文章编号:1004-0609(2015)02-0384-08

ECAPT工艺下纯铝粉末-包套变形行为的数值模拟与实验

王晓溪1, 2,何 敏1,陆兴华1,薛克敏3,李 萍3

(1. 徐州工程学院 机电工程学院,徐州 221111;

2. 徐州工程学院 江苏省大型工程装备检测与控制重点建设实验室,徐州 221111;

3. 合肥工业大学 材料科学与工程学院,合肥 230009)

摘要:采用体积可压缩刚粘塑性热力耦合有限元法,对纯铝粉末-包套ECAPT变形行为进行数值模拟,并实验分析其在ECAPT过程中显微组织和力学性能的演变规律。结果表明:ECAPT工艺对纯铝粉末材料具有强烈的致密和细化效果;变形坯料在模具转角和螺旋通道两处所受剪切变形程度最大,挤压载荷增幅最为明显;ECAPT工艺在提高材料应变累积量的同时可显著改善其变形分布的均匀性。模拟分析与实验结果具有较好的一致性,纯铝粉末坯料经1道次ECAPT变形后实现有效固结,显微组织显著细化,力学性能大幅度提高。

关键词:纯铝粉末;大塑性变形;等径角挤扭;数值模拟

中图分类号:TG376 文献标志码:A

Numerical simulation and experiment of deformation behavior of pure aluminum powder in tubes by equal channel angular pressing and torsion

WANG Xiao-xi1, 2, HE Min1, LU Xing-hua1, XUE Ke-min3, LI Ping3

(1. School of Mechanical and Electrical Engineering, Xuzhou Institute of Technology, Xuzhou 221111, China;

2. Jiangsu Key Laboratory of Large Engineering Equipment Detection and Control,

Xuzhou Institute of Technology, Xuzhou 221111, China;

3. School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: The deformation behavior of pure aluminum powder in tubes during ECAPT was obtained by the coupled thermo-mechanical analysis based on the compressible rigid viscoplastic finite element method (FEM). Moreover, the microstructure and mechanical properties evolutions were investigated through experimental analysis. The results show that ECAPT process has a great efficiency on powder consolidation and grain refinement. The intense shear strains are imposed on the billet when passed the intersection part and twist channel, which causes the sharp increase of extrusion load. ECAPT process can lead to higher homogeneity of the effective strain distribution as well as higher values of the imposed strain for each pass. The FEM results and experimental results agree well. After 1 pass of ECAPT, full dense bulk aluminum achieves from powders with refined microstructures and improved mechanical properties.

Key words: pure aluminum powder; severe plastic deformation(SPD); equal channel angular pressing and torsion (ECAPT); numerical simulation

目前,采用大塑性变形技术(Severe plastic deformation,SPD)对粉末冶金材料进行深加工进行广泛而深入的研究[1-4]。SPD法的出现,为以粉末材料为原料、快速固结制备高致密度、组织结构均匀且力学性能优良的块体超细晶材料提供了一种有效而可行的新途径,具有十分广阔的应用前景。

等径角挤扭(Equal channel angular pressing and torsion,ECAPT)是近年来逐渐兴起的一种新型复合SPD技术[5-7]。它综合了等径角挤压(Equal channel angular pressing,ECAP)[8-10]和挤扭(Twist extrusion,TE)[11-13]两种传统SPD技术的优点,通过利用TE工艺的螺旋通道来增加材料在ECAP变形过程中的静水压力和塑性应变量,使得变形材料达到“一次挤压,两次剪切”复合变形目的,进而获得较高的应变累积效果和变形均匀程度。然而,由于ECAPT工艺研究起步较晚,且粉末材料的成形过程较为复杂,有关纯铝粉末在ECAPT变形过程中的致密行为和变形机理,至今文献中仍鲜见报道。

为此,本文作者拟以纯铝粉末颗粒为原料,采用数值模拟技术,系统研究了ECAPT变形过程中纯铝基体的变形致密行为,重点分析了挤压载荷、等效应变和相对密度等场量的变化规律,并对其组织和性能演变规律进行了实验分析。这些研究将为全面深入了解粉末材料ECAPT变形机理、优化ECAPT模具结构,进而制备出高性能的块体超细晶铝提供必要的理论支持。

1 有限元模拟

1.1 有限元分析模型

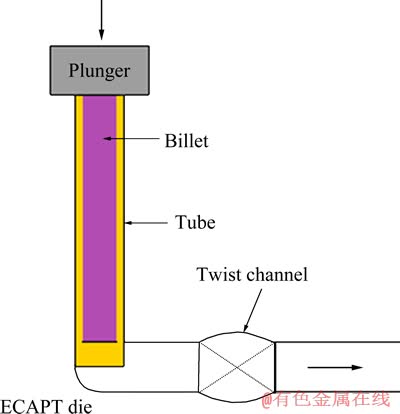

利用有限元程序DEFROMTM-3D,采用体积可压缩性刚粘塑性有限元法,对纯铝粉末-包套ECAPT变形过程进行热力耦合模拟。为增强粉末颗粒的塑性变形能力、促进粉末材料变形均匀化及提高粉末材料的致密程度,采用等温ECAPT工艺,模具和坯料温度为200 ℃,环境温度为20 ℃。选用程序自带的纯铝(Al 1100)作为基体材料,坯料初始相对密度为0.75,外形尺寸为d 7 mm×50 mm;包套材料为致密纯铝(Al 1100),外形尺寸为10 mm×10 mm×60 mm。ECAPT模具的内、外角分别为90°和37°,横截面旋转角为90°,螺旋通道长度为15 mm,过渡距离为15 mm。采用四节点四面体等参单元对变形坯料进行离散,模具和坯料间的摩擦接触采用常剪切模型,摩擦因数为0.05。在ECAPT变形过程中,不考虑冲头和凹模变形,将其均视为刚体,材料为热模具钢H13,挤压速度为1 mm/s。采用网格自适应技术以减小模拟过程中由于ECAPT剧烈变形而导致的局部网格畸变。最终建立起的有限元分析模型如图1所示。

图1 ECAPT变形有限元分析模型

Fig. 1 Finite element model of ECAPT process

1.2 ECAPT变形过程分析

图2和3所示为单道次ECAPT变形过程中,纯铝粉末-包套的变形情况以及挤压载荷-时间曲线。

根据变形材料的流动特征和挤压载荷的变化趋势,可将ECAPT变形过程分为如下5个阶段。

Ⅰ) 变形初始阶段,由于挤压材料与模具型腔之间存在微小间隙,变形坯料首先充填模具模腔,发生近似镦粗变形,逐渐与通道内壁紧密贴合。由于初始坯料内部孔隙较多,且处于被压缩状态,因此,一开始的变形类似于粉体材料压制过程,挤压载荷逐渐增大。随后,在竖直冲头的作用下,变形坯料产生屈服,被迫流入水平通道,发生ECAP变形。随着被剪切材料的增多,挤压载荷急剧上升。

Ⅱ) 在过渡通道内经短暂的刚性平移后,变形坯料头部开始进入螺旋通道。由于模具形状的约束以及螺旋通道的二次剪切作用,材料横截面内发生了剧烈的塑性变形,挤压载荷明显增大。当坯料头部完全进入螺旋通道后,挤压载荷达到一个局部最大值,约为11.7 kN。

Ⅲ) 随着变形坯料不断被挤入螺旋通道,材料连续、协调、平稳地发生旋转剪切变形,挤压载荷缓慢增加,数值大小相对稳定。

Ⅳ) 变形坯料头部完成ECAPT变形,退出螺旋通道,进入最后的方形截面通道。此时,由于材料已接近于完全致密,变形抗力逐渐增大,在螺旋通道出口处,金属流动受到了较大的阻力。同时,已完全变形的头部材料对后续未完全变形的材料起到了一个类似于反向背压的作用,挤压载荷出现再次升高现象,达到极值(13.7 kN)。

Ⅴ) 此时,变形坯料均已完全通过模具转角地带,该阶段等同于传统的TE变形。随着最终被挤出材料的不断增多,螺旋通道内发生剪切变形的材料越来越少,挤压载荷呈现逐渐下降的趋势。

图2 ECAPT变形过程示意图

Fig. 2 Schematic diagram of ECAPT process

图3 ECAPT工艺下坯料变形过程中的载荷-时间曲线

Fig. 3 Load-time curves of billet during ECAPT process

1.3 等效应变分析

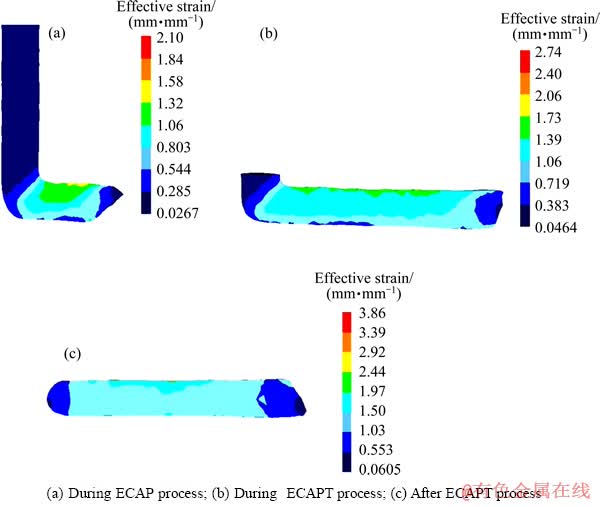

等效应变的大小和分布能够反映出材料塑性变形的累积效果,与材料内部晶粒细化、组织致密与变形均匀的程度密切相关。图4所示为ECAPT变形坯料中心纵截面的等效应变分布云图。

从图4可以看出,变形初始阶段,在模具转角的剪切作用下,头部变形复杂且不均匀。由于坯料上下表面金属流动速度存在差异,头部出现了“翘曲”现象,等效应变呈现出了明显的梯度分布,从上表面向下逐渐减小。随着ECAPT变形的继续,已变形坯料经短暂刚性平移后进入螺旋通道,变形开始进入稳定阶段。当竖直冲头运动结束时,变形坯料上下表面的应变梯度明显减小,内部形成了一个较大的均匀变形区,平均等效应变量约为1.4。随后,在水平冲头作用下,变形坯料继续完成TE变形,等效应变略有小幅增加。ECAPT变形结束后,除坯料头尾存在端部效应为小变形区外,材料整体变形较为均匀。

图4 ECAPT变形坯料中心纵截面的等效应变分布云图

Fig. 4 Effective strain contours of central longitudinal plane of billet processed by ECAPT

为了更加清楚地表示出材料内部各质点在ECAPT过程中的变形与致密效果,选取变形坯料中心横截面上的5个不同节点进行跟踪分析(见图5(a)),得到了其在ECAPT变形过程中的等效应变分布变化规律,其结果如图5(b)所示。

图5 变形坯料中心横截面等效应变分布

Fig. 5 Distribution of effective strain on central transverse plane (TP) of billet

观察图5(b)可以发现,各跟踪点等效应变的变化趋势基本相同,即随着变形时间的延长,等效应变逐渐增大。其中,在模具转角、螺旋通道入口及出口处,由于剧烈的剪切作用,等效应变出现了较大的应变梯度,增幅较大。其他时刻变形则相对平稳,等效应变数值变化不大[14]。在试样横截面上,靠近模具内角处质点(P5)的等效应变要高于靠近模具外角处的质点(P3)以及中心处的质点(P1);沿坯料厚度方向,各点的等效应变基本相同(P1,P2,P4)。当变形坯料经过螺旋通道时,原横截面上的5个质点被同时旋转了90°,此时P1、P3、P5位于坯料的中心对称面,P2、P4处于上下表面边缘处。由于TE变形使得材料发生二次剪切,所获得的应变从中心到边缘依次递增,因此,变形结束时,边缘处的P2和P4所获得的累积等效应变略高于中心点P1处的累积等效应变。

图6中进一步分析了ECAPT某一变形时刻(t=45 s),坯料在4个不同变形区域(即压制变形区(区域1)、转角变形区(区域2)、ECAP变形区(区域3)和ECAPT变形区(区域4))内中心纵截面的等效应变累积情况。由图6可以看出,该变形时刻,区域1内的坯料变形刚刚开始,类似于粉末材料的压制阶段,各点等效应变较小,约为0.25。区域2位于模具转角地带,由于模具L型通道的剧烈剪切变形作用,各点应变开始急剧增大,其中靠近内角处的质点(P3)增幅最为明显。区域3处于ECAP稳定变形阶段,等效应变形成了从上到下逐渐递减的梯度分布。在区域4内,由于螺旋通道的剪切作用,等效应变进一步缓慢增大,位于中心的质点P2增幅较小,而边缘处的两点(P1和P3)应变累积效果较为明显。此外,相对于区域3,ECAPT工艺在一定程度上改善了变形坯料纵截面上等效应变不均匀的现象。

图6 t=45 s时不同变形区域中心纵截面的等效应变

Fig. 6 Effective strain of tracking points on central longitudinal plane (LP) at t=45 s

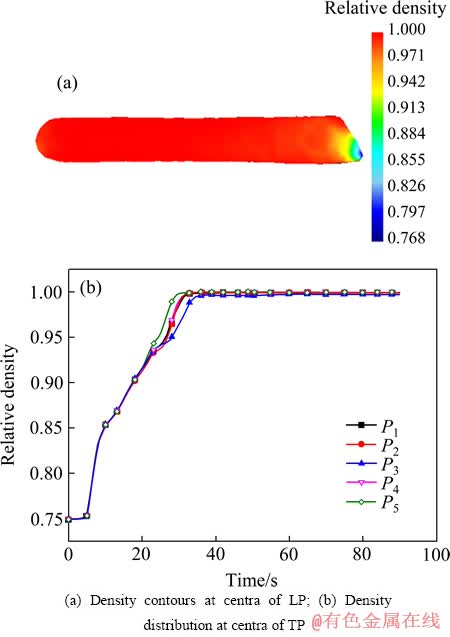

1.4 致密行为分析

图7(a)为ECAPT变形结束时变形坯料中心纵截面(LP)的相对密度分布云图。由图7(a)可以看出,单道次变形结束后,除变形坯料的头部为低密度区外,材料内部形成了一个均匀分布的高密度区,相对密度高达0.999,几乎完全致密。这是由于坯料头部为小变形区,材料所受的剪切变形非常有限,因此,其相对密度相对于其他部位要低。而位于坯料尾部的材料虽然没有受到剪切变形作用,但由于已变形材料对未变形材料的反向背压以及挤压冲头的压力作用,该部分材料处于较高的静水压力状态,从而使得内部孔隙有效收缩,相对密度显著增加。

图7 ECAPT变形后变形坯料内部相对密度分布

Fig. 7 Relative density distribution of billet after ECAPT process

图7(b)所示为ECAPT变形过程中中心横截面 (TP)上5个跟踪点的相对密度变化情况。从图7(b)中可以发现,横截面上各点的密度变化趋势基本相同,变形坯料的致密过程主要发生在ECAP变形阶段。虽然螺旋通道的二次剪切作用对于提高材料致密程度的能力非常有限,但却显著改善了变形坯料密度分布的均匀性。仔细对比图7和图5(b)可知,变形坯料相对密度的变化趋势与其等效应变存在较好的一致性,通常在等效应变累积量较大的区域,材料的致密度也较高。这是由于剪切作用使得原始孔隙的形状发生了变化,由近似的圆球状演变成为了狭长的椭球状,而当材料内部处于较为有利的静水压力状态时,孔隙体积不断减小,有效地收缩与闭合,大大提高变形坯料的整体致密效果[15]。

2 实验验证

2.1 实验材料及方法

实验材料为工业用纯铝粉末,其主要化学成分(质量分数)如下:Fe(<0.6%),Cu(<0.05%),Si(<0.3%),其余为Al。图8所示为初始纯铝粉末颗粒的SEM像。由图8可以看出,纯铝粉末颗粒多呈近球形,表面光滑,尺寸大小不一,但整体分布较为均匀,未产生明显的颗粒团聚现象。采用Mastersizer 2000型激光粒度分析仪对其进行了粒度测试,测算出其初始颗粒平均尺寸约为40.6 μm。

图8 纯铝粉末颗粒的SEM像

Fig. 8 SEM image of pure aluminum powder particles

实验前,为提高粉末材料的塑性变形能力,将松散的纯铝粉末颗粒装入纯铝金属包套内,并使其具有一定的初始紧实度(约为75%)。在自行设计的ECAPT模具上,进行纯铝粉末-包套ECAPT等温变形实验,变形温度为200 ℃,挤压速度约为 1 mm/s。实验过程中,为减小变形过程中变形坯料与模具内壁之间的摩擦,采用MoS2进行润滑。

实验结束后,线切割去除外部纯铝包套。利用4XB-TV倒置光学金相显微镜观察变形坯料横截面上的显微组织,腐蚀剂为3%HF(体积分数)水溶液(3mL HF+97 mL H2O);采用MH-3型显微维氏硬度计测量变形坯料横截面上的显微硬度,施加载荷为25 N,加载时间为10 s;室温采用排水法对变形坯料进行相对密度测试,检测试样的体积约为2 cm2。

2.2 显微组织观察

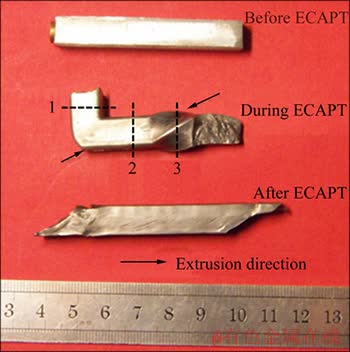

200 ℃时纯铝粉末-包套顺利地完成了单道次ECAPT变形。图9所示为ECAPT变形前后试样宏观实物形貌。

图9 ECAPT变形前后试样宏观形貌

Fig. 9 Macrographs of billets before, during and after ECAPT process

从图9中可以看出,ECAPT变形后,试样完整,包套表面未观察到裂纹等缺陷的出现。为了更加清楚地研究ECAPT变形过程中材料内部不同部位组织与性能的演变情况,选取如图9所示的3个不同变形区域(压制阶段、ECAP变形阶段、ECAPT变形阶段)进行跟踪观察。

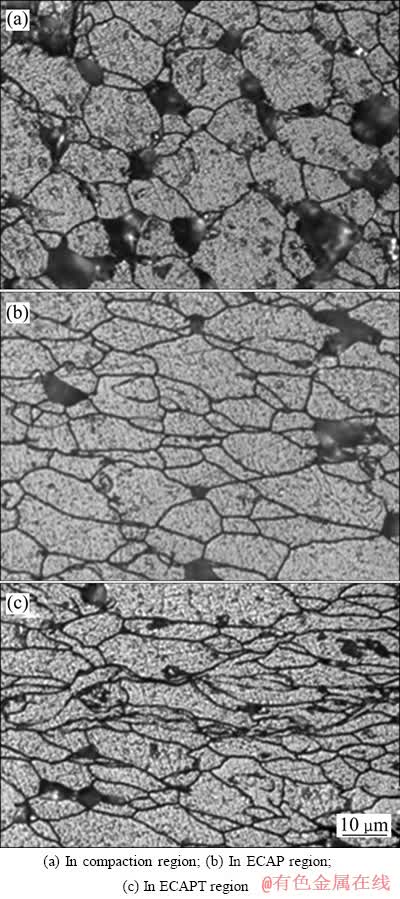

图10所示为单道次ECAPT变形后试样不同部位的光学显微组织。由图10可以看出,变形材料的内部组织直接取决于其变形特征,ECAPT工艺对粉末材料的致密度和细化效果十分显著。

区域1的材料处于粉末压制变形阶段。在挤压冲头的作用下,变形材料内部产生了较高的静水压力。纯铝粉末颗粒发生了相对滑动和位置重排,大多数颗粒之间相互接触。但由于此时塑性变形量较小,材料内部依然含有较多的孔隙。基体组织变化不大,晶粒近似呈等轴状,大小和分布都不均匀。区域2的材料通过了模具转角,完成了ECAP变形。由于变形材料受到了来自转角区域强烈的剪切变形,原始粗大的等轴晶沿剪切面发生了明显的拉长和变形,在组织内部形成了许多细长且与挤压方向约呈30°~40°的剪切变形带,晶粒得到了显著细化。此外,由于螺旋通道的反向背压作用变形和有利的温度条件(200 ℃),粉末颗粒之间充分接触,紧密地结合在一起,残余孔隙的大小和数目明显减少。区域3的材料经历了螺旋通道的二次剪切作用,变形程度最为剧烈。在旋转和剪切的双重作用下,晶粒形状更加狭长,尺寸继续减小。同时,由于变形材料内部累积了较大的塑性变形能,粉末颗粒内部、粉末颗粒与颗粒之间均得到了有效固结,材料致密度进一步提高。总之,单道次ECAPT变形结束后,变形坯料固结良好,残余孔隙已基本得到了完全焊合,光学显微镜下已很难观察到孔隙的存在。

图10 ECAPT变形下试样不同部位的金相显微组织

Fig. 10 Optical microstructures of different regions of billet under ECAPT

不难发现,ECAPT工艺下粉末材料的致密和细化

过程与传统粉末烧结工艺存在很大差别。粉末烧结致密成形的过程较为缓慢,主要机理为扩散机制,通常需要在较长的时间和较高的温度下(一般高于0.8Tm)才能进行,且烧结后的坯料通常含有一定量的残余孔隙,很难达到完全致密。相反,ECAPT变形时,强大的剪切作用力和有利的压应力状态使得原始粉末颗粒的形状和大小均发生了显著改变,通过颗粒间的不断破碎、细化和旋转,颗粒与颗粒之间在充分接触的同时得到了有效固结。因此,只需较低的变形温度和较短的变形时间,粉末颗粒之间便可以形成良好的固 结[16]。

2.3 力学性能分析

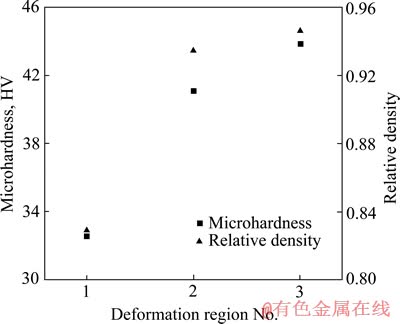

图11所示为不同变形区域内材料显微硬度及相对密度。

图11 不同变形区域内材料显微硬度及相对密度

Fig. 11 Microhardness and relative density of billet at different regions

对比图10可以发现,变形材料的显微组织与力学性能具有较好的一致性。在压制变形区域,由于粉末材料内部含有大量微孔隙,材料致密度较低(约为82.9%),显微硬度仅为32.6HV。在ECAP变形剧烈的剪切作用下,材料得到了有效的固结和细化,整体相对密度增至93.5%,显微硬度达到41.2HV,增幅约为20.7%。此后,在ECAPT变形过程中,材料组织进一步细化和致密,但相对密度和显微硬度的增幅逐渐变缓,最终分别为94.6%和44 HV。这一研究结果与XIA等[17]采用的BP-ECAC工艺有益效果相似,从而显示出ECAPT工艺在加速残余孔隙的收缩与闭合、提高变形坯料的力学性能以及促进粉体材料致密化等方面的优势。

3 结论

1) ECAPT变形过程中,材料内部出现了加工硬化现象,变形越来越困难。其中,在模具转角和螺旋通道两处,材料所受剪切变形程度最为剧烈,挤压载荷增幅最大。当变形坯料头部退出螺旋通道时,挤压载荷达到极值。

2) 相比于传统的ECAP工艺,ECAPT变形的“双剪切”作用能够进一步增加材料所累积的塑性应变量。与此同时,变形坯料内部等效应变分布的均匀性也得到了明显改善。

3) ECAPT工艺对粉末材料具有强烈的致密和细化效果。在剧烈的剪切变形和强大的静水压力状态下,只需较低的变形温度和较短的变形时间,粉末颗粒之间便可以形成良好的固结。1道次变形结束时,纯铝粉末坯料实现有效固结,整体接近完全致密,显微组织显著细化,力学性能显著提高。

REFERENCES

[1] LANGDON T G. Twenty-five years of ultrafine-grained materials: Achieving exceptional properties through grain refinement[J]. Acta Materialia, 2013, 61: 7035-7059.

[2] NAGASEKHAR A V, TICK-HON Y, RAMAKANTH K S. Mechanics of single pass equal channel angular extrusion of powder in tubes[J]. Applied Physics A, 2006, 85(2): 185-194.

[3] MANI B, JAHEDI M, PAYDAR M H. Consolidation of commercial pure aluminum powder by torsional-equal channel angular pressing (T-ECAP) at room temperature[J]. Powder Technology, 2012, 219: 1-8.

[4] ZHILYAEV A P, LANGDON T G. Using high-pressure torsion for metal processing: Fundamentals and applications[J]. Progress in Materials Science, 2008, 53: 893-979.

[5] 王晓溪, 李 萍, 薛克敏, 王 雪, 张 翔. 等径角挤扭变形过程中纯铝粉末材料的显微组织与力学性能[J]. 航空材料学报, 2013, 33(2): 14-18.

WANG Xiao-xi, LI Ping, XUE Ke-min, WANG Xue, ZHANG Xiang. Microstructure characteristics and mechanical properties on consolidation of pure Al particles through equal channel angular pressing and torsion[J]. Journal of Aeronautical materials, 2013, 33(2): 14-18.

[6] LI Ping, XUE Ke-min, WANG Xiao-xi, QIAN Chen-hao. Refinement and consolidation of pure Al particles by equal channel angular pressing and torsion[J]. Transactions of Nonferrous Metals Society of China, 2014, 24: 1289-1294.

[7] 王晓溪, 薛克敏, 李 萍. 采用等径角挤扭工艺制备块体超细晶铝[J]. 中国有色金属学报, 2014, 24(6): 1414-1421.

WANG Xiao-xi, XUE Ke-min, LI Ping. Fabrication of bulk ultrafine-grained pure aluminum using multipass equal channel angular pressing and torsion[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(6): 1414-1421.

[8] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51(7): 881-981.

[9] 李 萍, 王 雪, 薛克敏. 纯钼粉末-包套等径角挤压的多尺度研究[J]. 粉末冶金材料科学与工程, 2013, 18(3): 452-458.

LI Ping, WANG Xue, XUE Ke-min. Multi-scale study of pure molybdenum powder material in tubes during equal channel angular pressing[J]. Materials Science and Engineering of Powder Metallurgy, 2013, 18(3): 452-458.

[10] KARAMAN I, HAOUAOUI M, MAIER H J. Nanoparticle consolidation using equal channel angular extrusion at room temperature[J]. Journal of Materials Science, 2007, 42(5): 1561-1576.

[11] ZENDEHDEL H, HASSANI A. Influence of twist extrusion process on microstructure and mechanical properties of 6063 aluminum alloy[J]. Materials and Design, 2012, 37: 13-18.

[12] LATYPOV M I, ALEXANDROV I V, BEYGELZIMER Y E, LEE S, KIM H S. Finite element analysis of plastic deformation in twist extrusion[J]. Computational Materials Science, 2012, 60: 194-200.

[13] ORLOV D, BEYGELZIMER Y, SYNKOV S, VARYUKHIN V, TSUJI N, HORITA Z. Plastic flow, structure and mechanical properties in pure Al deformed by twist extrusion[J]. Materials Science and Engineering A, 2009, 519: 105-111.

[14] KOCICH R, KUNCICKA L, MIHOLA M, SKOTNICOVA K. Numerical and experimental analysis of twist channel angular pressing (TCAP) as a SPD process[J]. Materials Science and Engineering A, 2013, 563: 86-94.

[15] 李维杰, 刘 咏, 刘延斌, 何晓宇, 王 斌. 纯钛粉末室温单道次等径角挤压变形行为[J]. 粉末冶金材料科学与工程, 2011, 16(1): 90-95.

LI Wei-jie, LIU Yong, LIU Yan-bin, HE Xiao-yu, WANG Bin. Deformation behavior of pure titanium powder extruded by single-pass equal channel angular pressing at room temperature[J]. Materials Science and Engineering of Powder Metallurgy, 2011, 16(1): 90-95.

[16] ELKHODARY K I, SALEM H G, ZIKRY M A. Equal channel angular pressing of canned 2124-Al compacts: Processing, experiments, and modeling[J]. Metallurgical and Materials Transactions A, 2008, 39(9): 2184-2192.

[17] XIA K, WU X, HONMA T, RINGER S P. Ultrafine pure aluminum through back pressure equal channel angular consolidation (BP-ECAC) of particles[J]. Journal of Materials Science, 2007, 42(5): 1551-1560.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51401177);江苏省高校自然科学研究面上项目(13KJD430005);江苏省大型工程装备检测与控制重点实验室开放性课题(JSKLEDC201309);江苏省前瞻性产学研联合创新资金项目(BY2013022)

收稿日期:2014-05-14;修订日期:2014-09-15

通信作者:王晓溪,讲师,博士;电话:0516-83105376;E-mail: wxx19851109@sina.com