轧制与退火处理对粉末冶金Cu/Invar电子封装复合材料结构和性能的影响

来源期刊:中国有色金属学报(英文版)2015年第6期

论文作者:吴丹 杨磊 史常东 吴玉程 汤文明

文章页码:1995 - 2002

Key words:electronic packaging material; Cu/Invar composite; rolling; annealing

摘 要:对粉末冶金制备的Cu/Invar复合材料,进行变形量至70%的轧制及750 °C退火处理,研究在此工艺过程中复合材料物相、组织结构及性能的变化。研究结果表明,轧制和退火处理后的Cu/Invar复合材料中体心立方(BCC) α-Fe(Ni, Co)相明显减少,部分Ni原子从Cu 中脱溶,并溶入α-Fe(Ni, Co)中,促使其向面心立方(FCC)的Invar合金转变。Cu/Invar复合材料的轧制变形过程分为3个阶段:当变形量小于40%时,Cu发生塑性变形,Invar颗粒随之发生位移,且颗粒间的气孔逐渐被压合;当变形量为40%~60%时,Invar合金和Cu发生协调变形,形成流线形结构;当变形量大于60%时,以Invar的变形为主,形成双连续网络状结构。经过变形量为70%的轧制及随后退火处理的Cu/Invar复合材料相对密度为98.6%,抗拉强度为360 MPa,伸长率为50%,热导率为25.42 W/(m·K),热膨胀系数为10.79×10-6 K-1。

Abstract: The Cu/Invar composites of 40% Cu were prepared by powder metallurgy, and the composites were rolled with 70% reduction and subsequently annealed at 750 °C. Phases, microstructures and properties of the composites were then studied. After that, the amount of α-Fe(Ni,Co) in the composites is reduced, because α-Fe(Ni,Co) partly transfers into γ-Fe(Ni,Co) through the diffusion of the Ni atoms into α-Fe(Ni,Co) from Cu. When the rolling reduction is less than 40%, the deformation of Cu takes place, resulting in the movement of the Invar particles and the seaming of the pores. When the rolling reduction is in the range from 40% to 60%, the deformations of Invar and Cu occur simultaneously to form a streamline structure. After rolling till 70% and subsequent annealing, the Cu/Invar composites have fine comprehensive properties with a relative density of 98.6%, a tensile strength of 360 MPa, an elongation rate of 50%, a thermal conductivity of 25.42 W/(m·K) (as-tested) and a CTE of 10.79×10-6 /K (20-100 °C).

Trans. Nonferrous Met. Soc. China 25(2015) 1995-2002

Dan WU1, Lei YANG2, Chang-dong SHI2, Yu-cheng WU3, Wen-ming TANG1,3

1. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China;

2. 43 Institute, China Electronics Technology Group Corporation, Hefei 230088, China;

3. Key Laboratory of Functional Materials and Devices of Anhui Province, Heifei University of Technology, Hefei 230009, China

Received 27 August 2014; accepted 18 December 2014

Abstract: The Cu/Invar composites of 40% Cu were prepared by powder metallurgy, and the composites were rolled with 70% reduction and subsequently annealed at 750 °C. Phases, microstructures and properties of the composites were then studied. After that, the amount of α-Fe(Ni,Co) in the composites is reduced, because α-Fe(Ni,Co) partly transfers into γ-Fe(Ni,Co) through the diffusion of the Ni atoms into α-Fe(Ni,Co) from Cu. When the rolling reduction is less than 40%, the deformation of Cu takes place, resulting in the movement of the Invar particles and the seaming of the pores. When the rolling reduction is in the range from 40% to 60%, the deformations of Invar and Cu occur simultaneously to form a streamline structure. After rolling till 70% and subsequent annealing, the Cu/Invar composites have fine comprehensive properties with a relative density of 98.6%, a tensile strength of 360 MPa, an elongation rate of 50%, a thermal conductivity of 25.42 W/(m·K) (as-tested) and a CTE of 10.79×10-6 /K (20-100 °C).

Key words: electronic packaging material; Cu/Invar composite; rolling; annealing

1 Introduction

In recent years, with the development of high density, multi-function, and high power electronic devices, requirements for high-performance electronic packaging materials, e.g., high thermal conductivity, strength and processability, low coefficient of thermal expansion (CTE) and low cost are urgent [1-4]. However, the commonly-used metal packaging materials such as Al, Cu, steel and Mo(W)-Cu, Invar and Kovar alloys have more or less performance deficiencies [3,5]. For example, Cu and Al have extremely high thermal conductivities, but their CTEs are too high to match with those of the ceramic carriers like AlN and Al2O3 [6]. It can induce high thermal stress in the electronic devices, and even lead to failure of them. Invar and Kovar alloys have good processabilities and low CTEs, but their thermal conductivities are rather poor. Mo(W)-Cu alloys have low CTEs, high thermal conductivities and strengths, but they are expensive, and their processabilities, machinabilities and electroplating properties are poor. To meet the requirements of the new electronic packaging materials mentioned above, composite technology may be the only path that can be used currently. That is, by combining the functions of the components, the composites of high comprehensive properties are possibly fabricated. One typical example is the development and application of the SiCp/Al composites with high SiC volume fraction [7]. However, the performances of machining, plating and soldering of the materials are not good, which restricts the application areas of the materials.

Since the 1990s, the new-style low expansion and high thermal conductivity Cu/Invar/Cu (CIC) layered electronic packaging composites have been developed by cold rolling high thermal conductivity Cu and low CTE Invar sheets together [3]. The CIC composites have high machinability, electroplating ability and solderability and have been used to partly replace some thermal management materials like Kovar alloy, 4J42 alloy (FeNi42) and Mo(W)-Cu alloys. However, the composites also have some disadvantages, e.g., the anisotropy in planar direction and thickness direction and the weak interface bonding strength. The Cu/Invar composites prepared by powder metallurgy (PM) have various advantages, which are described in detail in Refs. [8-10]. WU et al [11] have also prepared the PM treated Cu/Invar composites with the Cu content varied from 30% to 50%, and the microstructures and properties of the composites have been preliminarily studied. According to the previous works, two key issues on the Cu/Invar composites were presented. 1) Due to a low sintering activity of the Invar powders, high sintering temperature was required to improve a high relative density of the composites. It has been determined that although the composites with 40% Cu were sintered at 1000 °C, a relative density as low as 85.2% was achieved [11]. However, high sintering temperature may induce another question. 2) Although the Cu/Invar interface interdiffusion is negligible at the temperature below 700 °C [12], yet it increases considerably as the temperature rises, resulting in the deterioration of the physical properties of the composites. Generally, high relative density is the precondition to obtain high- performance Cu/Invar composites, but it is not obviously appropriate to improve the relative density just via increasing sintering temperature. Hence, exploration on other methods is definitely needed.

In this work, the technique of cold rolling and subsequent annealing of the Cu/Invar composites prepared by PM was investigated to improve the relative density and properties of the composites. Cold rolling of various deformation rates was employed to remove the pores and improve the density of the composites, and subsequent annealing was used to eliminate the deformed structures via the recovery and recrystallization mechanism. And, the out-dissolution of the Fe and Ni atoms in Cu was accelerated during annealing. It is beneficial to the improvement of the physical properties of the composites.

2 Experimental

2.1 Materials

Electrolytic Cu powder with an average particle size below 45 μm and a purity of 99.9% (mass fraction) was provided by Zhongjinyan New Materials Co., Ltd., Beijing, China. The composition is shown in Table 1. Fe32Ni4Co super Invar alloy powder with an average particle size below 75 μm and a purity of 99.8% was fabricated via a gas atomization technique, and its composition is listed in Table 2.

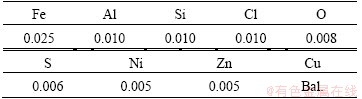

Table 1 Chemical composition of pure Cu (mass fraction, %)

Table 2 Chemical composition of super Invar alloy (mass fraction, %)

2.2 Processing

The Cu powder and the Invar powder were blended with a mass ratio of 40:60, in which 0.5% (mass fraction) zinc stearate powder was added as the lubricant agent. After mixing for 10 h, the mixture powders were uniaxially pressed with the pressure of 400 MPa and the holding time of 2 min, using a 769YP-40C type powder compressing machine. The green bodies were finally sintered at the temperature of 1000 °C with a heating rate of 5 °C/min for 60 min of holding time, employing a GSL-1600X type atmosphere protecting furnace. The whole sintering process of the specimens was in a H2 atmosphere with a flowing rate of 100 mL/min. The sintered Cu/Invar composite specimens were multi-pass cold-rolled in a LG500 type two-roller cold mill with a rolling force of 500 kN, roller sizes of d180 mm × 400 mm and the deformation reduction for each pass of less than 5%. When the thickness of the specimens was reduced by 50%, an intermediate annealing treatment was prepared for the next rolling process by eliminating the inner stress and reducing the hardness of the composites. The annealing temperature was set to be 850 °C and the holding time was 1 h. After rolling, the specimens were annealed at 750 °C for 2 h for the final heat treatment. The intermediate and final heat treatments were both performed in an OTF-1200X type atmosphere protecting furnace, and the annealing process was protected in a H2 atmosphere and cooled via furnace cooling.

2.3 Measurement and characterization

Archimedes method was employed to measure the density of the materials. Phases of the composite specimens were analyzed by a D/MAX-2500V type X-ray diffractometer (XRD) using Cu Kα radiation at a scan rate of 2 (°)/min and a scan range of 10°-90° with a tube voltage and current of 40 kV and 40 mA, respectively. The specimens were etched in an aqua regia solution with a volume ratio of concentrated hydrochloric acid to nitric acid of 3:1. Microstructures of the specimens were observed using a MR5000 type optical microscope (OM) and the Cu grain size was directly measured under the OM observation. Hardness of the specimens was measured using a HV-10A type Vickers hardness tester with a load of 50 N and a holding time of 10 s. Tensile mechanical properties were measured using a CMT5105 type microcomputer control electron universal testing machine with a stretching rate of 0.5 mm/min. Room-temperature electrical resistance was measured by a U3606A type desktop multimeter. And thus, the electrical resistivity of the specimens was deduced, according to the Ohm’s law. Thermal conductivity values were then calculated in terms of the Wiedemann-Franz law [13]. Thermal conductivities of the specimens of d10 mm × 1 mm in size were also measured using a LFA457 laser thermal conductivity analyzer. The CTEs of the specimens of 50 mm × 10 mm × 1 mm in size were tested in a PCY-Ⅲ type expansion coefficient tester in a test temperature range of 20-100 °C.

3 Results and discussion

3.1 XRD analyses

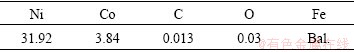

As shown in Fig. 1, (111), (200) and (220) peaks of FCC Cu and Invar alloy (γ-phase austenite) in the XRD pattern of the as-blended powder were marked. The (110) peak of BCC α-Fe(Ni, Co) was detected in the diffraction angle range 2θ=44°-45° in Fig. 1(b). It is known that the structure of the Invar alloy is extremely sensitive to its Ni and Co compositions. The alloy has a BCC structure when the mass fractions of Ni and Co are less than 30% [14]. During sintering, the Ni atoms in the Invar particles diffuse into Cu, resulting in the reduction of the content of Ni in the Invar alloy. In those Invar particles adjacent to Cu, Ni diffusion may be server, resulting in the structure change of the alloy from FCC to BCC. And hence, the Invar effect [15] of the alloy disappears, and CTE of the alloy increases sharply. Compared with Fig. 1(b), the intensity of the α-Fe(Ni, Co) (111) peak in the XRD pattern of the rolled Cu/Invar composites is higher. This is because that in the rolling process, the intermediate annealing at 850 °C was performed, resulting in the increase of the Cu/Invar interface diffusion, and thus, more α-Fe(Ni, Co) phase formed (Fig. 1(c)). Compared with that of the rolled specimen (Fig. 1(c)), the Cu diffraction peak migrates to the left (low diffraction angle orientation), after annealing the specimens at 750 °C, indicating the out-dissolution of the Fe and Ni atoms in Cu [11]. The dissolution of the Fe and Ni atoms out of Cu into α-Fe(Ni, Co) takes place to form the FCC Invar alloy again [10,13]. Accordingly, the decrease of α-Fe(Ni, Co) diffraction peak intensity indicates the reduction of the content of α-Fe(Ni, Co) in the composites (Fig. 1(d)).

Fig. 1 XRD patterns of Cu/Invar composites in different processing stages

3.2 Microstructures

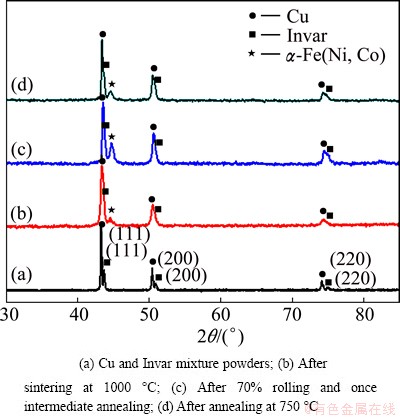

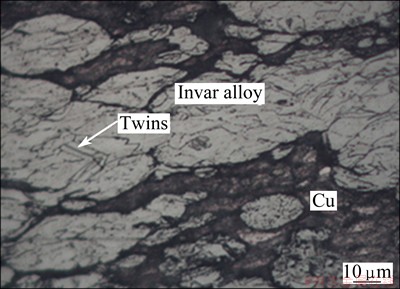

After sintering, there are lots of pores in the Cu/Invar composites. Most of them distribute among the Invar particles and/or at the Cu/Invar interfaces (Fig. 2(a)). In the rolling process, these pores were seamed gradually, and the densification of the composites enhances with the rolling reduction increasing. When the rolling reduction is 30%, the deformation behavior of the composites is undertaken by Cu, in which the Invar particles move. It is helpful to the reduction of the pores in the composites (Fig. 2(b)). When the rolling reduction is increased to 40%, many Invar particles begin to deform plastically, the shape of them changes from approximate sphericity to spheroidicity. Meanwhile, Cu is still elongated, and the porosity of the composites decreases further (Fig. 2(c)). Microstructures of the Cu/Invar composites with different rolling reductions of 50%, 60% and 70% are shown in Figs. 2(d)-(f). With the rolling reduction increasing, the Invar particles extend along the rolling direction to form a streamline structure. Finally, the streamlines connect each other to construct a continuous network structure. Meanwhile, Cu distributed among the Invar particles also deforms and transforms into the continuous network structure (Fig. 2(f)). This kind of the bi-continuous network structure of the Cu/Invar composites is very ideal, it can increase the electrical and thermal conductivity of the composites via the continuous Cu network; on the other hand, it can also lower the CTE of the composites via the continuous low CTE Invar alloy network. Definitely, the bi-continuous structure Cu/Invar composites cannot be fabricated by PM technology.

Fig. 2 Microstructures of Cu/Invar composites after rolling and annealing with different rolling reductions

The rolling deformation behavior of the Cu/Invar composites can be divided into three stages: 1) The plastic deformation of Cu takes place firstly, the Invar particles do not deform, but move with Cu, and thus, the pores in the composites are seamed gradually; 2) The plastic deformation of Cu and Invar takes place coordinately, the pores in the composites are seamed completely and a streamline structure is formed; 3) The Invar alloy deforms to form a bi-continuous network structure. The XRD results in Fig. 1 show that the Cu/Invar composites are mainly composed of Cu and Invar phases. Each of them has a FCC structure and good plastic deformability. Compared with Cu, the Invar alloy has higher hardness (Cu: HV 58; Invar: HV 144) [11] and yield strength (Cu: 60 MPa; Invar: 340 MPa) [9], and hence, the deformability of Invar is rather poor. At a small rolling reduction, Cu in the composites deforms firstly and elongates along the rolling direction. The Invar particles do not deform, but move along the Cu deformation direction, resulting in the elimination of the pores in the composites. As the rolling reduction increases, the work-hardening or dislocation- strengthening effect of Cu is enhanced, so, the deformation resistance of Cu increases, till that the plastic deformations of Cu and Invar both occur at the same time. Two parts of the composites deform coordinately, and a streamline structure is formed gradually. When the rolling reduction is more than 60%, the plastic deformation of Cu may reach its limitation, Cu has been pulled very thinly, the next deformation of the composites is mainly undertaken by the Invar alloy. It is known that the Invar alloy also has low stacking fault energy, therefore, the deformation of the Invar alloy may carry out in terms of the twin deformation, besides the slipping deformation [16]. As shown in Fig. 3, there are plenty of deformation twins in the Invar alloy grains after rolling.

The relative density of the composites raises with increasing the rolling reduction, because the pores in the composites are gradually seamed under the rolling force. As shown in Fig. 4, the relative density increases rapidly at the beginning of the rolling process. When the rolling reduction is more than 30%, the relative density increases slowly as the rolling reduction increases. At the rolling reduction of 70%, the relative density of the composites reaches 98.6%. Moreover, the grain size of Cu in the composites during annealing is reduced, i.e., the recrystallization grain refinement takes place (Fig. 4). Because the recrystallization temperature of Cu is as low as 433 °C, much lower than the annealing temperature of the Cu/Invar composites (750 °C), therefore, recrystallization of the deformed structure of Cu likely happens. And as the rolling reduction increases, the distortion energy of the composites improves, the thermodynamic driving force of recrystallization of the deformed structures increases, therefore, the recrystallization refinement of the deformed grains takes place more rapidly and thoroughly in the annealing process.

Fig. 3 Microstructure of Cu/Invar composites with 50% rolling reduction

Fig. 4 Relationships between relative density, Cu grain size of Cu/Invar composites and rolling reduction

3.3 Properties

3.3.1 Mechanical properties

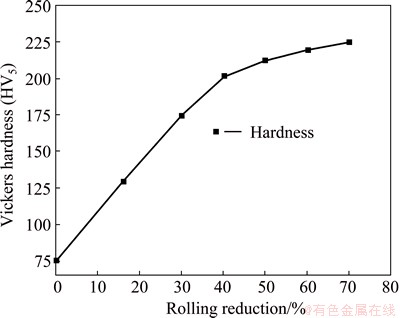

As the rolling reduction increases from zero to 40%, the hardness of the composites increases rapidly (Fig. 5). In this stage, both relative density and work hardening of the composites increase quickly, leading to the remarkable increase of the hardness. When the rolling reduction is more than 40%, the hardness of the composites increases slowly. In addition, after 70% rolling and final annealing, the tensile strength of the Cu/Invar composites is tested to be 360 MPa, and the elongation rate is 50%. On the contrary, the Cu/Invar composites with 43% Cu developed by JHA [8] through extrusion forming at room temperature have a higher work-hardening rate and a higher tensile strength (448.3 MPa), but the elongation rate of the composites is only 13%. Therefore, the Cu/Invar composites developed in this work have better plastic deformability. It may be a more important property for the composites used in fabricating the electronic packaging devices with complex shape in a plastic deformation process.

Fig. 5 Relationship between hardness of Cu/Invar composites and rolling reduction

3.3.2 Physical properties

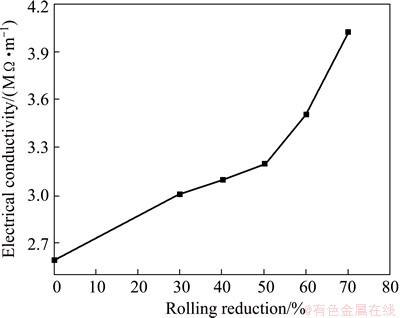

Relationship between the electrical conductivity of Cu/Invar composites and the rolling reduction is shown in Fig. 6. The electrical conductivity of the Cu/Invar composites mainly depends on the conductive Cu phase, and also the preparation process of the materials. It is mostly affected by four factors [1,8,17]. 1) The relative density. The relative density of the composites increases with the rolling reduction increasing. The free electron scattering in Cu is then reduced, and thus the electrical conductivity of the composites increases. 2) The grain size. During annealing, the recrystallization refinement of the Cu grains takes place, resulting in the increase of the Cu grain boundaries. Hence the free electron scattering in Cu increases, deteriorating the electrical conductivity of the composites. 3) The formation of the solid solution. In the solid solution, the solvent crystal lattices are distorted due to the dissolution of the solute atoms, increasing the free electron scattering, leading to the decrease of the electrical conductivity. During sintering and intermediate annealing of the Cu/Invar composites, the Fe and Ni atoms diffuse into Cu from the Invar alloy. The Fe atoms reduce the electrical conductivity of Cu significantly, which is 9.2 μΩ·cm for every percent of Fe [18]. 4) Microstructures. With increasing the rolling reduction, Cu distributes in the composites from the discontinuous state to the continuous network. It can greatly improve the electrical and thermal conductivities of the Cu/Invar composites.

Fig. 6 Relationship between electrical conductivity of Cu/Invar composites and rolling reduction

When the rolling reduction is less than 50%, increasing plastic deformation raises the relative density of the Cu/Invar composites, and there is a corresponding increase of the electrical conductivity of the composites. Meanwhile, the decrease of the Cu grain size takes place, it causes the reduction of the electrical conductivity of the composites. Therefore, the electrical conductivity of the composites increases slightly in this rolling stage. When the rolling reduction is more than 50%, the Cu grain size refinement and the relative density increase of the Cu/Invar composites are not apparent, both of them have little influence on the electrical and thermal conductivities of the composites. The significant increase of the electrical conductivity of the composites mainly results from: 1) the bi-continuous network structure increases the electrical conductive ability of the composites considerably; 2) after large-scale rolling and final annealing at 750 °C, the Fe and Ni atoms dissolve out of Cu, resulting in the purification of Cu, and thus the electrical conductivity of the composites is greatly improved.

According to the Maxwell’s hypothesis [19], if the composites have two phases of A and B, B phase is uniformly distributed in the continuous A matrix, and their electrical conductivities are represented by sA and sB, respectively, the volume fraction of the dispersive B phase is φB, so the effective electrical conductivity s of the composites can be described in Eq. (1).

(1)

(1)

In the Cu/Invar composites, if Cu is supposed to be the continuous matrix, and the Invar alloy particles are the dispersive phase, the electrical conductivity upper limit of the Cu/Invar composites of 40% Cu should be 18.58×106 S/m. Conversely, if the Invar alloy is supposed to be the continuous matrix and Cu is the dispersive phase, the electrical conductivity lower limit of the composites should be 2.4×106 S/m. As mentioned above, after rolling and annealing, the Cu/Invar composites of the bi-continuous structure are formed. The electrical conductivity of the composites is believed to fall in between the upper and lower limits. The electrical conductivity of the Cu/Invar composites of 40% Cu was measured to be 4.03×106 S/m in this work, which situates between 18.58×106 S/m and 2.4×106 S/m, but is closer to the lower limit. The electrical conductivity of the composites is 2.5 times that of the Invar alloy (1.6×106 S/m) [9].

According to the Wiedemann-Franz (W-F) law, the thermal conductivity ke of metals is linear with its electrical conductivity s, as described in Eq. (2).

(2)

(2)

where L0 is the Lorenz constant (2.443×10–8 W/K2) and T is the temperature (K). Hence, the room temperature thermal conductivity of the Cu/Invar composites of 40% Cu is calculated to be 29.33 W/(m·K), which is very close to the measured value (25.42 W/(m·K)) of the composites. Although the thermal conductivity of the composites is much lower than that of Cu (400 W/(m·K) in theory), it is 2.5 times that of the Invar alloy (11 W/(m·K)) and about 2 times that of the stainless steel [2]. It is also much higher that of the PM treated Cu/Fe-Ni nanocrystalline composites of 40% Cu (13-27 W/(m·K) calculated by the W-F law) [10]. Another important result of the current study is that it is reasonable and feasible to deduce the thermal conductivity of the Cu/Invar composites via the W-F law just by measuring the electrical conductivity of the composites. It provides us an effective method in evaluating the thermal conductivity of the metal matrix electronic packaging materials [1,10,13]. Moreover, after 70% rolling and annealing, the CTE of the Cu/Invar composites of 40% Cu was measured to be 10.79×10-6 /K (20-100 °C), which is much lower than that of the pure Cu (17.7×10-6/K) [2].

The new-style Cu/Invar electronic packaging composites of a low CTE (<10×10-6 /K at room temperature to 100 °C) and a high thermal conductivity (>50 W/(m·K)) can be fabricated, if two key questions of the low density and the Cu/Invar interface diffusion are solved. In this work, the first question has been solved in terms of the rolling and subsequent annealing technique. After that, the composites are approximately fully dense. The authors plan to solve the second question by setting an effective Cu/Invar interface diffusion barrier. The study should be reported in near future.

4 Conclusions

1) During sintering the Cu/Invar composites, Fe and Ni atoms in the Invar phase diffuse into the Cu phase. The reduction of the Ni content in the Invar phase leads to the phase transformation of the Invar alloy partly from γ-Fe(Ni, Co) to α-Fe(Ni, Co). After rolling with 70% reduction and annealing at 750 °C, the dissolution of the Fe and Ni atoms out of Cu into α-Fe(Ni, Co) takes place to form the FCC Invar alloy again, resulting in the decrease of the α-Fe(Ni, Co) in the composites.

2) After rolling, the microstructure of the Cu/Invar composites changes significantly. The deformation behavior of the composites is divided into three stages: Firstly, the plastic deformation of Cu takes place, and the Invar particles move along the deformation direction, resulting in that the pores in the composites are seamed gradually; And then, the Invar alloy and Cu deform coordinately and the streamline structure is formed; At last, the Invar alloy also deforms to form the bi-continuous network structure of the composites.

3) After rolling till 70% and subsequent annealing at 750 °C, the Cu/Invar composites of 40% Cu have fine comprehensive properties, e.g., a relative density of 98.6%, a tensile strength of 360 MPa, an elongation rate of 50%, a thermal conductivity of 25.42 W/(m·K) (as-tested)/29.33 W/(m·K)(as-calculated) and a CTE of 10.79×10-6 /K (20-100 °C).

References

[1] TAGORE E R, UPADHYAYA A, PATHAK A V. Processing of silver for MIC packaging applications [J]. IEEE Transactions on Electronics Packaging Manufacturing, 2008, 31: 260-265.

[2] MA Ru-long, PENG Chao-qun, WANG Ri-chu, ZHANG Chun, XIE Li-chuan. Research progress of diamond/aluminum composites for electronic packaging [J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 689-699. (in Chinese)

[3] CAI Hui, WANG Ya-ping, SONG Xiao-ping, DING Bing-jin. Research progress in copper matrix composites for electronic packaging [J]. Materials Review, 2009, 23: 24-28. (in Chinese)

[4] TAO Jing-mei, ZHU Xin-kun, TIAN Wei-wei, YANG Peng, YANG Hao. Properties and microstructure of Cu/diamond composites prepared by spark plasma sintering method [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3210-3214.

[5] TONG Zhen-song, SHEN Zhuo-shen. Status and development of materials for metal packaging [J]. Electronics and Packaging, 2005, 5: 6-15. (in Chinese)

[6] LI Jin-feng, ZHENG Zi-qiao, LI Xi-wu, PENG Zhuo-wei. Application of shape memory alloy TiNi in low thermal expansion copper composites [J]. Materials and Design, 2009, 30: 314-318.

[7] GUO Ming-hai, LIU Jun-you, LI Yan-xia. Microstructure and properties of SiCp/Al electronic packaging shell produced by liquid-solid separation [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(4): 1039-1045.

[8] JHA S. Cuvar—A new controlled expansion, high conductivity material for electronic thermal management [C]//Proceedings of the 45th Electronics Components and Technology Conference. Las Vegas, NV, 1995: 542-547.

[9] COTTLE R D, CHEN X, JAIN R K, ELIEZER Z, RABENBERG L, FINE M E. Designing low-thermal-expansivity, high-conductivity alloys in the Cu-Fe-Ni ternary system [J]. JOM, 1998, 50: 67-69.

[10] STOLK J, MANTHIRAM A. Chemical synthesis and properties of nanocrystalline Cu-Fe-Ni alloys [J]. Materials Science Engineering B, 1999, 60: 112-117.

[11] WU Dan, WU Shi-pu, YANG Lei, SHI Chang-dong, WU Yu-cheng, TANG Wen-ming. Preparation of Cu/Invar composites by powder metallurgy [J]. Powder Metallurgy, 2015, 58: 100-105.

[12] LIU Ya-jun, ZHANG Li-jun, DU Yong, SHENG Guang, WANG Jiang, LIANG Dong. Atomic mobilities, zero-flux planes and flux reversals in fcc Cu-Fe-Ni alloys [J]. CALPHAD: Computer Coupling of Phase Diagrams and Thermochemistry, 2011, 35: 376-383.

[13] STERLING E A, STOLK J, HAFFORD L, GROSS M. Sodium borohydride reduction of aqueous silver-iron-nickel solutions: A chemical route to synthesis of low thermal expansion-high conductivity Ag-Invar alloys [J]. Metallurgy and Materials Transactions A, 2009, 40: 1701-1709.

[14] ZHOU Ying-hui, HARMELIN M, BIGOT J. Martensitic transformation in ultrafine Fe-Ni powders [J]. Materials Science and Engineering A, 1990, 124: 241-249.

[15] WANG Run. Physical properties of metallic materials [M]. Beijing: Metallurgical Industry Press, 1981. (in Chinese)

[16] ZHANG Dai-dong, WU Run. Fundamentals of materials science [M]. Beijing: Beijing University Press, 2011. (in Chinese)

[17] VERHOEVEN J D, CHUEH S C, GIBSON E D. Strength and conductivity of in situ Cu-Fe alloys [J]. Journal of Materials Science, 1989, 24: 1748-1752.

[18] LU Ya-feng, LIANG Ming, LI Cheng-shan, FENG Jian-qing, YU Ze-ming, XU Xiao-yan, LIU Qing, LIU Zhong-yuan. Interface and size effects in metal nano-composites [J]. The Chinese Journal of Nonferrous Metals, 2012, 22: 1650-1658. (in Chinese)

[19] MAXWELL J C. Electricity and magnetism [M]. Oxford: Oxford Press, 1881.

吴 丹1,杨 磊2,史常东2,吴玉程3,汤文明1,3

1. 合肥工业大学 材料科学与工程学院,合肥 230009;

2. 中国电子科技集团公司 第四十三研究所,合肥 230088;

3. 合肥工业大学 先进功能材料与器件安徽省重点实验室,合肥 230009

摘 要:对粉末冶金制备的Cu/Invar复合材料,进行变形量至70%的轧制及750 °C退火处理,研究在此工艺过程中复合材料物相、组织结构及性能的变化。研究结果表明,轧制和退火处理后的Cu/Invar复合材料中体心立方(BCC) α-Fe(Ni, Co)相明显减少,部分Ni原子从Cu 中脱溶,并溶入α-Fe(Ni, Co)中,促使其向面心立方(FCC)的Invar合金转变。Cu/Invar复合材料的轧制变形过程分为3个阶段:当变形量小于40%时,Cu发生塑性变形,Invar颗粒随之发生位移,且颗粒间的气孔逐渐被压合;当变形量为40%~60%时,Invar合金和Cu发生协调变形,形成流线形结构;当变形量大于60%时,以Invar的变形为主,形成双连续网络状结构。经过变形量为70%的轧制及随后退火处理的Cu/Invar复合材料相对密度为98.6%,抗拉强度为360 MPa,伸长率为50%,热导率为25.42 W/(m·K),热膨胀系数为10.79×10-6 K-1。

关键词:电子封装材料;Cu/Invar复合材料;轧制;退火

(Edited by Yun-bin HE)

Corresponding author: Wen-ming TANG; Tel/Fax: +86-551-62901362; E-mail: wmtang@hfut.edu.cn

DOI: 10.1016/S1003-6326(15)63808-0