DOI: 10.11817/j.issn.1672-7207.2016.11.004

金属材料喷射沉积3D打印工艺

单忠德,杨立宁,刘丰,戎文娟,刘倩

(机械科学研究总院 先进成形技术与装备国家重点实验室,北京,100083)

摘要:针对现有金属材料3D打印技术存在成本高、效率低的问题,提出一种由三维CAD模型驱动数控系统,直接实现多品种、小批量、结构复杂金属零部件柔性、高效制造的方法—喷射沉积3D打印成形,介绍该工艺原理。搭建了实验平台,并以铋锡合金为成形材料,采用单道、单层、实体分层次的工艺试验过程,分别研究喷头孔径、喷头移动速度、送气速度对单道成形轨迹的影响,成形路径、路径搭接率对单层成形表面形貌的影响,最后对喷射沉积3D打印成形铋锡合金实体的断口进行观察。研究结果表明:当喷头孔径为0.6 mm、送气速度为10 mL/min、喷头移动速度为10 mm/s时,所得单道成形轨迹均匀性较好;当采用S形路径及搭接率为50%时,可以获得较高质量单层成形表面;喷射沉积3D打印技术可以实现金属件的快速高效制造,成形效率可达50 cm3/h,为现有成熟金属件3D打印成形技术的2~3倍。

关键词:3D打印;喷射沉积;铋锡合金

中图分类号:TH164 文献标志码:A 文章编号:1672-7207(2016)11-3642-06

Three-dimensional printing technology based on metal spray and deposition

SHAN Zhongde, YANG Lining, LIU Feng, RONG Wenjuan, LIU Qian

(State Key Laboratory of Advanced Forming Technology & Equipment,

China Academy of Machinery Science & Technology, Beijing 100083, China)

Abstract: A three-dimensional printing (3DP) method was demonstrated based on spray and deposition techniques to advance the development in China's manufacturing industry and to address the high cost and low efficiency problems of the existing metal 3D printing technologies. Using a 3D-computer aided drawing (CAD) model-driven computer numerical control (CNC) system, multi-species, small quantities, and complex metal parts can be manufactured directly using 3DP. Single-channel and single-layer forming experiments were conducted on Sn-Bi alloy to examine the influence of different nozzle apertures, nozzle speeds, aspiration speed, forming paths, and lapping rate on track forming and the surface morphology. The 3DP method was then used for block forming; the fracture morphology of the structure was evaluated. The results show that the single-channel forming track has better uniformity under the following conditions: a nozzle aperture of 0.6 mm, an aspiration speed of 10 mL/min, and a nozzle speed of 10 mm/s; When use the S-shaped path and the path overlap rate is 50%, the formed single-layer surface quality is better; The 3DP technology bases on spray and deposition allows for fast and efficient manufacture of metal parts. The forming efficiency is 50 cm3/h, which is two to three-fold that of existing metal 3DP technologies.

Key words: three-dimensional printing (3DP); spray and deposition; Sn-Bi alloy

目前,金属零部件产品因其具有力学性能高、实用意义大等优点,在制造业中得到广泛的应用。而传统的金属件制造工艺,以铸造、锻造为主,存在工序繁琐、周期长、污染严重、材料浪费及可重复利用率低等问题,即不能满足市场对小批量、低成本、多品种、高质量、结构复杂产品的灵活制造需求,也不符合我国对工业发展的节能减排要求。以增材制造(俗称3D打印[1])为代表的大量快速、高效、清洁的柔性制造技术的产生,不但提升了产品设计及制造水平,有效解决了个性化、小批量生产与制造成本之间的矛盾,同时促进了传统的大批量制造模式向个性化制造模式的发展[2]。实现金属件的3D打印是该技术发展的重要目标和必然趋势。目前,较成熟的金属件增材制造技术主要有激光选区烧结[3-4]、选区激光熔化[5-7]、激光近净成形[8-11]和电子束选区熔化技术[12-15]等,虽然国内外在相关技术研究及设备开发方面取得了较多的成果,但仍然存在成形效率低、技术及设备成本高的问题。本文作者基于以上现状,提出一种由三维CAD模型驱动数控系统直接制造金属件的方法—喷射沉积3D打印成形技术。该技术源于离散/堆积的分层制造原理,是在真空或惰性气体保护环境下直接将预成形金属材料进行快速熔化,然后通过三维运动控制系统进行熔融金属的逐层沉积成形,最终实现多品种、小批量、结构复杂金属零部件的一次性高效制造。

1 工艺试验规划

本研究搭建了喷射沉积3D打印成形实验平台,以铋锡低熔点合金(成分为锡质量分数42%、铋质量分数58%,熔点为138 ℃)为成形原材料,采用单道、单层、实体分层次的试验过程进行工艺试验研究,验证该技术的可行性。试验过程首先将铋锡合金块材放入熔化炉中,然后在氮气保护环境下加热到160 ℃,静置30 min,待铋锡合金完全熔化后,通过调节向熔化炉腔内送入氮气的速度来控制熔融合金由下端喷嘴喷出的速度,同时通过PMAC控制软件来实现成形平台的三维移动。由于铋锡低熔点合金不易被氧化,因此试验过程在大气环境下进行。成形过程中,分层厚度D设定为1 mm,成形平台温度控制在60 ℃。

2 单道成形试验及结果分析

金属件的喷射沉积3D打印成形过程是由熔融金属按照预先规划好的单道沉积路径,经过交错叠加来成形金属件。因此单道成形性能对最终成形件的质量起到决定性作用。本文将成形轨迹宽度及轨迹均匀性作为评价单道成形性能的主要指标,研究在不同送气速度、喷头孔径及喷头移动速度条件下的单道成形性能。

喷头移动速度v1和熔融金属喷出速度v2的匹配是影响单道成形过程的关键因素,因此本研究首先在固定喷头孔径d的条件下,研究喷头移动速度和熔融金属喷出速度的匹配关系以及它们对单道成形轨迹宽度w的影响规律。由于本研究中采用送气速度来调节熔融金属的喷出速度,假设当熔化炉腔内气压达到平衡时的送气速度为L。将熔融金属单道沉积轨迹截面近似为矩形,则矩形的边长即为沉积轨迹宽度。在不考虑成形过程中材料出现膨胀和收缩的前提下,则有

(1)

(1)

则

(2)

(2)

由式(2)可见:如果喷头移动速度不变,随着送气速度的增加,沉积轨迹宽度变大;相反,如果送气速度不变,随着喷头移动速度的增大,沉积轨迹宽度变窄。因此,喷头移动速度和送气速度应合理匹配,喷头移动速度增大,送气速度也应相应增大;喷头移动速度减小,送气速度也应相应减小。

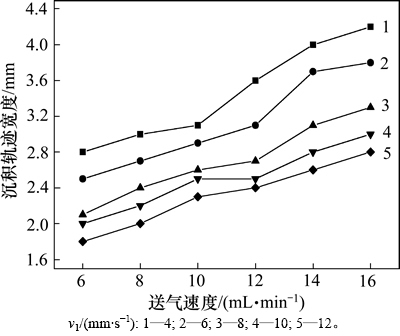

图1所示为固定喷头孔径d=0.5 mm时,在不同喷头移动速度和送气速度条件下的单道成形轨迹宽度数据对比。由图1可以看出:在喷头移动速度一定的条件下,随着送气速度的增加,单位时间内由喷头喷出熔融金属量增加,受到上端喷头的挤压限制,单道沉积轨迹宽度也不断变宽;当送气速度一定时,喷头移动速度的增加会使沉积熔融金属随喷头移动而被快速“拉长”,轨迹宽度变窄。在试验过程中同样发现,较大送气速度和较小喷头移动速度均会造成熔融金属的过堆积,影响成形精度。相反,较小送气速度和较大喷头移动速度会造成单位时间内从喷头喷出的熔融金属量小于实际路径填充所需金属量,出现沉积轨迹宽度不均匀、甚至不连续现象。

图1 不同喷头移动速度及送气速度条件下的单道沉积轨迹宽度数据对比

Fig. 1 Comparative data of a single-channel forming track width at various nozzle (movement) speeds and aspiration speeds

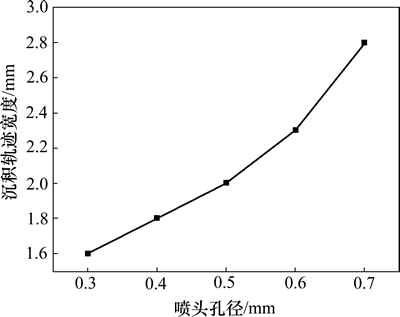

图2所示为固定喷头移动速度v1=12 mm/s及送气速度L=8 mL/min时,不同喷头孔径下所沉积单道轨迹宽度。由图2可以看出:随着喷头孔径的增大,单道沉积轨迹宽度逐渐变大。但喷头孔径过大会影响成形精度,而过小则容易形成喷头堵塞,成形无法正常进行。

图2 不同喷头孔径条件下的单道沉积轨迹宽度

Fig. 2 Single-channel forming track width for variations in nozzle aperture

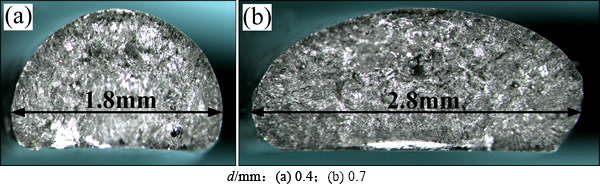

图3所示为喷头孔径d=0.4 mm和d=0.7 mm条件下所沉积单道轨迹宽度照片。试验过程中发现熔融金属流动性及其冷却速度对单道沉积轨迹宽度也有明显影响。当熔融金属及成形环境温度较高时,金属冷却速度变慢,流动性增强,较小的表面张力使金属液与成形基板间的浸润性变好,熔融金属在基板上迅速铺展开,形成较宽的沉积轨迹。

图3 不同喷头孔径条件下的单道沉积轨迹宽度试验照片

Fig. 3 Laboratory photographs of single-channel forming track width at various nozzle apertures

沉积轨迹均匀性是评价单道成形性能的又一个主要指标,本文设计正交试验来研究喷头孔径、送气速度和喷头移动速度这3个工艺参数对铋锡合金单道沉积轨迹均匀性的影响,并确定较优的工艺参数组。在以上试验基础上,分别给3个工艺参数赋以3个水平,如表1所示,然后按照L9(34)正交表安排正交试验。

表1 因素与水平

Table 1 Factors and levels

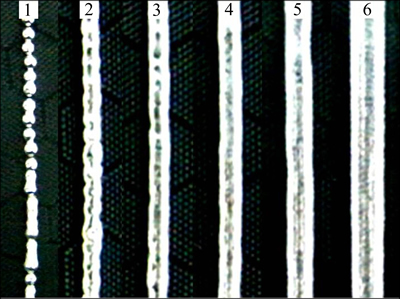

将不同参数条件下的铋锡合金单道沉积轨迹均匀性分为6个层次,各层次用数字1~6来代表,如图4所示。其中:1代表沉积轨迹不连续;2代表沉积轨迹呈连续节状;3代表沉积轨迹边缘不均匀,且呈间断分节;4代表沉积轨迹边缘不均匀,但无明显分节;5代表沉积轨迹边缘较均匀且无明显分节;6代表沉积轨迹呈连续均匀直线型。

图4 各数字所代表单道沉积轨迹均匀性形貌特征

Fig. 4 Single-channel forming trajectory morphologies

正交试验表及极差分析结果如表2所示。

由表2结果可看出:喷头孔径和送气速度对沉积轨迹均匀性的影响较大,当工艺参数为喷头孔径d=0.6 mm、送气速度L=10 mL/min及喷头移动速度v1=10 mm/s时所得单道沉积轨迹均匀性较好。

表2 正交试验表L9(34)及极差分析结果

Table 2 Orthogonal test scheme L9(34) and range analysis results

3 单层成形试验及结果分析

成形路径是金属件喷射沉积3D打印成形工艺中的又一主要参数,它影响成形过程中的温度变化、成形件的残余应力和致密度等。本文在固定送气速度L=10 mL/min、喷头移动速度v1=10 mm/s及喷头孔径d=0.6 mm参数条件下,分别采用S形、“回”形以及回填路径进行单层铋锡合金成形试验,研究成形路径及路径搭接率对成形层表面质量及致密度的影响。

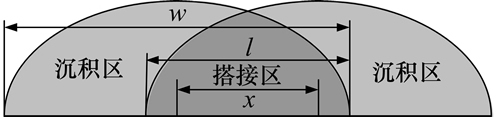

图5所示为两相邻沉积轨迹之间形成搭接区域的示意图。图中:x为两道沉积轨迹中心之间的距离,也即成形两道轨迹时所设定的喷头垂直于单道轨迹方向的单位移动距离,l为搭接区域的宽度。

图5 两相邻沉积轨迹之间形成搭接区域的示意图

Fig. 5 Schematic diagram of overlap region formed between two adjacent trajectories

搭接率 为搭接区域宽度与单道沉积轨迹宽度之比,用下式表示:

为搭接区域宽度与单道沉积轨迹宽度之比,用下式表示:

(3)

(3)

由式(3)可见:在单道沉积轨迹宽度不变条件下,通过设定成形时喷头垂直于单道轨迹方向的单位移动距离即可得到具有不同搭接率的单层成形试样。

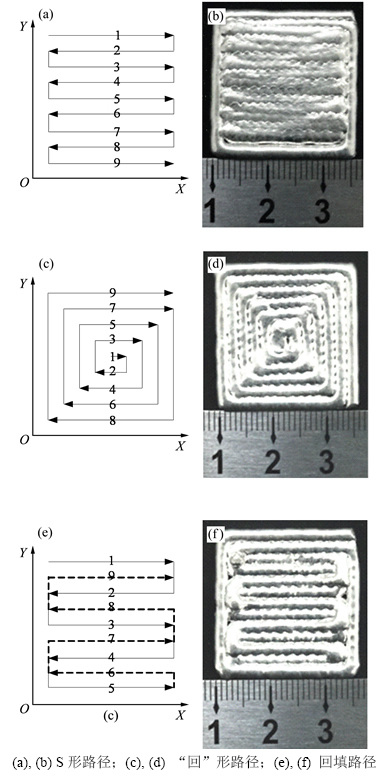

图6所示为S形、“回”形、回填3种路径示意图及采用这些路径所成形单层铋锡合金表面情况,试验采用路径搭接率为50%。

图6 不同成形路径示意图及对应成形层表面情况

Fig. 6 Schematic diagrams of three different forming paths and formed single-layer surface morphology resulting from each

由图6可以看出:当采用S形路径进行单层成形时,成形表面质量较好;当采用“回”形路径进行单层成形时,由于在“回”形的转弯处,喷头的运动存在一个减速、加速的过程,会造成较短时间的停留,使得拐角处形成熔融金属的过堆积,影响成形表面质量;当采用回填路径进行单层成形时,在回填过程中,由于熔融金属的无间断喷出,同样会造成路径重合点处的熔融金属过堆积,影响表面质量。

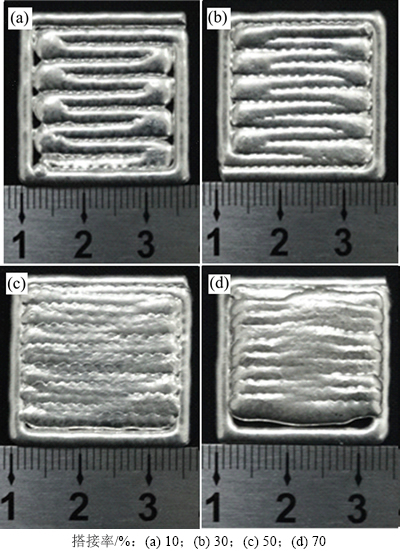

路径搭接率对单层成形表面质量及致密度也有较大的影响。图7所示为不同搭接率条件下所成形单层铋锡合金表面情况,试验采用S形路径进行单层成形。

由图7可以看出:当采用S形路径进行单层成形时,路径搭接率过小,如图7(a)和7(b)所示,会造成路径填充不完整,相邻路径间有较深的凹痕,相应表面质量及致密度也较差;而路径搭接率过大,如图7(d)所示,虽然致密度变好,但会造成熔融金属的局部过堆积,形成凸起,影响成形表面质量。在本试验条件下,当搭接率为50%时,成形表面质量及致密度均较好。

熔融金属流动性及冷却速度对单层成形表面质量及致密度也有明显影响。当熔融金属流动性好及冷却速度慢时,相邻沉积轨迹间有足够时间去填充低势能的凹痕区域,最终相互黏结成一个平整、致密的成形面。

图7 不同成形路径及路径间距条件下的单层成形表面形貌

Fig. 7 Formed single-layer surface conditions at different path overlap rates

4 实体成形试验及结果分析

本文在喷头孔径d=0.6 mm、送气速度L=10 mL/min、喷头移动速度v1=10 mm/s及路径搭接率 =50%的参数条件下,采用逐层反向的S形成形路径进行铋锡合金实体的成形试验。成形实体尺寸为100 mm×100 mm×100 mm,成形效率为50 cm3/h。

=50%的参数条件下,采用逐层反向的S形成形路径进行铋锡合金实体的成形试验。成形实体尺寸为100 mm×100 mm×100 mm,成形效率为50 cm3/h。

采用JSM-6510型扫描电子显微镜对成形实体的断口进行观察,图8所示为不同放大倍数下的断口观察照片。由图8可以看出:成形实体不仅断口致密,且层间结合良好,无明显层间剥离现象。

图8 不同放大倍数下铋锡合金实体断口扫描电镜照片

Fig. 8 SEM images showing fracture morphology under different magnifications

5 结论

1) 喷头孔径、喷头移动速度、送气速度对单道沉积轨迹宽度均有明显影响;相比喷头移动速度,喷头孔径和送气速度对成形轨迹均匀性的影响较大。

2) 路径搭接率对单层成形表面质量影响较大,搭接率过大会造成熔融金属的局部过堆积,而搭接率过小会造成路径填充不完整;相比“回”形及回填路径,采用S形路径所成形单层铋锡合金的表面质量较好。

3) 采用喷射沉积3D打印技术进行尺寸(长×宽×高)100 mm×100 mm×100 mm铋锡合金实体的成形,成形效率达到50 cm3/h,为现有成熟金属件3D打印成形技术的2~3倍。

4) 除了本文所研究的喷头孔径、喷头移动速度、熔融金属喷出速度、成形路径及路径搭接率外,影响金属件喷射沉积3D打印成形精度的工艺参数还有喷头及成形室温度、分层厚度、延迟时间等。在后续的研究工作中,我们将通过工艺试验对这些工艺参数对金属件喷射沉积3D打印成形精度的影响进行深入、系统研究。

参考文献:

[1] 刘厚才, 莫健华, 刘海涛. 三维打印快速成形技术及其应用[J]. 机械科学与技术, 2008, 27(9): 1184-1190.

LIU Houcai, MO Jianhua, LIU Haitao. A review of three dimensional printing technology and its application[J]. Mechanical Science and Technology for Aerospace Engineering, 2008, 27(9): 1184-1190.

[2] 单忠德, 樊东黎, 范宏义, 等. 机械装备工业节能减排制造技术[M]. 北京: 机械工业出版社, 2014: 367-390.

SHAN Zhongde, FAN Dongli, FAN Hongyi, et al. Manufacturing technology of energy conservation and emission reduction in industrial machinery and equipment[M]. Beijing: China Machine Press, 2014: 367-390.

[3] 颜永年, 张人佶, 林峰. 激光快速成形技术的新进展[J]. 新技术新工艺, 2006(9): 7-9.

YAN Yongnian, ZHANG Renji, LIN Feng. New development of laser rapid prototyping technique[J]. New Technology & New Process, 2006(9): 7-9.

[4] 李怀学, 巩水利, 孙帆, 等. 金属零件激光增材制造技术的发展及应用[J]. 航空制造技术, 2012(20): 26-31.

LI Xuehuai, GONG Shuili, SUN Fan, et al. Development and application of laser additive manufacturing for metal component[J]. Aeronautical Manufacturing Technology, 2012(20): 26-31.

[5] 孙会来, 赵方方, 林树忠, 等. 激光熔覆研究现状与发展趋势[J]. 激光杂志, 2008, 29(1): 4-6.

SUN Huilai, ZHAO Fangfang, LIN Shuzhong, et al. Research progress and development trend on laser cladding[J]. Laser Journal, 2008, 29(1): 4-6.

[6] KRUTH J P, MERCELIS P, Van VAERENBERGH J, et al. Binding mechanisms in selective laser sintering and selective laser melting[J]. Rapid Prototyping Journal, 2005, 11(1): 26-36.

[7] MORGAN R, SUTCLIFFE C J, O'NEILL W. Density analysis of direct metal laser re-melted 316L stainless steel cubic primitives[J]. Journal of Materials Science, 2004, 39(4): 1195-1205.

[8] 杨毅, 王剑彬. 激光直接快速成形金属零件的研究进展[J]. 热处理技术与设备, 2006, 27(3): 13-17.

YANG Yi, WANG Jianbin. Research progress of laser direct rapid forming metallic components[J]. Heat Treatment Technology and Equipment, 2006, 27(3): 13-17.

[9] COSTA S E, MASANARI S, KOZO O, et al. Rapid manufacturing of metal components by laser forming[J]. International Journal of Machine Tools and Manufacture, 2006, 46(12/13): 1459-1468.

[10] WU X, MEI J. Near net shape manufacturing of components using direct laser fabrication technology[J]. Journal of Materials Processing Technology, 2003, 135(2/3): 266-270.

[11] Pinkerton Andrew J, LI Lin. The significance of deposition point standoff variations in multiple-layer coaxial laser cladding (coaxial cladding standoff effects)[J]. International Journal of Machine Tools and Manufacture, 2004, 44(6): 573-584.

[12] 齐海波, 颜永年, 林峰. 电子束快速制造技术制备SiCP/Al复合材料[J]. 材料工程, 2005(1): 61-64.

QI Haibo, YAN Yongnian, LIN Feng. SiCp/Al composite made by electron beam rapid manufacturing[J]. Journal of Materials Engineering, 2005(1): 61-64.

[13] 颜永年, 齐海波, 林峰, 等. 三维金属零件的电子束选区熔化成形[J]. 机械工程学报, 2007, 43(6): 87-92.

YAN Yongnian, QI Haibo, LIN Feng, et al. Produced three-dimensional metal parts by electron beam selective melting[J]. Chinese Journal of Mechanical Engineering, 2007, 43(6): 87-92.

[14] MATZ J E, EAGAR T W. Carbide formation in Alloy 718 during electron-beam solid freeform fabrication[J]. Metallurgical and Materials Transaction A: Physical Metallurgy and Materials Science, 2002, 33(8): 2559-2567.

[15] 杨光, 巩水利, 锁红波, 等. 电子束快速成形TC18合金多次堆积的组织特征研究[J]. 航空制造技术, 2013(8): 71-74.

YANG Guang, GONG Shuili, SUO Hongbo, et al. Microstructure characterization of multi-deposited TC18 alloy by electron beam rapid manufacture[J]. Aeronautical Manufacturing Technology, 2013(8): 71-74.

(编辑 陈爱华)

收稿日期:2016-01-08;修回日期:2016-03-26

基金项目(Foundation item):机械科学研究总院技术发展基金项目(201406) (Project(201406) supported by the Technical Development Fund Project of China Academy of Machinery Science & Technology)

通信作者:单忠德,研究员,博士生导师,从事绿色制造技术与装备研究;E-mail: shanzd@cam.com.cn