文章编号:1004-0609(2014)10-2642-10

高铅渣还原炉内气液两相流的数值模拟与结构优化

闫红杰1,夏 韬1,刘 柳1,何秋安2,何志军2,李全清2

(1. 中南大学 能源科学与工程学院,长沙 410083;

2. 安阳市岷山有色金属有限责任公司,安阳 455000)

摘 要:基于Fluent软件,耦合Realizable k-ε湍流模型和VOF多相流模型对液态高铅渣还原炉内气液两相流动过程进行数值模拟。依据相似原理建立了水模型实验,得到气泡/气团频率、气泡直径和喷枪直径比值的实验结果,其结果和数值计算结果吻合较好,验证数值计算模型的有效性。运用该耦合模型研究熔池深度、喷枪直径、喷枪倾角和喷枪间距等因素对还原炉的影响。再通过正交实验和矩阵分析方法,综合考虑熔池气含率、熔体平均流速和熔体湍动能等指标,得到还原炉最优工况为喷枪角度为10°,熔池深度为800 mm,喷枪直径为60 mm,间距为950 mm。

关键词:高铅渣;熔池熔炼;气液两相流;数值模拟;矩阵分析法

中图分类号:TF812 文献标志码:A

Numerical simulation and structural optimization of gas-liquid two-phase flow in reduction furnace of lead-rich slag

YAN Hong-jie1, XIA Tao1, LIU Liu1, HE Qiu-an2, HE Zhi-jun2, LI Quan-qing2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Anyang Shi Minshan Nonferrous Metals Co., Ltd., Anyang 455000, China)

Abstract: Based on Fluent software, the gas-liquid two-phase flow in reduction furnace was simulated by Realizable k-ε Turbulent model coupling with VOF multiphase model. The experiments on the bubble frequency and the ratio of the bubble diameter and the lance diameter were carried out in a water model based on the similarity principle, and the results were compared with the numerical results and the feasibility of the model was verified. The influences of some parameters, such as the pool depth, the lance diameter, the lance inclination and the lance spacing, were studied on reduction furnace. Using the orthogonal experimental design and matrix analytic method and overall considering the gas holdup, mean velocity and turbulent kinetic energy of the melt optimum indexes, the optimal operation condition can be achieved with the lance inclination angle of 10°, the pool depth of 800 mm, the lance diameter of 60 mm and the lance spacing of 950 mm.

Key words: lead-rich slag; bath smelting; gas-liquid two phase flow; numerical simulation; matrix analytic method

液态高铅渣还原炉是直接炼铅过程中还原工序的主要设备。相比于传统鼓风炉而言,该还原炉具有现场操作环境好、能源消耗率低等优点[1-2]。然而,该还原炉在运行过程中仍可能存在气含率分布不均匀、炉内熔体喷溅严重和喷枪寿命较短等问题,对生产造成不利的影响。

高铅渣的底吹熔池熔炼还原过程是以天然气(或煤粉)作为还原剂,将高铅渣中的氧化铅还原成金属铅[3]。在还原过程中,气体通过炉子底部的喷枪进入熔池,并利用气体所具有的动能对熔融液态高铅渣进行搅拌,使其和还原剂充分接触,提高还原反应速率。可见炉内气液两相的流动过程对提高底吹熔池熔炼还原炉运行效率至关重要。国内外很多学者对熔池熔炼过程的多相流动行为进行了研究,DAVIS等[4-5]对HIsmelt工艺中的熔融还原炉进行了数值模拟,研究在顶吹氧枪和侧吹氧煤喷枪作用下炉内的流动和传热现象及其影响分析,并对熔炼炉进行了数值模拟优化。NAZMUL等[6]研究了浸没顶吹熔炼炉内的多相流动行为对还原反应的影响。VLADIMIR等[7]采用数值模拟的方法完成铁浴反应器内的温度场和流场优化分析。詹树华[8]等对浸入式侧吹方式下熔池搅拌现象进行研究,并采用气液两相多流模型描述了侧吹熔池内的两相流运动行为和熔池搅动情况。

由于炉内气液两相流动过程受多方面因素的影响,需要进行优化设计,而设计过程需要选择合适的参数作为评价指标来量化结果。张振扬等[9-10]选择熔池内气含率、熔体平均流速和熔体湍动能作为炼铜过程中富氧底吹炉优化设计的指标;NAN等[11]选择炉体上部氧气浓度和燃尽率作为熔池内部流场和温度场的评价指标。然而,多个评价指标不可能直观的量化反映最终结果,往往需要进行多目标优化分析。JAFARI等[12]、COMAKLI等[13]和张振扬等[14]基于田口方法对多目标实验结果进行优化分析,但该方法中目标权重仅由专家决定,存在主观因素影响。而矩阵分析方法[15-16]因采用数学手段得到各个因素的权重矩阵,所得结果较为客观且可靠。

本文作者采用数值模拟的方法对底吹熔池熔炼炉内气液两相流进行研究,考虑熔池深度、喷枪直径、喷枪倾角和喷枪间距对还原炉的影响,选择熔池气含率、熔体平均流速和熔体湍动能作为评价指标,采用矩阵分析方法对底吹熔池熔炼炉进行多目标优化分析,为底吹熔池熔炼炉的实际操作过程提供理论依据。

1 物理建模及网格划分

1.1 研究对象

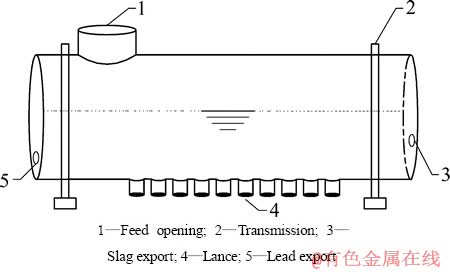

以直径为1.59 m,炉长为17.38 m的卧式液态高铅渣还原炉为研究对象,其喷枪直径为0.05 m,共10支,沿炉底依次排布,其结构示意图如图1所示。

1.2 物性参数

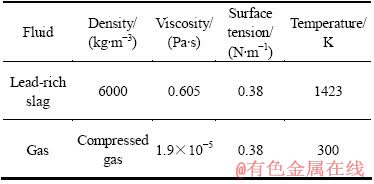

对底吹熔池熔炼还原炉内高铅渣进行取样和化验,并结合现场生产记录对混合气体物性参数进行折算,其结果如表1所列。

图1 底吹熔池熔炼还原炉的示意图

Fig. 1 Schematic diagram of bottom-blown bath smelting reduction furnace

表1 还原炉内流体性能参数

Table 1 Pysical parameters of fluids in bottom-blowing bath smelting reduction furnace

1.3 网格划分

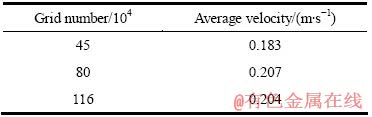

基于Gambit软件平台,采取混合网格划分方法,用分块网格和局部加密的方法对底吹熔池熔炼还原炉几何模型进行离散化。为了保证计算的准确性,需要进行网格无关性检验,选择熔池区域的流体平均运动速度为指标,分别使用网格数量为45万、80万和116万的3组网格进行网格无关性检查。计算稳定时,统计熔池区域流体平均速度,结果如表2所列。

由表2可知,网格数量为45万时,流体平均速度偏小,80万和116万所得数据基本相等,基于节约计算成本的原则,选择80万网格模型为计算网格。

表2 不同网格数量时的流体平均速度

Table 2 Average velocity of rich-lead slag with different girds

2 数学模型及边界条件

高铅渣还原过程中,底部喷枪喷入的天然气与炉内高铅渣发生冶金还原反应,该过程涉及到气体和熔体之间的相互作用,需要进行合理的简化与假设。

2.1 模型的简化与假设

1) 在本研究中重点关注高铅渣的还原过程中熔池内多相流动行为,因而暂未考虑加渣、放渣和放铅等间断性过程,故可假设熔池深度不变;2) 由于熔池内流动和反应过程十分复杂,本研究中主要关注各参数对流动性的影响,故未考虑化学反应,而化学反应热可以用源项的形式加入;3) 气液交界面作自由液面处理; 4) 固体壁面看作无滑移边界,靠近壁面处的边界层内采用标准壁面函数处理。

2.2 数学模型

选用VOF模型来计算还原炉内气相的分布以及熔池自由液面的流动特征,其方程描述如下。

1) 体积分数方程

在VOF模型中,追踪界面主要是通过求解一相或多相的体积分数的连续性方程来完成的,连续性方程如式(1)所示:

(1)

(1)

式中:t为模拟时间; 表示第q相的体积分数;

表示第q相的体积分数; 为第q相的密度;

为第q相的密度; 为第q相的速度;

为第q相的速度; 是p相到q相的质量输送;

是p相到q相的质量输送; 是q相到p相的质量输送;

是q相到p相的质量输送; 为q相的源项;

为q相的源项; 为算子符号,表达式为

为算子符号,表达式为 。

。

2) 动量方程

VOF多相流模型的速度场是由各相共享的,是通过求解整个区域内的单一的动量方程来得到,如方程(2)所示。

(2)

(2)

式中: 为流体密度;p为压力;g为重力加速度;F为作用于控制容积上的体积力;v为流体速度;

为流体密度;p为压力;g为重力加速度;F为作用于控制容积上的体积力;v为流体速度; 为动力黏度。

为动力黏度。

3) 湍流模型

在液态高铅渣还原炉内,底部喷枪喷入的混合气体以射流的形式进入熔池,该流动行为是一个强湍流过程。数值计算过程中对湍流流动的数学描述主要有Standard k-ε模型、DNG k-ε模型和Realizable k-ε模型。闫红杰等 [10]通过数值计算和水模型实验得出计算熔体多相流动过程时Realizable k-ε模型更接近实验结果,其数学描述如下。

(3)

(3)

(4)

(4)

对于式(4), ,

, ,

, ,

, ,

, ,

, ;

; ,

, ,

, ,

, ;k为湍流脉动动能;v为速度,

;k为湍流脉动动能;v为速度, 为湍动能耗散率;Gk是由平均速度梯度而产生的湍流动能;Gb是由浮力产生的湍流动能;YM表示在可压缩流中,过渡的扩散中产生的波动;Sk和

为湍动能耗散率;Gk是由平均速度梯度而产生的湍流动能;Gb是由浮力产生的湍流动能;YM表示在可压缩流中,过渡的扩散中产生的波动;Sk和 是用户自定义源项;

是用户自定义源项; 为层流黏度;

为层流黏度; 为湍流涡黏度。

为湍流涡黏度。

2.3 边界条件

1) 入口条件

喷枪入口为质量流量边界条件,入口工质由氮气、氧气和天然气组成的可压缩混合气体,入口流量为0.16kg/s,湍流强度为4.9%,水力直径为0.05 m。

2) 出口条件

烟气出口设置为压力出口边界条件,出口压力设置为-72 Pa。

3) 壁面边界条件

不考虑壁面的散热,作绝热壁面处理;认为在壁面处的流体速度为0,即无滑移壁面边界条件,近壁面区域采用标准壁面函数处理。

3 数学模型的验证

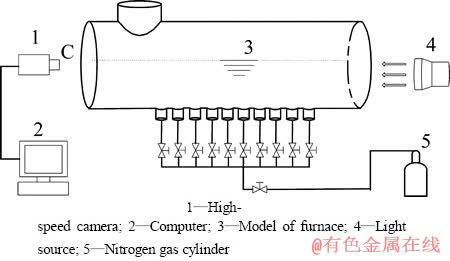

利用相似原理,以某公司底吹熔炼炉为原型,按照10:1的比例建立水-氮气模型试验装置(见图2),并用高速摄影仪对实验结果进行采集,然后对计算结果和实验结果进行定性和定量比较分析,以此验证所用数学模型的可靠性。

图2 水模型实验装置示意图

Fig. 2 Sketch diagram of water model experiment

1) 定性分析

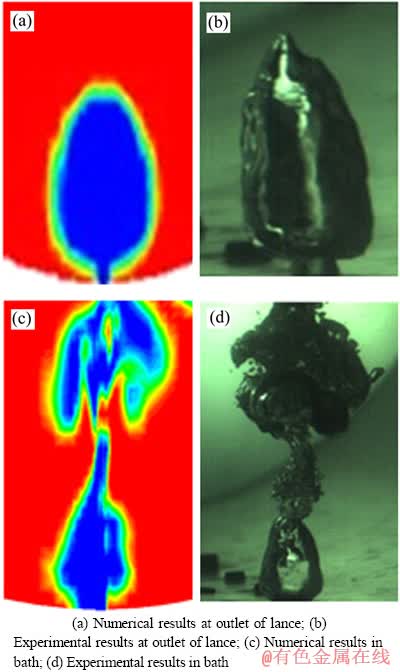

依据相似原理设计的水模型实验方案进行实验,并用高速摄影仪记录喷枪根部及熔池中气泡的形态,然后对比数值模拟计算结果,如图3所示。

对比发现,图3(a)和(b)吻合较好,出口气泡均呈椭球形,且气泡并不会贴着壁面形成,而是形成一定长度的“颈”部。图3(c)和(d)所得的气泡/气团形态基本一致,气泡/气团在熔池中不断生长,并伴随着破碎和变形。

图3 数值计算与水模型实验所得气泡形态图

Fig. 3 Bubble shapes of numerical calculation and water model experiment

2) 定量分析

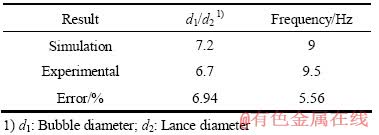

模型实验和数值计算所用的喷枪直径各不相同,所产生的气泡直径不具有可比性,故引入无量纲直径(dL=d1/d2,dL为无量纲直径,d1为气泡直径,d2为喷枪直径)和气泡频率进行定量分析对比,其结果如表3所列。

表3 数值计算结果与水模型实验结果比较表

Table 3 Comparison of simulation results with experiment data

数值模拟与实验观测所得气泡/气团形态相似,而无量纲直径和气泡产生频率均存在一定的误差,但是都在可接受的误差范围以内。因此,本文作者所建立的底吹熔池熔炼还原炉的三维数学模型准确可靠,可以用来模拟底吹炼铅熔炼炉内的多相流动行为。

4 讨论与分析

4.1 关键参数对熔炼过程的影响

底吹炼铅还原炉熔炼过程中,喷枪倾角、喷枪直径、熔池深度和喷枪间距等因素对熔池熔炼过程影响较为明显。

4.1.1 喷枪倾角对熔炼过程的影响

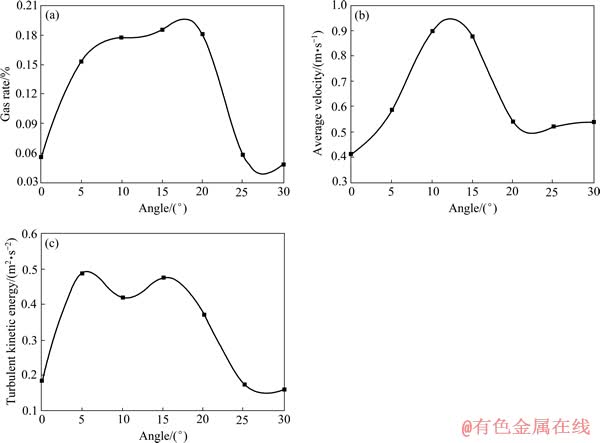

喷枪倾角是指喷枪中心线和还原炉的纵截面之间所形成的角度。在保证入口流量不变的前提下,对不同喷枪角度下熔池的气含率、熔体平均流速和熔体湍动能进行监测,其结果如图4所示。

由图4可知,当喷枪角度在0°~10°时,气相穿过熔池的作用距离变长,延长了在熔池中的停留时间,熔池气含率、平均流速和湍动能逐渐增大,强化了熔池熔炼过程;而当倾角大于17°之后,气体对熔池的搅拌集中在还原炉一侧,且随着角度的增加,熔池气含率、平均流速和湍动能越来越小;当喷枪角度大于25°以后,熔池气含率、平均流速和湍动能等参数的值与0°时的工况接近。故认为还原炉喷枪倾角在10°~17°之间最佳。

4.1.2 喷枪直径对熔炼过程的影响

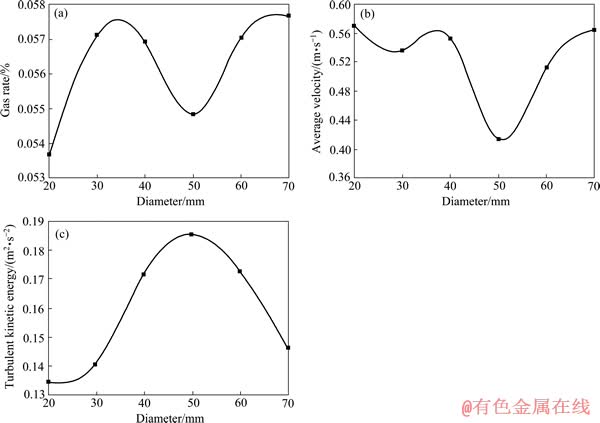

喷枪直径的大小直接影响到操作压力和气体流量等参数的设定,因而在实验过程中有必要考虑不同喷枪直径对熔池的影响规律,其结果如图5所示。

图4 熔池气含率、熔体平均流速和熔体湍动能随喷枪倾角的关系

Fig. 4 Relationships among gas holdup(a), average velocity(b) and turbulent kinetic energy(c) and lance inclination

图5 熔体气含率、平均流速和湍动能随喷枪倾角的关系

Fig. 5 Relationships among gas holdup(a), average velocity(b) and turbulent kinetic energy(c) and lance diameter

由图5可知,当喷枪直径在30~40 mm和60~70 mm时,熔池气含率和熔体平均流速均维持在较好的水平;当喷枪直径为50 mm时,熔体气含率和熔体平均流速均偏小,而熔体湍动能则优于其他工况时的。因此,综合考虑3个因素的影响,认为还原炉喷枪直径为40~60 mm时较为合适。

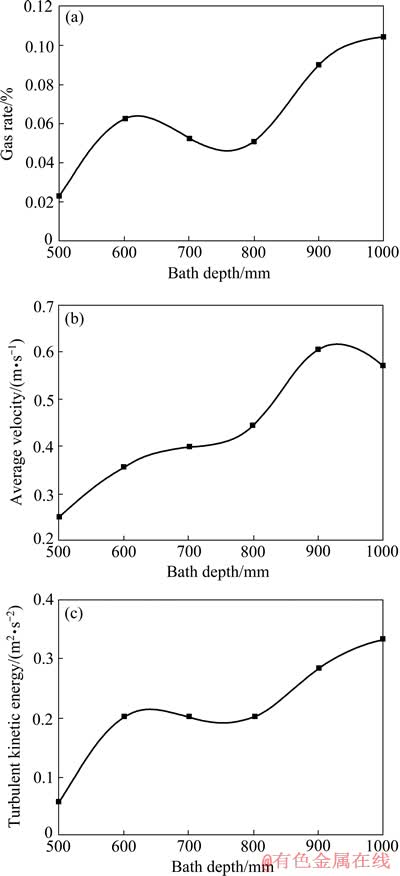

4.1.3 熔池深度对熔炼过程的影响

熔池深度是指静止状态下还原炉底部到熔体自由界面之间的垂直距离。该因素直观衡量了还原炉的冶炼能力,但生产经验表明,熔池深度一般不超过还原炉的设计半径。提取了不同熔池深度下熔池的气含率、熔体平均流速和湍动能的变化曲线,其结果如图6所示。

图 6 熔体气含率、平均流速和湍动能随熔池深度变化关系

Fig. 6 Relationships among gas rate(a), average velocity(b) and turbulent kinetic energy(c) and bath depth

由图6可看出,随着熔池深度不断增加,熔池气含率、平均流速和湍动能均呈增长趋势。特别是当熔池深度从800 mm变化到900 mm的过程中,3个指标变化较为剧烈。但是在生产过程可能仍需要紧急转炉,考虑到转炉过程的安全因素,认为该熔池深度一般不超过1000 mm。综上所述,还原炉的最佳熔池深度800~1000 mm。

4.1.4 喷枪间距对熔炼过程的影响

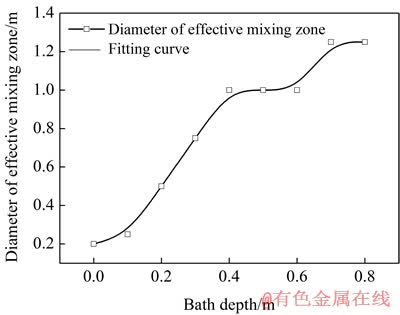

引入有效搅拌区域直径后将喷枪间距作无量纲处理,假设有效搅拌区域直径为R,喷枪间距为L,蔡志鹏等[17]认为当R/L为1.2~1.5时,喷枪间距最佳。然而,有效搅拌区域内熔体的速度不为零,故可以根据熔体速度的变化来确定有效搅拌区域的直径,图7中给出了不同熔池深度截面上对应的有效搅拌区域直径,当底吹熔池熔炼还原炉的熔池深度为800 mm时,对应的有效搅拌区域直径R为1250 mm,故底吹熔池熔炼还原炉的最佳的喷枪间距L为900~1000 mm。

图7 有效搅拌区域直径与熔池深度的关系

Fig. 7 Relationship between diameter of effective mixing zone and bath depth

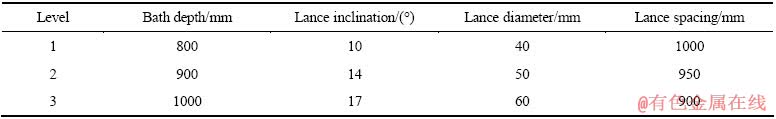

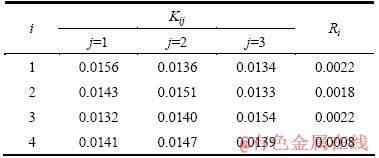

4.2 正交试验方案及结果

基于前面的底吹熔池熔炼还原炉各关键影响因素对于熔池熔炼过程的单因素影响分析,选择熔池深度(A)、氧枪倾角(B)、氧枪直径(C)和氧枪间距(D) 4个影响因素的三水平L9(34)正交实验方案对底吹炼铅熔炼炉进行优化分析,具体因素水平配置表及正交实验如表4所列。

根据正交试验方案表对还原炉进行9组实验,得到如表5所列的熔池气含率、熔体平均流速和熔体湍动能。

由于选用了3个不同的评价指标,因而不能直观地得到最优的方案,需要用矩阵方法进行多目标优化分析,以便确定各因素的权重及其最优方案。

表4 正交实验因素水平配置表

Table 4 Orthogonal experimental factors level configuration

表5 正交实验方案数值模拟结果

Table 5 Orthogonal experiment results analysis

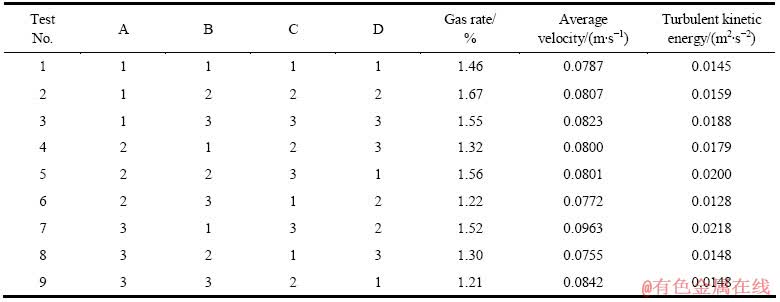

4.3 试验结果的矩阵分析

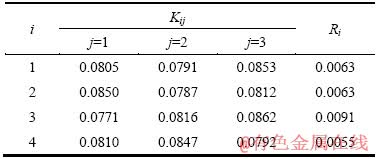

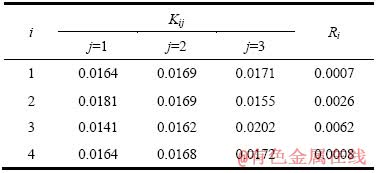

运用矩阵方法进行多目标优化分析, 需要建立一个三层数据结构模型,第一层为实验考察指标层,第二层为因素层,第三层为水平层,然后通过数学运算得到各个因素的权重大小,进而确定因素的主次顺序,达到快速寻优的目的。定义实验考察指标层矩阵:若正交实验中有i个因素,每个因素有j个水平,因素i的第j个水平上的实验指标平均值为Kij,因素i在所有水平上的极差为Ri。在本研究中,共有3个评价指标(气含率、平均流速和平均湍动能),每个评价指标有4个因素(熔池深度、氧枪倾角、氧枪直径和氧枪间距,分别用i=1, 2, 3, 4表示),每个因素分别对应3个水平(j=1, 2, 3)。表6、7和8分别给出了3个评价指标层矩阵的分析结果。

表6 气含率考察指标层的矩阵分析结果

Table 6 Matrix analysis result of gas holdup

表7 平均流速考察指标层的矩阵分析结果

Table 7 Matrix analysis result of average velocity

表8 平均湍动能考察指标层的矩阵分析结果

Table 8 Matrix analysis result of turbulent kinetic energy

而因素层矩阵则由 组成。水平层矩阵由

组成。水平层矩阵由 组成,其中,Si为正交实验中第i因素的极差。以气含率指标为例,在底吹还原熔炼过程中,气含率越大越好,则令

组成,其中,Si为正交实验中第i因素的极差。以气含率指标为例,在底吹还原熔炼过程中,气含率越大越好,则令 ,建立式(5)、(6)和(7)所示的矩阵。

,建立式(5)、(6)和(7)所示的矩阵。

(5)

(5)

(6)

(6)

(7)

(7)

将矩阵M1、T1和S1代入 中,则应用Matlab软件计算,结果如下:

中,则应用Matlab软件计算,结果如下:

,

, ,

,

则综合权重矩阵为

(8)

(8)

(9)

(9)

通过上述分析得各个因素对正交实验指标值影响的主次顺序依次为C、B、A、D,即喷枪直径对还原炉的影响最明显,喷枪倾角和熔池深度次之,喷枪间距最小。同时得出最优工况为C3B1A1D2,即选用喷枪直径为60 mm,喷枪角度为10°,熔池深度为800 mm,间距采用950 mm混合搭配所得工况较好。

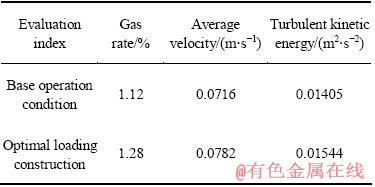

4.4 优化工况与基准工况对比

依据正交实验所得最优工况对底吹熔池熔炼炉进行物理、数学建模,仿真计算得到的熔池熔炼过程各项评价指标与基准工况对比分析如表9所列。

表9 优化工况与基准工况分析结果的对比

Table 9 Comparison of analysis results between optimal combination and original combination

由表9可知,气含率、熔池区域流体平均运动速度及平均湍动能三评价指标均有不同程度的优化,分别增大了12.5%、9.22%和9.89%。熔池气含率的增大意味着熔池中富氧空气相浓度及气液交互面积的增大,有利于冶金反应的进行;熔池区域流体平均运动速度及平均湍动能的增大意味着气相对于熔池的搅拌效果更好,更有利于熔池对于冶金物料的卷吸和底吹炼铅熔池熔炼过程的进行。

5 结论

1) 通过对比数值计算和水模型实验结果可以看出,数值计算结果和实验结果基本吻合,并且验证了VOF多相流模型和Realizable k-ε湍流模型描述还原炉内气液两相流动过程的可靠性。

2) 在单因素优化过程中,考虑喷枪倾角、喷枪直径、喷枪间距和熔池深度对还原炉运行过程的影响。认为最佳的喷枪倾角为10°~17°,喷枪直径为40~60 mm,喷枪间距为900~1000 mm,熔池深度为800~1000 mm。

3) 通过正交试验和矩阵分析可知,喷枪直径对还原炉的影响最明显,喷枪倾角和熔池深度次之,喷枪间距最小。4个因素的最优组合为C3B1A1D2,即选用喷枪直径为60 mm,喷枪角度为10°,熔池深度为800 mm,间距采用950 mm所得工况较好。

4) 优化后工况相对于基准工况各评价指标均有不同程度的优化,其中气含率增大了12.5%,熔池区域流体平均运动速度增大了9.22%,平均湍动能增大了9.89%。

REFERENCES

[1] 蒋继穆. 我国铅锌冶炼现状与持续发展[J]. 中国有色金属学报, 2004, 14(1): 52-62.

JIANG Ji-mu. Status and sustainable development of lead and zinc smelting industry in China[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(1): 52-62.

[2] 汪金良, 吴艳新, 张文海. 铅冶炼技术的发展现状及漩涡闪速炼铅工艺[J]. 有色金属科学与工程, 2011(2): 14-18.

WANG Jin-liang, WU Yan-xin, ZHANG Wen-hai. Development status of lead smelting technology and the lead vortex flash smelting process[J]. Nonferrous Metals Science and Engineering, 2011(2): 14-18.

[3] 李 栋. 高铅渣直接还原炉的研发设计[J]. 中国有色冶金, 2012, 2(1): 35-37.

LI Dong. Research and design of direct reduction furnace of lead-rich slag[J]. China Nonferrous Metallurgy, 2012, 2(1): 35-37.

[4] DAVIS M, DRY R J, SCHWARZ M P. Flow simulation of the hismelt process[C]// The Third International Conference on CFD in the Minerals and Process Industries. Melbourne: CSIRO, 2003: 305-312.

[5] DAVIS M, PERICLEOUS K, CROSS M, SCHWARZ P. Mathematical modeling tools for the optimization of direct smelting processes[J]. Applied Mathematical Modeling, 1998, 22(1): 921-940.

[6] NAZMUL H, NASER J, BROOKS G, REUTER M A, MATUSEWICZ R W. A Computational fluid dynamic modeling study of slag fuming in top submerged lance smelting furnace[C]// Proceedings of the World Congress on Engineering. London: IAENG, 2010: 39-44.

[7] VLADIMIR P, JOHN T, OLEG O. Analysis of performance of an iron-bath reactor using computational fluid dynamics[J]. Applied Mathematical Modeling, 2002, 26:203-221.

[8] 詹树华, 赖朝斌, 萧泽强. 侧吹金属熔池内的搅动现象[J]. 中南工业大学学报: 自然科学版, 2003, 34(2): 148-151.

ZHANG Shu-hua, LAI Chao-bin, HSIAO Tse-qing. CFD analysis of gas stirring behavior in side-blown metallic bath[J]. Journal of Central South University of Technology: Natural Science, 2003, 34(2): 148-151.

[9] 张振扬, 陈 卓, 闫红杰, 刘方侃, 刘 柳, 崔志祥, 申殿邦. 富氧底吹熔炼炉内气液两相流动数值模拟[J]. 中国有色金属学报, 2012, 22(6): 1826-1834.

ZHANG Zhen-yang, CHEN Chuo, YAN Hong-jie, LIU Fang-kan, LIU Liu, CUI Zhi-xiang, SHEN Dian-bang. Numerical simulation of gas-liquid multi-phase flows in oxygen enriches bottom-blow furnace[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(6): 1826-1834.

[10] 闫红杰, 刘方侃, 张振杨, 高 强, 刘 柳, 崔志祥, 申殿邦. 喷枪布置方式对熔池熔炼过程的影响[J]. 中国有色金属学报, 2012, 22(8): 2393-2400.

YAN Hong-jie, LIU Fang-kan, ZHAN zhen-yang, GAO Qiang, LIU Liu, CUI Zhi-xiang, SHEN Dian-bang. Influence of lance arrangement on bottom-blowing bath smelting process[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2393-2400.

[11] NAN Wang, SHAN Yu, LEI Shao. Numerical simulation of fluid flow and temperature field of iron bath reactor[C]// TMS Annual Meeting. San Francisco: Metals & Materials Society, 2009: 653-658.

[12] JAFARI A, TYNJALA T, MOUSAYI S M, SARKOMAA P. CFD simulation and evaluation of controllable parameters effect on thermo magnetic convection in ferro fluids using Taguchi technique[J]. Computers & Fluids, 2008, 37(10): 1344-1353.

[13] COMAKLI K, SIMSEK F, COMAKLI O, SAHIN B. Determination of optimum working conditions R22 and R404A refrigerant mixtures in heat-pumps using Taguchi method[J]. Applied Energy, 2009, 86(11): 2451-2458.

[14] 张振扬, 闫红杰, 刘方侃, 王计敏. 富氧底吹熔炼炉内喷枪结构参数的优化分析[J]. 中国有色金属学报, 2013, 23(5): 1471-1478.

ZHANG Zhen-yang, YAN Hong-jie, LIU Fang-kan, WANG Ji-min. Optimization analysis of lance structure parameters in oxygen enriched bottom-blow furnace[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1471-1478.

[15] 魏效玲, 薛冰军, 赵 强. 基于正交实验设计的多指标优化方法研究[J]. 河北工程大学学报: 自然科学版, 2010, 27(9): 95-99.

WEI Xiao-ling, XUE Bing-jun, ZHAO Qiang. Optimization design of the stability for the plunger assembly of oil pumps based on multi-target orthogonal test design[J]. Journal of Hebei University of Engineering: Natural Science Edition, 2010, 27(9): 95-99.

[16] 周玉珠. 正交实验设计的矩阵分析方法[J]. 数学的实践与认识, 2009, 39(1): 202-206.

ZHOU Yu-zhu. A matrix analysis of orthogonal design[J]. Mathematics in Practice and Theory, 2009, 39(1): 202-206.

[17] 蔡志鹏, 梁 云, 钱占民, 马恩祥, 魏伟胜, 何玉林, 王林生. 底吹氧气连续炼铅模型实验研究(一)底吹枪距与隔墙的合理布置[J]. 过程工程学报, 1985(4): 113-121.

TSAI Chih-peng, LIANG Yun, MA En-xiang, QIAN Zhan-min, WEI Wei-sheng, HE Yu-lin, WANG Lin-sheng. A model study on the continuous lead making process with bottom oxygen injection[J]. The Chinese Journal of Process Engineering, 1985(4): 113-121.

(编辑 李艳红)

基金项目:国家基金委创新群体项目(61321003)

收稿日期:2014-01-13;修订日期:2014-05-14

通信作者:闫红杰,教授,博士;电话:13873102530;E-mail: s-rfy@csu.edu.cn