Al-6Mg-0.4Mn-0.2Sc铝合金的高温变形行为及热加工图

文智,易丹青,王斌,张艳可

(中南大学 材料科学与工程学院,湖南 长沙,410083)

摘要:采用Gleeble-1500热/力模拟试验机进行压缩实验,研究Al-6Mg-0.4Mn-0.2Sc铝合金在变形温度为300~500 ℃、应变速率为0.001~10 s-1范围内的变形行为。计算应力指数和变形激活能,并采用Zener-Hollomon参数法构建合金高温塑性变形的本构关系。根据材料动态模型,计算并分析合金的加工图。研究结果表明:热变形过程中的稳态流变应力可用双曲正弦本构关系式来描述,平均激活能为158.92 kJ/mol,大于其自扩散激活能。根据加工图确定了热变形的流变失稳区,并且获得了热变形过程的最佳工艺参数,其热加工温度为430~480 ℃,应变速率为5~10 s-1,温加工温度为320~400 ℃、应变速率为0.01~0.001 s-1。

关键词:流变应力;加工图;热变形;铝合金

中图分类号:TG146.21 文献标志码:A 文章编号:1672-7207(2013)03-0914-07

Hot deformation and processing maps of Al-6Mg-0.4Mn-0.2Sc aluminum alloy

WEN Zhi, YI Danqing, WANG Bin, ZHANG Yanke

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The hot deformation behavior of Al-6Mg-0.4Mn-0.2Sc aluminum alloy was investigated by hot compressive tests on Gleeble-1500 thermal simulation test machine at 300-500 ℃ and strain rates of 0.001-10 s-1. The stress exponent and the deformation activation energy at elevated temperatures were calculated. The constitutive equation of the plastic deformation of Al-6Mg-0.4Mn-0.2Sc alloy at elevated temperatures was obtained by introducing Zener-Hollomon parameter. The processing maps were calculated and analyzed according to the dynamic materials mode. The results show that the flow behaviour is described by the hyperbolic sine constitutive equation, and an activation energy of 158.92 kJ/mol is greater than the activation energy for self-diffusion in Al. The process of hot deformation in the temperature range and different strain rate can be attained by the maps. The hot deformation temperature is 430-480 ℃, strain rate is around 5-10 s-1, warm deformation temperature is 320-400 ℃ and strain rate is 0.01-0.001 s-1. The instability zones of flow behaviour can also be recognized by the maps.

Key words: flow stress; processing maps; hot deformation; aluminum alloy

Al-Mg系合金具有良好的成形性、耐蚀性和可焊接性, 在汽车、航天、航空等领域有着广阔的应用前景。Al-Mg-Sc合金是在Al-Mg合金基础上添加微量钪而研发出来的新一代中强可焊耐蚀铝合金[1-2]。由于钪的添加,部分Sc元素能与铝基体发生反应生成Al3Sc粒子,作为异质形核核心,强烈细化组织,该相还能钉扎位错,具有强烈的析出强化作用[3-4]。另外,钪元素的加入使其热加工性能有所改善[5],但Al-Mg系合金的热加工工艺仍存在一系列缺点,如变形温度区间窄、道次变形量较低、形变不均匀、容易出现局部应力集中导致热加工开裂等。针对铝镁合金的上述特点,聂波等[5]通过高温瞬时拉伸试验研究Al-Mg-Sc合金在高温下的塑性变形时发现,随试验温度升高,合金高温瞬时拉伸强度下降,而塑性增加,在350~400 ℃时,合金的变形抗力相对较低,热塑性较好;潘清林等[6]研究含锆Al-Mg-Sc合金热变形时的流变应力行为时发现,含锆Al-Mg-Sc合金在低温高应变速率时表现出动态回复特征,在低温低应变速率或者高温时表现出动态再结晶特征。但对Al-Mg-Sc合金热加工工艺的研究,尤其是针对不同温度,不同应变速率下Al-Mg-Sc合金的高温变形行为及热加工图的研究鲜见报道。热压缩试验可获得不同条件下流变应力的连续数据,不仅可用于流变行为研究,而且还可用于计算获得材料的加工图。加工图是变形温度与应变速率空间中的功率耗散图与失稳图的叠印。根据加工图可以判别材料变形过程中的流变失稳区,还可根据非失稳区内最大功率耗散系数区与显微组织来制定材料的最佳加工工艺制度(变形温度与应变速率)。本文作者通过热压缩试验,获得了Al-6Mg-0.4Mn-0.2Sc合金的流变应力,研究了流变应力模型及加工图,分析了材料的最佳热加工条件,为Al-6Mg-0.4Mn-0.2Sc铝合金热加工工艺的制定与优化提供实验数据及理论依据。

1 实验方法

实验用合金名义成分(质量分数,%)为Al-6Mg- 0.4Mn-0.2Sc,半连铸技术制备Al-6Mg-0.4Mn-0.2Sc合金铸锭,铸锭直径为90 mm。经350 ℃/8 h均匀化退火处理后,机加工成10 mm×15 mm(直径×长度)的圆柱形压缩试样,两端开9 mm×0.2 mm(直径×深度)的浅槽,加入含石墨的固体润滑剂以减少压缩时试样两端的摩擦力。热压缩模拟在GLEEBLE-1500热/力模拟试验机上进行,应变速率分别为0.001,0.01,0.1,1,10 s-1,聂波等[5]认为Al-Mg-Sc合金在350~420 ℃内塑性较好,温度过高时轧制开裂的几率变大,故本实验选择的变形温度分别为300,350,400,450,500 ℃,变形程度为70%。压缩前试样升温速度为2 ℃/s,保温5 min,变形结束后立即水淬,以保留高温下的变形组织进行后续的组织分析。变形结束后,利用试验得到的应力、应变数据采用动态材料模型中的方法计算加工图。变形后的试样经锯切、镶嵌、研磨和抛光后,用2 mL氢氟酸、3 mL盐酸和5 mL硝酸、250 mL水的混合液浸蚀其组织。使用Leica DM ILM HC金相显微镜观察侵蚀后试样的显微组织。

2 实验结果与分析

2.1 变形条件对Al-6Mg-0.4Mn-0.2Sc合金流变应力影响

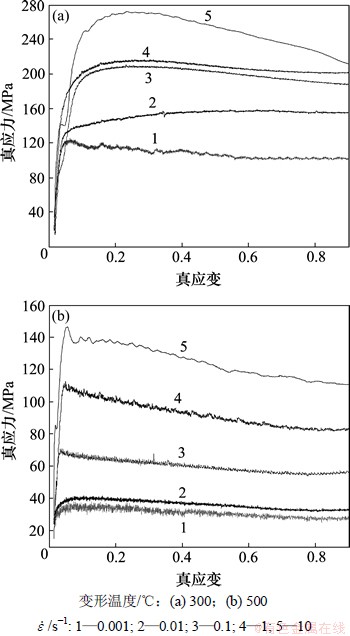

合金热变形过程中的真应力-真应变曲线如图1所示。变形温度为300 ℃,应变速率为0.01~10 s-1时,流变应力先随应变的增加迅速升高,当真应变超过一定值后,真应力并不随应变量的继续增大而发生明显的变化,即呈现稳态流变特征,而且流变曲线为平滑直线,说明变形过程中动态回复是主要的软化机制;而其他条件下(如图1(b)所示)出现了明显的峰值应力, 流变曲线呈现出锯齿形,具体表现在温度较高的真应力-应变曲线中,为典型的动态再结晶特征。在相同的变形温度下,当合金进入稳态流变,随着应变速率的增加,材料的真应力水平升高,该合金是一种正应变速率敏感材料。

图1 Al-6Mg-0.4Mn-0.2Sc合金热压缩变形的真应力-真应变曲线

Fig.1 True stress-true strain curves of Al-6Mg-0.4Mn-0.2Sc aluminium alloy during hot compression deformation

2.2 Al-6Mg-0.4Mn-0.2Sc合金高温变形过程的动态回复及动态再结晶

金属材料热变形过程中会同时发生形变硬化和形变软化2个过程。形变软化取决于形变过程中的动态回复和动态再结晶。Al属于层错能较高的金属,位错易交滑移,一般认为动态回复是这类材料热形变过程中形变软化的原因。

Al-6Mg-0.4Mn-0.2Sc合金是一种高镁含量的铝合金,Mg元素的加入降低了层错能,如向铝中加入质量分数为0.12%和0.36% Mg,可使其层错能由200 J/m2分别降低到108.65 J/m2和50 J/m2,后者与铜的层错能属于同一个数量级[7],这时位错交滑移变得困难,高温变形时较易发生动态再结晶。另外,Sc的加入能使合金基体中形成弥散共格的Al3Sc第二相粒子,这些质点可以降低位错的可动性,使位错亚结构并保持稳定,阻碍亚晶界和晶界迁移,提高发生动态回复所需的临界应变值,使材料中积蓄起足够的储能从而诱发动态再结晶[8]。含锆Al-Mg-Sc合金中的Zr能使基体中形成Al3(Sc,Zr)第二相离子,同样起到Al3Sc粒子所起到的作用,促进动态再结晶的发生[6]。

Al-6Mg-0.4Mn-0.2Sc合金在变形温度为300 ℃,应变速率为0.01~10 s-1时,表现为动态回复特征。这是因为随应变量的继续增大,材料内部空位浓度也提高,位错的攀移在过渡变形阶段的中后期也开始产生作用,参与软化过程。最后,由于位错的交滑移、攀移以及位错的脱钉等引起的软化与应变硬化达到动态平衡时,变形进入稳态流变阶段。而在其他条件下,表现为连续动态再结晶特征。这是因为温度越高,再结晶就越容易发生;而应变速率越慢,即变形时间越长,再结晶行为进行得越彻底。变形量的进一步增加使位错密度进一步提高,超过一定的形变量后变形储存能成为再结晶的驱动力,再结晶可以消除或改变原来的形变织构,发生动态再结晶软化。由于其动态软化大于加工硬化,从而使真应力-真应变曲线下降[6]。

2.3 Al-6Mg-0.4Mn-0.2Sc合金变形激活能及应力应变间本构关系的确定

通过对不同热加工数据研究,Jonas等[9]提出了一种包含变形激活能Q和温度T的双曲正弦形式的本构方程,稳态应力满足双曲正弦模型:

(1)

(1)

式中: 为应变速率;R为摩尔气体常数,8.314 J/(mol·K);T为热力学温度,K;Q为变形激活能,J/mol,又称动态软化激活能,它反映高温塑性变形时应变硬化与动态软化过程之间的平衡关系;A,α和n为与温度无关的常数,n为应力指数,反映变形速率与应力之间的关系,α可由指数关系模型(

为应变速率;R为摩尔气体常数,8.314 J/(mol·K);T为热力学温度,K;Q为变形激活能,J/mol,又称动态软化激活能,它反映高温塑性变形时应变硬化与动态软化过程之间的平衡关系;A,α和n为与温度无关的常数,n为应力指数,反映变形速率与应力之间的关系,α可由指数关系模型( )中的n1与幂指数模型(

)中的n1与幂指数模型( )中的β共同确定,

)中的β共同确定, 。

。

和

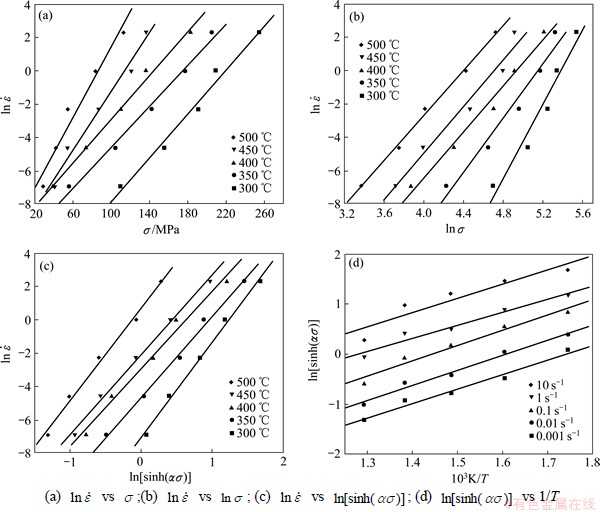

和 的线性关系如图2所示。由线性回归求得:

的线性关系如图2所示。由线性回归求得: =0.007 45 MPa-1。

=0.007 45 MPa-1。

当应变速率为常数时,假定在很小的温度范围内变形激活能Q保持不变,对式(1)两边取自然对数可得如下线性关系:

(2)

(2)

由式(2)可求出变形激活能Q为:

(3)

(3)

如图2(c)和2(d)所示, 分别与

分别与 和

和 成线性关系,通过回归分析,其线性相关系数均在0.97以上,说明双曲正弦模型能准确描述流变应力与应变速率的关系。由图2(c)和图2(d)中的直线的斜率可计算出合金的平均变形激活能Q为158.92 kJ/mol,与文献报道Al-Mg-Sc合金变形激活能152.33 kJ/mol[6]与157.9 kJ/mol[10]相差不大,大于铝合金自扩散激活能(142.8 kJ/mol[11])。

成线性关系,通过回归分析,其线性相关系数均在0.97以上,说明双曲正弦模型能准确描述流变应力与应变速率的关系。由图2(c)和图2(d)中的直线的斜率可计算出合金的平均变形激活能Q为158.92 kJ/mol,与文献报道Al-Mg-Sc合金变形激活能152.33 kJ/mol[6]与157.9 kJ/mol[10]相差不大,大于铝合金自扩散激活能(142.8 kJ/mol[11])。

在金属和合金的热加工变形时,应变速率受到热激活的控制,变形温度和应变速率对变形的影响由Zener和Hollomon通过引入参数Z来表示[12]:

(4)

(4)

式中:Z为Zener-Hollomon参数,其物理意义为温度补偿的应变速率因子。将Z参数代入式(1)可得如下关系:

(5)

(5)

由图3(c)可知:其截距为 。将变形激活能Q的平均值代入

。将变形激活能Q的平均值代入 中,即得到A=2.5015× 1011 s-1,而其斜率为1/n,则可求得材料常数n=7.37。

中,即得到A=2.5015× 1011 s-1,而其斜率为1/n,则可求得材料常数n=7.37。

根据双曲正弦函数的定义,可以将流变应力表达为Zener-Hollomon参数的函数:

(6)

(6)

将Q的平均值代入式(4)可得热加工参数Z的近似表达式:

(7)

(7)

高温稳态流变应力对应变不敏感,因此,忽略应变的影响,将 和n的平均值代入式(6)可得用Z参数表示的峰值应力

和n的平均值代入式(6)可得用Z参数表示的峰值应力 、应变速率

、应变速率 和温度T的本构关系式:

和温度T的本构关系式:

(8)

(8)

2.4 加工图

在一定的温度和应变下,热加工工件所受的应力σ与应变速率 存在如下动态关系[13]:

存在如下动态关系[13]:

(9)

(9)

式中:K 表示应变速率为1时的流变应力;m为应变速率敏感因子,可表达为[14]:

(10)

(10)

对于Al-Mg-Sc铝合金,当温度不变时, 与

与 的一元线性回归系数大于97%,,说明

的一元线性回归系数大于97%,,说明 与

与 之间存在线性关系,m值可以通过上式计算得出。

之间存在线性关系,m值可以通过上式计算得出。

图2 合金高温塑性变形峰值应力与应变速率及温度的关系

Fig.2 Relationship between strain rate  and temperature T as a function of peak stress σ of high temperature plastic deformation

and temperature T as a function of peak stress σ of high temperature plastic deformation

加工图是加工变量空间(应变速率,温度)中功率耗散图与失稳图的叠印图。功率耗散图代表材料显微组织改变时功率的耗散,其变化率可用反映材料功率耗散特征的无量纲参数η来表示,其定义式如下:

(11)

(11)

失稳图是根据不可逆热力学极值原理,用无量纲参数 表示大塑性流变时的连续失稳判据[15]:

表示大塑性流变时的连续失稳判据[15]:

(12)

(12)

当 <0时,为非稳态流变。含有温度与应变速率的变量

<0时,为非稳态流变。含有温度与应变速率的变量 构成了失稳图。将功率耗散图与失稳图重叠就可获得加工图。应用热加工图来分析合金的加工性能不仅可以优化加工工艺而且可以避免流变不稳定区域。

构成了失稳图。将功率耗散图与失稳图重叠就可获得加工图。应用热加工图来分析合金的加工性能不仅可以优化加工工艺而且可以避免流变不稳定区域。

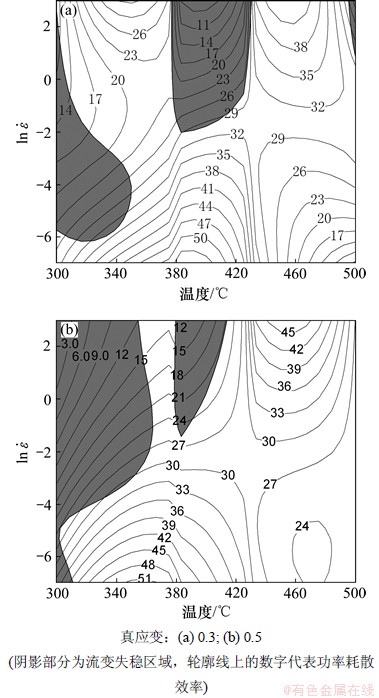

图3所示为Al-6Mg-0.4Mn-0.2Sc合金在真应变分别为0.3和0.5时的加工图,其他应变的加工图与此类似。由图3可以看出,图中失稳区较少,说明该合金可加工性较好。

真应变为0.3与0.5的加工图中出现2个类似峰区。峰区1的温度范围为430~480 ℃,应变速率为5~10 s-1,峰值效率大于40%,峰值对应的温度和应变速率分别为450 ℃与10 s-1;峰区2的温度范围为320~400 ℃,应变速率为0.01~0.001 s-1,峰值效率大于40%,峰值对应的温度和应变速率分别为350 ℃与0.001 s-1。

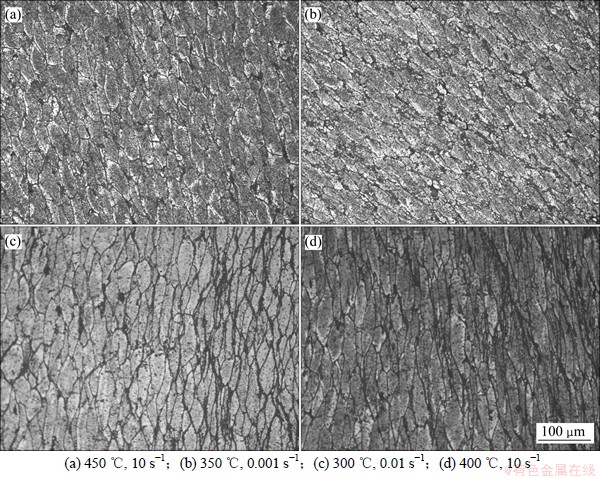

功率耗散图是由功率耗散系数的等值线组成,加工图中局部区域存在功率耗散效率最大值,它代表特殊的显微组织或流变失稳机制,常要结合变形后试样的金相组织来进一步确认。不同热变形条件下合金的金相组织见图4。图4(a)和图4(b)为峰值点或接近峰值点所对应的金相组织。由图4可以看出,峰区内的金相组织具有以下特点:峰区1的晶粒成等轴形,尺寸细小均匀,且有因压缩变长变大的趋势,峰区2的晶粒沿垂直压缩方向明显拉长,晶界比较明晰,沿晶界方向有析出的再结晶晶粒。

真应变为0.3的加工图呈现出个2 个非稳定区域:区域1的温度为380~430 ℃,应变速率为1~10 s-1;区域2的温度为300~350 ℃,应变速率为0.1~0.01 s-1。真应变为0.5的加工图呈现出个2 个非稳定区域:区域1的温度为380~400 ℃,应变速率为1~10 s-1;区域2的温度为300~350 ℃,应变速率为0.01~10 s-1。

图3 Al-6Mg-0.4Mn-0.2Sc合金在应变约为0.3与0.5时的热加工图

Fig.3 Processing maps of Al-6Mg-0.4Mn-0.2Sc alloys obtained at strain of 0.3 and 0.5

由图3可以看到,在这些区域,功率耗散效率急剧减小,这有可能是变形应力集中造成的,从而出现加工失稳,变形不均匀等现象(如图4(c)和(d)所示)。因此,加工中应尽量避免这些区域。

在中温区,变形温度为430~480 ℃、应变速率为5~10 s-1时,其功率耗散系数最大值达到0.48,其组织细小(图4(a)),但有长大的趋势,在这个温区可进行热锻、热挤压等变形,是该合金的最佳热加工区域;而在较低温度区域,即变形温度为320~400 ℃、应变速率约为0.01~0.001 s-1,是该合金的温加工区域,获得的锻件组织更加细小(图4(b)),具有良好的韧性和强度。

图4 在不同热变形条件下合金的金相显微组织

Fig.4 Optical microstructures of specimens compressed under different conditions

3 结论

(1) Al-6Mg-0.4Mn-0.2Sc铝合金热变形时,在一定的变形温度和应变速率下,真应力并不随应变量的继续增大而发生明显的变化,即呈现稳态流变特征,流变曲线为平滑直线,说明变形过程中动态回复是主要的软化机制;而其他条件下出现了明显的峰值应力,流变曲线呈现出锯齿形,为典型的动态再结晶特征。在相同的变形温度下,随着应变速率的增加,材料的真应力水平升高,该合金是一种正应变速率敏感材料。

(2) Al-6Mg-0.4Mn-0.2Sc铝合金的稳态流变应力满足双曲正弦本构关系式,其材料参数为α=0.007 45 MPa-1,n=7.37,A=2.501 5×1011 s-1,其平均激活能为158.92 kJ/mol。

(3) 采用Zener-Hollomon参数法构建的Al-6Mg- 0.4Mn-0.2Sc铝合金高温塑性变形峰值应力σ、应变速率 和变形温度T之间的本构关系为:

和变形温度T之间的本构关系为:

其中,

(4) 在中温区,变形温度为430~480 ℃、应变速率约为5~10 s-1时,其功率耗散系数最大值达到0.48,可进行热锻、热挤压等变形,是该合金的最佳热加工区域。

(5) 而在较低温度区域,即变形温度为320~400 ℃、应变速率约为0.01~0.001 s-1,其功率耗散系数最大值为0.52,是该合金的温加工区域,获得的锻件具有良好的韧性和强度。

参考文献:

[1] Filatov Y A,Yelagin V I,Zakharov V V. New Al-Mg-Sc alloys[J]. Materials Science and Engineering A, 2000, 280: 97-101.

[2] 牟申周, 徐国富. 退火温度对Al-6Mg-Sc-Zr 合金组织与性能的影响[J]. 中国有色金属学报, 2007, 17(11): 1827-1832.

MOU Shenzhou, XU Guofu. Influence of annealing temperature on structure and properties of Al-6Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1827-1832.

[3] 许栩达, 姜锋, 熊翔, 等. 微量Sc、Zr对 ZLl09 组织与性能的影响[J]. 铸造, 2008, 57(4): 381-383.

XU Xuda, JIANG Feng, XIONG Xiang, et a1. Effect of trace Sc and Zr on microstructure and properties of ZL109 alloy[J]. Foundry, 2008, 57(4): 381-383.

[4] 杜刚, 杨文, 闫德胜, 等. Al-Mg-Sc-Zr 合金中初生相的析出行为[J]. 中国有色金属学报, 2010, 20(6): 1083-1087.

DU Gang, YANG Wen, YAN Desheng, et al. Precipitation behaviors of primary phases in Al-Mg-Sc-Zr alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1083-1087.

[5] 聂波, 尹志明. Al-Mg-Sc合金热塑性和热加工工艺[J]. 中国有色金属学报, 2007, 17(11): 1792-1797.

NIE Bo, YIN Zhiming. Thermo-plasticity and heat rolling processing of Al-Mg-Sc alloy[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1792-1797.

[6] 潘清林, 张小刚, 李文斌, 等. Al-Mg-Sc合金热压缩变形的流变应力行为[J]. 中南大学学报: 自然科学版, 2009, 40(4): 926-931.

PAN Qinglin, ZHANG Xiaogang, LI Wenbin, et al. Flow stress behavior of Al-Mg-Sc alloy during hot compression[J]. Journal of Central South University: Science and Technology, 2009, 40(2): 179-181.

[7] 林均品. Mg含量对Al-Mg合金动态再结晶的影响[J]. 北京科技大学学报, 1997, 19(1): 47-51.

LIN Junpin. Effect of Mg content on dynamic recrystallization of Al-Mg alloys[J]. Journal of University of Science and Technology of Beijing, 1997, 19(1): 47-51.

[8] Cavanaugh M K, Birbilis N, Buchheita R G, et al. Investigating localized corrosion susceptibility arising from Sc containing intermetallic Al3Sc in high strength Al-alloys[J]. Scripta Materialia, 2007, 56: 995-998.

[9] Jonas J J, Sellars C M, MeG W J. Strength and structure under hot-working conditions[J]. Metallurgical Reviews, 1969, 14: 1.

[10] 李文斌, 潘清林, 梁文杰, 等. 含Sc超高强Al-Zn-Cu-Mg-Sc-Zr合金的热压缩变形流变应力[J]. 中国有色金属学报, 2008, 18(5): 777-782.

LI Wenbin, PAN Qinglin, LIANG Wenjie, et al. Flow stress of super-high strength Al-Zn-Cu-Mg-Sc-Zr alloy containing Sc under hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(5): 777-782.

[11] Nagahama K, Miki I. Precipitation during recrystallization in Al-Mn and Al-Cr alloys[J]. Transactions of Japan Institute of Metals, 1974, 15(3): 185-192.

[12] 王宏伟, 易丹青, 王斌, 等. Mg-6.3Zn-0.7Zr-0.9Y-0.3Nd镁合金的高温塑性变形行为的热压缩模拟[J]. 中国有色金属学报, 2010, 20(3): 378-384.

WANG Hongwei, YI Danqing, WANG Bin, et al. Hot compressive deformation simulation of Mg-6.3Zn-0.7Zr- 0.9Y-0.3Nd magnesium alloy at elevated temperatures[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(3): 378-384.

[13] 王斌, 易丹青, 顾威, 等. Mg-5.3Zn-0.8Zr 镁合金高温变形行为的热模拟研究[J]. 中南大学学报: 自然科学版, 2009, 40(1): 123-128.

WANG Bin,YI Danqing, GU Wei, et al. Thermal simulation of hot deformation behavior for Mg-5.3Zn-0.8Zr magnesium alloy[J]. Journal of Central South University: Science and Technology, 2009, 40(1): 123-128.

[14] 李展志, 李慧中, 王海军, 等. 6069铝合金的热变形行为和加工图[J]. 粉末冶金材料科学与工程, 2011, 16(2): 155-161.

LI Zhanzhi, LI Huizhong, WANG Haijun, et al. Hot deformation behavior and processing map of 6069 aluminum alloy[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(2): 155-161.

[15] 李红英, 刘洋, 胡继东, 等. ZA27合金的热变形及加工图[J]. 中国有色金属学报, 2012, 22(2): 365-370.

LI Hongying, LIU Yang, HU Jidong, et al. Hot deformation and processing map of ZA27 alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(2): 365-370.

(编辑 赵俊)

收稿日期:2012-04-02;修回日期:2012-07-20

基金项目:国家自然科学基金资助项目(51071177);国家重点基础研究发展计划(“973”计划)项目(2012CB619506)

通信作者:易丹青(1954-),男,湖南湘乡人,教授,博士生导师,从事高强高韧铝合金及镁合金研究;电话:0731-88830263;E-mail: yioffice@csu.edu.cn