文章编号:1004-0609(2016)-01-0023-08

Zr对挤压铸造Al-5.0Cu-0.4Mn合金显微组织和力学性能的影响

孟凡生,张卫文,张大童,杨 超,肖志瑜

(华南理工大学 机械与汽车工程学院,广州 510640)

摘 要:采用拉伸力学性能测试、宏观腐蚀、扫描电镜(SEM)、透射电镜(TEM)等,研究不同Zr含量对挤压铸造Al-5.0Cu-0.4Mn合金显微组织和力学性能的影响,并与重力铸造的合金的显微组织和力学性能进行对比分析。结果表明:针对铸态合金,无论是挤压铸造还是重力铸造,在Zr含量(质量分数)为0.25%时,合金获得最佳的抗拉强度、屈服强度和伸长率;而对于热处理态合金,当Zr含量从0增加到0.35%时,合金的抗拉强度和屈服强度都随着Zr含量的增加而增加,但伸长率在Zr含量为0.15%时达到最大值。挤压铸造可以显著改善不同Zr含量合金的伸长率,但对铸态合金伸长率的提升幅度明显优于热处理态合金的。Zr在铸态合金中的强化作用主要是细晶强化,而合金经T6热处理后,固溶强化以及Al3Zr粒子和θ'相的弥散强化是主要强化机制,挤压铸造可以显著改善Al3Zr粒子的弥散强化效果。

关键词:Al-Cu-Mn合金;挤压铸造;力学性能;显微组织

中图分类号:TG249.3 文献标志码:A

铸造铝铜合金是一类非常重要的铸造铝合金,因其具有强度高、耐热性能好、加工性能优良等特点,在航空、航天、交通、运输等行业中得到了广泛的应用。

微合金化是改善铝合金性能的重要途径。其中Zr是变形铝合金中常见的微量添加元素,有关研究表明,在铝合金中添加微量元素Zr能够细化晶粒,显著改善合金的力学性能。此外,热处理过程中生成细小弥散的Al3Zr强化相,能够钉扎位错,抑制再结晶,使得合金的性能得到进一步提升[1-5]。目前,国内外针对Zr在铝铜合金中的作用也开展了一些研究,JIA等[6]研究了铸造Al-Cu合金中Al3Zr的析出行为,发现亚稳Al3Zr析出相在枝晶中部均匀形核析出,而在枝晶间存在螺旋形和长条形Al3Zr,并且周围还包围着球形的细小Al3Zr析出物,合金中的Cu元素加速Al3Zr沉淀相从L12结构向DO23结构转变。TSIVOULAS等[7]系统地研究了Zr在Al-Cu-Li合金中的非均匀分布以及Al3Zr在合金中的析出行为,发现Zr与亚稳的θ'相并不反应,但与平衡态的θ相反应生成两种类型的颗粒,一种是θ相内仅含有Zr,另一种是θ相内同时含有Zr和Mn,此外Zr也会出现在Al20Cu2Mn3颗粒中。张云崖等[8]研究了Al3Zr析出相对Al-Zn-Mg-Cu合金板组织、织构与性能的影响,发现分级均匀化可促进Al3Zr粒子在晶界区域的析出,与基体共格的Al3Zr粒子既能阻碍基于应力作用的位错运动,又能阻碍亚晶界、晶界的热激活运动,影响热轧过程中的动(静)态回复和再结晶,提高材料的力学性能。鲍子成等[9]对Al3Zr在 Al-7.81Zn-1.62Mg-1.81Cu合金中的析出行为进行研究表明,均匀化处理过程中均匀、弥散析出的条状MgZn2平衡相粒子具有异质形核作用,能够促进Al3Zr粒子在晶内和晶界均匀析出。大量研究表明,同时添加Zr和其他微量合金元素可进一步提升铝合金的性能。WANG等[10]的研究发现:在高Mg含量的铸造铝合金中,同时添加Sc和Zr有很好的细化效果,继续添加Ti后细化效果更佳。复合添加Sc、Zr和Ti导致Al-10Mg合金峰值硬度更高的原因是合金中产生了细小的析出相Al3(Sc,Zr),Al3(Sc,Ti)和Al3(Sc,Zr,Ti)。PENG等[11]研究表明,在Al-Mg-Mn合金中添加Zr和Sc可以改善合金的超塑性,添加Zr和Sc合金的伸长率远远高于未添加微量元素合金的,且可以降低合金的超塑性变形激活能。陈康华等[12]针对Zr、Cr、Pr在Al-Zn-Mg-Cu合金中的复合作用进行研究,结果表明复合添加3种元素可形成细小弥散含Zr的PrCr2Al20弥散相,显著提高合金的再结晶抗力,提高合金的抗拉强度、屈服强度和断裂韧性,改善合金的塑性。

采用先进的铸造工艺也是改善铸造铝铜合金性能的重要途径之一。挤压铸造是一种结合了铸造和塑性加工特点的短流程、高效、精确成形技术,常用来制备高性能的材料和零件。前期研究工作表明,采用挤压铸造技术制备的铝铜合金具有非常优异的性 能[13-15],通过添加Zr等微合金化元素有望进一步提升这类挤压铸造铝合金的性能,但目前对于Zr在铝合金中的作用主要集中在变形铝合金中,针对的合金体系以Al-Zn-Mg系为主,针对挤压铸造Al-Cu合金中的研究还未见报道。本文作者重点研究微量元素Zr对挤压铸造Al-5.0Cu-0.4Mn合金的显微组织与力学性能的影响,并与重力铸造的合金进行对比,为进一步开发高性能Al-5.0Cu-0.4Mn合金奠定基础。

1 实验

合金熔炼在电阻炉的石墨坩埚中进行,每次熔炼10 kg。试验原材料为99.95%高纯铝、Al-50%Cu、Al-10%Mn、Al-10%Zr(质量分数)中间合金。待纯铝熔化后依次加入Al-Cu、Al-Mn和Al-Zr中间合金,合金熔化过程中采用钠盐覆盖,熔化完全后搅拌,并在730 ℃左右进行氮气精炼除气,合金的浇注温度约为730 ℃。

挤压铸造试验在100 t立式压机中进行,采用直接挤压铸造工艺。模具预热温度为200 ℃,保压时间约30 s,挤压时的比压分别为0 MPa和100 MPa,获得的圆柱形铸件尺寸为直径80 mm,高度约100 mm。不同Zr含量铸锭成分的光谱分析结果见表1。采用540 ℃固溶12 h,175 ℃时效8 h的热处理工艺。

在铸件中心约30 mm的圆周上采用线切割截取直径约10 mm的圆棒,加工直径为5 mm,标距为25 mm的标准拉伸试样。拉伸试验在SANS CMT5105型微机控制万能材料试验机上进行,拉伸速度1 mm/min,每种拉伸试样至少3个样品。将铸件对开后获得宏观腐蚀样品,宏观腐蚀剂为45%HCl、15%HNO3、15%HF和25%H2O(体积分数)的混合溶液。观察金相组织采用0.5%(体积分数)的HF溶液作为腐蚀剂,金相组织观察在Quanta 2000型扫描电子显微镜(SEM)上进行。TEM样品先采用双喷减薄,溶液为体积比3:7的硝酸甲醇溶液,温度-25 ℃;在JEM-2200FS型上进行组织分析,观察时的加速电压为200 kV。

表1 合金的主要化学成分

Table 1 Chemical composition of alloy

2 实验结果

2.1 合金的力学性能

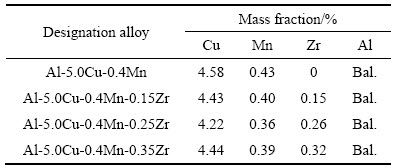

不同压力和Zr含量铸态合金的力学性能如图1所示。由图1可知:随着Zr含量的增加,合金的抗拉强度、屈服强度和伸长率都是先增加后降低。在挤压压力为0 MPa时,当Zr由0增加至0.25%时,合金的抗拉强度由201 MPa增加为218 MPa,增幅为8.5%;合金的屈服强度由102 MPa增加为128 MPa,增幅为25.5%;合金的伸长率由13.3%增加为16.1%,增幅为21.1%;当Zr由0.25%增加至0.35%时,合金的抗拉强度下降约7%;屈服强度下降约21%,伸长率下降约18%。挤压压力为100 MPa时,当Zr由0增加至0.25%时,合金的抗拉强度由201 MPa增加为226 MPa,增幅为12.4%;合金的屈服强度由105 MPa增加为133MPa,增幅为26.7%,合金的伸长率由19.3%增加为21.9%,增幅为13.5%;当Zr由0.25%增加至0.35%时,合金的抗拉强度、屈服强度和伸长率分别下降约4.0%、12.0%和10.0%。

图1 不同压力和Zr含量的铸态合金力学性能

Fig. 1 Mechanical properties of as-cast alloys at different applied pressures and Zr contents

挤压铸造显著改善了铸造合金的力学性能,特别是合金的伸长率。如当Zr含量为0.25%时,100 MPa下的合金抗拉强度、屈服强度和伸长率分布比重力铸造下的合金提高了3.7%、3.9%和36.0%。

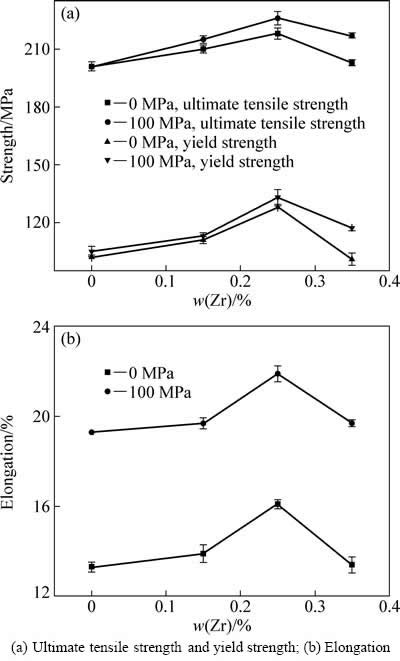

不同压力和Zr含量热处理态合金的力学性能如图2所示。当Zr含量由0增加至0.25%时,无论是挤压铸造还是重力铸造,合金的抗拉强度和屈服强度都有一定的上升,如0 MPa合金的抗拉强度由386 MPa增加到402 MPa,增幅为4.1%,屈服强度由301 MPa增加为312 MPa,增幅为3.6%;100MPa合金的抗拉强度由388 MPa增加为408 MPa,增幅为5.1%,屈服强度由302 MPa增加为315 MPa,增幅为4.3%。当继续增加Zr含量到0.35%,合金的抗拉强度和屈服强度变化不明显。随Zr含量的增加,无论是挤压铸造还是重力铸造,合金的伸长率均呈现抛物线变化,但伸长率的最大值出现在Zr含量为0.15%时。继续增加Zr含量,合金的伸长率显著下降,如当Zr含量由0.15%增加到0.35%时,重力铸造合金的伸长率从16.9%降低到13.4%,降幅为20.7%;100 MPa挤压铸造合金的伸长率从17.3%降低到15.1%,降幅为12.7%。

图2 不同压力和Zr含量的热处理态合金力学性能

Fig. 2 Mechanical properties of heat-treated alloys at different applied pressures and Zr contents

2.2 合金的宏观组织

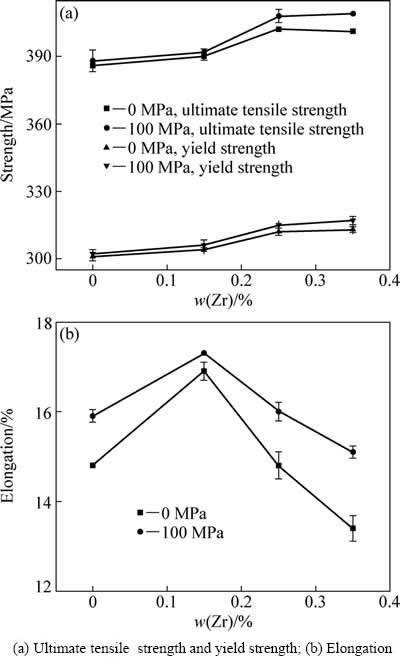

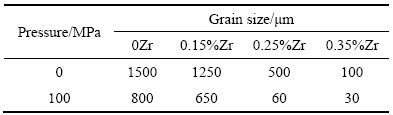

图3所示为不同压力和Zr含量铸态Al-5.0Cu-0.4Mn合金的宏观腐蚀形貌。从图3可见,在相同压力下,合金组织随着Zr含量的增加而不断细化,当Zr含量低于0.15%时,合金组织边部可见明显的柱状晶区,当Zr含量达到0.25%时,边部柱状晶基本消失。在相同Zr含量下,挤压铸造合金的晶粒度明显小于重力铸造合金的晶粒度。对距离铸锭表面10 mm的圆周处测量不同压力和Zr含量合金的平均晶粒大小,结果如表2所列。从表2可见,当Zr含量为0.35%、挤压压力为100 MPa时,合金的组织最细小,晶粒度达到30 μm,远小于未添加Zr的重力铸造合金的晶粒度(1500 μm)。

2.3 合金的显微组织

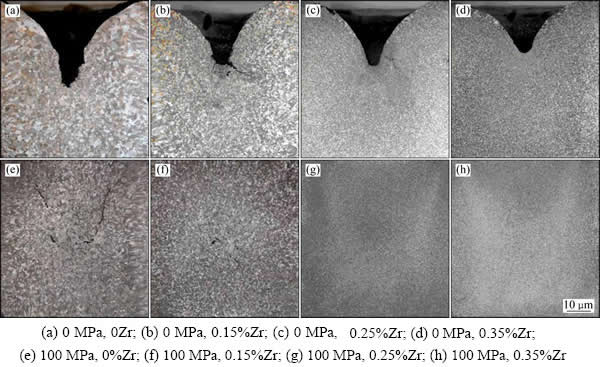

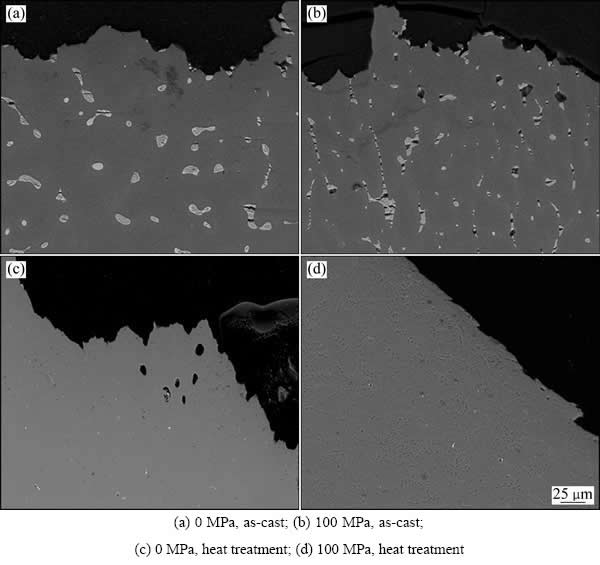

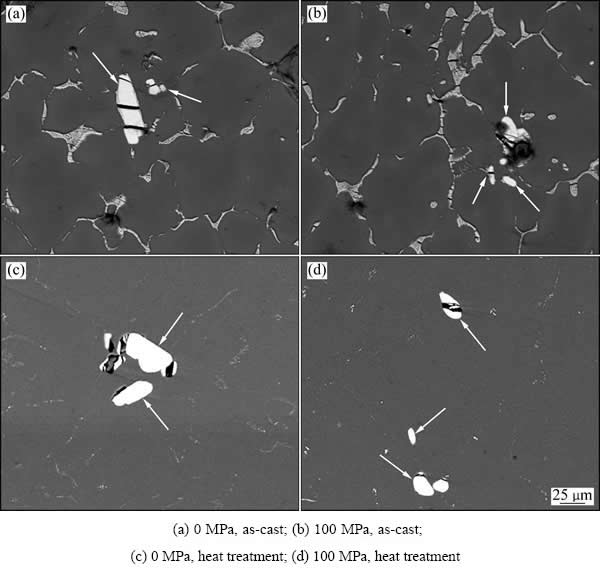

图4所示为Zr含量为0.25%时,不同状态的拉伸样品纵向断口的微观组织形貌。从图4中可见,针对铸态合金(见图4(a)和(b)),基体上分布大量的θ(Al2Cu)相与T(Al20Cu2Mn3)相,图4(a)中这些相分布较为分散,在靠近断口的部分出现了断裂;图4(b)中这些相的密度明显较大,且大部分出现了断裂。图4(c)和(d)所示为热处理态的纵向断口形貌,θ与T相都已经固溶进α(Al)基体中。图5所示为Zr含量为0.35%时不同状态的拉伸样品纵截面的显微组织形貌。从图5可见,针对铸态合金,基体上除大量分布的θ相与T相外,还出现了一定数量随机分布的亮白色块状相,该相生长方向性较强,棱角较尖锐,长宽比较大,长度在10~50 μm之间,由于是拉伸样品,在这些相中大部分出现了断裂,如图5(a)和(b)中的箭头所示。对该亮白色块状相进行能谱分析,Al与Zr摩尔比为72:28,结合文献[16-17]的分析可知,当铝合金中的Zr含量过高或者采用不同的熔炼浇铸工艺,容易导致Zr元素的偏聚;在Zr含量超过0.3%时,将导致生成粗大的枝状初生Al3Zr相,是铸造过程中由于Zr含量过高生成的一次Al3Zr相。合金经过T6热处理态后,θ相与T已经完全溶解固溶到α(Al)基体中,但白色的块状相仍然存在,其大小和形貌与铸态合金没有明显区别,能谱分析Al与Zr摩尔比为75:25,判定其仍为铸态合金中生成的一次Al3Zr相,如图5(c)和(d)中箭头所示。对比挤压铸造和重力铸造的合金,白色块状相的尺寸略有减小。

图3 不同Zr含量和挤压压力下合金的宏观腐蚀形貌

Fig. 3 Macrostructures of ingots solidified at different pressures and Zr contents

表2 不同压力和Zr含量合金晶粒大小

Table 2 Grain sizes of alloys at different pressures and Zr contents

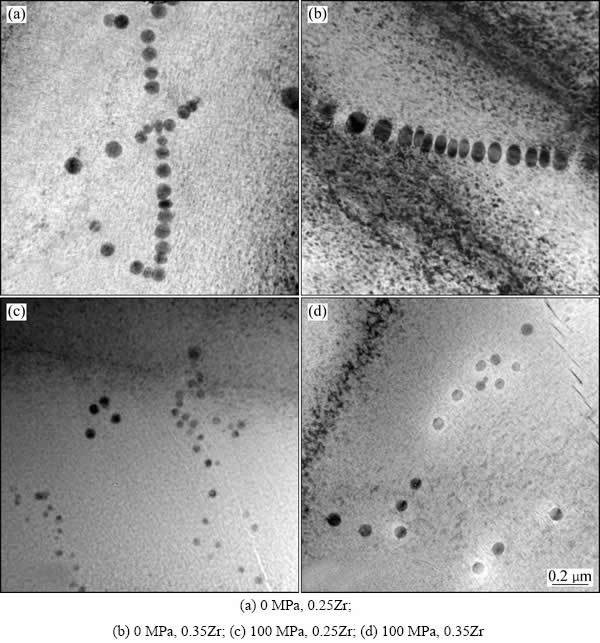

图6所示为不同Zr含量和不同挤压压力下T6热处理合金基体中的第二相形貌。当合金中Zr含量低于0.25%时,无论是挤压铸造还是重力铸造的合金,基体中只存在弥散分布的θ'相,没有出现球状的第二相。当Zr含量达到0.25%后,合金基体内出现了一定数量的球状第二相,能谱分析该球状相中Al、Cu、Zr的摩尔比为84:4:12,结合有关文献[18-19]可认定该相为次生的Al3Zr相。从图6还发现,挤压铸造条件下的合金中Al3Zr粒子直径约为40~60 nm,而重力铸造下的合金中Al3Zr粒子呈线性排列,直径约为70~100 nm,可见,挤压铸造条件下的合金中Al3Zr粒子的尺寸比重力铸造下合金的更细小,分布也更加均匀。当Zr含量从0.25%变化到0.35%时,对合金基体中的Al3Zr粒子数量影响不大。

3 分析与讨论

在铸态Al-5.0Cu-0.4Mn合金中,无论是重力铸造还是挤压铸造,添加不超过0.25%的Zr元素会使得合金的抗拉强度、屈服强度、伸长率都得到提升,其主要原因是Zr对铸态合金的晶粒细化作用,且当Zr含量为0.25%时晶粒细化效果最显著,故Zr含量为0.25%时获得最佳的抗拉强度和屈服强度。当继续增加Zr含量(如0.35%Zr),虽然合金的晶粒变得更细小,但由于Zr含量超过其在Al合金中的固溶度,容易在枝晶间生成粗大的块状初生Al3Zr相(见图5),这种相在样品拉伸过程中容易产生应力集中,形成早期的断裂源,恶化材料性能,导致合金强度下降。挤压铸造合金由于是在压力下凝固,能有效消除合金中的铸造缺陷,如缩孔、缩松等。此外,挤压压力下合金的凝固速度加快,这些都有利于晶粒的细化和组织的致密化,这也是挤压铸造合金能够使得合金伸长率得到大幅度提升的重要原因。

图4 含0.25%Zr时不同状态拉伸样品的显微组织

Fig. 4 Microstructures of tensile samples with 0.25%Zr at different pressures and states

图5 含0.35%Zr时不同状态拉伸样品的显微组织

Fig. 5 Microstructures of tensile samples with 0.35%Zr at different pressures and states

图6 不同Zr含量和压力下T6热处理合金基体中的第二相形貌

Fig. 6 Second phase morphologies of alloys by T6 treatment with different Zr contents and at different pressures

含Zr的Al-5.0Cu-0.4Mn合金经过T6热处理后,当Zr含量从0增加到0.35%时,合金的抗拉强度和屈服强度都随着Zr含量的增加而增加,但增幅最明显的区间是添加0~0.25%Zr的区间。其原因在于Al-5.0Cu-0.4Mn合金经过固溶+峰值时效处理(T6)后,低Zr含量的合金中,Zr主要以固溶状态存在于α(Al)基体中,固溶强化起主要作用,由于Zr在α(Al)中的固溶度较小,固溶强化对合金的性能提升有限。随着Zr含量的增多,在合金α(Al)基体内将析出次生的Al3Zr粒子,这种二次析出的亚稳Al3Zr粒子与α(Al)的错配度仅0.8%,是一种非常有效的强化弥散体,能够明显提升合金的抗拉强度和屈服强度。虽然这种Al3Zr粒子的大量出现有利于合金的强化,但对合金的伸长率是不利的,因此,合金在伸长率在Zr含量为0.15%时达到峰值。当Zr含量超过0.25%后,由于合金在铸态时即出现的大块初生Al3Zr相在热处理过程中没有发生明显变化,仍存在合金中产生应力集中和成为断裂源,之所以没有引起合金强度的迅速下降,主要是因为热处理态合金中除了亚稳Al3Zr粒子的弥散强化效应外,θ'相的沉淀析出效应起了重要作用。从试验结果可知,热处理后的挤压铸造合金可获得比重力铸造合金更优异的力学性能,除了挤压铸造使得合金组织致密、消除铸造宿松等缺陷外,由于合金在压力下凝固,冷却速度提升,抑制了Al3Zr粒子的长大,使得热处理过程中析出的二次Al3Zr粒子分布更加弥散均匀,这也是热处理态挤压铸造合金性能得到提升的重要原因之一。

4 结论

1) 针对铸态Al-5.0Cu-0.4Mn合金,无论是挤压铸造还是重力铸造,在Zr含量为0.25%时,合金获得最佳的抗拉强度、屈服强度和伸长率;而对于热处理态合金,当Zr含量从0增加到0.35%时,合金的抗拉强度和屈服强度都随着Zr含量的增加而增加,但伸长率在Zr含量为0.15%达到最大值。

2) 挤压铸造可以显著改善不同Zr含量Al-5.0Cu-0.4Mn合金的伸长率,但对铸态合金伸长率的提升幅度明显优于热处理态合金的。

3) 添加Zr元素能细化铸态Al-5.0Cu-0.4Mn合金的晶粒,Zr在铸态合金中的强化机制主要是细晶强化,而合金T6热处理后,固溶强化以及Al3Zr粒子和θ'相的弥散强化是合金的主要强化机制,挤压铸造可以显著改善Al3Zr粒子的弥散强化效果。

REFERENCES

[1] 朱宝宏, 熊柏青, 张永安, 熊益民. 热处理工艺对微量Mn、Zr作用下的高纯Al-Cu-Mg-Ag合金性能的影响[J]. 稀有金属材料与工程, 2010, 39(1): 144-148.

ZHU Bao-hong, XIONG Bai-qing, ZHANG Yong-an, XIONG Yi-min. Effect of heat treatments on properties of high purity Al-Cu-Mg-Ag alloy with trace Mn and Zr[J]. 2010, 39(1): 144-148.

[2] 贺永东, 张新明, 游江海. 复合添加微量 Sc、Zr 对 Al-Zn-Mg-Cu合金组织性能的影响.稀有金属材料与工程[J]. 2007, 36(4): 665-670.

HE Yong-dong, ZHANG Xin-ming, YOU Jiang-hai. Effects of minor contents of Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu alloy[J]. Rare Metal Materials and Engineering, 2007, 36(4): 665-670.

[3] 孙立明, 于化顺, 闵光辉, 张 静. Zr对Al-Zn-Mg-Cu合金组织和性能的影响[J]. 特种铸造及有色合金, 2007, 27(5): 380-381.

SUN Li-ming, YU Hua-shun, MIN Guang-hui, ZHANG Jing. Effects of Zr on microstructure and properties of Al-Zn-Mg-Cu alloy[J]. Special Casting & Nonferrous Alloys, 2007, 27(5): 380-381.

[4] 王凤春. Zr与V对Al-4.6Mg-0.7Mn合金薄板组织与性能的影响[J]. 轻合金加工技术, 2012, 40(9): 37-40.

WANG Feng-chun. Effect of Zr and V on microstructure and properties of Al-4.6Mg-0.7Mn alloy sheet[J]. Light Alloy Fabrication Technology, 2012, 40(9): 37-40.

[5] 赵志浩, 王高松, 张翼航, 崔建忠. Sc与Zr对Al-Zn-Mg-Cu铝合金组织及力学性能的影响[J]. 东北大学学报(自然科学版), 2011, 32(11): 1574-1577.

ZHAO Zhi-hao, WANG Gao-song, ZHANG Yi-hang, CUI Jian-zhong. Effects of Sc and Zr on microstructure and mechanical properties of Al-Zn-Mg-Cu aluminum alloy[J]. Journal of Northeastern University(Natural Science), 2011, 32(11): 1574-1577.

[6] JIA Zhi-hong, COUZINIE Jean-philippe, CHERDOUDI N, GUILLOT I, ARNBERG L, ASHOLT P, BRUSETHAUG S, BARLAS B, MASSINON D. Precipitation behaviour of Al3Zr precipitate in Al-Cu-Zr and Al-Cu-Zr-Ti-V alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1860-1865.

[7] TSIVOULAS D, ROBSON J D. Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al-Cu-Li alloys[J]. Acta Materialia, 2015, 93: 73-86.

[8] 张云崖, 邓运来, 万 里, 张新明. Al3Zr 析出相对 Al-Zn-Mg-Cu 合金板组织、织构与性能的影响[J]. 中国有色金属学报, 2012, 22(2): 358-364.

ZHANG Yun-ya, DENG Yun-lai, WAN Li, ZHANG Xin-ming. Effects of precipitation of Al3Zr particles on microstructures, textures and properties of Al-Zn-Mg-Cu alloy hot-rolled plate[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 358-364.

[9] 鲍子成, 万 里, 张云崖, 邓运来. Al3Zr析出对Al-7.81Zn-1.62Mg-1.81Cu合金组织和织构的影响[J]. 中国有色金属学报, 2011, 21(8): 1820-1827.

BAO Zi-cheng, WAN Li, ZHANG Yun-ya, DENG Yun-lai. Effect of Al3Zr precipitation on microstructures and textures of Al-7.81Zn-1.62Mg-1.81Cu alloy plates[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1820-1827.

[10] WANG Xu, CHEN Guo-qin, LI Bing, WU Lian-mei, JIANG Da-ming. Effects of Sc, Zr and Ti on the microstructure and properties of Al alloys with high Mg content[J]. Rare Metals, 2010, 29(1): 66-71.

[11] PENG Yong-yi, YIN Zhi-min, NIE Bo, ZHONG Li. Effect of minor Sc and Zr on superplasticity of Al-Mg-Mn alloys[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(4): 744-750.

[12] 陈康华, 方华婵, 陈 祥. 复合添加 Zr、Cr和Pr对Al-Zn-Mg-Cu合金组织和性能的影响[J]. 中国有色金属学报, 2010, 20(2): 195-201.

CHEN Kang-hua, FANG Hua-chan, CHEN Xiang. Effects of Zr, Cr and Pr additions on microstructure and properties of Al-Zn-Mg-Cu alloys[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(2): 195-201.

[13] 李彦霞, 倪东惠, 赵海东, 张卫文, 李元元. 不同压力下挤压铸造铝铜合金的组织与性能[J]. 铸造, 2005, 54(8): 764-766.

LI Yan-xia, NGAI Tunghui, ZHAO Hai-dong, ZHANG Wei-wen, LI Yuan-yuan. Microstructure and properties of squeeze cast Al-Cu alloy with different applied pressure[J]. Foundry, 2005, 54(8): 764-766.

[14] 柏振海, 赵 楠, 罗兵辉. 挤压铸造对Al-Cu合金性能的影响[J]. 轻合金加工技术, 2002, 30(5): 17-18.

BAI Zhen-hai, ZHAO Nan, LUO Bing-hui. The effects of squeeze casting on the properties of Al-Cu alloy[J]. Light Alloy Fabrication Technology, 2002, 30(5): 17-18.

[15] 张 明, 赵海东, 张卫文, 罗宗强, 李元元. 间接挤压铸造Al-Cu-Mn支架的工艺及性能[J]. 华南理工大学学报(自然科学版), 2007, 35(3): 16-21.

ZHANG Ming, ZHAO Hai-dong, ZHANG Wei-wen, LUO Zong-qiang, LI Yuan-yuan. Processing and properties ofAl-Cu-Mn supporting frame by indirect squeeze casting[J]. Journal of South China University of Technology (Natural Science Edition), 2007, 35(3): 16-21.

[16] 谢优华, 杨守杰, 戴圣龙, 陆 政. 锆元素在铝合金中的应用[J]. 航空材料学报, 2002, 22(4): 56-61.

XIE You-hua, YANG Shou-jie, DAI Sheng-long, LU Zheng. Application of element Zr in aluminum alloys[J]. Journal of Aeronautical Materials, 2002, 22(4): 56-61.

[17] HIDEO Y, YOSHIO B. The role of zirconium to improve strength and stress-corrosion resistance of Al-Zn-Mg and Al-Zn-Mg-Cu alloys[J]. Transactions of the Japan Institute of Metals, 1982, 23(10): 620-630.

[18] 潘青林, 尹志民, 张传福. Sc和Zr复合微合金化在Al-Mg合金中的存在形式与作用[J]. 航空材料学报, 2002, 22(1): 6-10.

PAN Qing-lin, YIN Zhi-min, ZHANG Chuan-fu. Effect of minor Sc and Zr joint additions on microstructure and tensile properties of Al-Mg alloy[J]. Journal of Aeronautical Materials, 2002, 22(1): 6-10.

[19] 尹志民, 高拥政, 潘青林, 张永红, 尹松波. 微量Sc和Zr对Al-Mg合金铸态组织的晶粒细化作用[J]. 中国有色金属学报, 1997, 7(4): 75-78.

YIN Zhi-min, GAO Yong-zhen, PAN Qing-lin, ZHANG Yong-hong, YIN Song-bo. Effect of trace Sc and Zr on grain refinement of as-cast Al-Mg alloys[J]. The Chinese Journal of Nonferrous Metals.1997, 7(4): 75-78.

Effect of Zr on microstructures and mechanical properties of squeeze cast Al-5.0Cu-0.4Mn alloy

MENG Fan-sheng, ZHANG Wei-wen, ZHANG Da-tong, YANG Chao, XIAO Zhi-yu

(School of Mechanical and Automotive Engineering, South China University of Technology, Guangzhou 510640, China)

Abstract: The effect of Zr on the microstructures and mechanical properties of Al-5.0Cu-0.4Mn alloy prepared by squeeze casting was studied by tensile test, macro corrosion test, scanning electron microscopy (SEM), transmission electron microscopy (TEM), and took comparative analysis with the gravity cast alloy. The results show that the best tensile strength, yield strength and elongation are obtained for both the squeeze cast and gravity cast alloys in as-cast state when the Zr content is 0.25% (mass fraction). As for the heat-treated alloys, the tensile strength and yield strength increase when Zr content increases from 0 to 0.35%. However, the elongation reaches the maximum value when Zr content is 0.15%. Squeeze casting can significantly improve the elongation of the alloys with different Zr contents, but the improvement of the elongation of the as-cast alloys is significantly better than that of the heat-treated alloys. The dominant strengthening mechanism of Zr in the as-cast alloy is the grain refinement. However, the solid solution strengthening and dispersive strengthening of Al3Zr particles and q' phase are the main strengthening mechanisms in the alloy after T6 heat treatment. Squeeze casting can significantly improve the dispersion strengthening effect of Al3Zr particles.

Key words: Al-Cu-Mn alloy; squeeze casting; mechanical property; microstructure

Foundation item: Project (51374110) supported by the National Natural Science Foundation of China; Project (2015A030312003) supported by the Guangdong Natural Science Foundation for Research Team, China

Received date: 2015-07-09; Accepted data: 2015-10-30

Corresponding author: ZHANg Wei-wen; Tel: +86-13642315239; E-mail: mewzhang@scut.edu.cn

(编辑 龙怀中)

基金项目:广东省自然科学基金研究团队资助项目(2015A030312003);国家自然科学基金资助项目(51374110);教育部博士点基金资助项目(20120172110045)

收稿日期:2015-07-09;修订日期:2015-10-30

通信作者:张卫文,教授,博士;电话:13642315239;E-mail: mewzhang@scut.edu.cn