形变时效工艺对低铍Cu-Ni-Be合金力学性能和

电导率的影响

刘楚明,刘娜,曾祥亮,陈志永,李慧中,徐雷

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘 要:运用正交设计研究形变时效工艺(冷变形量、时效温度和时效时间)对低铍含量Cu-Ni-Be合金力学性能和电导率的影响,并通过光学显微镜、扫描电镜和透射电镜对其显微组织进行分析。研究结果表明:在形变时效处理的3个主要工艺参数中,时效时间对抗拉强度、屈服强度和相对电导率的影响最大,时效温度次之,冷变形量最小;合金在经过37.5%冷变形的轧制后,在470 ℃时效2 h,γ″析出物细小且弥散分布在基体中,合金具有较好的综合性能。

关键词:Cu-Ni-Be合金;形变时效;力学性能;电导率

中图分类号:TG156.93 文献标志码:A 文章编号:1672-7207(2010)02-0508-06

Effects of deformation aging on mechanical properties and electricity conductivity of Cu-Ni-Be alloy

LIU Chu-ming, LIU Na, ZENG Xiang-liang, CHEN Zhi-yong, LI Hui-zhong, XU Lei

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The effects of deformation aging process including the quantity of cooling deformation, the aging temperature and the aging time on the mechanical and electricity conductivity of Cu-Ni-Be alloy were studied. The microscopic structure of the alloy was observed by the optical microscope, the scanning electron microscopy and the transmission electronic microscopy. The results show that among the three parameters, the aging time has the heaviest impact on the tensile strength, the yield strength and the electricity conductivity, the next is the aging temperature, and the quantity of cooling deformation comes last. In detail, at 470 ℃, 37.5 % of cold deformation aging for 2 h can get a type of alloy with best comprehensive quantity, in which abundant of exiguous and disperse γ″ phase occurs.

Key words: Cu-Ni-Be alloy; deformation aging; mechanical property; electricity conductivity

Cu-Ni-Be合金是一种优质弹性材料,具有优良的综合力学性能和电学性能,被广泛应用于机械电子、航空航天等工业领域。近年来,为满足电子产品小型化、高密度化的要求,需要采用具有高强度、高导电性的Cu-Ni-Be合金制作各种各样的高性能元件[1-4]。然而,目前使用的Cu-Ni-Be合金绝大多数局限于高铍含量合金,因其生产成本高,价格昂贵,且对环境污染非常严重,极大地限制了其开发和应用[5-7]。因此,开发高性能、环境友好型低铍含量Cu-Ni-Be合金具有广阔的应用前景。以往研究表明形变时效处理是提高Cu-Ni-Be合金性能的一种有效方法[8-13]。本文作者拟采用正交试验方法,研究形变时效工艺对低铍含量Cu-Ni-Be合金力学性能和电导率的影响,以便为高性能低铍含量Cu-Ni-Be合金的制备提供实验和理论依据。

1 试验材料和方法

1.1 试验材料

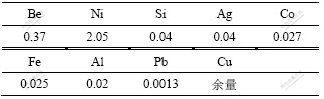

试验合金真空熔炼及热轧开坯后,冷轧至厚度,分别为0.56,0.65,0.70,0.80和0.89 mm的板材,其实测化学成分如表1所示。可见,合金铍含量较低。

表1 试验材料的实测化学成分

Table 1 Measured chemical composition of material

质量分数/%

1.2 正交试验设计

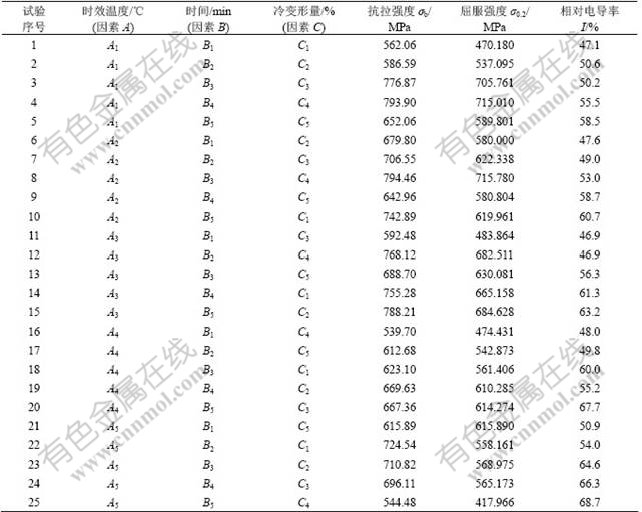

本研究以Cu-Ni-Be合金热处理工艺参数中影响较大的时效温度、时效时间和冷变形量作为正交试验的3种因素,分别标记为因素A、因素B和因素C。实验中每个因素各选取5 个水平,其中:A1~A5分别为440,455,470,480和490 ℃;B1~B5分别为60,90,120,150和180 min;C1~C5分别为10.7%,23.1%,28.6%,37.5%和43.8%。选用正交表L25(56)进行试 验[14-16],结果如表2所示。

1.3 试验方法及设备

固溶处理在箱式电炉中进行,加热至温度920 ℃保温45 min;冷轧在双辊精轧机上进行,合金全部轧至厚度为0.5 mm;时效处理在箱式电阻炉中进行;拉伸试验在CSS-44100电子万能试验机上进行;相对电导率在单双臂两用电桥上进行测量;合金的拉伸断口形貌观察在Sirion 200场发射扫描电镜上进行;时效析出物的观察在Neophot-Ⅱ光学显微镜和Tecnai G2 20透射电镜下进行。

2 结果与讨论

2.1正交试验结果与极差分析

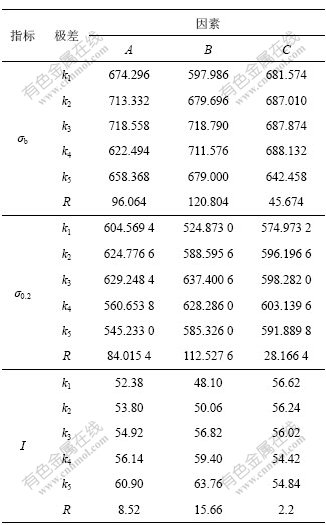

正交试验结果如表2所示。从表2可以看出:在因素A每个水平所在的每组试验中,其他因素(B和C)的5个水平都只出现1次。为了综合分析因素A的5个水平对试验结果的影响,把因素A 的每一个水平所处的组内试验数据(抗拉强度σb、屈服强度σ0.2和相对电导率I)相加,并分别除以水平重复数(本试验为5),记为k1,k2,k3,k4和k5。这样,因素B和C对k1~k5的影响是一致的,k1~k5之间的差异可以认为是因素A的水平不同而引起的。用同样的方法分析因素B和C对σb,σ0.2和I的影响,最后,求出每列k值的最大值与最小值之差R(极差),计算结果见表3。

表2 正交试验安排及结果

Table 2 Scheme and results of orthogonal experiment

由表3中的极差R可以看出:无论是对σb和σ0.2,还是对I的影响,因素B的R均最大,因素A的R次之,因素C的R最小。这说明在低铍含量Cu-Ni-Be合金形变时效处理中,时效时间的变化对各性能指标的影响最大,是主要因素;而时效温度、冷变形量的改变对各性能指标的影响依次减小。

表3 极差分析结果

Table 3 Results of range analysis

从表3中σb和σ0.2的k变化规律可以看出:σb和σ0.2的k变化趋势基本相似,峰值位置基本相同,均随着时效温度的增加先升高,在470 ℃左右达到峰值后再降低;表3中I的k则随时效温度的增加而增加,考虑到各时效温度下的I均较高,能够达到性能要求,因而,时效温度选取强度达到峰值时的470 ℃。同理,分析时效时间和冷变形量变化对σb,σ0.2和I的k的影响,得出低铍含量Cu-Ni-Be合金形变时效较优工艺参数为:37.5%冷变形+470 ℃/2 h时效。

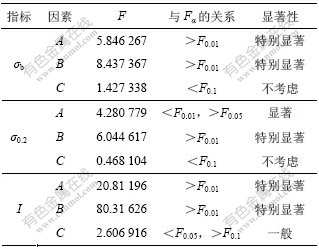

2.2 方差分析

为了区分某因素各水平所对应的试验结果间的差异,对试验结果进行方差分析。各因素的自由度均为4,误差项自由度为12,查F检验的临界值(Fα) 表[14],可知,当α=0.01,0.05和0.1 时,Fα分别为:F0.01(4, 12)=5.41;F0.05(4, 12)=3.26;F0.1(4, 12)=2.48。通过计算得出σb,σ0.2和I的F及方差,如表4所示。由表4可知:方差分析结果与极差分析结果基本吻合,极差分析结果有效。

表4 方差分析结果

Table 4 Results of variance analysis

3 验证试验及其显微组织分析

从上述分析结果可知:低铍含量Cu-Ni-Be合金最佳形变时效工艺参数为37.5%冷变形+470 ℃/2 h时效。为此,进行了多次验证试验,发现在该工艺下合金抗拉强度达到820 MPa,屈服强度超过730 MPa,相对电导率I超过53%,伸长率达到9%,综合性能达到并超过了材料使用要求,为高性能低铍含量Cu-Ni-Be合金的制备提供了实验依据。

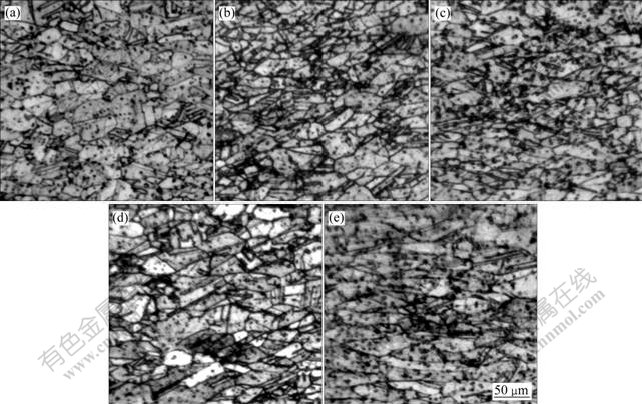

合金经不同形变时效工艺处理后的显微组织和透射电镜像如图1和图2所示。经不同变形量冷变形后,合金在470 ℃时效2 h的显微组织如图1所示。可见:经较小冷变形量变形后再进行时效处理的合金(图1(a)),晶粒较粗大,呈等轴状,加大冷变形量变形后再进行时效处理的合金(图1(b)和图1(c)),晶粒沿轧向仍有被拉长的迹象,晶粒更加细小。

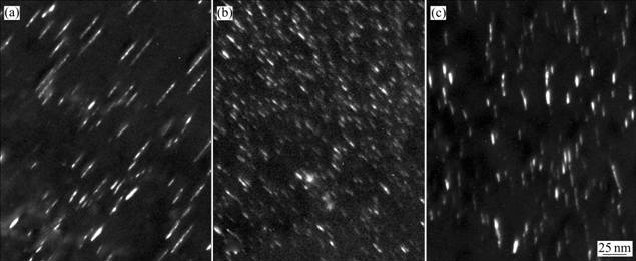

冷变形量较小时,合金基体畸变量小,晶粒细化效果不明显。此时,基体形成的位错和空位少,为其后时效过程中γ″析出物的析出提供的形核位置和储能 少[17],γ″析出物密度小,尺寸大,如图2(a)所示。冷变形量增大后,合金晶粒沿轧向拉长,形成纤维状组织,晶粒细化均匀。此时,基体形成大量位错和空位,为其后时效过程中γ″析出物的析出提供了大量的形核位置和储能,析出的γ″析出物非常细小弥散,强化效果明显,如图2(b)所示。

(a) 10.7%冷变形+470 ℃/2 h时效;(b) 28.6%冷变形+470 ℃/2 h时效;(c) 37.5%冷变形+470 ℃/2 h时效;

(d) 37.5%冷变形+470 ℃/3 h时效;(e) 37.5%冷变形+440 ℃/2 h时效

图1 不同形变时效条件下合金的显微组织

Fig.1 Microstructures of alloys in different deformation aging processes

(a) 10.7%冷变形+470 ℃/2 h时效;(b) 37.5%冷变形+470 ℃/2 h时效;(c) 37.5%冷变形+470 ℃/3 h时效

图2 不同形变时效条件下合金的TEM像

Fig.2 TEM images of alloys in different deformation aging processes

由图1(c)和图2(b)可见:合金经过37.5%冷变形、470 ℃时效2 h后,晶粒较细小均匀,析出物也细小均匀地弥散分布在基体中,起到了很好的强化效果,此时,合金强度较高,综合性能也较好。由图1(d)和图2(c)可知:随着时效时间的延长,晶粒尺寸增大,析出物聚集、粗化,强化效果下降,合金的强度降低,同时,晶界和析出物对电子的散射作用也有所降低,合金的相对电导率上升。

图3所示为合金经不同形变时效工艺时效2 h后拉伸断口的SEM形貌。可见:合金的拉伸断口呈现韧性断裂特征,为等轴韧窝,韧窝较小、较浅;时效温度较高时断口的韧窝较深;温度较低时断口的韧窝不均匀,撕裂痕迹不明显。这是由于合金经过冷变形后,产生加工硬化,强度上升,塑性下降。此时,合金经时效加热后,发生回复和再结晶[18],使合金塑性被部分恢复。图1(e)所示为合金经过37.5%冷变形、440 ℃保温2 h时效后的显微组织。由于时效温度过低,回复和再结晶不充分,合金仍以变形组织为主,塑性较低。而在470 ℃时效后,合金再结晶程度加大,变形组织被部分消除(图1(c)),塑性提高。

(a) 37.5%冷变形+440 ℃/2 h 时效;

(b) 37.5%冷变形+470 ℃/2 h时效

图3 合金拉伸断口的SEM形貌

Fig.3 SEM morphologies of tensile fracture section of alloys

4 结论

(1) 时效时间对低铍含量Cu-Ni-Be合金的抗拉强度、屈服强度和相对电导率的影响最大,时效温度次之,冷变形量最小。时效前的冷变形可以使合金晶粒细化,为时效析出提供了储能和形核位置;合理的时效工艺可以使大量细小的析出物弥散分布在基体中。

(2) 最佳的形变时效工艺参数为:37.5%冷变形+470 ℃/2 h时效。在该工艺条件下,合金含有大量细小弥散的γ″析出物,抗拉强度达到820 MPa,屈服强度超过730 MPa,相对电导率超过53%,伸长率达到9%,合金综合性能最佳,达到并超过了材料使用要求,为高性能低铍含量Cu-Ni-Be合金的制备提供了实验依据。

参考文献:

[1] 阎永, 汪治军, 董超群. 我国铍铜产业科技进步回顾与展望[J]. 稀有金属, 2003, 27(1): 66-68.

YAN Yong, WANG Zhi-jun, DONG Chao-qun. Review and prospect of Chinese beryllium copper industry[J]. Chinese Journal of Rare Metals, 2003, 27(1): 66-68.

[2] Eldrup M, Singh B N. Influence of composition, heat treatment and neutruon irradiation on the electrical conductivity of copper alloys[J]. Journal of Nuclear Materials, 1998, 258-263: 1022-1027.

[3] 潘奇汉. 铍铜合金性能与其元件生产[J]. 电子元件与材料, 2004, 123(2): 44-45.

PAN Qi-han. Beryllium copper alloy: properties and application[J]. Electronic Components and Materials, 2004, 123(2): 44-45.

[4] Savo S, Bo?tjan M. Microstructural characterization of alloys of the quasibinary Cu-NiBe system[J]. Zeitschrift fur metallkunde, 2003, 94: 876-879.

[5] 董超群, 易均平. 铍铜合金市场与应用前景展望[J]. 稀有金属, 2005, 29(3): 350-356.

DONG Chao-qun, YI Jun-ping. Prospect of beryllium copper alloy’s market and application[J]. Chinese Journal of Rare Metals, 2005, 29(3): 350-356.

[6] 陈文革, 罗启文, 沈宏芳, 等. 热处理对QBe2、QCr0.5及QAl9-4组织与性能的影响[J]. 特种铸造及有色合金, 2006, 26(5): 276-278.

CHEN Wen-ge, LUO Qi-wen, SHEN Hong-fang, et al. Effects of heat treatment on microstructure and properties of QBe2, QCr0.5 and QAl9-4 alloys[J]. Special Casting & Nonferrous Alloys, 2006, 26(5): 276-278.

[7] Cheong B, Hono K, Laughlin D E. Bain strain relaxation during early stage decomposition of a hyper-eutectoid CuBe alloy[J]. Acta Metallurgica et Materialia, 1994, 42(7): 2387-2400.

[8] Monzen R, Seo T, Sakai T, et al. Precipitation processes in a Cu-0.9mass%Be single crystal[J]. Materials Transactions, 2006, 47(12): 2925-2934.

[9] Rotem A, Shechtman D, Rosen A. Correlation among microstructure, strength and electrical conductivity of Cu-Ni-Be alloy[J]. Metallurgical Transactions, 1988, 19A(9): 2279-2285.

[10] Varschavshy A, Donoso E. Adifferential scanning calorimetric study of precipitation in Cu-2Be[J]. Thermochimica Acta, 1995, 266: 257-275.

[11] 孙守功. 铍青铜弹簧热处理工艺改进[J]. 金属热处理, 2003, 28(8): 60-61.

SUN Sou-gong. Improvement of heat treatment process for beryllium bronze spring[J]. Heat Treatment of Metals, 2003, 28(8): 60-61.

[12] Dunlevey F, Lorenz C. How to heat treat beryllium copper parts[J]. Heat Treating, 1990, 22(6): 30-32.

[13] 潘志勇, 汪明朴, 李周, 等. 超高强度Cu-5.2Ni-1.2Si合金的形变热处理[J]. 中国有色金属学报, 2007, 17(11): 1821-1826.

PAN Zhi-yong, WANG Ming-pu, LI Zhou, et al. Thermomechanical treatment of super hing strength Cu-5.2Ni-1.2Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1821-1826.

[14] 高允彦. 正交及回归试验设计方法[M]. 北京: 冶金工业出版社, 1988.

GAO Yun-yan. Design method for orthogonal and regression test[M]. Beijing: Metallurgical Industry Press, 1988.

[15] 狄平. 铍青铜形变时效工艺的优化[J]. 金属热处理, 2003, 28(2): 63-65.

DI Ping. Optimization of deformation aging process of beryllium bronze[J]. Heat Treatment of Metals, 2003, 28(2): 63-65.

[16] 邓姝皓, 龚竹青, 易丹青, 等. 电沉积制备铁-镍-铬纳米晶合金箔工艺的正交设计[J]. 中南大学学报: 自然科学版, 2005, 36(6): 938-943.

DENG Shu-hao, GONG Zhu-qing, YI Dan-qing, et al. Orthogonal design of technology for electrodeposition nanocrystalline Fe-Ni-Cr alloy foil[J]. Journal of Central South University: Science and Technology, 2005, 36(6): 938-943.

[17] Ota S, Muramatsu N, Sengoku K, et al. Mechanical and electrical properties and microstructure in Cu-Ni-Be alloys[J]. Journal of Society of Materials Science, Japan, 2007, 56(6): 531-536.

[18] 李国俊, 姚家鑫, 曹阳. QBe2铜合金再结晶与时效析出交互作用机制的研究[J]. 金属热处理学报, 1996, 17(4): 31-35.

LI Guo-jun, YAO Jia-xin, CAO Yang. The interaction mechanism of precipitation and recrystallization in Cu-Be alloy[J]. Transactions of Metal Heat Treatment, 1996, 17(4): 31-35.

收稿日期:2009-04-30;修回日期:2009-09-15

基金项目:国防科工委项目(JPPT-115-184)

通信作者:刘楚明(1960-),男,湖南张家界人,博士,教授,从事高性能有色金属材料加工工艺与微观组织及性能相关性研究;电话:0731-88830257;E-mail: cmliu@mail.csu.edu.cn

(编辑 陈爱华)