文章编号:1004-0609(2010)07-1346-07

发泡压力对中间相沥青基泡沫炭结构及性能的影响

肖 锋,张红波,熊 翔,李万千,夏伦刚

(中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以AR中间相沥青为原料,在4、5、7、10 MPa下用恒压自发泡工艺制备泡沫炭生料,经炭化、石墨化处理后分别获得炭化泡沫炭和石墨化泡沫炭。采用SEM和OM观察泡沫炭的微观形貌,采用XRD分析泡沫炭的晶体结构,并测定泡沫炭的压缩强度和热导率。结果表明:随着发泡压力的升高,孔泡变得均匀,韧带片层结构变得规则有序,但发泡压力增大到一定程度后,闭孔增多,韧带有序结构变差;当发泡压力为10 MPa时,炭化和石墨化试样的压缩强度达到最大值,分别为8.16 MPa和3.42 MPa;当发泡压力为7 MPa时,石墨化试样的热导率达到最大值,61.0 W/(m?K)。

关键词:AR中间相沥青;泡沫炭;压缩强度;热导率

中图分类号:TQ127 文献标志码:A

Effects of foaming pressure on microstructures and properties of mesophase-pitch-derived carbon foams

XIAO Feng, ZHANG Hong-bo, XIONG Xiang, LI Wan-qian, XIA Lun-gang

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The nascent foams were prepared from AR mesophase pitch by self-foaming technology at constant pressure under foaming pressures of 4, 5, 7 and 10 MPa. Carbonized and graphitized carbon foams were formed by carbonization and graphitization. The microstructures and crystal parameters of carbon foams were characterized by SEM, OM and XRD. The compressive strength and thermal conductivity were also measured. The results show that the bubble holes distribute uniformly and the structures of the ligaments become more ordered with increasing the foaming pressure. But the number of obturated pores increases and the ligaments become more disorderly when the pressure reaches a certain degree. The maximum compressive strengths of carbonized and graphitized carbon foams are obtained at foaming pressure of 10 MPa, which are 8.19 MPa and 3.42 MPa, respectively. The thermal conductivity of graphitized carbon foam reaches the maximum value of 61.0 W/(m·K) at foaming pressure of 7 MPa.

Key words: AR mesophase pitch; carbon foam; compressive strength; thermal conductivity

泡沫炭是一种由孔泡和相互连接的孔泡壁组成的具有三维网状结构的轻质多孔炭材料。中间相沥青具有独特的各向异性、良好的流变性、较高取向性和可石墨化性,是制备高性能炭材料的优质前驱体[1]。美国橡树岭国家实验室(ORNL)的KLETT 等[2-4]以中间相沥青为前驱体,采用“自发泡”技术制得泡沫炭生料,经炭化、石墨化后得到了孔径分布均匀和热导率较高的泡沫炭。中间相沥青基泡沫炭具有强度高、热导率高、电导率高、密度低及热膨胀系数小等优点,已成为传热、导电和吸波材料等领域的研究热 点[5-7]。

大量研究[8-15]表明,发泡压力对泡沫炭的孔结构和材料性能有着重要的影响。WANG等[8]选用两种不同软化点中间相沥青在不同发泡压力下制备了体积密度和孔结构不同的泡沫炭材料,表明通过选择不同的前驱体和适当的发泡压力能制备出结构和性能各异的泡沫炭。安秉学等[9]研究了发泡条件对中间相沥青基泡沫炭结构和性能的影响,表明压力是影响泡沫炭的密度、开孔率、孔隙率及热导率的重要因素。陈峰[10]较系统地研究了工艺参数(发泡压力、发泡温度、预发泡温度和保温时间等)、热处理温度及改性处理对中间相沥青基泡沫炭结构和性能的影响。目前,研究者多采用KLETT方法[4]作为泡沫炭的发泡手段,在发泡过程中,随着气体的增多,体积膨胀,反应釜内压力逐渐增大,使得初始压力和最终压力有较大的差别。大多数研究者[8-14]只考察了初始压力对泡沫结构和性能的影响,而最终压力的情况则不太详细。CAO等 [15]采用不同发泡压力在恒压下制备了泡沫炭,研究了压力对泡沫炭结构的影响,但关于发泡压力对泡沫炭性能的影响的研究鲜见报道。本文作者采用不同发泡压力用恒压自发泡工艺制备泡沫炭,研究恒压发泡压力对泡沫炭的微观结构、压缩性能和导热性能的影响,并对其影响机制进行分析,为进一步优化制备工艺提供理论依据。

1 实验

1.1 原料

前躯体为日本Mitsubishi公司生产的AR中间相沥青,其软化点为283.7 ℃,中间相含量为100%(质量分数)。

1.2 中间相沥青基泡沫炭的制备

将中间相沥青颗粒粉碎至150 μm,称取适量沥青粉末放入容器,置于高压反应釜中,用N2置换釜内空气,随后加压至不同的发泡压力(4、5、7、10 MPa),采用恒压自发泡工艺,以2 ℃/min的升温速率加热至 430 ℃,保温2 h后,自然冷却得泡沫炭生料。将生料在炭化炉中于850 ℃炭化处理,再将炭化试样在石墨化炉中于2 300 ℃石墨化处理。所得炭化泡沫炭分别记作CCF-I-4、CCF-I-5、CCF-I-7和CCF-I-10,石墨化泡沫炭分别记作GCF-I-4、GCF-I-5、GCF-I-7和GCF-I-10。

1.3 分析和表征

1.3.1 微观形貌分析

采用日本Jeol-6360LV型扫描电子显微镜(SEM)观察泡沫炭的微观形貌。采用POLYVAR-MET大型金相光学显微镜(OM)观察泡沫炭的偏光形貌。

1.3.2 体积密度测试

将试样加工成圆柱样,用如下公式计算试样的体积密度(ρV):

(1)

(1)

式中: m为试样质量;D为试样平均直径;h为试样高度。

1.3.3 压缩强度测试

采用机械工业部长春试验机研究所生产的CSS-44100电子万能试验机测量试样的压缩强度。试样尺寸为d10 mm×15 mm,加载速率为0.5 mm/min,用如下公式计算压缩强度(s):

(2)

(2)

式中:F为破坏载荷;A为试样的受压截面积。

1.3.4 X射线测试

石墨化度根据Mering和Maire公式计算:

(3)

(3)

式中:d002为(002)面的层间距,d002=λ/(2sin θ);λ为入射X射线波长;θ为半衍射角;g为石墨化度;0.344 0 nm为完全未石墨化炭的层面距;0.335 4 nm为理想石墨晶体的层面距。

微晶在002方向的尺寸Lc由Scherrer公式计算:

(4)

(4)

式中:λ为入射X射线波长;B为衍射峰积分宽度;θ为半衍射角。

1.3.5 热导率测试

采用热脉冲法(又称闪光法,Flash Method)测试热扩散率,所用仪器为JR-3型激光导热仪。试样尺寸为d10 mm×4 mm,用如下公式计算试样的热导率λ:

(5)

(5)

式中:λ为热导率;α为热扩散率;Cp为定压比热容;ρV为试样的体积密度。

考虑到试样孔隙的存在,本实验测试热导率时,每组选择3个试样,最终的热导率值是三者的平均值。

2 结果与分析

2.1 发泡压力对泡沫炭微观结构的影响

2.1.1 炭化泡沫炭

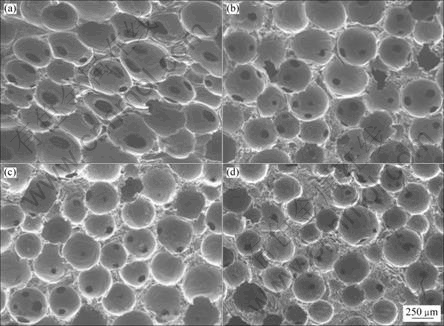

图1所示为不同发泡压力下炭化泡沫炭的SEM

图1 不同发泡压力下炭化泡沫炭的SEM像

Fig.1 SEM images of carbonized carbon foams at different foaming pressures: (a) 4 MPa; (b) 5 MPa; (c) 7 MPa; (d) 10 MPa

像。由图1可以看出,不同发泡压力下制备的炭化泡沫炭的孔泡形状、孔径及韧带结构差异较大。在发泡过程中,中间相沥青会发生一系列的物理化学变化,如液化、分解、分子重排、脱氢等,沥青中一些轻质相组分和小分子被释放出来,形成的气体在液相沥青中溶解、饱和、成核及长大。在加热过程中,随着温度的升高,沥青的黏度逐渐降低,形成的气泡内压逐渐增大,导致气泡较容易长大、运动和合并。在温度升高到发泡温度430 ℃的过程中,沥青黏度经历了由小变大的过程,此时气泡的扩散与长大受到阻碍。根据Laplace方程可知,气泡内外压差Dp关系[15]为:

(6)

(6)

式中:pq为气泡内压;py为气泡外压,py=ρgh+pw(pw为液体所受环境压力,即本实验的发泡压力);s为表面张力;r为气泡半径。

在泡沫生长过程中,发泡压力对泡沫的作用产生两个主要结果:一是对于少数的大气泡,气泡内外压差Dp已接近平衡,外压的出现破环了该平衡,周围液体压力可能大于气泡内气体压力,导致大泡破裂,剩下的气泡孔径相近;二是减小内外压差,也就减弱了气泡膨胀的动力,限制和减缓了气泡的生长,导致闭孔产生[16]。当发泡压力为4 MPa时,中间相沥青产

生的气体使得气泡内外压差较大,导致气泡迅速长大、运动和合并,气泡来不及成型、固定,致使孔泡形状不规则,呈现近椭圆形状,孔径分布不均匀,多为开孔结构,韧带结构不完整,如图1(a)所示。当发泡压力为5 MPa时,气泡内外压差变小,气泡长大、合并减缓,此时孔泡分布变得较为均匀,椭圆形的孔泡演变成规则的圆孔,但开孔结构仍然较多,如图1(b)所示。当发泡压力为7 MPa时,孔径变得更加均匀,开孔结构适中,韧带结构规整有序,如图1(c)所示。当发泡压力为10 MPa时,气泡内外压差较小,阻碍了气泡的长大合并,在沥青黏度较大时,这种阻碍更加严重,导致气泡存留在沥青中,最终形成了较多的闭孔,故孔泡不连续,孔径分布不均匀,如图1(d)所示。

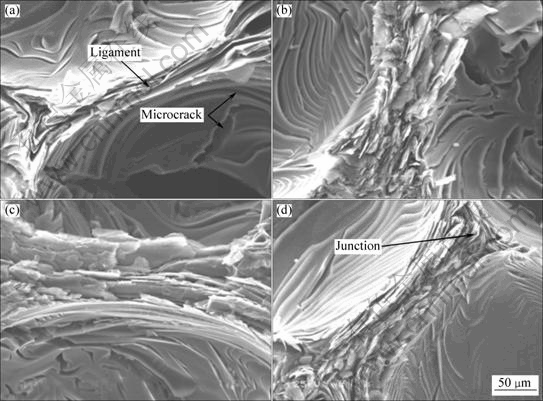

2.1.2 石墨化泡沫炭

图2所示为不同发泡压力下石墨化泡沫炭的SEM像。由图2可以看出,当发泡压力为4 MPa时,微裂纹较宽,布满了整个孔泡壁,韧带窄,却呈现了较好的片层结构,但韧带结点处片层结构变得杂乱无序,如图2(a)所示。当发泡压力为5 MPa时,韧带宽度明显增大,片层结构较清晰,微裂纹呈放射式分布,如图2(b)所示。当发泡压力为7 MPa时,韧带片层排列清晰可见,韧带表现出良好的有序性,如图2(c)所示。当发泡压力为10 MPa时,韧带结构有些杂乱,片层结构被打乱,如图2(d)所示。

图3所示为发泡压力为7、10 MPa时石墨化泡沫炭韧带的OM像。由图3可以看出,GCF-I-7韧带中间呈橙色单色区,表明韧带结构高度有序,而GCF-I-10韧带中间为浅蓝色和少量橙色的混合区,表明韧带有序性受到了一定程度的破环,这与从图2观察到的结果一致。

图2 不同发泡压力时石墨化泡沫炭的SEM像

Fig.2 SEM images of graphitized carbon foams at different foaming pressures: (a) 4 MPa; (b) 5 MPa; (c) 7 MPa; (d) 10 MPa

图3 石墨化泡沫炭韧带的OM像

Fig.3 OM images of ligaments of graphitized carbon foams: (a) GCF-I-7, 7 MPa; (b) GCF-I-10, 10 MPa

由图2和3可知,经过石墨化处理,泡沫炭的韧带有序度显著提高,但孔壁上出现了较多的微裂纹。微裂纹增多的主要原因有二:其一,炭化泡沫炭在 2 300 ℃石墨化处理时,非碳元素进一步脱去,生成轻质相气体,在扩散过程中形成的通道作为裂纹残留下来;其二,炭化试样在高温下发生一定量的收缩,产生的应力导致了裂纹的增加。

2.2 发泡压力对泡沫炭体积密度和压缩强度的影响

图4所示为不同发泡压力下制备的炭化和石墨化泡沫炭的体积密度与压缩强度。由图4(a)可以看出,随着发泡压力的增加,炭化和石墨化试样的体积密度

图4 泡沫炭的体积密度和压缩强度

Fig.4 Bulk densities (a) and compressive strengths (b) of carbon foams

都随之增加,石墨化试样的体积密度较炭化试样的大。这是因为随着发泡压力的增加,气泡内外压差减小,气泡的长大、运动和合并变得困难,并且沥青中的一些轻质相组分和小分子以及聚合、缩聚产生的气体难以逸出,残留在液相沥青中,导致体积密度增加,GCF-I-10的体积密度最大值为0.708 g/cm3。另外,炭化试样在2 300 ℃石墨化处理时,释放的非碳元素较少,泡沫体主要发生体积收缩,导致单位体积内的泡沫固相物质增多,故石墨化后体积密度进一步提高,GCF-I-10的体积密度最大值为0.734 g/cm3。

由图4(b)可以看出,炭化和石墨化泡沫炭的压缩强度随着发泡压力的增加而增加,但石墨化试样的压缩强度明显低于炭化试样的。当发泡压力为4 MPa时,炭化和石墨化试样的压缩强度最低,分别仅为3.45 MPa和1.73 MPa;当发泡压力为10 MPa时,炭化和石墨化试样的压缩强度达到最高值,分别为8.19 MPa和3.42 MPa。多孔材料的力学性能与前驱体和材料的微观结构等因素相关。当前驱体相同时,多孔材料的力学性能与韧带宽度成正比,与韧带长度成反比。根据脆性材料断裂理论[17]可知,炭材料的力学性能取决于微区裂纹的数量和长度,且与a-1/2 (a为裂纹长度)成正比。由图1和2可知,在较低发泡压力下制备的炭化泡沫炭的孔径分布不均匀,韧带狭窄,长度较长,故此时的压缩强度最低;随着发泡压力的增加,炭化泡沫炭的孔径逐渐变得均匀,韧带宽度增加,长度变短,固相承载面积增多,因而压缩强度逐渐增加。炭化试样经石墨化处理,孔壁上微裂纹明显增多,故石墨化试样的压缩强度降低。

2.3 发泡压力对泡沫炭导热性能的影响

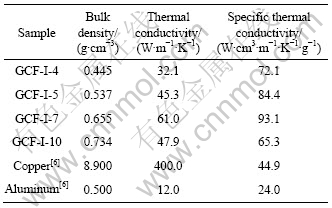

表1所列为不同发泡压力下制备的石墨化泡沫炭与传统导热材料的密度、热导率与比热导率(热导率/密度)等数据。从表1可以看出,随着发泡压力的增加,石墨化泡沫炭的热导率和比热导率呈现先增加后减小的趋势。当发泡压力为7 MPa时,热导率和比热导率达到最大值,分别为61.0 W/(m·K)和93.1 (W·cm3)/(m?K?g)。与传统导热材料(铜和泡沫铝)相比,实验制备的石墨化泡沫炭的比热导率都较高。

表1 石墨化泡沫炭和其它材料的热性能比较

Table 1 Comparison of thermal properties of graphitized carbon foams and other materials

DRUMA等[18]研究表明,泡沫材料的有效热导率,可以通过有限元法进行推算和定义。为了简化,忽略气孔中气体的热传导和热辐射,假设所有的热都是通过固体部分传递的,可得:

(7)

(7)

式中: Ke为有效热导率;ρb为体积密度;ρs为真密度;n为经验常数。

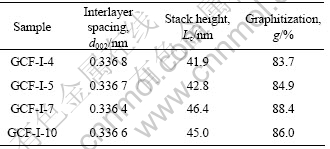

由式(7)可以看出,同种泡沫材料的有效热导率与体积密度成正比。由图4(a)可知,随着发泡压力的增加,石墨化泡沫炭的体积密度逐渐增加。当发泡压力为10 MPa时,石墨化泡沫炭的体积密度最大。根据上述理论,此时热导率应该最大,但实验结果却表明热导率显著降低,这可由炭-石墨材料的热传导机理来解释。SAVAGE[19]研究表明,室温下炭-石墨材料的热导率主要由声子的平均自由程(L)决定。L的大小取决于声子的碰撞和散射,与材料微晶尺寸基本成正比。通过XRD得到石墨化泡沫炭的晶体结构参数(见表2)。由表2可以看出,GCF-I-7的面间距d002仅为 0.336 4 nm,非常接近理想石墨晶体的层间距0.335 4 nm;此时,微晶尺寸Lc和石墨化度g分别为46.4 nm和88.4%,均高于其他三者,即石墨微晶结构更完善,有序度更高,晶格缺陷更少。因此,GCF-I-7的平均自由程L最大,最利于导热,故热导率最大。

表2 石墨化泡沫炭的XRD分析结果

Table 2 XRD analysis results of graphitized carbon foams

3 结论

1) 采用AR中间相沥青在不同发泡压力和430 ℃发泡温度下,以恒压自发泡工艺制备出性能良好的泡沫炭。

2) 当发泡压力较低时,泡沫炭的开孔较多,孔径不够均匀;随着发泡压力的增大,泡沫炭的开孔逐渐减少,孔径变得均匀;但发泡压力为10 MPa时,闭孔增多,韧带有序结构变差。

3) 随着发泡压力的增大,炭化和石墨化泡沫炭的体积密度与压缩强度逐渐增大,炭化泡沫炭的体积密度和压缩强度的最大值分别为0.708 g/cm3和8.19 MPa;石墨化泡沫炭的体积密度和压缩强度的最大值分别为0.734 g/cm3和3.42 MPa。石墨化泡沫炭的热导率随着发泡压力的增大表现了先增加后减小的趋势,最大值为61.0 W/(m·K)。

REFERENCES

[1] 黄美荣, 李新贵. 中间相沥青的制备与应用[J]. 石油化工, 1998, 27(1): 62-66.

HUANG Mei-rong, LI Xin-gui. Preparation and application of mesophase pitch[J]. Petrochemical Technology, 1998, 27(1): 62-66.

[2] KLETT J W, MCMILLAN A D, GALLEGO N C, WALLS C A. The role of structure on the thermal properties of graphitic foams[J]. Journal of Materials Science, 2004, 39(11): 3659- 3676.

[3] GALLEGO N C, KLETT J W. Carbon foams for thermal management[J]. Carbon, 2003, 41(7): 1461-1466.

[4] KLETT J W. Process for making carbon foam: US 6033506[P]. 2000-03-07.

[5] GALLEGO N C, BURCHELL T D, KLETT J W. Irradiation effects on graphite foam[J]. Carbon, 2006, 44(4): 618-628.

[6] KLETT J, HARDY R, ROMINE E, WALLS C, BURCHELL T. High-thermal-conductivity, mesophase-pitch-derived carbon foams: Effect of precursor on structure and properties[J]. Carbon, 2000, 38(7): 953-973.

[7] 李 凯, 栾志强. 中间相沥青基炭泡沫[J]. 新型炭材料, 2004, 19(1): 77-78.

LI Kai, LUAN Zhi-qiang. Mesophase pitch-based carbon foam[J]. New Carbon Materials, 2004, 19(1): 77-78.

[8] WANG M X, WANG C Y, LI T Q, HU Z J. Preparation of mesophase-pitch-based carbon foams at low pressures[J]. Carbon, 2008, 46(1): 84-91.

[9] 安秉学, 李同起, 王成扬. 发泡条件对中间相沥青基泡沫炭形成的影响[J]. 炭素技术, 2005, 24(6): 1-4.

AN Bing-xue, LI Tong-qi, WANG Cheng-yang. Effect of foaming conditions on formation of mesophase pitch-based carbon foams[J]. Carbon Techniques, 2005, 24(6): 1-4.

[10] 陈 峰. 中间相沥青基炭泡沫的制备及其性能研究[D]. 长沙: 中南大学, 2008.

CHEN Feng. Preparation and properties researching of mesophase-pitch-derived carbon foams[D]. Changsha: Central South University, 2008.

[11] 沈曾民, 戈 敏, 迟伟东, 刘 辉. 中间相沥青基炭泡沫体的制备、结构及性能[J]. 新型炭材料, 2006, 21(3): 193-201.

SHEN Zeng-min, GE Min, CHI Wei-dong, LIU Hui. Preparation, structures and properties of mesophase pitch-based carbon foams[J]. New Carbon Materials, 2006, 21(3): 193-201.

[12] 钟继明, 王新营, 郁铭芳, 王依民. 石墨化碳泡沫导热性能研究[J]. 材料导报, 2006, 20(z1): 268-270.

ZHONG Ji-ming, WANG Xin-ying, YU Ming-fang, WANG Yi-min. The studying of the thermal conductivity of carbon foam[J]. Materials Review, 2006, 20(z1): 268-270.

[13] GE M, SHEN Z M, CHI W D, LIU H. Anisotropy of mesophase pitch-derived carbon foams[J]. Carbon, 2007, 45(1): 141-145.

[14] 闫 曦, 史景利, 宋 燕, 郭全贵, 刘 郎. 中间相沥青基泡沫炭的制备及性能[J]. 宇航材料工艺, 2006, 36(2): 56-59.

YAN Xi, SHI Jing-li, SONG Yan, GUO Quan-gui, LIU Lang. Preparation and performance of mesophase pitch-derived carbon foam[J]. Aerospace Materials & Technology, 2006, 36(2): 56-59.

[15] CAO Min, ZHANG Shu, WANG Yong-gang. Influence of preparation conditions on the pore structure of carbon foam[J]. New Carbon Materials, 2005, 20(2): 134-138.

[16] 王 松, 谢 凯, 洪晓斌. 变压发泡工艺对聚氨酯泡沫泡孔结构控制的研究[J]. 塑料科技, 2001, 29(4): 7-10.

WANG Song, XIE Kai, HONG Xiao-bin. Study of controlling cell structure of polyurethane foam by varying pressure in foaming[J]. Plastics Science and Technology, 2001, 29(4): 7-10.

[17] 金宗哲, 包亦望. 脆性材料力学性能评价与设计[M]. 北京: 中国铁道出版社, 1996: 110-111.

JIN Zong-zhe, BAO Yi-wang. Characterization of mechanical properties for brittle materials and ceramics[M]. Beijing: China Railway Press, 1996: 110-111.

[18] DRUMA A M, ALAM M K, DRUMA C. Analysis of thermal conduction in carbon foams[J]. International Journal of Thermal Sciences, 2004, 43(7): 689-695.

[19] SAVAGE G. Carbon carbon composites[M]. London: Chapman & Hall, 1993: 309-317.

(编辑 杨 华)

基金项目:国家重点基础研究发展计划资助项目(2006CB600907)

收稿日期:2009-08-25;修订日期:2010-01-19

通信作者:张红波,教授,博士;电话:0731-88877393;E-mail: zhanghb@hnu.cn