一种表征紧耦合气雾化中熔滴冷却速率的新方法

欧阳鸿武,陈 欣,余文焘,黄伯云

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:通过分析熔体破碎模式和非晶态颗粒的形成机制,提出一种表征紧耦合气雾化过程中熔滴冷却速率的新方法。结果表明:在一定的工艺条件下,紧耦合气雾化存在多种破碎模式,熔滴的冷却速率因直径、雾化位置的差异,相同直径熔滴经历结晶和非晶化2种不同冷却行为; 依据Al基合金粉末的粒度分布和微观结构,结合熔体的雾化过程及冷却模式,确定熔滴冷却速率的上、下限;实验得出熔滴的冷却速率为104~108 K/s,Al-Ni-Y合金的非晶化临界冷却速率为105 K/s,能形成非晶态的熔滴最大直径为25 μm左右,实验结果与理论分析结果较吻合,比较客观地反映紧耦合气雾化的复杂过程。

关键词:非晶;粉末;紧耦合气雾化;冷却速率

中图分类号:TF123.1 文献标识码:A 文章编号:1672-7207(2007)03-375-06

A new approach to evaluate cooling rates of melt droplets in

close-coupled gas atomization

OUYANG Hong-wu, CHEN Xin, YU Wen-tao, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Based on the formation mechanism of amorphous particle in atomized Al-Ni-Y alloy powders, combining with the analysis of breakup modes of melt, a new approach to evaluate cooling rates of melt droplets in close-coupled gas atomization was presented. The results indicate that the cooling rate of melt droplet that can not break further depends not only on its diameter, but also on its position in atomizing chamber. As a result, the same sized particles in different positions show different cooling rates and two different kinds of microstructures (amorphous and crystal). The cooling rates of melt droplets range from 104 to 108 K/s, and the critical cooling rate for glass formation of Al-Ni-Y is about 105 K/s. Moreover, the corresponding maximum diameter of amorphous particles is 25 μm, which accords well to the theoretical analysis results. The new approach, reflecting the complexity of close-coupled gas atomization objectively, is available and effective to evaluate the cooling behaviors of close-coupled gas atomization (CCGA).

Key words: amorphous; powder; close-coupled nozzle; cooling rate

紧耦合气雾化中,气流出口与金属液流的导液管口距离非常短,雾化气体与金属熔体之间的能量转换率高,熔滴获得的冷却速率高,具有快速冷凝的特征,可以形成非晶态粉末,将非晶粉末固结成形,成为制备块体非晶材料的可行途径,引起了广泛重视[1-3]。

非晶态的形成取决于合金的非晶形成能力(GFA) 以及冷却速率,对于确定合金成分,显然冷却速率是决定性因素[4]。因而,探明紧耦合气雾化中熔滴的冷却速率特征将为非晶粉末的高效制备提供一定的基础和参考。关于雾化熔滴的冷却过程,Sobolev等[5-6]提出了喷射成形中熔滴冷却的数值模型, Liu等[7]研究了多级雾化中的大过冷及形核机制,孙剑飞等[8]对喷射成形中熔滴的结晶行为进行了研究,Krauss等[9]在线检测了熔滴飞行过程中的冷却速率以及温度场。但是这些研究都忽略了熔体破碎过程的具体特点,没有将熔滴的冷却行为同紧耦合气雾化的复杂流场联系起来,常规的方法(如二次枝晶间距法)又无法客观而全面地评估粉末(尤其是对于非晶颗粒)的冷却速率。因此,紧耦合气雾化中熔滴的冷却行为仍未明了。在实际研究和应用中,紧耦合气雾化粉末还存在着粒度分布较宽、组织结构不甚均一以及非晶颗粒产出比例小等诸多亟待解决的问题[10]。

本文作者根据确定成分合金具有非晶化临界冷却速率以及Al基合金非晶化临界冷却速率高的特点[11],结合紧耦合气雾化熔体破碎模式的复杂性以及Al-Ni-Y合金非晶颗粒的形成机制,提出一种表征熔滴冷却速率的新途径,并以此评估紧耦合气雾化中熔滴的独特冷却行为。

1 实 验

实验中所用合金成分为Ni 10.00%, Y 5.00%,余量Al;金属的纯度分别为:Al 99.995%;Ni 99.9%;Y 99.99%。采用英国PSI紧耦合气雾化制粉设备及GP30(30 kW)高频真空感应炉(石墨坩埚)。将感应炉腔抽真空至10-2 Pa以下,将金属铝、镍、钇分别按名义质量分数配制并称取后依次投入到石墨坩埚中,待其充分熔化均匀后浇铸。为保证元素分布均匀,将铸锭重熔1次。然后在各个铸锭表面多处取样并混合均匀,再测定铸锭中各元素的实际含量。

将铸锭放入氧化铝坩埚后将其一并置于真空室抽真空至13.3 Pa并升温。待合金充分熔化后在过热度为200 K时进行雾化,所用雾化介质为氩气,气压为1.96 MPa。

将雾化粉末收集后过筛分以获得粒度分布。采用日本理学Rigaku X射线衍射仪对筛分后将细粉和粗粉分别进行X射线衍射,扫描速度为4(?)/min,Cu Kα靶。将细粉用502胶制成金相试样,经过机械研磨、抛光和腐蚀后在日本产JEOL JSM-6500LV扫描电镜上观察其形貌与微观组织。

2 结 果

Al-Ni-Y合金粉末的SEM表面形貌见图1。粉末颗粒大小不一,粒度分布较宽;粉末的形貌与粒度相关,粒度越小,球形度越好,表面越光滑;粉末越大则表面越粗糙。

图1 Al-Ni-Y合金粉末的SEM表面形貌

Fig.1 Surface morphology of Al-Ni-Y alloy powder

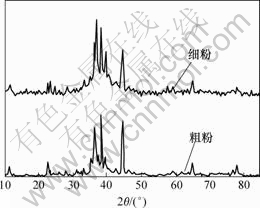

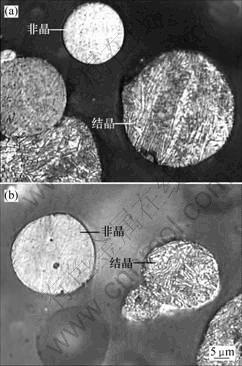

图2所示为Al-Ni-Y合金粉末的X射线衍射图谱,由图可知,细粉(直径小于25 μm)的X射线衍射谱与粗粉相比出现了明显的峰钝化与峰宽化,X射线衍射谱中出现宽带峰和晶相尖的共存,说明非晶中夹带晶相[12],即存在非晶颗粒。图3所示为Al-Ni-Y合金粉末的显微组织照片。由图3(a)可见,较大颗粒呈现出明显的晶态组织,而较小颗粒则未见明显晶态结构,其颗粒最大直径为25 μm左右。司鹏程等[12]发现当颗粒直径小于25 μm时为非晶,这也进一步证实所制得粉末中含有非晶。但在图3(b)中,小于25 μm的颗粒也并非都是非晶态,直径小于25 μm的颗粒呈现出典型的晶态组织。

图2 Al-Ni-Y合金粉末的X射线衍射谱

Fig.2 XRD patterns of Al-based alloy powder

图3 Al基合金粉末的显微组织

Fig.3 Microstructures of Al-based alloy powder

3 讨 论

3.1 紧耦合气雾化中熔体的雾化过程

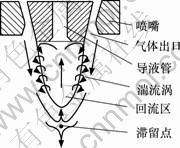

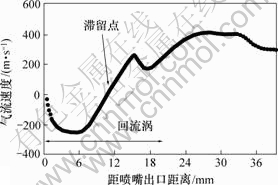

与传统雾化过程相似,紧耦合气雾化中熔体的雾化过程大致存在初始破碎、二次破碎和冷却凝固3个阶段。但由于紧耦合喷嘴下方存在一个流场结构十分复杂的气体回流区,如图4所示,其间的气体速度分布极不均匀,熔体和气流的作用异常复杂。图5所示为在实验气压1.96 MPa时,气体速度沿喷嘴中心线的分布曲线[1]。

图4 气体回流区的流场结构示意图

Fig.4 Schematic profile of recirculation zone

图5 气压为1.96 MPa时沿喷嘴中心线的气体速度分布

Fig.5 Gas velocity along centerline of nozzle at 1.96 MPa

3.1.1 初始破碎

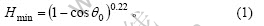

在初始破碎过程中,从导液管出来的柱状金属液流进入回流区,首先被拉成薄膜。稳定薄膜的最小厚度Hmin取决于气液界面的接触角θ,如下式所示[13]:

液体薄膜紧接着在气体射流的作用下表面形成波纹,表面波的不稳定性发展,液膜进一步被抽成丝或带状。丝或带的直径dL取决于液膜的厚度H以及最大不稳定波数Κs[14]:

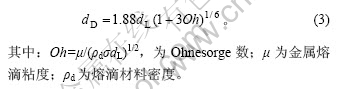

带状的金属液由于Rayleigh-Taylor不稳定性,最终破碎成细小的熔滴。熔滴的直径dD可由下式计算[14]:

3.1.2 二次破碎

初始破碎后的熔滴随即进行二次破碎,该阶段遵循Weber数准则:

只有当熔滴的We数达到临界值(一般认为是10.7)才能进一步发生破碎;随We数的从小到大变化,熔滴的二次破碎相应表现为“哑铃式”(Twins),“袋式”(Bag),“延展式”(Film stripping)和“爆炸式”(Catastrophic)这4种模式[15]。在每一种破碎模式下,熔滴会经历不同的形变破碎过程,获得的熔滴直径差异较大。

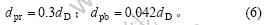

在哑铃式破碎中,二次破碎后获得的熔滴直径dp可由下式计算:

对于袋式破碎模式,环形边缘破碎成较大熔滴,其直径由dpr表示;空心袋破碎后的熔滴直径较小,可由dpb表示为[16]:

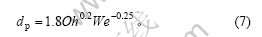

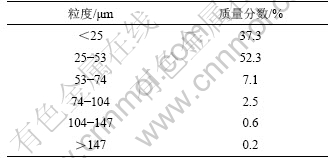

在延展式破碎模式中,破碎产生的熔滴直径dp可由下式表示为[17]:

一般来说,初始破碎中形成的液膜厚度往往不连续,初始破碎后得到的熔滴大小也不均匀。在接下来的二次破碎中,由于回流区复杂结构以及气体速度分布不均匀性(呈高斯分布),不同位置的熔滴U和dD差异较大,根据式(4),其We数相应差异较大。熔滴(We>10.7,可以继续破碎)的二次破碎模式往往为多种模式的混合作用(常规工艺条件下爆炸式破碎一般很难实现)。因此,紧耦合气雾化破碎后得到的熔滴直径呈高斯分布且分布较宽,最终得到的粉末不可避免地存在粒度分布较宽、组织结构不均匀等问题,表1所列为实验得到的粉末粒度分布。

表1 Al-Ni-Y合金粉末的粒度分布

Table1 Particle size distribution of powders

3.1.3 紧耦合气雾化中熔体的冷却过程描述

雾化过程中,对于球形熔滴,热量的传导主要以对流和辐射为主,可由下式表示[18]:

式中:Td为熔滴温度;Tg为气体温度;Tw为环境壁温度;cd,l为熔滴材料的定热容;h为对流传热系数;σ和ε分别为辐射系数和熔滴材料的黑度;ρd和d分别为熔滴密度和直径;λ为材料的导热率。金属液的热传导性高,因此,所考虑金属的Biot数较低(Bi=hd/λ?1),可以忽略熔滴内部的温度梯度,视为牛顿冷却。

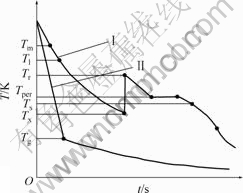

熔滴开始冷却后,温度下降很快,直至凝固成粉末,其冷却过程一般经历图6中曲线Ⅰ所示的5个过程:液相的冷却、再辉、偏析凝固、包晶转变和固态相的冷却,其中,Tm,Tl,Tr,Tper,Tx和Tg分别为熔点、液相线、再辉、包晶、结晶和非晶转变温度。但如果金属熔滴具备极高的冷却速率(达到非晶化转变值),则能够由高温直接通过熔点Tm不发生结晶化,成为过冷熔滴后,再继续冷却到玻璃转变温度Tg,凝固成为非晶态颗粒,如图6中曲线Ⅱ所示。这个过程主要取决于冷却速率,因此,熔滴要转变成非晶态,就必须以极高的冷却速度将温度降低到Tg以下。

图6 雾化熔滴的冷却曲线

Fig.6 Cooling curve of melt droplets

3.2 紧耦合气雾化中熔滴的冷却速率表征

熔体破碎的速度远比其冷却快,因此,只有不再继续破碎的熔滴才开始纯粹的冷却过程。这些熔滴包括初始破碎后无法继续二次破碎的熔滴(熔滴直径已经足够小,We数小于临界值10.7)。根据式(8),在工艺参数确定的情况下,熔滴冷却过程中的冷却速率(dT/dt)取决于对流传导系数h、辐射传导系数σ、温差ΔT以及熔滴的直径d。对流传热系数h的计算公式为:

式中:Nu为传质努塞尔数;Re为雷诺数;Pr为普朗特数;μ为熔体粘度,u为熔滴速度。在传热介质、面积以及材料已经确定的情况下,高速度有利于获得较高的对流传热系数,从而提高冷却速率。但当熔滴直径d达到微米级后,粘度与速度的影响相对直径来说是次要的[10]。

辐射传导系数主要取决于传热距离。在气雾化器中,熔滴冷却的环境可视为圆筒壁,热量由圆筒内部向外部环境传导,显然辐射传导能力由雾化室中心径向向外逐渐增大。同时,从回流区的温度场及气体速度分布来看,相同直径熔滴在边沿的速度以及温差ΔT(气体温度较低)也相对较大。因此,对于相同直径的熔滴,处于雾化室边沿时由于传热系数高且温差ΔT大而获得的冷却速率相对中心位置熔滴较高,相同直径熔滴冷却速率分布大致为由雾化室中心径向向外逐渐增高。

对于同一位置不同直径的熔滴,其冷却速率取决于自身直径的大小,根据式(8),即冷却速率与d成反比。因此,在同一位置处,直径较小的熔滴获得的冷却速率高,直径较大的熔滴获得冷却速率较低。

如果熔滴冷却速率达到非晶化转变值则凝固成非晶态,一般来说,小熔滴更容易凝固成非晶态,大熔滴较难达到非晶化冷却速率而只能形核结晶。但是,由于传热系数的差异,相同直径的熔滴处于不同位置时可能获得不同的冷却速率从而经历不同的冷却过程(结晶化或非晶化),实验结果如图3所示。不同位置不同直径的熔滴可能获得相同的冷却速率。

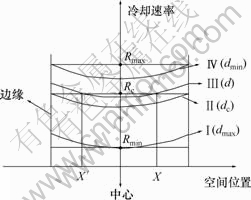

紧耦合气雾化中熔滴冷却速率与直径和位置的复杂关系可由图7表示,横轴为熔滴距雾化室中心的径向距离(原点为中心),纵轴为熔滴的冷却速率,不同曲线即为不同直径熔滴在不同位置的冷却速率曲线。紧耦合熔滴破碎后的直径一般呈正态分布,因此可以取占绝大质量比例部分的熔滴(忽略占极小比例的超细及超大熔滴)来表征。dmax和dmin分别表示有效直径中的最大和最小值,曲线Ⅰ和Ⅳ分别为相应直径最大和最小熔滴的冷却速率分布曲线,Rmax和Rmin为相应的冷却速率最高和最低值,即为当次雾化中有效直径熔滴冷却速率的上下极限。曲线Ⅱ表示能达到非晶化转变值的最大直径dc熔滴的冷却速率分布,Rc为非晶化临界转变速率,即大于dc的熔滴都无法形成非晶态只能形核结晶,小于dc的熔滴则有可能实现非晶转变。曲线Ⅲ表示某一直径d(dmin<d<dc)熔滴的冷却速率分布曲线,显然只有距中心半径大于L的熔滴才能达到非晶化冷却速率,而位于X和X′之间的熔滴只能形核结晶。

图7 熔滴的冷却速率分布示意图

Fig.7 Schematic diagram of distribution of cooling rate

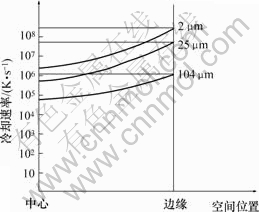

根据上述分析,对冷却速率进行计算,参数见表2。取占质量比例99%以上的颗粒作为有效直径范围,分别计算最大直径为104 μm,最小直径为2 μm以及非晶颗粒最大直径为25 μm,3个直径熔滴在雾化室中心及边沿位置的冷却速率,结果如图8所示,可见,本实验中熔滴冷却速率范围为104~108 K/s。此外,根据公式γ=Tx/(Tl+Tg),其中,Tx,Tl和Tg分别为晶化温度、液相线温度和非晶化转变温度[4],Al-Ni-Y合金的临界冷却速率Rc可以大致估算为105 K/s,再根据式(8)可反推得到临界直径dc为25 μm左右,直径小于25 μm的颗粒都有可能为非晶态,但由于熔滴所处雾化位置不同,导致冷却速率不一致,有些熔滴达不到Rc而凝固成枝晶组织,因此制得的Al-Ni-Y合金粉末中出现了相同直径颗粒呈现不同组织形态的现象。

表2 冷却过程的传热参数

Table 2 Heat transmission parameters

图8 Al-Ni-Y合金熔滴冷却速率的分布

Fig.8 Maximum and minimum of cooling rates droplets

4 结 论

a. 紧耦合气雾化中,熔体的雾化过程极为复杂,熔滴的冷却速率受到直径、雾化位置等多因素的影响,难以用常规的方法有效表征。

b. 结合紧耦合气雾化机理以及非晶颗粒的形成机制,根据确定成分合金具有非晶化临界冷却速率以及Al基合金非晶化临界冷却速率高的特点,提出了一种表征紧耦合气雾化熔滴冷却速率的新方法,比较客观地反映了紧耦合气雾化的复杂过程。

c. 实验得出熔滴的冷却速率为104~108 K/s,Al-Ni-Y合金的非晶化临界冷却速率为105 K/s,能形成非晶态的熔滴的最大直径为25 μm;相同直径的熔滴(小于25 μm)由于雾化位置的差异获得的冷却速率不同,呈现出结晶和非晶化2种冷却行为。实验结果与理论分析结果相吻合。

参考文献:

[1] Ting J, Anderson I E. A computational fluid dynamics (CFD) investigation of the wake closure phenomenon[J]. Mater Sci Eng A, 2004, A379: 264-276.

[2] Inoue A, Kita K, Ohtera K. Al-Ni-Y amorphous powders prepared by high pressure gas atomization[J]. Journal of Materials Science Letter, 1988, 11(7): 1287-1290.

[3] Cardoso K R, Escorial A G, Lieblich M, et al. Amorphous and nanostructured Al-Fe-Nd powders obtained by gas atomization[J]. Mater Sci Eng A, 2001, A305: 89-97.

[4] Lu Z P, Liu C T. A new approach to understanding and measuring glass formation in bulk amorphous materials[J]. Intermetallic, 2004, 12: 1035-1043.

[5] Sobolev V V, Guilemany J M, Martin A J. Formation of powder particles during thermal interaction of liquid and solidified drops in the process of metal atomization[J]. Journal of Materials Processing Technology, 1996, 62: 216-224.

[6] Liu D M, Zhao J Z, Ye H Q. Modeling of the solidification of gas-atomized alloy droplets during spray forming[J]. Materials Science and Engineering A, 2004, 372: 229-234.

[7] Liu Y Z. Large undercooling, rapid solidification, and nucleation mechanism during multistage atomization[J]. Powder Metallurgy, 2002,45 (2): 134-138.

[8] Sun J F, Shen J, Li Z Y, et al. Heat transfer behavior of superalloy droplets during spray forming[J]. Acta Metallurgica Sinica, 2000, 13(2): 800-805.

[9] Krauss M, Bergmann D, Fritsching U. In-situ particle temperature,velocity and size measurements in the spray forming process[J]. Mater Sci Eng A, 2002, A326: 154-164.

[10] 李清泉. 紧密耦合气体雾化制粉原理[J]. 粉末冶金工业, 1999, 9(5): 3-16.

Li Qing-quan. The principle of powder production by the close-coupled gas atomization[J]. Powder Metallurgy Industry, 1999, 9(5): 3-16.

[11] Inoue A, Kimura H. Fabrications and mechanical properties of bulk amorphous, noncrystalline, nanoquasicrystalline alloys in aluminum-based system[J]. Journal of Light Metals, 2001, 1(1): 31-41.

[12] 司鹏程, 饶 雄, 李细江, 等. 大块非晶合金形成的控制因素与制备技术[J]. 材料工程, 1998, 11(2): 3-7.

SI Peng-cheng, RAO Xiong, LI Xi-jiang, et al. Controlling factors and fabrication technologies of bulk metallic glass[J]. Journal of Materials Engineering, 1998, 11(2): 3-7.

[13] El-Genk M S, Saber H H. Minimum thickness of a flowing down liquid film on a vertical surface[J]. International Journal of Heat and Mass Transfer, 2001, 44(4): 2809-2825.

[14] Senecal P K, Schmidt D P, Nouar I, et al. Modeling high-speed viscous liquid sheet atomization[J]. International Journal of Multiphase Flow, 1999, 25(3): 1073-1097.

[15] Joseph D, Belanger J, Beavers G S. Breakup of a liquid drop suddenly exposed to a high-speed air stream[J]. International Journal of Multiphase Flow, 1999, 25(4): 1263-1303.

[16] Chou W H, Faeth G M. Temporal properties of secondary drop breakup in the bag breakup regime[J]. International Journal of Multiphase Flow, 1998, 24(9): 889-912.

[17] Fritsching U, Huang Z, Czisch C, et al. Powder production from melts by controlled gas atomization[C]//Euro PM2004 Conference Proceedings. Shrewsbury, Vienna: European Powder Metallurgy Association, 2004: 65-70.

[18] Bergmann D, Fritsching U, Bauckhage K. A mathematical model for cooling and rapid solidification of molten metal droplets[J]. International Journal of Thermal Science, 2000, 39(2): 53-62.

收稿日期:2007-01-08

基金项目:国家自然科学基金资助项目(50574103)和(10476043)

作者简介:欧阳鸿武(1964-),男,湖南长沙人,教授,博士,从事粉末制备和非晶合金的研究

通讯作者:欧阳鸿武,男,教授,博导,博士;电话:0731-8877192;E-mail:oyhw@mail.csu.edu.cn