文章编号:1004-0609(2012)1-0258-07

热处理对高岭石结构转变及活性的影响

匡敬忠,邱廷省,施 芳

(江西理工大学 资源与环境工程学院,赣州 341000)

摘 要:采用煅烧高岭石的方法制备矿物聚合材料,采用DTA-TG、XRD和IR分析等手段研究高岭石经过热处理后的结构转变过程。结果表明:热处理直接影响到高岭石结构转变及煅烧高岭石的活性。煅烧后,高岭石的结构转变经历了脱羟基(约541 ℃)、偏高岭石化(541~850 ℃)和Al2O3分凝(>950 ℃)3个过程,煅烧温度达到950 ℃后,生成新相γ-Al2O3。通过对煅烧高岭石所制备的矿物聚合材料抗折强度的评价确定了煅烧高岭石活性较适宜的热处理制度:煅烧温度为850 ℃,煅烧时间3 h。煅烧高岭石的长程无序特征是煅烧高岭石具有较高活性的原因,γ-Al2O3的生成是导致煅烧高岭石活性下降和矿物聚合材料抗折强度降低的主要原因。

关键词:高岭石;煅烧;活性;结构转变;矿物聚合材料

中图分类号:TQ177 文献标志码:A

Effect of heat treatment on structure transformation and activities of kaolinite

KUANG Jing-zhong, QIU Ting-sheng, SHI Fang

(Faculty of Resource and Environmental Engineering, Jiangxi University of Science and Technology,

Ganzhou 341000, China)

Abstract: The geopolymers were prepared by calcining kaolinite. The structure transformation for calcined kaolinite was studied by means of differential thermal analysis-thermal gravity, X-ray diffraction and infrared. The results show that heat treatment directly affects the structure transformation of kaolinite and activity of calcination kaolinite. The structure transformation for calcined kaolinite is undergone some stages including kaolinite dehydroxylation (about 541 ℃), metakaolinite formation (541-850 ℃) and Al2O3 segregation (>950 ℃). The new phase formed at 950 ℃ is γ-Al2O3. The activity of calcined kaolinite is estimated by testing the bending strength of geopolymers which are made of calcined kaolinite, the heat treatment of proper calcined kaolinite activity is calined at 850 ℃ for 3 h. The calcined kaolinite has a high activity because of long-range disorder of metakaolinite structure characteristic. The activity of calcined kaolinite and bending strength of geopolymers decrease because of γ-Al2O3 forming.

Key words: kaolinite; calcination; activity; structure transition; geopolymer

高岭石是一种层状结构的铝硅酸盐粘土矿物,原矿高岭石并不具备制备矿物聚合材料所需的火山灰活性,要使之获得活性,必须对它进行活化处理[1-2]。处理方法是对高岭石进行煅烧,使高岭石脱去其铝氧八面体中的—OH,改变Al的配位数,使原来为有序结构的高岭石变成无序结构的偏高岭石以获得活性[3]。煅烧高岭石的活性取决于生料的性质(矿物组成、结晶状况等)和煅烧条件,其中煅烧过程中的温度条件是研究最多的参数之一[4-6]。对于煅烧高岭石活性的评价,相关文献分别采用XPS、IEP、X射线衍射分析、热重分析和扫描量热分析进行评价[7-8],但郭文瑛等[9]认为评价煅烧高岭石活性最有效的方法是直接用偏高岭石制备矿物聚合材料并养护到一定龄期后,通过测试其强度来评价煅烧高岭石的活性。尽管许多学者对高岭石的活化处理进行了大量研究,但高岭石在热处理过程中的结构转变情况尚不清楚,尤其是没有弄清高岭石在热处理过程中高岭石结构转变与其活性之间的内在联系。

本文作者首先采用DTA-TG分析确定高岭石的煅烧温度范围,然后采用XRD 、IR和SEM分析煅烧高岭石的结构转变和微观结构,并以煅烧高岭石制备矿物聚合材料的强度来讨论煅烧温度和时间对煅烧高岭石活性的影响,以探讨高岭石在热处理过程中结构转变与其活性之间的内在联系。

1 实验

1.1 原料和方法

高岭石为水洗高岭石,其化学组成如表1所列;工业级水玻璃,模数为3.0~3.2;分析纯的NaOH;骨料为某钨矿的尾矿。

表1 高岭石的化学组成

Table 1 Chemical composition of kaolinite (mass fraction, %)

用煅烧高岭石制备矿物聚合材料并养护到一定龄期后,测试其抗折强度来评价煅烧高岭石的活性,高岭石煅烧实验参数如表2所列。

1.2 结构表征

热分析采用美国PE公司的PYRISDIAMOND TG/DTA型综合热分析仪,实验采用样品为粒径小于0.074 mm的高岭石粉,参比样为α-Al2O3粉;由室温开始,按照20 ℃/min速率升温至1 200 ℃。物相分析所用仪器为日本理学miniflex型X射线衍射分析仪,测定样品的XRD谱,然后利用Hanawalt方法检索JCPDS卡片,确定样品中含有的晶相种类,采用Cu Kα线辐射(λ=1.541 78 ?),扫描范围为5°~80°。采用KBr压片法在 Thermo Nicolet公司生产的FT-IR AVATAR 370型红外光谱仪上测定各试样的红外吸收光谱,光谱测定波数范围为400~4 000 cm-1。将试样喷金后,采用Philips公司的XL30型扫描电镜观察其显微结构。采用KZJ500-1型水泥电动抗折实验机测定矿物聚合材料的抗折强度,试样尺寸为40 mm × 40 mm × 160 mm。

表2 高岭石煅烧实验参数

Table 2 Parameters of kaolinite calcination

2 结果分析与讨论

2.1 高岭石的DTA分析

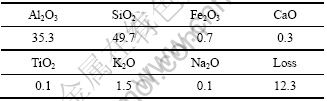

高岭石的DTA-TG测试结果如图1所示。由图1的DTA曲线可知,第一个吸热峰值为70 ℃,这是由于高岭石的吸附水被蒸发;第二个吸热峰值为541 ℃,这是因为高岭石脱去羟基发生吸热反应所致;随着温度继续升高,出现了放热峰,起始温度为965 ℃左右,放热峰值温度为1 013 ℃,这主要是由于一些物质的晶型转变或生成了新物质放热而形成的。由图1的 TG曲线可知,高岭石经过煅烧后,样品总质量损失率为13.3%,其中以结构水的损失最大,损失率为8.7%。而在541~965 ℃之间,此时高岭石可能以偏高岭石的形式存在,在该温度范围内,煅烧高岭石的活性较高,可能是煅烧高岭石的适宜温度区间。因此,选择在不同温度(650、750、850、950 ℃)下进行高岭石煅烧,煅烧时间在1~3 h较为适宜。按高岭石的煅烧时间分别为1、2、3 h制定高岭石煅烧的实验表进行煅烧实验,结果如表2所列。

图1 高岭石DTA-TG

Fig. 1 DTA and TG curves of kaolinite

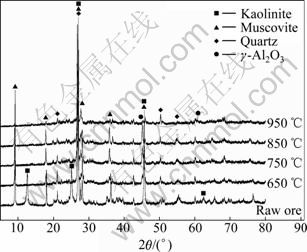

2.2 煅烧高岭石的XRD分析

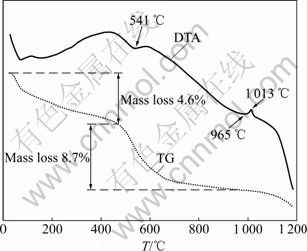

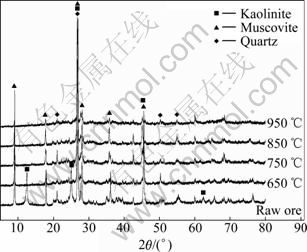

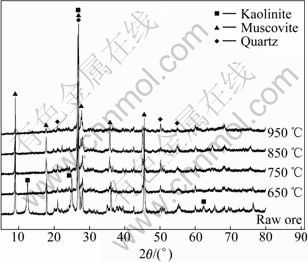

对不同煅烧条件下的高岭石及高岭石原矿样进行XRD衍射分析,结果如图2~4所示。由图2~4可见:原矿高岭石未经过煅烧时,其XRD谱线中高岭石的特征峰明显,同时还有石英和白云母的特征峰;而经过650~850 ℃煅烧后,其XRD谱线中已经没有高岭石的特征峰,其结构内羟基大量脱除,晶体结构受到破坏,反映高岭石结晶结构特征的衍射锐峰强度迅速降低或消失,呈现出无定形物质的衍射特点,表明热变高岭石呈非晶态结构特征,即具有长程无序特点。不同温度煅烧后偏高岭石微结构差别主要决定于结构基元之间的连接和无序性。偏高岭石中原子排列不规则,呈现热力学介稳状态,在适当条件激发下具有胶凝性。

经过950 ℃煅烧时,其XRD谱线中出现了强度很弱的γ-Al2O3的特征峰,说明在950 ℃,煅烧时高岭石再分解出γ-Al2O3。因此,可以认为高岭石在加热过程中的结构转变过程和分解反应为

Al2O3·2SiO2·2H2O

Al2O3·2SiO2(metakaolinite)+2H2O

Al2O3·(2-x)SiO2(metakaolinite)

γ-Al2O3+(2-x)SiO2(metastable)

图2 不同温度煅烧1 h高岭石的XRD谱

Fig. 2 XRD patterns of kaolinite calcined at different temperatures for 1 h

图3 不同温度煅烧2 h高岭石的XRD谱

Fig. 3 XRD patterns of kaolinite calcined at different temperatures for 2 h

图4 不同温度煅烧3 h高岭石的XRD谱

Fig. 4 XRD patterns of kaolinite calcined at different temperatures for 3 h

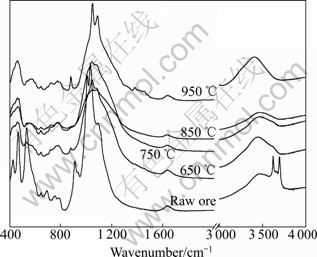

2.3 煅烧高岭石的IR分析

图5~7所示为高岭石原矿及在不同煅烧制度下煅烧高岭石的红外光谱。由图5~7可知,高岭石原矿的IR谱与标准高岭石的几乎完全一致,其高频区吸收峰(3 695和3 621 cm-1)为高岭石羟基基团的振动特征峰,其中3 695 cm-1归属于表面羟基的振动,3 621 cm-1归属于面内羟基的振动;经过650 ℃煅烧后,这两个吸收峰完全消失,合并为一宽的吸收带3 450 cm-1。VALERIA等[10]研究了偏高岭石红外光谱,指出3 450和1 650 cm-1宽带属于样品中的吸附水。此时高岭石羟基已大量脱除,晶体结构发生崩塌。

图5 不同温度煅烧1 h高岭石的IR曲线

Fig. 5 IR spectra of kaolinite calcined at different temperatures for 1 h

图6 不同温度煅烧2 h高岭石的IR曲线

Fig. 6 IR spectra of kaolinite calcined at different temperatures for 2 h

图7 不同温度煅烧3 h高岭石的IR曲线

Fig. 7 IR spectra of kaolinite calcinedat different temperatures for 3 h

中低频区(1 200~400 cm-1)的特征峰虽然不具备高频区那样明显的鉴别特征,但是这些峰特征仍是具有较高有序度的高岭石的标志[11],1 088 cm-1归属于Si—O的伸缩振动,Si—O—Al的振动为810 cm-1, 而Si—O的弯曲振动为470 cm-1;950~900 cm-1属于Al—O—OH的弯曲振动,934 cm-1为表面羟基的面内弯曲振动,912 cm-1为内部羟基的振动。而经过650 ℃到950 ℃煅烧后,在400~1 350 cm-1范围内只留下了表征Si—O伸缩振动的1 085 cm-1、Al—O—Si振动 的800 cm-1和Si—O弯曲振动的470 cm-1 3条谱带,并变成了几个宽带,这些吸收带均为偏高岭石形成的特征吸收带;而高岭石934 cm-1表面羟基振动和912 cm-1内部羟基振动消失。由于高岭石中铝氧八面体层羟基的脱出,必然导致部分Al—O—Al的出现,GRANIZO等[12]指出810 cm-1属于偏高岭石四面体Al中的Al—O键吸收峰。另外,图5~7所示的红外光谱结果也表明,在950 ℃煅烧时出现了570和750 cm-1两个新的吸收带。魏存第等[13]认为这是γ-Al2O3产生的吸收带,同时他通过27AlMAS NMR证实950 ℃时为γ-Al2O3。这表明本研究结果与其研究结果是一致的。前面XRD分析提到高岭石经过950 ℃煅烧后出现了强度很弱的γ-Al2O3的特征峰,这与IR结构分析的观点相吻合。

2.4 高岭石和煅烧高岭石的微观结构分析

高岭石是含结构水的层状硅酸盐矿物,结构单元层由一层四面体片与一层八面体片叠置在一起构成,其中的结构羟基分布在铝氧八面体层中。当结构水脱出时,铝氧八面体层的结构会被破坏,而硅氧四面体层则基本保持原有的层状结构特征,使得偏高岭石保持了层片状结构特征。图8所示为高岭石原矿的SEM像。由图8可见,高岭石原矿很明显呈层片状。图9所示为高岭石在850 ℃煅烧3 h后的SEM像。由图9可见,在850 ℃煅烧后的高岭石虽然脱去了内外羟基,但它仍然保持部分高岭石层片状的结构特征,说明偏高岭石具有层片状碎片的中程有序结构特点。偏高岭石这种层片状结构与高岭石不同的是铝氧八面体层的结构产生了无序化,从而导致了煅烧高岭石的长程无序特征,因此,煅烧后的高岭石具有较高的活性[14]。此外,前面的XRD分析结果中也没有发现偏高岭石的特征峰,说明其不具有晶相的特性,可能为无定形结构,也是其具有活性的原因所在。

图8 高岭石原矿的SEM像

Fig. 8 SEM image of raw kaolinite

图9 在850 ℃煅烧3 h的高岭石SEM像

Fig. 9 SEM image of kaolinite calcined at 850 ℃ for 3 h

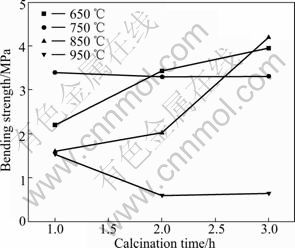

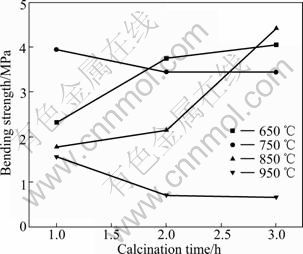

2.5 煅烧高岭石的活性评价

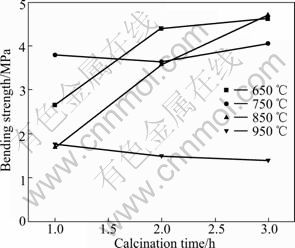

根据代新祥和文梓芸[15]的实验研究,采取以下实验条件进行偏高岭石制备矿物聚合材料的实验:偏高岭石占固相含量20%、硅酸钠占液相含量60%(两者皆为质量分数)、固液质量比为4.0、养护温度60 ℃、养护时间24 h后脱模,测试其制品在3、7和28 d的抗折强度。通过抗折强度的大小来评价煅烧制度对煅烧高岭石活性的影响,确定煅烧高岭石的最佳煅烧制度。不同煅烧制度下的高岭石制备的矿物聚合材料的实验条件和抗折强度结果如表3所列,煅烧制度对抗折强度的影响如图10~12所示。

由图10~12可知,煅烧温度和煅烧时间对煅烧高岭石制备的矿物聚合材料的抗折强度影响较大,矿物聚合材料的抗折强度越大说明煅烧高岭石的活性越高。在相同煅烧温度下,随着煅烧时间的延长,高岭石的活性总体随之升高。这表明随着煅烧时间的延长,高岭石脱羟基更加彻底,从而显示出更高的活性。在相同煅烧时间下,随着煅烧温度的不同,煅烧高岭石的活性表现出先升高后降低的趋势。在煅烧温度为750 ℃、煅烧时间为3 h时,其相应的抗折强度低于在650和850 ℃煅烧3 h时的,可能与Si—O键、Al—O—Si键的振动有关。曹德光等[14]研究表明,这两个结构特征峰的强度和位置反映了煅烧高岭石的键合反应能力。由图7所示的IR谱线可知,在750 ℃煅烧时,Si—O键伸缩振动的1 085 cm-1、Al—O—Si键振动的800 cm-1和Si—O弯曲振动的470 cm-1这3条谱带的吸收强度都低于在650和850 ℃煅烧时的,这可能导致煅烧温度为750 ℃时,其相应的抗折强度低于在650和850 ℃煅烧时的抗折强度。当煅烧温度为 650 ℃、煅烧时间为3 h时,尽管其相应的28 d抗折强度与在850 ℃煅烧时的很接近,但其相应的3 d和7 d抗折强度明显较低,说明其早期强度偏低。综合考虑各因素,可认为煅烧温度为850 ℃、煅烧时间为3 h时煅烧高岭石的活性最高。

表3 煅烧高岭石制备矿物聚合材料的实验条件和抗折强度

Table 3 Experimental conditions and bending strength of geopolymers made by calcined kaolinites

图10 矿物聚合材料3 d抗折强度

Fig. 10 Bending strength of geopolymers for 3 d

图11 矿物聚合材料7 d抗折强度

Fig. 11 Bending strength of geopolymers for 7 d

图12 矿物聚合材料28 d抗折强度

Fig. 12 Bending strength of geopolymers for 28 d

由图10~12可知,在950 ℃煅烧时,其相应的抗折强度明显降低。当煅烧温度达到950 ℃时,高岭石由于煅烧温度过高开始产生了γ-Al2O3新相,导致煅烧高岭石的活性下降,由其所制备矿物聚合材料的抗折强度也较低。其主要原因是结晶相γ-Al2O3中的Al为四配位和六配位,而偏高岭石中的Al为四配位、五配位和六配位[16-17];偏高岭石在碱激发下能形成矿物聚合材料的基本构成单元PS(—Si—O—Al—)、PSS (—Si—O—Al—O—Si—)和PSD(—Si—O—Al—O—Si—O—Si—O))[18],而γ-Al2O3无法形成类似结构单元,失去胶凝性造成强度降低。FLETCHER等[19]研究了SiO2/Al2O3比对矿物聚合材料强度的影响,指出氧化铝的增加会导致强度下降,其结论与本文的实验结果是一致的。

由此可见,煅烧制度与煅烧高岭石的反应活性密切相关。根据煅烧高岭石制备的矿物聚合材料的抗折强度可以确定高岭石活化的较适宜条件为煅烧温度850 ℃,煅烧时间为3 h。

3 结论

1) 高岭石经过热处理后,其结构转变经历了脱羟基(约541 ℃)、偏高岭石化(541~850 ℃)和Al2O3分凝(>950 ℃)等过程,煅烧温度达到950 ℃后生成了新相γ-Al2O3。

2) 通过对所制备的矿物聚合材料的抗折强度评价可知:煅烧制度会改变煅烧高岭石的结构,煅烧后高岭石的羟基大量脱除、高岭石有序度降低,铝氧八面体层的结构产生了无序化,从而导致了偏高岭石的长程无序特征,使煅烧高岭石具有较高的活性,但偏高岭石仍保持了层片状的结构特征。煅烧高岭石的较适宜热处理制度为煅烧温度850 ℃,煅烧时间3 h。

3) 烧温度高于950 ℃后,γ-Al2O3的生成会导致煅烧高岭石的活性下降,其相应的矿物聚合材料的抗折强度也降低。

REFERENCES

[1] de SILVA P S, MINDESS S. Pozzolanic activation of metakaolin [J]. Adv Cem Res, 1992, 4(16): 167-178.

[2] DAVIDOVITS J. Geopolymers: Inorganic polymeric new materials[J]. J Therm Anal, 1991, 37: 1633-1656.

[3] WANG M R, JIA D C, HE P G, ZHOU Y. Influence of calcination temperature of kaolin on the structure and properties of final geopolymer[J]. Materials Letters, 2010, 64: 2551-2554.

[4] 白志民, 肖仪武. 低温煅烧高岭土火山灰活性对水泥石结构的影响[J]. 硅酸盐学报, 2003, 31(7): 715-720.

BAI Zhi-min, XIAO Yi-wu. Effect of pozzolanic activity of calcined kaolinite on structure of cement mortar[J]. Journal of the Chinese Ceramic Society, 2003, 31(7): 715-720.

[5] 魏存弟, 杨殿范, 李 益, 三国彰. 煅烧温度对高岭土相转变过程及Si、Al活性的影响[J]. 矿物学报, 2005, 25(3): 197-202.

WEI Cun-di, YANG Dian-fan, LI Yi, SAN Guo-zhang. Influence of temperature on phase transformation of calcined kaolinite and Si and Al activity[J]. Acta Mineralogical Sinica, 2005, 25(3): 197-202.

[6] 诸华军, 姚 晓, 张祖华. 高岭土煅烧活化温度的初选[J]. 建筑材料学报, 2008, 11(5): 621-625.

ZHU Hua-jun, YAO Xiao, ZHANG Zu-hua. Optimization of calcined temperature for kaolin activation[J]. Journal of Building Materials, 2008, 11(5): 621-625.

[7] TORRES SANCHEZ R M, BASALDELLA E I, MARCO J F. The effect of thermal and mechanical treatment on Kaolinite: Characterization by XPS and IEP measurements[J]. Journal of Colloid and Interface Science, 1999, 215: 339-344.

[8] KAKALI G, PERRAKI T, TSIVILIS S, BADOGINANIS E. Thermal treatment on Kaolin: The effect of mineralogy on the pozzolanic activity[J]. Applied Clay Science, 2001, 20: 73-81.

[9] 郭文瑛, 吴国林, 文梓芸, 殷素红. 偏高岭土活性评价方法的研究[J]. 武汉理工大学学报, 2006, 28(3): 76-79.

GUO Wen-ying, WU Guo-lin, WEN Zi-yun, YIN Su-hong. Research on the estimation method for the reactivity of metakaolin[J]. Journal of Wuhan University of Technology, 2006, 28(3): 76-79.

[10] VALERIA F F, BARBOSA J D, MACKENZIE K, THAUMATURG O. Synthesis and characterization of materials based on inorganic polymers of alumina and silica: Sodium polysialate polymers[J]. International Journal of Inorganic Materials, 2000, 2: 309-317.

[11] 王鸿灵, 李海红, 冯治中, 田 农, 阎逢元. 不同活性高岭土矿物聚合反应的研究[J]. 材料科学与工程学报, 2004, 22(4): 580-583.

WANG Hong-ling, LI Hai-hong, FENG Zhi-zhong, TIAN Nong, YAN Feng-yuan. Study of geopolymer based on kaolinite with different activation[J]. Journal of Materials Science and Engineering, 2004, 22(4): 580-583.

[12] GRANIZO M L, BLANCO-VARELA M T, PALOMO A. Influence of the starting kaolin on alkali-activated materials based on metakaolin: Study of the reaction parameters by isothermal conduction calorimetry[J]. Journal of Materials Science, 2000, 35: 6309-6315.

[13] 魏存弟, 马鸿文, 杨殿范, 李 益, 三国彰. 煅烧煤系高岭土的相转变[J]. 硅酸盐学报, 2005, 33(1): 77-81.

WEI Cun-di, MA Hong-wen, YANG Dian-fan, LI Yi, SAN Guo-zhang. Phase transformation for calcined coal measures kaolinite[J]. Journal of the Chinese Ceramic Society, 2005, 33(1): 77-81.

[14] 曹德光, 苏达根, 杨占印, 宋国胜. 偏高岭土的微观结构与键合反应能力[J]. 矿物学报, 2004, 24(4): 366-372.

CAO De-guang, SU Da-gen, YANG Zhan-yin. SONG Guo-sheng. Study of the microstructure of metakaolinite with IR, TG, SEM, XRD methods[J]. Acta Mineralogica Sinica, 2004, 24(4): 366-372.

[15] 代新祥, 文梓芸. 土聚水泥的应用及研究现状[J]. 水泥, 2001(10): 11-14.

DAI Xin-xiang, WEN Zi-yun. Application and present status of geopolymeric cement[J]. Cement, 2001(10): 11-14.

[16] 何宏平, 胡 澄, 郭九皋, 张惠芬. 高岭石及其热处理产物的29Si, 27Al魔角旋转核磁共振研究[J]. 科学通报, 1993, 38(6): 570-572.

HE Hong-ping, HU Cheng, GUO Jiu-gao, ZHANG Hui-fen. 29Si, 27Al magic-angle-spinning nuclear magnetic resonance studies of kaolinite and its thermal transformation products[J]. Chinese Science Bulletin, 1993, 38(6): 570-572.

[17] ROCHA J, KLINOWSKI J. 29Si and 27Al megicangle-spinning NMR studies of the thermal transformation of kaolinite[J]. Phys Chem Minerals, 1990, 17(2): 179-182.

[18] de SILVA P, SAGOE-CRENSTIL K, SIRIVIVATNANON V. Kinetcs of geopolymerization: Role of Al2O3 and SiO2[J]. Cement and Concrete Research, 2007, 37: 512-518.

[19] FLETCHER R A, MACKENZIE K J D, NICHOLSON C L, SHIMADA S. The composition range of aluminosilicate geopolymers[J]. Journal of the European Ceramic Society, 2005, 25(9): 1471-1477.

(编辑 何学锋)

基金项目:江西省主要学科学术和技术带头人培养计划资助项目(2007DD00700);江西省教育厅科技计划资助项目(GJJ09242);江西省自然科学基金资助项目(2008GZC0030)

收稿日期:2010-12-16;修订日期:2011-05-28

通信作者:匡敬忠,教授,博士;电话:0797-8312259; E-mail: kjz692@163.com