AA6082铝合金在热拉伸变形过程中的真应力-真应变曲线如图3所示。由图3可知,在变形温度为425~525 ℃、应变速率为0.01~1 s-1 的条件下,AA6082铝合金高温变形时,流变应力先随着应变的增加而迅速增大,当增加到一定程度后,流变应力增加平缓。到热变形后期,应力下降。出现这种现象的原因是在铝合金热变形过程中,存在着加工硬化、加工软化及损伤演化。在变形的初始阶段,材料内部位错密度增加,材料硬化明显。由于变形量较小,晶内储存能较小,导致加工软化的回复和再结晶等不显著。因此,流变应力迅速增加。随着变形量的不断增加,晶内储存能升高,合金发生动态回复和再结晶等软化行为,从而抵消部分加工硬化[8-9]。当变形进行到一定程度时,材料内部的微孔洞发生形核和长大,相邻的孔洞发生聚合,最终导致拉伸件断裂[10]。

图3 AA6082铝合金在不同温度和应变速率下的真应力-真应变曲线

Fig. 3 True stress-true strain curves of AA6082 aluminum alloy at different temperatures and strain rates

在同一变形温度时,流变应力随着应变速率的升高而增加,因为应变速率增大,单位时间内产生的位错数目增多,位错运动程度增加。同时由于塑性变形时间缩短,动态软化程度减弱,因此,导致流变应力增加,说明AA6082铝合金具有正的应变速率敏感 性[9]。同时,应变速率对该合金断裂应变影响比较显著。由于晶粒长大过程是扩散过程,因此当应变速率小时,晶粒具有较多的时间长大,大晶粒不易发生晶界滑移和晶粒转动,从而降低了材料的延展性。当变形速率增大时,晶粒来不及长大,小晶粒容易发生晶界滑移和晶粒转动,因此在高应变率下延展性比低应变率下好。6xxx系铝合金高温下变形表现出类似的性质[10-11]。在材料变形后期,损伤迅速增加导致材料失效,直至达到断裂应变值。在同一应变速率时,流变应力随着变形温度的增加而降低。因为温度升高,原子间动能增强,原子间结合力降低,材料的抗拉能力下降,从而导致材料的流变应力降低[9, 12]。

3 损伤本构模型的建立

3.1 损伤演化方程的建立

在金属热成形过程中,微孔洞损伤通常产生于晶界处、第二相粒子和夹杂附近。高温下,断裂机理主要为微孔洞的形核、长大和聚合导致的韧性断裂[13]。6xxx系铝合金中存在多种不同的第二相粒子和夹杂,第二相粒子和夹杂与基体的性质之间存在一定的差别。在塑性变形增加过程中,第二相粒子和夹杂与基体间差别造成的影响越来越大,引起应力和应变的集中。从而促使第二相粒子或夹杂与基体的界面分离,或者造成第二相粒子或夹杂本身的破裂,造成内部微孔洞的产生。随着塑性应变的增加,孔洞逐渐增长,同时会有新的孔洞形核。当孔洞增长到一定程度时,孔洞之间的相互作用显著增加,导致孔洞之间的连接聚合。当孔洞之间的韧带不断断裂,多个孔洞相继聚合,最终导致断裂发生。在损伤演化及韧性断裂过程中,塑性应变、塑性应变率和变形温度等因素产生很大的影响[10]。

为深入了解AA6082铝合金在高温变形时的损伤断裂机制,将在变形温度475 ℃和应变速率1 s-1条件下拉断后试样的断口附近材料剪下,制成样品,用于扫描电子显微镜(SEM)观察。利用扫描电子显微镜对样品表面进行观察,可以发现图4(a)中的微孔洞。在图4(b)中,微孔洞长大,形成大的孔洞。在图4(c)中,相邻孔洞发生聚合。这与韧性材料通常表现出的损伤破坏规律相符。

图4 AA6082铝合金的损伤破坏特征

Fig. 4 Characteristics of damage of AA6082 aluminum alloy

连续介质损伤力学通过引入损伤变量来描述整个材料介质内部的缺陷,比如微孔洞和微裂纹等。进而根据损伤与成形因素之间的关系建立损伤演化方程。本文作者依据以上提到的热成形损伤演化机理,建立了考虑损伤变化率、损伤值、塑性应变、塑性应变率和变形温度的损伤演化方程,参考文献[10]和[14]中损伤方程形式,并在此基础上,减少方程参数数量和降低方程复杂程度,其表达式如下:

(1)

(1)

式中: 为损伤变化率;

为损伤变化率; 为塑性应变率;fd为损伤值;

为塑性应变率;fd为损伤值; 为塑性应变;变量d1,d2和D2为非温度相关的材料常数;D1为温度相关的材料常数,可通过Arrhenius方程形式表示为

为塑性应变;变量d1,d2和D2为非温度相关的材料常数;D1为温度相关的材料常数,可通过Arrhenius方程形式表示为

(2)

(2)

式中:D10为方程系数;QD1为材料的相应常数的激活能;Rg为摩尔气体常数;T为变形温度。

3.2 统一黏塑性本构模型的建立

高温下,金属在外部环境下变形表现出明显的黏塑性。黏塑性变形通常是指材料发生与时间相关的不可以恢复的变形。材料要发生黏塑性流动时,需要克服初始屈服应力k,即 要大于0,用麦考利括号形式表示为

要大于0,用麦考利括号形式表示为 。当流变应力克服初始屈服应力后,材料发生变形。变形时,位错开始增殖及位错之间发生相互作用等导致材料的加工硬化,材料硬化量定义为RH。由此在变形过程中,材料进行黏塑性流动还需要克服材料硬化,表示为

。当流变应力克服初始屈服应力后,材料发生变形。变形时,位错开始增殖及位错之间发生相互作用等导致材料的加工硬化,材料硬化量定义为RH。由此在变形过程中,材料进行黏塑性流动还需要克服材料硬化,表示为 。当材料变形温度较高时,材料的应力表现出明显的应变率相关性。由此,流动规则由式(3)表示[8]:

。当材料变形温度较高时,材料的应力表现出明显的应变率相关性。由此,流动规则由式(3)表示[8]:

(3)

(3)

式中:n1为非温度相关的材料常数,也称为黏塑性指数。为考虑温度对材料变形的影响,K和k为温度相关的材料常数:

(4)

(4)

(5)

(5)

其中:K0和k0为方程系数;QK和Qk分别为材料相应常数的激活能;Rg为摩尔气体常数;T为温度。

材料硬化RH由塑性变形过程中位错积累引起。由于位错密度在材料变形过程中很难定量,因此采用正则化位错密度 来表示,

来表示, ,其中

,其中 为瞬时位错密度,

为瞬时位错密度, 为初始位错密度,

为初始位错密度, 为位错饱和状态时的位错密度[15]。因此,变形初始时正则化位错密度

为位错饱和状态时的位错密度[15]。因此,变形初始时正则化位错密度 为0,位错饱和状态时正则化位错密度

为0,位错饱和状态时正则化位错密度 为1。一般认为,硬化常数RH与正则化位错密度

为1。一般认为,硬化常数RH与正则化位错密度 成正比[16],关系式为

成正比[16],关系式为

(6)

(6)

式中:B为温度相关变量,表达式为

(7)

(7)

式中:B0为方程系数;QB为材料的相应常数的激活能。

高温成形过程中,位错密度随着塑性应变的演变而增加。同时,在高温下,材料会发生回复和再结晶等,导致位错密度下降,位错密度表达式为[17]

(8)

(8)

式中:A和n2为非温度相关的材料常数;C为温度相关的材料常数,表达式为

(9)

(9)

式中:C0为方程系数;QC为材料的相应常数的激活能。

同时,考虑弹性段部分,由胡克定律得

(10)

(10)

式中:σ为应力;εp为塑性应变;σT为总应变。

弹性模量为温度相关变量,表达式为

(11)

(11)

式中:E0为方程系数;QE为材料相应常数的激活能。

式(3)~(11)构成铝合金基于位错密度的统一黏塑性本构模型,并未考虑损伤的影响。为考虑损伤的影响,将损伤演化方程耦合入基于位错密度的统一黏塑性本构模型中:

(12)

(12)

式(2)、(4)、(5)、(7)、(9)、(11)和(12)构成了针对铝合金热变形的统一黏塑性损伤本构模型。

3.3 损伤本构模型中材料常数的确定

本文作者采用遗传算法工具箱来确定方程中的材料常数。模型由常微分方程组成,是非线性和高度耦合的。采用传统的代数方法求解难度很大。而遗传算法是基于自然界优胜劣汰的生存法则建立的随机搜索方法。可以随机给定初始值,一次搜索后对给定的参数值进行评估,对优良的参数值进行保留,对差的参数值进行淘汰。然后通过交叉和变异等产生子代。可以通过设置种群规模、遗传代数来提高搜索空间和搜索精度。具有较高的全局优化能力,适合用于求解多值优化问题[18-19]。

应用遗传算法工具箱需要建立目标函数,目标函数用来表达模型预测值与试验值之间的相近度。本研究中以流变应力的计算值和试验值的“距离”编写m(Matlab/M-file)文件[8, 20],其表达式如下所示:

(13)

(13)

式中:X为需要优化的材料常数,X=(x1,x2,…,xs),s为材料常数的个数;f(X)为流变应力的残差;M为试验曲线的条数;Nj为第j条流变应力曲线上所取的数据点点数; 为应变i时流变应力的计算值,可以通过损伤模型计算求得,

为应变i时流变应力的计算值,可以通过损伤模型计算求得, 为应变i时流变应力的试验值。通过不断搜索最优解集来降低目标函数值,直到达到所设定的精度。

为应变i时流变应力的试验值。通过不断搜索最优解集来降低目标函数值,直到达到所设定的精度。

本文作者建立的损伤本构模型中共有18个材料常数,分别为K0、QK、k0、Qk、B0、QB、C0、Qc、E0、QE、D10、QD1、n1、A、n2、d1、d2和D2。根据不同变形温度和不同应变速率下得到的真应力-真应变曲线,通过遗传算法工具箱来确定材料常数的具体值。具体求解方法主要分为以下4个步骤。

1) 根据变形温度为425 ℃,不同应变速率(0.01、0.1和1 s-1)下的试验数据来确定方程中的材料常数。

2) 固定步骤(1)中确定的非温度相关的材料常数值。根据变形温度为525 ℃,应变速率为0.01、0.1和1 s-1时的试验数据来确定温度相关的材料常数。

3) 通过步骤1)和2)得到两组温度相关的材料常数值。可以通过这两组结果来确定Arrhenius方式(2)、(4)、(5)、(7)、(9)和(11)中的方程系数(如K0)和激活能(如QK)。

4) 将通过步骤1)~3)求得的材料常数代入方程中,对未参与参数求解的不同工况下的材料应力应变关系进行预测,用于验证所求得材料常数的准确性。

确定方程中的材料常数也可以同时将所有的试验数据编入目标函数中,或者先确定不考虑损伤时的材料常数,再考虑损伤相关常数的数值。常微分方程的程序编写可以采用前进欧拉法和龙格库塔法等方法。

通过遗传算法工具箱确定的AA6082铝合金损伤本构模型中的材料常数如表2所列。

3.4 本构模型的验证

将确定的材料常数带入本构模型中,用来预测未参与材料常数求解的不同变形条件下的材料应力应变关系,并与试验数据点进行对比,其结果如图5所示。图5中曲线为模型预测值,符号为试验值。由图5可知,该模型可以较好地描述AA6082铝合金热变形过程中的流变应力。为铝合金热成形工艺和有限元模拟提供一定的参考。

表2 AA6082损伤本构模型中的材料常数

Table 2 Material constants of damage constitutive model of AA6082

图5 AA6082铝合金损伤模型预测值(曲线)与试验值(符号)对比

Fig. 5 Comparison between predicted values (curves) and experimental results (symbols) of damage constitutive model of AA6082 aluminum alloy

4 结论

1) 变形温度和应变速率对AA6082铝合金热变形时的流变应力影响显著,流变应力随变形温度的下降和应变速率的提高而增加。AA6082铝合金热拉伸变形经历了初始硬化段、稳态变形段和由于损伤导致的流变应力陡降段。

2) 根据AA6082铝合金热变形损伤机理,建立了AA6082统一黏塑性损伤本构模型,模型综合考虑了位错、硬化、损伤、应变、应变速率和变形温度等因素,从而可以对铝合金热变形过程中的流变应力陡降段进行描述。

3) 利用遗传算法工具箱确定模型中的材料常数。该模型可以较好地预测AA6082铝合金在不同变形温度和应变速率下的流变应力。同时可以较好地描述材料热变形过程中的损伤演化行为。

致谢:本文全体作者衷心感谢北京科技大学材料科学与工程学院的边建华老师,在扫描电子显微镜实验中给予的帮助和指导。

REFERENCES

[1] WANG Hui, LUO Ying-bing, FRIEDMAN P, CHEN Ming-he, GAO Lin. Warm forming behavior of high strength aluminum alloy AA7075[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 1-7.

[2] 傅 垒, 王宝雨, 马闻宇. 6111铝合金固溶工艺多目标优化[J]. 中国有色金属学报, 2014, 24(5): 1127-1132.

FU Lei, WANG Bao-yu, MA Wen-yu. Multi-objective optimization of solution process of 6111 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1127-1132.

[3] ZHOU Jing, WANG Bao-yu, LIN Jian-guo, FU Lei. Optimization of an aluminum alloy anti-collision side beam hot stamping process using a multi-objective genetic algorithm[J]. Archives of Civil and Mechanical Engineering, 2013, 13(3): 401-411.

[4] HOSSAIN M M, HONG S T, PARK K Y, NA Y S. Microforming of superplastic 5083 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(S3): s656-s660.

[5] 李雪松, 陈 军, 张鸿冰. 6082铝合金热变形的本构模型[J]. 中国有色金属学报, 2008, 18(10): 1769-1774.

LI Xue-song, CHEN Jun, ZHANG Hong-bing. Constitutive model for hot deformation of 6082 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(10): 1769-1774.

[6] 丁贤飞, 张利欣, 孙冬柏, 王志海,王立臣,李恒奎. 6005A 与 6082 铝合金热变形流变行为[J]. 北京科技大学学报, 2012, 34(9): 1041-1047.

DING Xian-fei, ZHANG Li-xin, SUN Dong-bai, WANG Zhi-hai, WANG Li-chen, LI Heng-kui. Flow behaviors of 6005A and 6082 aluminum alloys during hot deformation[J]. Journal of University of Science and Technology Beijing, 2012, 34(9): 1041-1047.

[7] 陈学海, 陈康华, 董朋轩, 彭国胜, 陈送义. 7085 铝合金的热变形组织演变及动态再结晶模型[J]. 中国有色金属学报, 2013, 23(1): 44-50.

CHEN Xue-hai, CHEN Kang-hua, DONG Peng-xuan, PENG Guo-sheng, CHEN Song-yi. Microstructure evolution and dynamic recrystallization model of 7085 aluminum alloy during hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(1): 44-50.

[8] 傅 垒, 王宝雨, 林建国, 周 靖,马闻宇. 耦合立错密度的 6111 铝合金热变形本构模型[J]. 北京科技大学学报, 2013, 35(10): 1333-1339.

FU Lie, WANG Bao-yu, LIN Jian-guo, ZHOU Jing, MA Wen-yu. Constitutive model coupled with dislocation density for hot deformation of 6111 aluminium alloy[J]. Journal of University of Science and Technology Beijing, 2013, 35(10): 1333-1339.

[9] 李展志, 李慧中, 王海军, 梁霄鹏, 曾 敏, 刘楚明. 6069 铝合金的热变形行为和加工图[J]. 粉末冶金材料科学与工程, 2011, 16(2): 155-161.

LI Zhan-zhi, LI Hui-zhong, WANG Hai-jun, LIANG Xiao-peng, ZENG Min, LIU Chu-ming. Hot deformation behavior and processing map of 6069 aluminum alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(2): 155-161.

[10] MOHAMED M S, FOSTER A D, LIN J, BALINT D S, DEAN T A. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling[J]. International Journal of Machine Tools and Manufacture, 2012, 53(1): 27-38.

[11] LASSANCE D, FABREGUE D, DELANNAY F, PARDOEN T. Micromechanics of room and high temperature fracture in 6xxx Al alloys[J]. Progress in Materials Science, 2007, 52: 62-129.

[12] 汪洪峰, 左敦稳, 黄铭敏, 陈明和. 5050铝合金板材高温流变行为研究[J]. 材料工程, 2011(1): 23-27.

WANG Hong-feng, ZUO Dun-wen, HUANG Ming-min, CHEN Ming-he. High temperature rheological behavior of Aluminum alloy sheet 5050[J]. Journal of Materials Engineering, 2011(1): 23-27.

[13] LIN J, LIU Y, DEAN T A. A review on damage mechanisms, models and calibration methods under various deformation conditions[J]. International Journal of Damage Mechanics, 2005, 14(4): 299-319.

[14] 周 靖, 王宝雨, 徐伟力, 黄鸣东, 易生虎, 校文超. 耦合损伤的 22MnB5 热变形本构模型[J]. 北京科技大学学报, 2013, 35(11): 1450-1457.

ZHOU Jing, WANG Bao-yu, XU Wei-li, HUANG Ming-dong, YING Sheng-hu, XIAO Wen-chao. Damage-coupled constitutive model of 22MnB5 steel in hot deformation[J]. Journal of University of Science and Technology Beijing, 2013, 35(11): 1450-1457.

[15] LIN J, DEAN T A. Modelling of microstructure evolution in hot forming using unified constitutive equations[J]. Journal of Materials Processing Technology, 2005, 167(2): 354-362.

[16] NES E. Modelling of work hardening and stress saturation in FCC metals[J]. Progress in Materials Science, 1997, 41(3): 129-193.

[17] GARRET R P, LIN J, DEAN T A. An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: Experimentation and modelling[J]. International Journal of Plasticity, 2005, 21(8): 1640-1657.

[18] LIN J, CHEONG B H, YAO X. Universal multi-objective function for optimising superplastic-damage constitutive equations[J]. Journal of Materials Processing Technology, 2002, 125: 199-205.

[19] LI B, LIN J, YAO X. A novel evolutionary algorithm for determining unified creep damage constitutive equations[J]. International Journal of Mechanical Sciences, 2002, 44(5): 987-1002.

[20] LIN J, YANG J B. GA-based multiple objective optimisation for determining viscoplastic constitutive equations for superplastic alloys[J]. International Journal of Plasticity, 1999, 15(11): 1181-1196.

(编辑 龙怀中)

基金项目:现代交通金属材料与加工技术北京实验室基金资助项目;教育部高等学校博士学科点专项科研基金资助项目(20120006110017);材料成形与模具技术国家重点实验室开放课题研究基金资助项目(P2014-15)

收稿日期:2014-06-30;修订日期:2014-12-28

通信作者:王宝雨,研究员,博士;电话:010-82375671;E-mail:bywang@ustb.edu.cn