ZK60镁合金的CO2激光焊接工艺研究

谢丽初1,陈振华2,俞照辉2

(1. 邵阳学院 机械与能源工程系,湖南 邵阳,422000;

2. 湖南大学 材料科学与工程学院,湖南 长沙,410082)

摘要:采用CO2激光焊接ZK60高强镁合金薄板,并使用金相显微镜、万能拉伸试验机、扫描电子显微镜等分析测试手段,研究CO2激光焊接接头各区域的显微组织、接头的力学性能、断口形貌特征等,分析主要焊接参数(包括激光功率、焊接速度)对焊接质量的影响,探讨高强镁合金的激光焊接工艺特点。研究结果表明:在本实验条件下,采用CO2激光焊接工艺能够实现镁合金ZK60的连接;通过适当地选择工艺参数可以获得比较理想的焊缝,接头抗拉强度可达母材强度的80.4%。

关键词:镁合金;激光焊接;激光功率;焊接速度;微观组织

中图分类号:TG456.7 文献标志码:A 文章编号:1672-7207(2011)05-1332-06

CO2 laser welding process on ZK60 magnesium alloy

XIE Li-chu1, CHEN Zhen-hua2, YU Zhao-hui2

(1. Department of Mechanical and Energy Engineering, Shaoyang College, Shaoyang 422000, China;

2. School of Materials Science and Engineering, Hunan University, Changsha 410082, China)

Abstract: The CO2 laser beam was used to weld ZK60 magnesium alloy plates. The microstructure, mechanical properties and fracture surface were investigated by optical microscope (OM) and scanning electron microscope (SEM). And the effect of processing parameters including laser power and welding speed on the welding quality was researched. The results show that the ZK60 magnesium alloy can be joined successfully by CO2 laser welding process under the condition of this experiment. Laser power and welding speed have the important influence on the weld seam, and the joint ultimate tensile strength is up to 80.4% of that of the base metal.

Key words: magnesium alloys; laser welding; laser power; welding speed; microstructure

随着环境和能源问题越来越突出,世界各国都提出“绿色制造”概念,即考虑环境影响和资源消耗的现代制造模式[1-2]。镁合金具有较高的比强度和比刚度、回收性能好、无污染和资源丰富等特点,已成为材料研究和应用的一大热门,被广泛地应用于航空航天、汽车、电讯等领域[3-4]。与常用的AZ(Mg-Al-Zn)和AM(Mg-Al-Mn)系镁合金相比,ZK(Mg-Zn-Zr)系镁合金具有更高的强度、优异的抗应力腐蚀开裂性能及可热处理强化等优点,广泛地应用于制造质量轻、强度高的航空零部件,如飞机的翼肋、直升飞机的齿轮箱等[5]。其中最典型的ZK60镁合金不但在热加工态下具有较高的塑性,而且在室温下的力学性能也很高,挤压的ZK60镁合金经过实效后,室温强度是常规商用变形镁合金中最高的。因此,ZK60镁合金可以成为发展高强度镁合金很有潜力的一种基础合金[6]。但是,该系合金中的主要强化元素是Zn,随着Zn含量的增加,结晶温度区间变宽,热裂倾向增大,焊接性能变差[7]。由于传统的电弧焊方法[8-9]具有较高的热输入,焊接接头性能较差,同时,导致较大的焊接变形和较高的残余应力,难以对ZK60镁合金实现稳定连接。激光焊接作为一种先进的连接技术,具有速度快、线能量输入低、焊后变形小、接头强度高等优点[10-15],成为焊接ZK60镁合金的优选方法。目前,镁合金激光焊接技术的研究还处于起步阶段,对镁合金的激光焊接研究主要集中在镁合金的连续CO2激光焊接和脉冲YAG激光焊接领域,焊接的材料也多集中在AZ与AM系列,对ZK系列镁合金焊接的研究较少。在此,本文作者采用连续CO2激光焊接设备对高强度ZK60镁合金薄板进行焊接,并对焊接工艺参数(激光功率、焊接速度)对ZK60镁合金激光焊接接头的成形性能、显微组织及力学性能进行研究。

1 试验方法

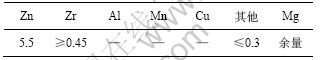

试验采用经挤压、轧制加工而成的ZK60镁合金薄板,厚度为2 mm,其抗拉强度为355 MPa,伸长率为9.6%。其化学成分见表1。采用剪板机将板材剪成长×宽为120 mm×50 mm的长方形试样,然后,用刨床刨平端面,再用钢丝刷去除其表面的氧化层。焊前采用丙酮清洗以去除表面的油脂,干燥后分别用砂布和钢刷去除氧化膜。用99.99%的高纯氩气作为焊接保护气体。

表1 ZK60镁合金的化学成分(质量分数)

Table 1 Chemical composition of ZK60 magnesium alloy %

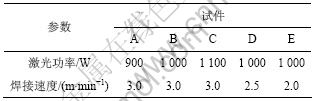

焊接设备采用GS-TFL-5KW型高功率横流CO2激光器,激光束连续输出。焊接时采用对接方式,不加填充金属,双面氩气保护,单面焊双面成形。为防止焊接变形,焊件两端采用夹具固定。在试验过程中主要研究激光功率和焊接速度变化对ZK60镁合金焊接质量的影响,具体工艺参数如表2所示。焊接试验后,采用线切割对焊件进行切割并打磨,去除表面的凹坑及背面的余高,随后利用WDW-E200的微机控制电子万能试验机对焊接接头进行拉伸,取各参数条件下3个试样的测试平均值作为该状态下的强度,再在JSM-5610扫描电镜上观察其断口形貌,在Leitz MM-6金相显微镜上观察微观组织。

表2 ZK60镁合金激光焊接试验的工艺参数

Table 2 Process parameters of ZK60 magnesium alloy in laser welding

2 试验结果及分析

2.1 焊缝成型特点

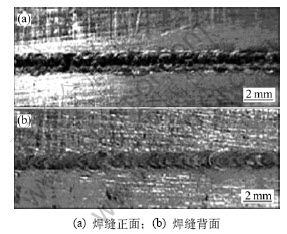

ZK60镁合金激光焊接典型的焊缝表面形貌如图1所示。从图1可见,在合适的工艺条件下,ZK60镁合金试样完全被焊透,焊缝正面的宽度约为2.0 mm,而背面的宽度为1.5 mm左右。由于激光高能量密度及ZK60镁合金相对较低的熔点(341 ℃),使焊缝的正面出现了凹陷的挥发坑。但焊缝的背面成形美观,鱼鳞纹均连续均匀,无明显的气孔、裂纹及未熔合等表面缺陷存在。

图1 ZK60镁合金激光焊接的典型焊缝形貌

Fig.1 Typical weld appearance of laser welded ZK60 magnesium alloys

2.2 工艺参数对焊接质量的影响

2.2.1 焊缝宏观成形

激光功率是影响焊接接头质量的重要因素。图2所示为不同激光功率条件下的ZK60镁合金焊接接头宏观形貌。从图2可以看出:焊缝熔深和熔宽随激光功率的增加而增大。图2(a)中试件A没有完全熔透,

图2 激光功率对焊缝成形的影响

Fig.2 Effects of laser power on weld shaping

说明激光功率太低,无法获得使焊接界面处金属完全熔化所需的热量,难以形成稳定的焊缝,并有一定的错边。图2(c)中试件C焊缝熔宽最大。这是因为激光功率增大,热输入增加,使得熔化的金属量增加,熔宽也就相应增大;另外,在焊缝的上表面出现了一定凹陷。究其原因,一方面是镁合金表面张力小,在高功率激光的冲击过程中,易造成气化物和熔化物的抛出;另一方面是合金成分对下塌量的影响也较大,合金中的低熔点元素Mg和Zn在激光高能束的作用下很快达到沸点而蒸发,形成金属蒸汽,金属蒸汽快速蒸发对熔池产生很大的反作用力,使得熔池产生爆炸性飞溅,也会导致焊缝下塌;同时,产生的飞溅易造成反射聚焦镜污染,再加上过高的激光功率也容易使透镜过热变形,焦点随之改变,从而造成焊接过程的不稳定。

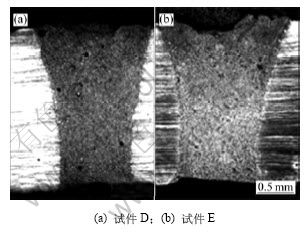

在激光功率一定的条件下,焊接速度是影响焊缝熔池形状及焊接质量的重要因素之一。焊接速度不同,则熔池中心及边缘温度梯度、熔池形状不同。图3所示为焊接速度对焊缝成形的影响。从图3可以看出:试件E的焊缝熔宽明显大于试件D的焊缝熔宽,且它们都大于图2中试件B的焊缝熔宽。说明在一定的激光功率下,随着焊接速度的减小,焊接热输入增加,熔池体积增大,焊缝的熔宽明显增加。这是因为随着焊接速度的变小,熔池流动方式和尺寸将会改变,低速下熔池大而宽,且容易产生下塌(如图3(b)所示),此时,熔化金属的含量较大,金属熔池的重力太大,表面张力难以维持处于焊缝中的熔池,而从焊缝中间滴落或下沉,在表面形成凹坑;同时,焊接速度减小,会使单位长度的热输入增加,导致熔化金属增多,接头尺寸增大;同时,小孔区的温度上升,小孔内的金属蒸汽压力增加导致小孔尺寸增大,对激光的吸收也增加,因此,熔宽也就相应增大。高速焊接时,匙孔尾部原朝向焊缝中心强烈流动的液态金属由于来不及重新分布,便在焊缝两侧凝固,形成咬边缺陷[16],如图2(b)所示。可见:焊接速度对焊缝熔宽有显著的 影响。

图3 焊接速度对焊缝成形的影响

Fig.3 Effects of welding speed on weld shaping

2.2.2 接头微观组织

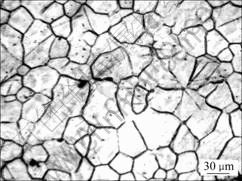

图4所示为ZK60镁合金母材的微观组织。由图4看出:母材的晶粒呈典型六角晶,晶界均为大角度晶界,无明显的变形孪晶,为典型的经轧制成形后进行完全的退火再结晶组织。

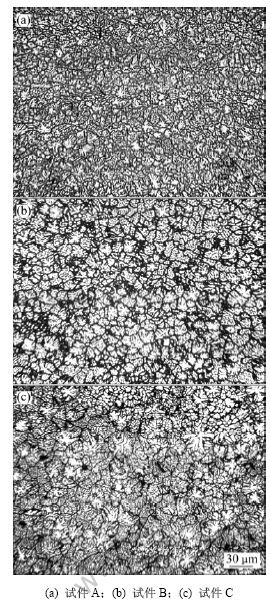

为了更好地对比焊接工艺参数对ZK60镁合金焊接接头显微组织的影响,金相照片均取自于焊缝上表面以下1 mm的焊缝中心区域。图5所示为激光功率对焊缝中心观组织的影响。从图5可以看出:当焊接

图4 ZK60镁合金母材的微观组织

Fig.4 Microstructure of base metal of ZK60 magnesium alloys

图5 激光功率对焊接接头微观组织的影响

Fig.5 Effects of laser power on microstructure of weld joint

速度一定时,随着激光功率的增大,焊缝中组织晶粒逐渐长大;当激光功率较小时,加热到高温的区域减小,在高温的停留时间短,熔池的冷却速度很大,使晶粒细化,形成细小的等轴晶(如图5(a)所示);当激光功率较大时,因热输入量增加,在高温的停留时间增长,熔池的冷却速度减小,随着凝固过程的进行,溶质在界面附近富集,导致成分过冷的出现,同时,温度梯度也随着凝固过程的进行而变小,形成了比较大的等轴晶(如图5(c)所示);当激光功率介于以上两者之间时,冷却速度和温度梯度的变化相对比较平稳并形成均匀的等轴晶,其晶粒粒径介于试件A和试件C的之间(如图5(b)所示)。

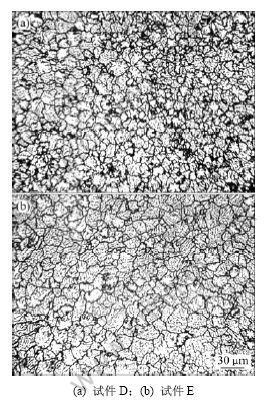

图6所示为焊接速度对接头微观组织的影响。从图6可见:在激光功率不变的情况下,增大焊接速度,焊缝区晶粒尺寸减小。这是因为提高焊接速度将会使熔池中心的温度梯度下降,成分过冷增大,晶粒成长的平均线速度(即结晶速度)也增大,结晶加快;又因激光能量高,镁合金导热系数高,致使焊接接头处的温度梯度很大,同时,晶粒细化元素限制了晶粒长大,因此,快速焊接时,在焊缝中心往往会出现细小均匀的等轴晶(如图5(b)所示);而低速焊接时,单位时间内输入熔池的能量较多即热输入增加,冷却速度减慢,焊缝中出现的等轴晶较大(如图6(b)所示);当焊接速

图6 焊接速度对焊接接头微观组织的影响

Fig.6 Effects of welding speed on microstructure of weld joint

度居中时,在焊接接头中出现了较细的等轴晶(如图6(a)所示)。由于激光焊能量密度高,焊接速度大,因此,焊缝中心的晶粒较细。

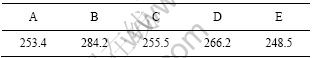

2.3 拉伸试验结果

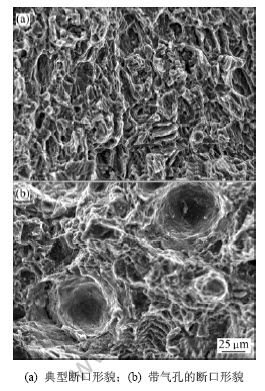

对不同工艺参数下形成的焊接接头进行了抗拉强度的测量,试验结果如表3所示。在拉伸试验中发现:在拉应力作用下,试样都是在焊缝处被拉断。从表3可见:在激光功率为1 kW,保护气体氩气流量为15 L/min,焊接速度为3 m/min的条件下,焊接接头的抗拉强度最高,可达284.2 MPa,为母材强度的80.4%。图7所示为焊接接头拉伸断口的SEM形貌。断裂发生在焊缝区,显示为混合断口形式,焊缝处没有明显的颈缩。从图7(a)可以看到:激光焊接件焊缝表面呈现脆性断裂的特征,断裂时产生解理面;焊缝中心位置呈现断裂特征,分布有大量韧窝,表现出韧性断裂特征,也有部分脆性断裂,但以韧性断裂为主。由图7(b)可知:断口表面有一些孔洞存在,它将成为接头

表3 ZK60镁合金激光焊接接头的抗拉强度

Table 3 Joint ultimate tensile strength of ZK60 magnesium alloy in laser welding MPa

图7 断口形貌的扫描电镜照片

Fig.7 SEM images of fracture surface

发生断裂的裂纹源。因为氢在溶解过程中溶解度急剧减小,焊缝冷却后有一部分氢来不及逸出而形成气孔,所以,焊前必须清除接头端面处的油污和氧化膜并加强对熔池的保护,采用干燥的氩气加强对激光熔池的保护,并控制好氩气的流量。实验证明:焊前对镁合金板材进行彻底清洗和加强保护气氛能有效地减少焊缝气孔。

3 结论

(1) 利用CO2激光焊接系统焊接的ZK60镁合金接头变形小,正、反面宽度均小于2 mm。焊缝截面呈深酒杯状,为典型的深熔焊接头。

(2) 激光功率和焊接速度是影响焊缝成形和接头微观组织的2个主要工艺参数。激光功率增加,焊接速度减小导致热输入量大,焊缝熔深和熔宽增大;焊缝中的晶粒尺寸随着激光功率的增大而增大,随焊接速度的变小而增大。合适的焊接工艺参数有利于焊缝获得细小的等轴晶组织。

(3) 激光功率与焊接速度对镁合金板材焊接接头的力学性能有很大的影响。当激光功率为1 kW,保护气体氩气流量为15 L/min,焊接速度为3 m/min时,焊接接头的抗拉强度可达到母材强度的80.4%,断口表面为混合断裂。

参考文献:

[1] Friedrich H, Schumann S. Research for a “New Age of Magnesium” in the automotive industry[J]. Journal of Materials Processing Technology, 2001, 117(3): 276-281.

[2] Clow B B. Magnesium industry overview[J]. Advanced Mater & Proc, 1996(10): 33-36.

[3] 曾小勤, 王渠东, 吕宜振, 等. 镁合金应用新进展[J]. 铸造, 1998(11): 39-43.

ZENG Xiao-qing, WANG Qu-dong, L? Yi-zhen, et al. The latest progress of magnesium alloy application[J]. Casting, 1998(11): 39-43.

[4] 陈力禾, 赵慧杰. 镁合金压铸及其在汽车工业中的应用[J]. 铸造, 1999(10): 45-57.

CHEN Li-he, ZHAO Hui-jie. Magnesium die casting and its application in automobile industry[J]. Casting, 1999(10): 45-57.

[5] Avedesian M M, Baker H. Magnesium and magnesium alloys (ASM specialty handbook)[M]. Ohio: ASM Metals Park, 1999: 30.

[6] 陈振华, 夏伟军, 严红革, 等. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 28.

CHEN Zhen-hua, XIA Wei-jun, YAN Hong-ge, et al. Wrought magnesium alloy[M]. Beijing: Chemical Industry Press, 2005: 28.

[7] Kearns W H. Welding handbook, Vol 4[M]. 7th ed. Florida: American Welding Society, 1982: 396.

[8] 苗玉刚, 刘黎明, 王继锋, 等. 镁合金薄板TIG焊自适应弧长控制[J]. 焊接学报, 2003, 24(6): 33-36.

MIAO Yu-gang, LIU Li-ming, WANG Ji-feng, et al. Adaptive arc length control for magnesium alloy sheets TIG welding[J]. Transaction of the China Welding Institution, 2003, 24(6): 33-36.

[9] Asahina T, Tokisue H, Katoh K. Solidification crack sensitivity of TIG welded AZ31 magnesium alloy[J]. Journal of the Japan Institute of Light Metal, 1999, 49(12): 595-599.

[10] Weisheit A, Galun R, Mordike B L. CO2 laser beam welding of magnesium-based alloys[J]. Welding Journal, 1998, 77(4): 148-154.

[11] Hirage H, Inoue T, KZKado S, et al. Effect of shielding gas and laser wave length in laser welding of magnesium alloy sheet[J]. Quarterly Journal of the Japan Welding Society, 2001, 19(4): 591-599.

[12] Barrallier L, Fabre A, Masse J E, et al. Residual stress measurements using neutron diffraction in magnesium alloy laser welded joints[J]. Material Science Forum, 2002, 404/407: 399-404.

[13] 宋刚, 刘黎明, 王继锋, 等. 变形镁合金AZ31B的激光焊接工艺研究[J]. 应用激光, 2003, 23(6): 327-330.

SONG Gang, LIU Li-ming, WANG Ji-feng, et al. Study of YAG laser welding process on wrought magnesium[J]. Applied Laser, 2003, 23(6): 327-330.

[14] 王红英, 李志军. 焊接工艺参数对镁合金CO2激光焊焊缝表面成形的影响[J]. 焊接学报, 2006, 27(2): 64-68.

WANG Hong-ying, LI Zhi-jun. Effect of welding parameters on CO2 laser welding of magnesium alloys[J]. Transaction of the China Welding Institution, 2006, 27(2): 64-68.

[15] 全亚杰, 陈振华, 黎梅, 等. AM60变形镁合金薄板激光焊接接头的组织与性能[J]. 中国有色金属学报, 2007, 17(4): 525-529.

QUAN Ya-jie, CHEN Zhen-hua, LI Mei, et al. Microstructure and properties of joint of wrought magnesium alloy AM60 plates welded by laser beam welding[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 525-529.

[16] 陈彦宾. 现代激光焊接技术[M]. 北京: 科学出版社, 2005: 70-78.

CHEN Yan-bin. Modern laser welding technology[M]. Beijing: Science Press, 2005: 70-78.

(编辑 赵俊)

收稿日期:2010-07-10;修回日期:2010-11-24

基金项目:湖南省自然科学基金资助项目(07JJ6083)

通信作者:谢丽初(1966-),女,湖南冷水江人,讲师,从事金属材料焊接研究;电话:13973963790;E-mail: Xielichu@163.com