基于体系可靠度的钢桁梁结构优化设计

刘扬1, 2,鲁乃唯1, 2,殷新锋1, 2

(1. 长沙理工大学 土木与建筑学院,湖南 长沙,410114;

2. 长沙理工大学 桥梁工程湖南省高校重点试验室,湖南 长沙,410114)

摘要:建立钢桁梁结构体系可靠性优化的数学模型,在常规优化模型的基础上,以纵梁和横梁的弯曲失效、腹杆拉应力和屈曲失效为主要失效模式,采用β约界法构建出相关性较低的构件并组建成失效树。提出适用于钢桁梁结构的体系可靠性优化方法,该方法采用神经网络方法求解具有隐式功能函数复杂结构的体系可靠度,然后将体系可靠度通过罚函数的方式引入到个体适应度计算中,通过遗传算法实现体系可靠性优化。采用2种优化方案对某悬索桥钢桁梁结构进行体系可靠性优化分析。研究结果表明:该结构最初失效状态主要表现为腹杆的压应力屈曲失效,最终失效状态表现为纵梁和横梁跨中弯曲失效;2种方案的优化结果都表现为纵、横梁截面面积的减小和腹杆截面面积的增加,这表明该结构的纵梁和横梁的抗弯刚度较大,而腹杆屈曲强度储备稍不足。

关键词:钢桁梁;优化设计;体系可靠度;遗传算法;失效树

中图分类号:U443.35 文献标志码:A 文章编号:1672-7207(2014)10-3629-08

Structural optimization design of steel truss beam based on system reliability

LIU Yang1, 2, LU Naiwei1, 2, YIN Xinfeng1, 2

(1. College of Civil Engineering and Architecture, Changsha University of Science and Technology,

Changsha 410114, China;

2. Hunan Province University Key Laboratory of Bridge Engineering, Changsha University of Science and Technology,

Changsha 410114, China)

Abstract: The system reliability models of steel truss beam structure were established. Bending failure modes of beam and carling were selected to be the main failure mode. The β unzipping method was used to establish the failure tree composed by components with lower correlation based on the convention optimization model. The structural optimization design method was presented based on system reliability. Neural network was used to analyze the system reliability with implicit function, and then system reliability was introduced into the genetic algorithm in the form of penalty function. Two optimization analysis schemes were put forward to analyze the system reliability optimal results of a steel truss beam structure. The results show that the initial structural failure mode is bucking failure of web member and the final structural failure mode is bending failure mode of beam and carling; the results of the two schemes are the decrease of the beam cross section area and the increase of the area of the web member, the beam flexural rigidity of the beam is enough, but the bucking strength is insufficient.

Key words: steel truss beam; optimization design; system reliability; genetic algorithm; failure tree

钢桁梁结构一般由主桁架、联结系和桥面系主成。主桁架是主要承重结构,它由上、下弦杆和腹杆组成[1]。对于钢桁梁这类具有高次超静定的复杂结构的优化设计,设计变量与结构受力响应已不存在简单的显式关系,这使得此类结构的约束优化分析较为困难。文献[2]建立了桥梁主桁架的挠度、弯曲应力与结构尺寸的函数表达式,采用响应面法对桥梁主桁架结构进行了优化设计,并对优化结果进行了有限元分析和验证。文献[3]提出了将BP神经网络和遗传算法相结合用于结构优化设计的方法。考虑构件制作误差和荷载的变异性等随机因素时,确定性的优化设计并不能保证其可靠性[4],加之钢桁梁杆件较多,难以把握整体安全性[5]。事实上,把结构可靠度引入到工程结构优化设计数学模型中,考虑多个失效模式及失效路径,基于体系可靠性对钢桁梁结构进行优化设计,即能达到优化目的,又可保证结构体系的安全性。文献[6]建立了半刚性连接框架的拓扑模型,并结合遗传算法进行了基于体系可靠度的结构优化设计,认为不考虑可靠度的优化设计结构存在安全隐患。文献[7]建立了具有体系可靠性约束的随机桁架结构优化设计数学模型,提出了一种通过可靠度分配和再分配的方法,解决了基于体系可靠性优化中可靠性求解的问题。文献[8]采用随机有限元法计算结构系统的响应量,通过对主要失效模式方程线性化研究,计算失效模式安全余量之间的相关系数,采用概率网络估算技术计算出结构系统的失效概率。上述学者对结构体系可靠性优化概念和方法作了一定的研究,但是针对钢桁梁这类具有明显失效历程的结构,尚无全面而深入的体系可靠性优化分析。本文作者从体系可靠度的角度出发,建立钢桁梁结构体系可靠性优化的数学模型,提出基于遗传算法和神经网络的结构体系可靠性优化方法。最后应用于某悬索桥钢桁梁结构体系可靠性优化设计中,通过两种优化方案进行分析。

1 钢桁梁结构体系可靠性优化的数学模型

1.1 体系可靠性优化的数学模型

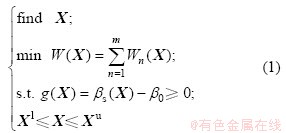

工程结构优化设计一般以结构质量为目标函数,以应力或位移为约束函数[9]。针对钢桁梁结构的体系可靠性优化设计,选取桁架质量为目标函数,以体系可靠指标为约束函数,其数学模型可表示为

式中:X为设计变量;Wn为第n个构件的质量;W为结构总质量;g(X)为约束函数;βs和βo分别为结构体系可靠指标和目标体系可靠指标;Xu和Xl分别为设计变量上下限。

通过引入罚函数的方式,采用遗传算法可求解此类约束优化问题。为了使罚函数简单而又达到约束的目的,采用如下所示罚函数:

(2)

(2)

式中:p(x)为结构种群个体与约束产生的违反量;βc体系可靠指标的目标约束值;a和b为惩罚参数,并由试算得出;惩罚值m随着迭代次数的增加而减小;Ngen为当前迭代次数;Nmaxgen为最大迭代次数。

1.2 钢桁梁结构的失效模式

根据钢桁梁结构失效特点[10],选取纵梁、横梁弯曲失效E1、受压腹杆屈曲失效E2和受拉腹杆拉应力失效E3 这3种失效模式为该类结构的主要失效模式,它们的表达式分别为

(3)

(3)

式中:I1和I2分别为纵横梁和腹杆的截面抗弯惯性矩;h1为截面高度;σ为材料的屈服强度;E为材料的弹性模量;A为腹杆截面面积;L为腹杆的计算长度; 为纵、横梁跨中弯矩;

为纵、横梁跨中弯矩; 为第j个受压腹杆的压应力;

为第j个受压腹杆的压应力; 为第k个受拉腹杆的拉应力。

为第k个受拉腹杆的拉应力。 ,

, 和

和 可采用神经网络方法求解。

可采用神经网络方法求解。

根据体系失效特点,Ei包含的相继失效状态表示为 ,

, ,…,

,…, 。其中,

。其中, 表示第i个失效模式的第k个失效状态,Es表示结构体系失效,则Ei和Es可表示为

表示第i个失效模式的第k个失效状态,Es表示结构体系失效,则Ei和Es可表示为

(4)

(4)

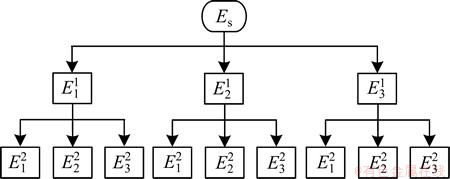

由式(4)可知:单个失效模式是由各失效状态并联而成,而体系失效是由各失效模式串联而成。根据PNET(概率网络估算技术)[11]的要求,考虑失模式间的相关性,在构建失效树时应尽可能地将相关性高的失效状态归为一类,并选择最易失效的失效状态作为代表。不同失效模式及不同荷载工况间的相关系数较低,因此采用β约界法筛选每层相关性较低的失效状态,将其表示为失效树的形式,如图1所示。

图1 钢桁梁结构的失效树

Fig. 1 Failure tree for steel truss beam

2 钢桁梁结构体系可靠性优化设计方法

2.1 基于遗传算法的体系可靠性优化设计方法

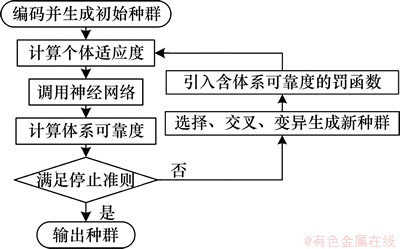

针对钢桁梁的体系可靠性优化设计,只要将优化设计模型与体系可靠度数学模型联系起来,就可以实现其体系可靠性优化设计。将优化设计的数学模型以遗传算法的形式作为主程序,体系可靠度的数学模型以罚函数方形式作为子程序,这样实现了以体系可靠度为约束函数的优化设计,该方法的流程如图2所示。

图2 结构体系可靠性优化设计流程图

Fig. 2 Flow chart for optimization design of structural system reliability

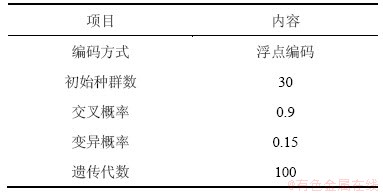

遗传算法的步骤有编码、产生初始群体、计算适应度、选择、交叉、变异等基本操作[12]。针对钢桁梁结构的多维、高精度的连续函数优化问题,各步骤的参数选取如下:

选择浮点编码为编码方式;按式(5)所示的随机方法进行种群初始化;以造价或质量为适应度函数;选用轮盘赌选择方法、多点交叉方法和变异等生成新个体的方法。

(5)

(5)

式中:Rand表示随机产生(0, 1)范围内的随机数。

体系可靠度计算方法采用RBF-MC (RBF神经网络和Monte Carlo抽样技术联合算法)。

2.2 基于RBF-MC方法的钢桁梁结构体系可靠性分析方法

钢桁梁结构功能函数(如式(3)所示)是具有高次非线性的隐式功能函数,要找出所有的失效模式,并用传统的FOSM(一次二阶矩法)或MCM(蒙特卡罗法)实现其可靠度求解极其困难[13]。事实上,采用神经网络和有限元方法可以映射出随机变量与单元应力和节点位移关系,然后用MCM对相应的神经网络抽样分析,可以求解且具有高次非线性的隐式功能函数的失效概率,然后由β约界法和PNET方法得出结构失效树,就可以实现体系可靠度的求解。

考虑到结构体系可靠性求解时,结构体系逐渐变化,按照β约界法的要求仅有少数主要失效模式,因此只需构建主要失效的神经网络。神经网络训练完成且满足精度要求后输出,在遗传算法主程序中被调用,因此神经训练过程并不参与遗传算法的循环过程,这也大大减小了计算时间。该方法的流程如图3所示。

构建神经网络的目的是为了精确映射出结构各个隐式功能函数,即各随机变量与有限元分析结果(应力、位移等)之间的关系。为了保证神经网络能够满足计算精度要求,下面从样点选取和神经网络选取方面寻求更高效的神经网络构建方法。

图3 RBF-MC方法计算体系可靠度的流程图

Fig. 3 Flow chart for calculating system reliability with RBF-MC method

选取足够多的神经网络样本点数据才能保证其拟合精度,但考虑到实际工程应用的要求,样本点应尽量少。UD(均匀设计)[14]与正交设计相比,有更好的均匀性,且同样试验次数可安排较多的水平数,因此本文采用DPS(数据处理系统)[15]的均匀试验设计功能,通过多次迭代实现具有多因素和更多水平数的均匀试验设计方案。

选取逼近能力、分类能力、泛化能力和学习速度等方面均优于BP神经网络的RBF神经网络[16],其核函数为高斯函数:

(6)

(6)

式中:cj和σj分别为RBF网络数据中的均值和标准差;T为求范数的转置矩阵。

如式(6)所示的神经元将依据其输入距离高斯函数中心点的远近来决定它的兴奋程度。RBF神经网络可以根据精度要求逐步增加神经元数量,但为了提高RBF网络的泛化能力,避免陷入局部最优,要选取合适的梯度步长和精度要求。

实际工程结构一般存在大量的失效模式,通过β约界法可以寻找各个主要失效模式。再将各失效模式通过一定的串并联关系,可以求解体系可靠度。神经网络训练完成后,在遗传算法的主程序中调用该网络,计算体系可靠度。

采用遗传算法搜索验算点[17],然后在验算点处采用重要抽样蒙特卡罗方法得到失效概率为:

(7)

(7)

式中:I[g(X)]为示性函数;fx(vi)为验算点处抽样值vi在原分布函数处的概率密度;pV(vi)为vi的重要抽样概率密度,一般采用正态分布函数值。为保证计算结果的可靠性,若βo为目标可靠指标,则样本点数量N应满足以下关系[18]:

N≥ (8)

(8)

采用文献[19]提出的修正β约界法,则候选失效单元应满足以下要求:

βi<βmin+△β (i=1, …, m) (9)

式中:βi为各杆件的可靠指标;βmin为所有βi的最小值;△β在第一层次的失效单元选取时取3,以后取1。

3 某悬索桥钢桁梁结构的体系可靠性优化分析

3.1 工程概况

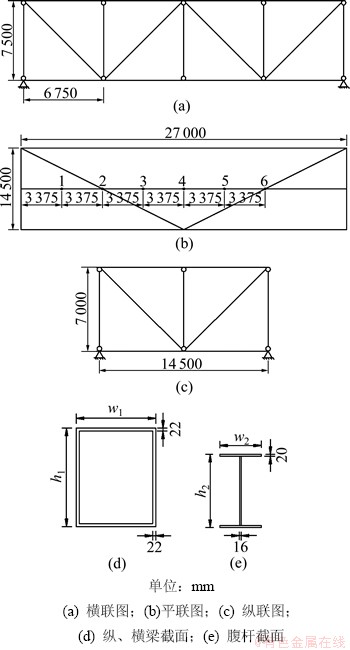

某悬索桥的桁架式主梁结构如图4所示。每个标准梁段长14.5 m,梁高7.5 m,桥面宽27 m。桥面为双向四车道,公路-I级荷载。主梁材料为Q345钢材,弹性模量E=206 GPa,容重ρ=7.85×103 kg/m3。主横桁架的上、下横梁和纵梁为箱形截面(见图4(d)),腹杆为工字形截面(见图4(e)),按照构造要求需满足h2= w1,各杆件的截面初始参数为:w1=640 mm,h1=802 mm,w2=340 mm。

图4 钢桁梁结构图示意图

Fig. 4 Diagram of steel truss beam structure

3.2 钢桁梁设计结构的体系可靠性分析

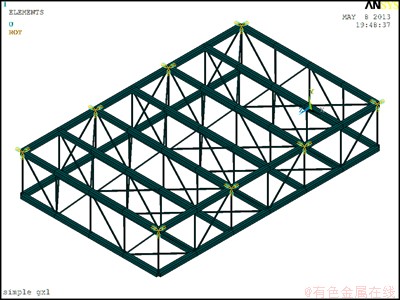

采用通用有限元软件ANSYS建立了3个标准梁段的简化有限元模型(如图5所示)。上弦杆、下弦杆上横梁和下横梁均为BEAM189梁单元,斜腹杆和竖腹杆为LINK8杆单元,在吊索位置施加简支约束。

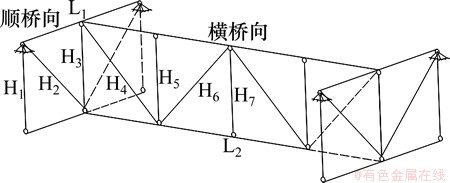

各杆件编号和失效位置如图6所示。

图5 3个标准梁段的钢桁梁有限元模型

Fig. 5 Finite element model for steel truss beam with three standard segments

图6 杆件编号和失效位置图

Fig. 6 Bar code and failure locations

荷载工况为:自重+集中力。其中,集中力按车辆重力标准值取550 kN[20],数量为4个,横向间距为3.375 m。集中力按影响线加载,按图4(b)所示位置,取以下3个工况:

工况1:考虑压杆H2、拉杆H4和横梁L1的失效,集中力加载位置为1,2,3和4号点。

工况2:考虑压杆H6的失效,集中力加载位置为3,4,5和6号点。

工况3:考虑横梁L2的失效,加载位置为3,4和5号点。

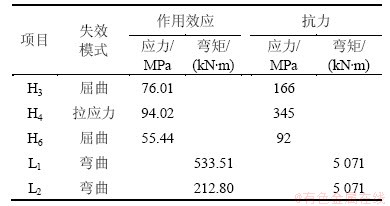

由设计结构的内力分析可知:H1和H7的内力较小,可忽略其失效特性。H2和H4同为拉应力且荷载布置相同,取拉应力较大的H4杆件为代表。H3和H5同为压应力且荷载布置相同,取压应力较大的H4杆件为代表。按照以上3个荷载工况与自重作用效应,钢桁梁的静力计算结果如表1所示。

表1 钢桁梁结构静力计算结果

Table 1 Static calculation results for steel truss beam structure

选取纵梁、横梁弯曲失效E1、受压腹杆屈曲失效E2和受拉腹杆拉应力失效E3 这3种失效模式。功能函数如式(3)所示,其中i=2,j=2,k=1,即弯曲失效杆件为L1和L2,屈曲失效杆件为H3和H6,拉应力失效杆件为H4。

选取横梁截面高度h1、宽度w1、腹杆截面高度h2和集中力F为随机变量。其中h1,w1和h2服从正态分布,均值为设计变量值,变异系数ξ1=0.05;F服从极值I型分布,均值为550 kN,变异系数为ξ2= 0.08[21]。

考虑钢桁梁的失效历程,当纵梁和横梁发生弯曲失效时,在失效位置增加塑性铰;当腹杆发生屈曲失效或拉应力失效时,删除该失效单元。在每次失效状态出现后,重新构建神经网络,继续加载分析,直至结构为变机动结构或出现过大变形。由此构建的失效树如图7所示。

图7 钢桁梁结构失效树

Fig. 7 Failure tree for steel truss beam structure

由图7可以看出:设计结构的最初失效状态表现为H3和H6杆件的屈曲失效,最终失效状态表现为L1和L2杆件弯曲失效后在跨中位置形成塑性铰,而出现不适宜加载的过大变形。其中L1出现塑性较后位移为11.2 cm,L2出现塑性铰后位移为12.4 cm。采用RBF-MC方法可得出该结构的体系可靠指标βs=5.49。

3.3 优化参数与结果分析

考虑2种独立的优化方案:

方案1是在保证结构体系可靠度情况下优化结构质量,即以标准梁段钢桁梁的质量W为目标函数,以原结构体系可靠指标βs=5.49为约束函数;

方案2是在保证结构质量不变的情况下,优化结构的体系可靠度,即以W为约束函数,以βs为目标函数。

由于h2=w1,因此设计变量有3个,分别为横梁截面高度h1、宽度w1和腹杆截面宽度w2。暂取设计变量范围为自身值的一半:h1∈(320, 960),w1∈(410, 1 203),w2∈(170, 510)。

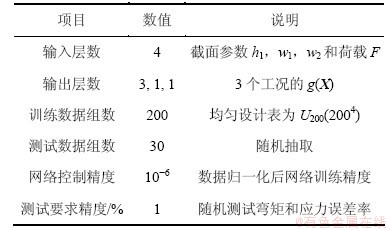

根据均匀设计、有限元模型和RBF神经网络结构要求,本文选用的RBF神经网络参数如表2所示。

表2 RBF神经网络参数

Table 2 Parameter for RBF neural network

按照图3所示流程图中神经网络构建流程,首先在设计变量范围内生成U200(2004)的均匀设计样本,然后采用MATLAB调用ANSYS以后台方式运行计算出各个样本值对应的g(X),最后采用MATLAB的RBF工具箱构建神经网络,测试网络精度数据如图8所示。

由图8可以看出:本次训练的神经网络泛化能力较好,满足精度满足要求。该神经网络在遗传算法主程序中被调用,遗传算法的参数如表3所示。

遗传算法是以目标函数的最大值为搜索目标,因此将2个方案的适应数函数分别选为

图8 神经网络预测值与实际值对比

Fig. 8 Comparison of predicted and actual value of neural network

表3 遗传算法参数

Table 3 Parameters for genetic algorithm

F=-W (11)

F=βs (12)

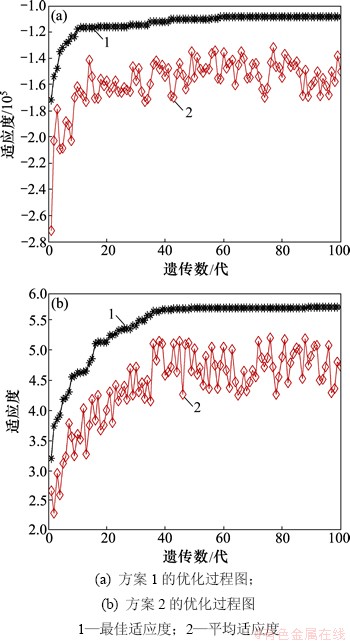

在MATLAB平台采用GA工具箱进行优化分析,优化过程如图9所示。

由图9可以看出:2种方案分别在第20代和第40代种群的适应度已经稳定并达到收敛,表明优化过程稳定,优化结果可靠。

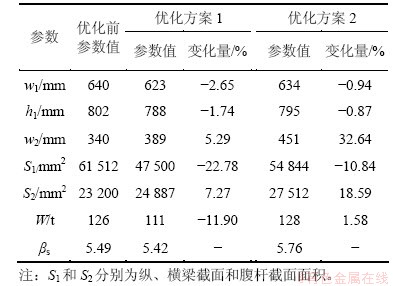

2种优化方案的优化结果与原设计方案的对比如表4所示。

由表4可知:方案1优化后,纵、横梁截面面积大幅减小,而腹杆截面面积小幅增加,致使钢桁梁重量减小11.9%,而体系可靠指标基本无变化;方案2优化后,纵、横梁截面尺寸小幅减小,而腹杆截面宽度大幅增加,致使纵、横梁截面面积小幅减小,而腹杆截面面积大幅增加,达到了体系可靠指标有所提升而钢桁梁质量基本不变的目的。

图9 2种方案的遗传算法优化过程

Fig. 9 Iteration process for genetic algorithm of two schemes

表4 钢桁梁杆件截面优化结果

Table 4 Optimum result for steel truss beam section

4 结论

1) 体系可靠性优化考虑了结构的失效过程,适合钢桁梁这类具有明显失效历程的结构可靠性优化分析。

2) 采用神经网络方法求解具有隐式功能函数复杂结构的体系可靠度,然后将体系可靠度通过罚函数的方式引入到个体适应度计算中,通过遗传算法可实现钢桁梁结构体系可靠性优化。

3) 悬索桥钢桁梁结构的最初失效状态表现为腹杆的压应力屈曲失效,最终失效状态表现为纵梁和横梁跨中的弯曲失效。

4) 2种方案的优化结果都表现为纵、横梁截面面积的减小和腹杆截面面积的增加,这表明设计钢桁梁结构的纵、横梁的抗弯刚度较大,而腹杆屈曲强度储备稍不足。

参考文献:

[1] 何旭辉, 余志武, 陈政清. 既有铁路钢桁梁桥基准有限元模型建立与验证[J]. 振动与冲击, 2007, 26(12): 117-121.

HE Xuhui, YU Zhiwu, CHEN Zhengqing. Establishment and verification of the baseline 3d finite-element model of existing rail way steel truss bridge [J]. Journal of Vibration and Shock, 2007, 26(12): 117-121.

[2] 杨书仪, 刘德顺, 文泽军. 基于响应面法的桥梁主桁架结构优化设计[J]. 机械设计, 2007, 24(6): 14-16.

YANG Shuyi, LIU Deshun, WEN Zejun. Structural optimization design of Bridge main truss based on response surface method [J]. Journal of Machine Design, 2007, 24(6): 14-16.

[3] 郭海丁, 路志锋. 基于BP神经网络和遗传算法的结构优化设计[J]. 航空动力学报, 2003, 18(2): 216-220.

GUO Haiding, LU Zhifeng. Structure design optimization based on BP-neural networks and genetic algorithms [J]. Journal of Aerospace Power, 2003, 18(2): 216-220.

[4] 黄小锋, 王荣辉. 钢桁梁制造和拼装误差对桁架内力的影响分析[J]. 科学技术与工程, 2012, 12(9): 4833-4838.

HUANG Xiaofeng, WANG Ronghui. The analysis about internal force by the effect of error by steel truss girders’ manufacturing and assembly [J]. Science Technology and Engineering, 2012, 12(9): 4833-4838.

[5] 韩衍群, 叶梅新. 连续钢桁结合梁桥桥面系受力状态及与桥面系刚度的关系[J]. 中南大学学报(自然科学版), 2008, 39(2): 387-393.

HANG Yanqun, YE Meixin. Relationship between load bearing and stiffness of floor system in continuous truss composite bridge [J]. Journal of Central South University (Science and Technology), 2008, 39(2): 387-393.

[6] 何嘉年. 基于体系可靠度的半刚性钢框架结构优化设计研究[D]. 汕头: 汕头大学工学院, 2010: 97-113.

HE Jianian. Study on optimal design of semi-rigid steel frame based on system reliability [D]. Shantou: Shantou University. College of Engineering, 2010: 97-113.

[7] 马洪波, 陈建军, 马孝松, 等. 基于体系可靠性的随机桁架结构优化设计[J]. 西安电子科技大学学报(自然科学版), 2005, 32(4): 93-598.

MA Hongpo, CHEN Jianjun, MA Xiaoshong, et al. Structural optimization design of random truss structures based on system reliability [J]. Journal of Xidian University (Science and Technology), 2005, 32(4): 93-598.

[8] 李海波, 刘宗民, 杨洪澜. 多随机变量的桁架结构系统的可靠性分析及优化设计[J]. 强度与环境, 2002, 29(2): 57-64.

LI Haibo, LIU Zhongmin, YANG Honglan. Reliability analysis and optimization design for truss structural systems with multiple random variables [J]. Structure & Environment Engineering, 2002, 29(2): 57-64.

[9] Lamberti L. An efficient simulated annealing algorithm for design optimization of truss structures [J]. Computers & Structures, 2008, 86 (19/20): 1936-1953.

[10] 黄永辉, 王荣辉, 饶瑞. 考虑整体节点刚域影响的钢桁梁桥空间受力计算分析[J]. 中国铁道科学, 2012, 33(5): 8-14.

HUANG Yonghui, WANG Ronghui, RAO Rui. The calculation and analysis of the spatial mechanical behavior for steel truss bridge considering the effect of integral joint rigid zone [J]. China Railway Science, 2012, 33(5): 8-14.

[11] Thoft-Christensen P, Sorensen J D. Reliability of structural systems with correlated elements [J]. Applied Mathematical Modeling, 1982, 6: 171-178.

[12] 孙仁范, 牟在根, 颜谋, 等. 遗传算法在桁架结构优化设计中的应用[J]. 建筑结构学报, 2004, 25(3): 75-79.

SUN Renfan, MOU Zaigen, YAN Mou, et al. Application of genetic algorithms in optimums design of truss structures [J]. Journal of Building Structures, 2004, 25(3): 75-79.

[13] 赵国藩. 结构可靠度理论[M]. 北京: 中国建筑工业出版社, 2000: 12-34.

ZHAO Guofan. Structural reliability theory [M]. Beijing: China Building Industry Press, 2000: 12-34.

[14] 方开泰. 均匀试验设计的理论、方法和应用: 历史回顾[J]. 数理统计与管理, 2004, 23(3): 69-80.

FANG Kaitai. The theory, method and application of uniform design: Historical review [J]. Application of Statistics and Management, 2004, 23(3): 69-80.

[15] Tang Q Y, Zhang C X. Data processing system (DPS) software with experimental design, statistical analysis and data mining developed for use in entomological research [J]. Insect Science, 2013, 20(2): 254-260.

[16] 朱劲松, 肖汝成, 何立志. 大跨度斜拉桥智能可靠度评估方法研究[J]. 土木工程学报, 2007, 40(5): 41-48.

ZHU Jinsong, XIAO Rucheng, HE Lizhi. Reliability assessment of large-span cable-stayed bridges based on artificial intelligence [J]. China Civil Engineering Journal, 2007, 40(5): 41-48.

[17] 张建仁, 刘扬. 遗传算法和人工神经网络在斜拉桥可靠度分析中的应用[J]. 土木工程学报, 2001, 34(1): 7-13.

ZHANG Jianren, LIU Yang. Application of genetic algorithm and artificial neural network in the reliability analysis of cable-stayed bridge [J]. China Civil Engineering Journal, 2001, 34 (1): 7-13.

[18] 张明. 结构可靠度分析方法与程序[M]. 北京: 科学出版社, 2009: 148-153.

ZHANG Ming. Structural reliability analysis method and program [M]. Beijing: Science Press, 2009: 148-153.

[19] 董聪. 现代结构系统可靠性理论及其应用[M]. 北京: 科学出版社, 2001: 119-133.

DONG Chong. Modern structural system reliability theory and its application [M]. Beijing: Science Press, 2001: 119-133.

[20] JTG B01—2003. 公路工程技术标准[S].

JTG B01—2003. Technical standard of highway engineering [S].

[21] 李扬海, 鲍卫刚, 郭修武, 等. 公路桥梁结构可靠度与概率极限状态设计[M]. 北京: 人民交通出版社, 1997: 203-209.

LI Yanghai, BAO Weigang, GUO Xiuwu, et al. Structural reliability and probabilistic limit state design of highway bridge [M]. Beijing: China Communication Press, 1997: 203-209.

(编辑 杨幼平)

收稿日期:2013-10-15;修回日期:2013-12-25

基金项目(Foundation item):国家自然科学基金资助项目(51108045, 51378081);教育部新世纪优秀人才支持计划项目(NCET-10-0139);桥梁工程湖南省高校重点实验室(长沙理工大学)开放基金资助项目(12KA04)(Projects (51108045, 51378081) supported by the National Natural Science Foundation of China; Project (NCET-10-0139) supported by Program for New Century Excellent Talents in University; Project (12KA04) supported by Open Fund of Hunan Province University Key Laboratory of Bridge Engineering (Changsha University of Sceince & Technology))

通信作者:鲁乃唯(1987-),男,河南周口人,博士研究生,从事桥梁结构可靠度评估与安全控制研究;电话:13787265433; E-mail: lunaiweide@163.com