DOI: 10.11817/j.issn.1672-7207.2017.06.011

热连轧轧制特性分析及轧制力动态锁定策略

彭文1,姬亚锋2,陈树宗1,张殿华1

(1. 东北大学 轧制技术及连轧自动化国家重点实验室,辽宁 沈阳,110819;

2. 太原科技大学 重型机械教育部工程研究中心,山西 太原,030024)

摘要:为获得热连轧最优厚度控制策略,进一步提高厚度控制精度,基于轧制特性过程分析,分析轧制过程中辊缝、来料厚度和温度等对出口成品厚度的影响,得到各影响因素的厚度影响系数。针对厚度计AGC和监控AGC存在相互干扰的问题,提出一种动态锁定轧制力控制策略,并将优化后的厚度策略应用于某热连轧厚度控制系统中。研究结果表明:对于典型规格的带钢,平均厚度偏差在±25 μm范围内厚度预测精度可达96.8%以上,偏差在±50 μm范围内厚度预测精度可达98.8%以上,优于现场控制要求。

关键词:热连轧;动态锁定轧制力策略;影响系数;监控AGC;厚度计AGC

中图分类号:TG333.5 文献标志码:A 文章编号:1672-7207(2017)06-1492-07

Rolling characteristics analysis and dynamic roll force locking strategy for hot strip mill

PENG Wen1, JI Yafeng2, CHEN Shuzong1, ZHANG Dianhua1

(1. The State Key Laboratory of Rolling and Automation, Northeastern University, Shenyang 110819, China;

2. Engineering Research Center for Department of Heavy Machinery Education,

Taiyuan University of Science and Technology, Taiyuan 030024, China)

Abstract: In order to obtain the thickness control scheme and improve the thickness precision in hot strip rolling, the rolling characteristics process was discussed, and the gap-position, primary thickness and the temperature which were related to the target thickness were taken into consideration, and finally the influences coefficients was received. Aiming at the problem which is mutual interference when the monitor automatic gauge control (AGC) is also used simultaneously with gauge meter AGC, a kind of novel dynamic locking force control strategy was proposed. The optimized control strategy was applied in the AGC system in one hot strip mill. The result indicates that the strip thickness deviation can be controlled within the target tolerances ±25 μm over 96.8%, and tolerances ±50 μm over 98.8%, satisfying the requirement of production.

Key words: hot strip mill; dynamic locking force control strategy; influence coefficient; monitor AGC; gauge meter AGC

热轧带钢作为冶金工业的重要产品广泛应用于国民经济的许多领域。随着生产和技术的发展,对热轧产品厚度控制精度提出了越来越高的要求。厚度自动控制(automatic gauge control,AGC)系统广泛应用于自动控制系统当中,对保证带钢全长厚度精度起着至关重要的作用,是现代化板带钢生产中重要的组成部分[1-5]。AGC系统主要包括前馈AGC、厚度计AGC和监控AGC,其中前馈AGC与厚度计AGC可以分别与监控AGC联合使用以获得良好的厚度精度,厚度计AGC与监控AGC联合使用作为消除带钢厚度偏差的主要控制策略,两者之间存在相互干扰的问题,诸多文献通过理论分析揭示其相互干扰的原因,采用由测厚仪测量厚度偏差结合厚度计AGC依据弹跳方程计算得出厚度偏差的策略解决厚度计AGC与监控AGC的相关性问题,但同时降低了监控AGC的控制精度[6-9]。本文作者采用影响系数法分析影响厚度控制精度的关键因素,并在此基础上提出动态锁定轧制力控制策略,解决了厚度控制中的相关性问题,消除厚度计AGC与监控AGC之间的相互干扰,提高了厚度控制精度,相应研究成果已成功应用于热连轧生产过程中,并取得了良好的厚度控制效果。

1 影响厚度的关键因素分析

1.1 厚度增量方程

热连轧生产过程中,每个外扰量(入口厚度波动、温度波动等)都会在机架间相互传递,造成机架参数的变换,除直接影响本机架工作之外,还将会影响其他机架的工作,并最终影响成品厚度。

热连轧生产过程中,将热连轧轧制力模型 代入弹跳方程的增量形式

代入弹跳方程的增量形式 ,忽略速度波动和精轧轧制过程中宽度变化,并且目前活套张力都能控制在极小范围内,热连轧增量厚度方程可以写成一般采用如下形式:

,忽略速度波动和精轧轧制过程中宽度变化,并且目前活套张力都能控制在极小范围内,热连轧增量厚度方程可以写成一般采用如下形式:

(1)

(1)

式中:i为机架号;(As)i为辊缝影响系数, ;

; 为来料厚度影响系数,

为来料厚度影响系数, ;

; 为变形抗力影响系数,

为变形抗力影响系数, 。

。

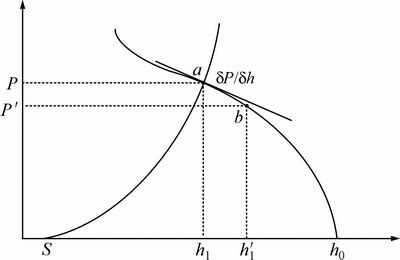

考虑到分析研究的对象是各参数的变动量,偏微分系数的求解可以通过采用在小变化范围内将非线性函数线性化的方法进行研究。采用以弦切线的近似方法进行计算(如图1所示),以 为例,通过改变机架的出口厚度

为例,通过改变机架的出口厚度 ,求出新的轧制力

,求出新的轧制力 ,从而计算得到偏微分系数。

,从而计算得到偏微分系数。

图1 割线替代法示意图

Fig. 1 Schematic of secant method

(2)

(2)

当b点无限接近于a点时,弦即成为切线,使用同样的方法可以计算 和

和 等偏微分系数。

等偏微分系数。

1.2 影响系数分析

在带钢的热连轧过程中,为了分析扰动量及控制量对目标量的影响,一般建立由目标量、扰动量和控制量组成的静态综合分析增量数学模型。对于热连轧机组来说,来料温度变化造成的硬度波动以及来料厚度的变化为扰动量,压下位置变动为控制量,出口目标厚度为目标量。采用影响系数法求解各影响因素相关增量形式代数方程组,可以有效分析各影响因素对出口厚度的影响[10-11]。

考虑到热连轧前一架的出口厚度变化为下一机架入口厚度变化这一特点,在分析任一扰动量或控制量对目标量的影响时,不但要计算其对本机架出口厚度影响,还需要计算本机架出口厚度变化对成品厚度的影响。

当研究辊缝位置变化 对最终成品厚度hn的影响,即第i机架的压下动作对成品厚度的影响时,由下式进行计算:

对最终成品厚度hn的影响,即第i机架的压下动作对成品厚度的影响时,由下式进行计算:

(3)

(3)

进一步有:

(4)

(4)

来料厚度波动 对最终成品厚度hn的影响系数为

对最终成品厚度hn的影响系数为

(5)

(5)

故:

(6)

(6)

在研究入口温度波动造成的变形抗力波动 对成品厚度hn的影响时,需要考虑以下2个方面:

对成品厚度hn的影响时,需要考虑以下2个方面:

1)  对每个机架都会产生影响,对每机架会有

对每个机架都会产生影响,对每机架会有 (

( );

);

2)  将使i机架产生

将使i机架产生 ,而

,而 又会影响后面各机架的出口厚度。

又会影响后面各机架的出口厚度。

一般由带钢温度变化造成,因此,

一般由带钢温度变化造成,因此,

(7)

(7)

式中: 为温度对变形抗力的影响系数;

为温度对变形抗力的影响系数; 为入口温度波动造成的变形抗力变化量。

为入口温度波动造成的变形抗力变化量。

可以得出温度波动对厚度的影响系数 :

:

(8)

(8)

故:

(9)

(9)

1.3 热连轧轧制特性分析

1.3.1 偏微分系数计算

某1 580 mm热连轧机组为例,轧辊直径760 mm,轧机刚度为5 800 kN/mm,对宽度1 250 mm钢种Q235的典型厚度带钢进行影响系数计算。

以厚度增量方程为基础,分别对实际生产过程中的典型轧制厚度进行偏微分系数计算,其中厚度5.20 mm带钢的偏微分系数如表1所示。以此为条件,以入口厚度波动1 mm,入口温度波动20 ℃,各机架辊缝偏差1 mm,进一步计算了带钢厚度分别为2.00 mm,3.52 mm以及7.00 mm的影响系数。

1.3.2 轧制特性分析

辊缝影响系数变化趋势如图2所示。由图2可以看出,对于各不同厚度的带钢,下游机架辊缝变化的影响呈上升趋势,并且随着成品厚度的增加,辊缝的影响变得更加重要。

上游机架F1~F3辊缝变化对不同厚度带钢的成品厚度有一定影响,随着目标厚度的减小,对成品厚度的影响逐渐增大,对于较厚带钢(厚度7.0 mm),F3机架影响系数小于0.02,投用AGC对成品厚度影响较小;但对于薄带钢(厚度2.0 mm),F3机架影响系数在0.05左右,对成品厚度影响相对较大。

最末机架F6和F7辊缝变化对成品厚度均有很大影响,因此在最后2个机架投用AGC对于保证成品厚度起到至关重要的作用。

厚度影响系数变化趋势如图3所示。由图3可以看出:来料厚度对F1和F2机架出口厚度的影响较大,而对下游机架的影响较小,说明热连轧机组本身具有减小原料绝对厚差的能力,且经过多机架轧制后来料厚度几乎对成品厚度无影响。

温度对出口厚度的影响主要体现在温度波动对变形抗力的影响,变形抗力的变化进一步影响出口厚度。温度影响系数变化趋势如图4所示。由图4可以看出:来料变形抗力变化对前四机架出口厚度有较大影响,对于后三机架的影响系数虽然下降,但仍然比较大,是影响机架出口厚度的重要因素,这也充分反映了由温度不均造成的变形抗力波动对所有机架出口厚度的影响都较大,具有重发性。

通过轧机影响系数分析可以得出,粗轧出口厚度偏差经热连轧精轧机组轧制后对成品厚度影响极小,而由带钢全长温度不均造成的变形抗力波动具有重发性,对带钢成品厚度偏差有很大影响。

表1 厚度5.20 mm带钢的偏微分系数

Table 1 Partial differential coefficients for strip steel with thickness of 5.20 mm

图2 辊缝影响系数变化趋势

Fig. 2 Trend of gap influence coefficient

图3 厚度影响系数变化趋势

Fig. 3 Trend of thickness influence coefficient

图4 温度影响系数变化趋势

Fig. 4 Trend of temperature influence coefficient

2 厚度计AGC与监控AGC的相关性

在AGC控制过程中,一般采用厚度计AGC和监控AGC相结合的策略保证成品厚度的控制精度,解决厚度计AGC和监控AGC的相关性问题是提高厚度控制精度的关键所在。

温度对成品厚度的影响主要体现在温度波动对变形抗力造成的影响。在热连轧生产过程中,带钢温度波动的原因有以下2种[12-14]:1) 由于带尾长时间暴露在空气中造成由带头到带尾的温度趋势性降低;2) 加热炉内导轨在钢坯表面造成的低温段,此段温度波动大,容易造成较大厚度波动。

消除同条带钢厚度偏差的主要策略是采用厚度计AGC,因此厚度计AGC不仅要消除由水印造成的厚度波动,还要消除带钢头尾温差造成的带钢全长趋势性厚度偏差,在带钢头尾温差较大时会造成厚度计AGC调节量较大且与监控AGC调节方向相反的情况,使监控AGC被迫中途停止工作。为解决上述问题,采取由厚度计AGC消除水印造成的厚度偏差,由监控AGC消除由带钢头尾温差造成的趋势性厚度偏差的控制策略。

2.1 动态锁定轧制力控制策略

厚度计AGC中锁定厚度由锁定辊缝值和锁定轧制力根据轧机弹跳特性曲线得出[15-16]。由于水印主要通过轧制力波动引起厚度波动,因此可以采用动态锁定轧制力的方式来减小由带钢头尾温差造成的轧制力波动对厚度计AGC的影响。

厚度计AGC方程:

(10)

(10)

式中:Km为轧机刚度,kN/mm;Q为轧件塑性系数,kN/mm;fH为轧机牌坊弹跳方程;fM为辊系挠曲方程;η为辊系挠曲修正因子;S为辊缝,mm;SL为锁定辊缝,mm。

由式(9)可得动态厚度偏差:

(11)

(11)

式中: 为动态锁定轧制力,kN。

为动态锁定轧制力,kN。

带钢头尾温差造成的轧制力波动随机前测温仪温度变化而变化,所以可由机前测温仪的温度变化趋势确定锁定轧制力变化趋势。

为了消除速度变化对带钢温度波动跟踪的影响,采用样本跟踪方式计算单位样本长度温度偏差:

(12)

(12)

式中: 为单位样本长度温度偏差,℃;ts为单位样本长度带钢温度,℃;tL为带钢头部温度锁定值,℃。

为单位样本长度温度偏差,℃;ts为单位样本长度带钢温度,℃;tL为带钢头部温度锁定值,℃。

定义 为相对于锁定温度的单位样本长度温度波动比例:

为相对于锁定温度的单位样本长度温度波动比例:

(13)

(13)

第i机架轧制带钢样本长度为

(14)

(14)

式中:L为带钢单位样本长度,mm;H为带钢来料厚度,mm;hi为第i机架钢带钢厚度,mm。

第i机架动态锁定轧制力 :

:

(15)

(15)

式中: 为机架带钢头部锁定轧制力,kN;μ为轧制力修正因子,与带钢材质、宽度及厚度有关。

为机架带钢头部锁定轧制力,kN;μ为轧制力修正因子,与带钢材质、宽度及厚度有关。

由式(11)和式(15)联立可得动态锁定轧制力控制方式下的厚度偏差:

(16)

(16)

式中:Si为第i机架辊缝,mm。

2.2 厚度计AGC与监控AGC的相关性分析

为使厚度计AGC和监控AGC的厚度基准保持一致,在计算锁定厚度时应综合考虑锁定过程中的出口厚度偏差 ,即厚度偏差

,即厚度偏差 为

为

(17)

(17)

从而得到监控AGC投入时,厚度计AGC的辊缝调节量 为

为

(18)

(18)

3 现场应用效果分析

本文的控制策略已成功应用于某热连轧生产线,采用对比生产试验的方式进行实际效果分析。图5和图6所示分别为钢种为Q235B,成品厚度5.20 mm的产品在传统AGC控制和基于动态锁定轧制力AGC控制策略下的实际厚度控制效果曲线。

由图5可以看出:在带钢头部厚度控制过程中存在监控AGC调节很快达到限幅的问题,仅依靠厚度计AGC很难保证带钢的成品厚度精度,造成成品带钢厚度偏差较大。由图6可以看出:采用基于动态锁定轧制力的AGC策略时,可以有效地避免2种AGC干扰的问题,将带钢的厚度偏差控制在较高精度以内,取得了良好的控制效果。

经过长时间的调试和参数优化,本控制策略已稳定应用于热连轧各规格产品的生产过程中,对一个轧制周期内252块带钢进行厚度偏差统计,统计结果如表2所示。统计数据表明,与传统控制策略相比,厚度偏差±25 μm的控制精度由87.8%提高至96.8%,厚度偏差±50 μm的控制精度由93.2%提高至98.8%,显著提高了产品质量。

图5 传统AGC系统控制效果

Fig. 5 Control effect of traditional AGC controlling system in hot strip mill

图6 基于动态锁定轧制力的AGC控制效果

Fig. 6 Control effect of AGC controlling system based on dynamic locking force in hot strip mill

表2 厚度控制精度统计

Table 2 Thickness precision statistic %

4 结论

1) 采用影响系数法分析辊缝、来料厚度和温度等参数对带钢出口厚度的影响,并确定由温度造成的变形抗力波动时是影响出口厚度的主要因素。

2) 以影响系数分析结果为基础,提出动态锁定轧制力控制策略优化AGC与监控AGC的相关性,提高AGC调节能力,提高控制系统精度。

3) 将采用AGC优化策略的控制系统应用于热连轧生产线。统计数据表明,对于典型厚度的带钢产品,厚度偏差±25 μm范围内厚度预测精度能够达到96.8%,厚度偏差±50 μm范围内厚度预测精度可达98.8%,提高了厚度控制精度,取得了良好的控制效果。

参考文献:

[1] GINZBURG V B. High quality steel rolling: theory and practice[M]. New York: Marcel Dekker Inc, 1993: 159-162.

[2] ZHANG Dianhua, ZHANG Hao, SUN Tao, et al. Monitor automatic gauge control strategy with a smith predictor for steel strip rolling[J]. Journal of University of Science and Technology Beijing, 2008, 15(6): 827-832.

[3] TAN Shubin, LIU Jianchang. Research on Mill Modulus Control of Strip Rolling AGC Systems[C]//2007 IEEE International Conference on Control and Automation, Washington: IEEE Computer Society, 2007: 497-500.

[4] 孙杰, 张浩宇, 李旭, 等. 广义预测控制在监控 AGC 系统中的应用[J]. 中南大学学报(自然科学版), 2012, 43(10): 3852-3856.

SUN Jie, ZHANG Haoyu, LI Xu, et al. Generalized predictive control scheme for monitor AGC system[J]. Journal of Central South University (Science and Technology), 2012, 43(10): 3852-3856.

[5] 童朝南, 孙一康, 陈百红, 等. 热连轧综合AGC系统的智能化控制[J]. 北京科技大学学报, 2002, 24(5): 553-555.

TONG Chaonan, SUN Yikang, CHEN Baihong, et al. Intelligent control of a multi-function AGC system in hot strip mills[J]. Journal of University of Science and Technology Beijing, 2002, 24(5): 553-555.

[6] HU Xianlei, WANG Zhaodong, ZHAO Zhong, et al. Gauge-meter model building based on the effect of the elastic deformation of rolls in plate mill[J]. Journal of University of Science and Technology Beijing, 2007, 14(4): 381-385.

[7] 孙杰, 张殿华, 李旭, 等. 厚度计AGC应用中存在的问题及对策[J]. 东北大学学报(自然科学版), 2009, 30(11): 1621-1627.

SUN Jie, ZHANG Dianhua, LI Xu, et al. Existing problems of gauge meter AGC in application and solutions[J]. Journal of Northeastern University (Natural Science), 2009, 30(11): 1621-1627.

[8] DONG Min, LIU Cai. Design and fault diagnosis observer for HAGC system on strip rolling mill[J]. Journal of Iron and Steel Research, International, 2010, 17(2): 22-22.

[9] 杨卫东. 带钢热连轧AGC系统的内在矛盾[J]. 北京科技大学学报, 1996, 18(1): 23-27.

YANF Weidong. Inhere contradictory of hot strip rolling AGC system[J]. Journal of University of Science and Technology Beijing, 1996, 18(1): 23-27.

[10] LIU Guangrning, DI Hongshuan, ZHOU Cunlong, et al. Tension and thickness control strategy analysis of two stands reversible cold rolling mill[J]. Journal of Iron and Steel Research, International, 2012, 19(10): 20-25.

[11] 刘光明, 邸洪双, 侯泽跃, 等. 双机架可逆冷轧机组动态特性分析[J]. 钢铁研究学报, 2010, 22(3): 9-12.

LIU Guangrning, DI Hongshuan, HOU Zeyue, et al. Analysis on dynamic characteristics of twin stand reversible cold rolling mill[J]. Journal of Iron and Steel Research, 2010, 22(3): 9-12.

[12] 沈丙振, 周进, 韩志强, 等. 热轧全流程带钢温度场数值模拟[J]. 清华大学学报(自然科学版), 2003, 43(5): 601-604.

SHEN Bingzhen, ZHOU Jin, HAN Zhiqiang, et al. Numerical simulation of plate temperature distribution during hot rolling[J]. Journal of Tsinghua University (Science and Technology), 2003, 43(5): 601-604.

[13] MOONA C H, LEE Y. An approximate method for computing the temperature distribution over material thickness during hot flat rolling[J]. International Journal of Heat and Mass Transfer, 2012, 55: 310-315.

[14] GUO W M, WANG Z C, Liu S, et al. Effects of finish rolling temperature on microstructure and mechanical properties of ferritic-rolled p-added high strength interstitial-free steel sheets[J]. Journal of Iron and Steel Research: International, 2011, 18(5): 42-46

[15] JI Yafeng, ZHANG Dianhua, SUN Jie, et al. Algorithm design and application of novel GM-AGC based on mill stretch characteristic curve[J]. Journal of Central South University, 2014, 21(3): 942-947.

[16] SUN Jie, ZHANG Dianhua, LI Xu, et al. Smith prediction monitor AGC system based on fuzzy self-tuning PID control[J]. Journal of Iron and Steel Research, International, 2010, 17(2): 22-22.

(编辑 赵俊)

收稿日期:2016-06-02;修回日期:2016-09-27

基金项目(Foundation item):国家自然科学基金资助项目(51074051);辽宁省博士启动基金资助项目(20131033);中央高校基本科研业务费专项资金资助项目(N160704004)(Project(51074051) supported by the National Natural Science Foundation of China; Project(20131033) supported by the PhD Start-up Fund of Natural Science Foundation of Liaoning Province, China; Project(N160704004) supported by the Fundamental Research Funds for the Central University)

通信作者:彭文,博士,从事轧制过程自动化领域的研究;E-mail:pengwen233@163.com