DOI: 10.11817/j.issn.1672-7207.2016.02.015

直齿-面齿轮传动啮合效率的计算与分析

盛兆华,唐进元,陈思雨,王艺欣雨

(中南大学 高性能复杂零件制造国家重点实验室,湖南 长沙,410083)

摘要:研究面齿轮传动啮合效率的理论计算方法,分析面齿轮设计参数对其传动啮合效率的影响。应用面齿轮传动啮合理论,建立含安装误差的啮合分析模型;根据面齿轮轮齿接触分析(TCA),数值计算啮合点的坐标和法向量。结合传动效率的定义,计算得到啮合点的瞬时啮合效率以及传动平均啮合效率;分析小齿轮齿数、传动比和安装误差对面齿轮传动啮合效率的影响规律。研究结果表明:面齿轮传动瞬时啮合效率随面齿轮滚动角的增大而先增大后减小,啮合至节点处达最大值;当齿间摩擦因数为0.1,面齿轮传动啮合效率达98.79%;面齿轮传动啮合效率随着小齿轮齿数的增加而增加,随着传动比的增加而减小;安装误差对面齿轮传动啮合效率有显著影响。通过控制安装误差范围,可减小面齿轮传动啮合效率损失,这对高性能面齿轮传动设计有参考价值。

关键词:轮齿接触分析;安装误差;传动比;小齿轮齿数

中图分类号:TH132.41 文献标志码:A 文章编号:1672-7207(2016)02-0459-08

Calculation and analysis of mesh efficiency about face-gear drive with spur involute pinion

SHENG Zhaohua, TANG Jinyuan, CHEN Siyu, WANG Yixinyu

(State Key Laboratory of Modern Complex Equipment Design and Extreme Manufacturing,

Central South University, Changsha 410083, China)

Abstract: The calculation method of mesh efficiency about face-gear drive theoretically and analyze the effect of design parameters on mesh efficiency were studied. Firstly, the mesh analysis model of face-gear drive considering alignment errors was developed by applying the theory of face-gear meshing. Secondly, based on the tooth contact analysis (TCA) of face-gear, the coordinates and normal vectors of mesh points were calculated by numerical method. According to the definition of drive efficiency, momentary mesh efficiency of mesh points and average mesh efficiency of face-gear drive were calculated. Finally, the effects of design parameters (i.e. number of pinion tooth, transmission ratio and alignment errors) on mesh efficiency were analyzed. The results indicate that the momentary mesh efficiency of face-gear drive increases at first and then decreases with the increase of roll-angle of face-gear and reaches maximum at pitch point. When the friction coefficient equals 0.1, the face-gear drive efficiency reaches 98.79%; the mesh efficiency increases with the increase of number of pinion tooth and decreases with the increase of transmission ratio, and the alignment errors have a significant impact on mesh efficiency of face-gear drive. The mesh efficiency losses can be deduced by controlling the limits of alignment errors, which have a reference value to the design of high-performance face-gear drive.

Key words: tooth contact analysis (TCA); alignment errors; transmission ratio; number of pinion teeth

面齿轮传动,具有传动装置轻量化、空间占用小、无需防错位设计以及精确分流等优势,使面齿轮在高速重载的航空领域有广泛的应用,如:直升机主减速器等[1-3]。LITVIN等[4-5]及其团队系统地研究了面齿轮啮合原理,从几何学角度分析了面齿轮根切和齿顶变尖现象,并提出了局部点接触啮合方式,以减少传动对安装误差的敏感性。在齿面接触分析方面,陈兴明[6]、何国旗等[7]对面齿轮传动进行了TCA分析。刘艳平[8]通过有限元软件对面齿轮进行了加载轮齿接触分析(LTAC)。在面齿轮精加工方面,国内外学者做了大量研究,如LITVIN等[9-11]提出了可靠的磨齿加工方法。在面齿轮动力学方面,HU等[12-16]建立了面齿轮传动的动力学模型,并进行了相关的理论分析。目前,面齿轮的研究主要涉及面齿轮精加工(磨齿)、面齿轮传动TCA/LTAC分析以及面齿轮动力学等方面,但有关面齿轮传动啮合效率的测定或计算,还未见有相关研究文献。一般而言,齿轮传动啮合效率可采用试验方法测定,如圆柱齿轮传动[17-19]。但测定会耗费大量齿轮试件,测定成本高且通用性差,特别对于加工难度大、加工精度不易保证的面齿轮来说,其传动效率的测定成本将更高,所以,本文作者选择面齿轮传动啮合效率的理论计算为突破点。在齿轮啮合效率的理论计算方面,XU等[20]建立了平行轴齿轮机械效率的理论预测模型,并通过效率试验机验证了该模型的有效性。姚建初等[21]推导出内外直齿轮传动啮合效率的解析公式,并证明了该效率公式的正确性。王成等[22-25]计算啮合点处的滑动摩擦损失并沿啮合线积分,得斜齿轮、人字齿轮啮合效率的表达式,揭示设计参数对啮合效率的影响。计算齿轮传动啮合效率,首先必须确定完整的传动啮合线。不同于圆柱齿轮传动具有简单的啮合线解析方程,面齿轮传动因点接触形式而无法获得其啮合线的解析表达式,这成为面齿轮效率计算的1个难点。为解决上述难点,本文作者通过面齿轮传动TCA分析,数值求解非线性接触方程,得到齿面接触点,然后通过坐标变换获取啮合线上点坐标。其次,从啮合点处驱动功率和阻力功率的角度出发,计算面齿轮传动瞬时、平均啮合效率。最后分析相关设计参数对啮合效率的影响规律,给出对面齿轮实际工况分析具有一定指导意义的结论。

1 含安装误差面齿轮接触分析

1.1 面齿轮传动坐标系的建立

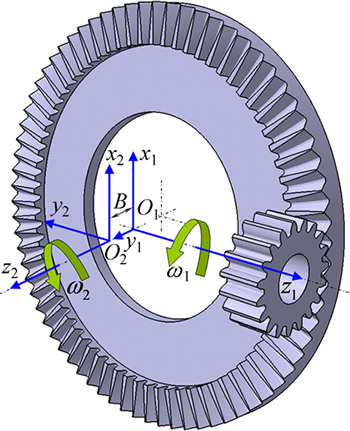

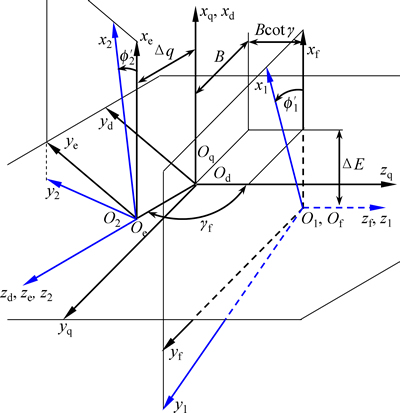

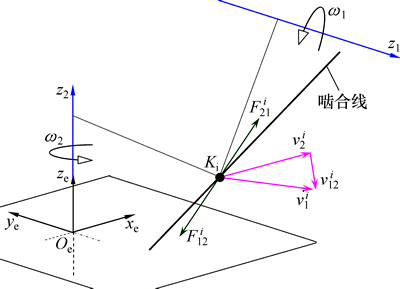

面齿轮传动模型与传动坐标系如图1~2所示。动坐标系S1和S2刚性固结在小齿轮和面齿轮上,其余辅助坐标系Sq,Sd以及Se刚性固结在机架上。假设面齿轮为主动轮,并且以角速度ω2绕z2轴旋转,小齿轮为从动轮,以角速度ω1绕z1轴旋转。

图1 面齿轮传动模型

Fig. 1 Transmission model of face-gear

图2 面齿轮传动坐标系

Fig. 2 Coordinate systems of face-gear drive

图2中:B为插齿刀与小齿轮轴线的间距;△E为小齿轮和面齿轮的两轴线相错时两轴线之间最短距离;△q为面齿轮轴向位移;△γ为2齿轮旋转轴夹角偏差;γf=γm+△γ,γm为面齿轮与小齿轮轴交角。本文使用△E,△q和△γ这3个参数描述小齿轮和面齿轮之间的安装误差。

1.2 小齿轮、面齿轮齿面接触轨迹的计算

在S1动坐标系下,小齿轮渐开线齿面方程r1和齿面单位法向量n1可表示为

式中:rb1为小齿轮基圆半径;θ01为小齿轮齿槽角。

将小齿轮齿面方程r1和齿面单位法向量n1转换至辅助坐标系Sf下:

其中:

在S2动坐标系下,面齿轮齿面方程r2和齿面单位法向量n2可表示为

式中:is2为插齿刀与面齿轮齿数比;rbs为插齿刀基圆半径;θ0s为插齿刀齿槽角。

由于n2项数较多,在此不再展开。同样将面齿轮齿面方程r2和齿面单位法向量n2转换至辅助坐标系Sf下:

其中:

根据齿轮局部接触原理,考察小齿轮 和面齿轮

和面齿轮 在坐标系Sf中的切触。两齿面的切触方程如下:

在坐标系Sf中的切触。两齿面的切触方程如下:

将式和展开,得到含有6个未知数 的5个独立非线性方程组。给出1组参数(见表1),假定

的5个独立非线性方程组。给出1组参数(见表1),假定 为输入参数,编写程序,数值求解后,即可得到小齿轮齿面接触轨迹

为输入参数,编写程序,数值求解后,即可得到小齿轮齿面接触轨迹 (i=1,…,m0,m0为接触点数)及其齿面单位法向量

(i=1,…,m0,m0为接触点数)及其齿面单位法向量 和面齿轮齿面接触轨迹

和面齿轮齿面接触轨迹 及其齿面单位法向量

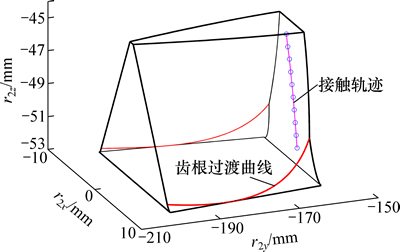

及其齿面单位法向量 。图3所示为面齿轮接触轨迹。

。图3所示为面齿轮接触轨迹。

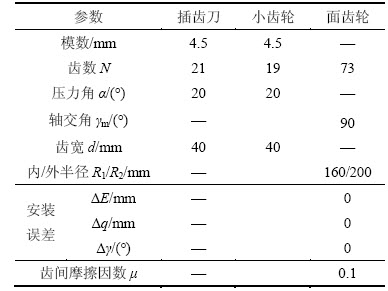

表1 面齿轮几何和传动参数

Table 1 Geometry and transmission parameters of face-gear drive

1.3 面齿轮传动啮合线的计算

将面齿轮齿面接触轨迹 变换至Se坐标系下,即可得到Se坐标系下面齿轮传动啮合线:

变换至Se坐标系下,即可得到Se坐标系下面齿轮传动啮合线: ;而将接触轨迹的齿面法向量变换至Se坐标系下,即可得到Se坐标系下啮合线的单位法向量:

;而将接触轨迹的齿面法向量变换至Se坐标系下,即可得到Se坐标系下啮合线的单位法向量: 。

。

(11)

(11)

图3 面齿轮传动接触轨迹

Fig. 3 Contact path of face-gear drive

(12)

(12)

其中: 。

。

同理,可以得到小齿轮齿面接触轨迹 变换至Sf坐标系下的传动啮合线

变换至Sf坐标系下的传动啮合线 以及单位法向量

以及单位法向量 。

。

(13)

(13)

(14)

(14)

其中, 。

。

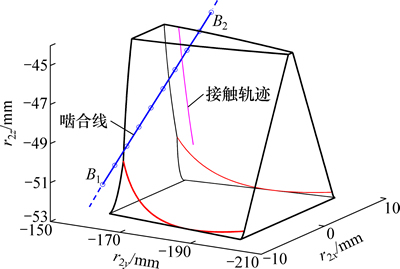

针对表1给出的面齿轮传动参数,数值计算得到Se和Sf坐标系下面齿轮传动啮合线。图4所示为Se坐标系下啮合线。

图4 面齿轮传动啮合线

Fig. 4 Line of action of face-gear drive

1.4 完整啮合线判断准则

为计算面齿轮传动啮合效率,首先必须确定面齿轮传动完整啮合线。完整啮合线判断准则是根据面齿轮啮合过程及连续传动条件而定。

1) 啮合起点B1处,小齿轮齿顶与啮合线相交,则有:

(15)

(15)

2) 啮合终点B2处,面齿轮齿顶与啮合线相交,则有:

(16)

(16)

式中:ra1为小齿轮齿顶圆半径;rms为插齿刀齿根圆半径;ε为足够小正数,本文取ε=10-4 mm。

采用二分法对式(15)和(16)进行逼近,得到完整啮合过程的面齿轮转角范围 ,从而确定完整啮合线B1B2。针对表1给出的面齿轮传动参数,完整啮合过程的面齿轮转角范围为(-0.087 9,0.033 0) rad。

,从而确定完整啮合线B1B2。针对表1给出的面齿轮传动参数,完整啮合过程的面齿轮转角范围为(-0.087 9,0.033 0) rad。

2 面齿轮传动啮合效率的计算

在计算面齿轮传动啮合效率之前,需要作以下假设以简化理论分析。

1) 所传递的力矩为常数。

2) 仅考虑单对轮齿啮合,忽略重合度、载荷分配等因素。

3) 啮合过程中,齿间摩擦因数为定常数,忽略滑动速度、润滑条件对摩擦因数的影响。

2.1 瞬时啮合效率的计算方法

图5所示为面齿轮传动啮合情况。在啮合过程中,面齿轮在啮合点Ki的速度为 ,小齿轮在啮合点的速度为

,小齿轮在啮合点的速度为 ,面齿轮与小齿轮齿间滑动速度为

,面齿轮与小齿轮齿间滑动速度为 。面齿轮对小齿轮的作用力为

。面齿轮对小齿轮的作用力为 ,可分解为法向力

,可分解为法向力 (与

(与 同向)和摩擦力

同向)和摩擦力 (与

(与 同向);小齿轮作用于面齿轮的全反力

同向);小齿轮作用于面齿轮的全反力 ,也可分解为法向力

,也可分解为法向力 (与

(与 同向)和摩擦力

同向)和摩擦力 (与

(与 同向)。作用力的数学表达式为:

同向)。作用力的数学表达式为:

(17)

(17)

(18)

(18)

(19)

(19)

(20)

(20)

在任意啮合点Ki处,驱动功率与克服阻力所需功率分别为:

(21)

(21)

(22)

(22)

图5 面齿轮传动啮合情况

Fig. 5 Meshing of face-gear drive

那么,Ki点瞬时效率为

(23)

(23)

下面证明基于假设1)~3)计算的面齿轮传动啮合效率与驱动力矩、驱动转速无关。

根据空间啮合基本定理,小齿轮、面齿轮在啮合点的速度沿公共法线的分量相等,即

(24)

(24)

式中:α1和α2为小齿轮、面齿轮速度与公共法线夹角,如图5所示。

根据假设2)有

(25)

(25)

结合式(17)~(25),Ki点瞬时效率为

(26)

(26)

由式(26)可见:基于本文假设计算的面齿轮传动啮合效率与驱动力矩、驱动转速无关,只与齿面摩擦因数、啮合点法向量、速度单位向量有关。

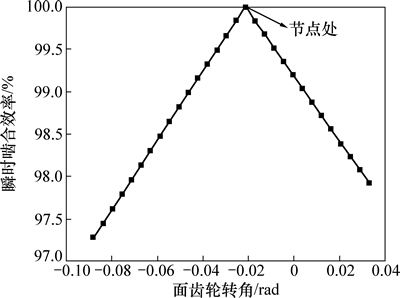

根据假设3),取齿间摩擦因数为定值0.1,针对表1所示为面齿轮传动参数,由式(23)计算得到面齿轮传动瞬时啮合效率ηi。瞬时啮合效率随面齿轮滚动角的变化曲线如图6所示。由图6可见:面齿轮传动瞬时效率随面齿轮滚动角的增大而先增大后减小,当啮合至节点(面齿轮和小齿轮两节面的切触线与瞬时回转轴的交点)处达到100%,这是因为在节点(pitch point)处,面齿轮与小齿轮齿面间的相对运动为纯滚动,滑动速度为0,即 。

。

2.2 平均啮合效率的计算方法

应用数值积分公式(这里采用梯形公式),将瞬时啮合效率先积分,后取均值,即得到面齿轮传动平均啮合效率:

(27)

(27)

对表1给出的面齿轮传动参数,由式(27)计算得到无安装误差时,面齿轮传动平均啮合效率为η=98.79%。

图6 面齿轮传动瞬时啮合效率

Fig. 6 Momentary mesh efficiency of face-gear drive

3 设计参数对啮合效率的影响

3.1 小齿轮齿数、传动比对啮合效率的影响

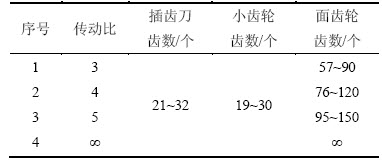

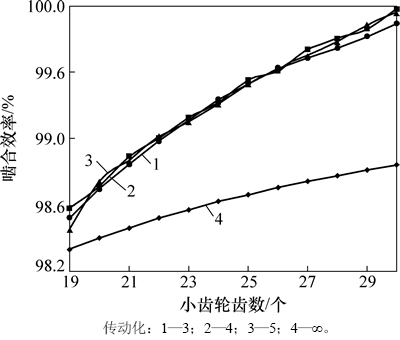

取面齿轮几何参数分别为:模数m=6 mm、压力角α=20°、轴交角γm=90°,4组面齿轮传动设计参数如表2所示。分别计算这4组参数下啮合效率,然后进行对比分析。当传动比趋于无穷大时,面齿轮传动等价于齿条与小齿轮啮合传动,故第4组参数的啮合效率由齿条与小齿轮传动啮合效率代替,而前3组参数的啮合效率由式(27)计算得到。计算结果如图7所示。由图7可见:当传动比为3,4和5,小齿轮齿数为19~30,面齿轮传动啮合效率范围为98.66%~ 99.97%;啮合效率随着小齿轮齿数的增加而增加;传动比为3~5对啮合效率影响不明显,但考虑到齿条与小齿轮传动(i21→∞)啮合效率明显小于面齿轮传动啮合效率,所以,可以推断,随着传动比的增加,面齿轮传动啮合效率减小。

表2 4组面齿轮传动设计参数

Table 2 4 groups design parameters of face-gear drive

图7 啮合效率随小齿轮齿数变化曲线

Fig. 7 Plot of mesh efficiency versus number of pinion teeth

3.2 安装误差对啮合效率的影响

针对表1的面齿轮传动参数,研究安装误差△E,△q和△γ独立作用时对啮合效率产生的影响。

3.2.1 △E的影响

限制安装误差△E=-0.2~0.2 mm,△q=0,△γ=0,按式(27)计算,啮合效率随安装误差△E的变化曲线如图8所示。由图8可见:啮合效率随安装误差△E的增大而减小。当安装误差-0.2<△E<0 mm时,传动啮合效率高于无安装误差时啮合效率,可见,安装误差△E在此范围内时对传动有利。

图8 安装误差△E独立作用时啮合效率变化曲线

Fig. 8 Plot of mesh efficiency versus alignment errors △E

3.2.2 △q的影响

经面齿轮TCA分析显示,当△q<0时,轮齿将产生边缘接触,故这里限制安装误差△q=0~0.4 mm,△E=0,△γ=0。同样,由式(27)计算出安装误差△q下的啮合效率。啮合效率随安装误差△q的变化曲线如图9所示。

图9 安装误差△q独立作用时啮合效率变化曲线

Fig. 9 Plot of mesh efficiency versus alignment errors △q

从图9可以看出:啮合效率随安装误差△q的增大而先增大后减小。当安装误差0<△q<0.273 mm时,传动啮合效率高于无安装误差时啮合效率,可见,安装误差△q在此范围内时对传动有利。

3.2.3 △γ的影响

限制安装误差△γ=-0.02°~0.02°,△E=0,△q=0,相应的啮合效率曲线如图10所示。从图10可以看出:啮合效率随着安装误差△γ的增大而增大,直至△γ>0.015°后趋于平缓。在安装误差0°<△γ<0.02°时,啮合效率高于无安装误差时的啮合效率,此安装误差范围内对传动有利。

图10 安装误差△γ独立作用时啮合效率变化曲线

Fig. 10 Plot of mesh efficiency versus alignment errors △γ

4 结论

1) 面齿轮传动瞬时啮合效率随着面齿轮滚动角的增加而先增加后减小,并在节点处达最大值100%。

2) 面齿轮传动啮合效率随着小齿轮齿数的增加而增加,随着传动比的增加而减小;面齿轮传动啮合效率大于齿条与小齿轮传动啮合效率。

3) 在本研究给定面齿轮几何参数下,当传动比为3~5,小齿轮齿数为19~30时,面齿轮传动啮合效率范围为98.66%~99.97%。

4) 当安装误差△E,△q和△γ独立作用时,啮合效率随着安装误差△E的增大而减小,随着安装误差△q的增大而先增大后减小,随着安装误差△γ的增大而增大。控制安装误差范围,可减小面齿轮传动啮合效率损失。

5) 本研究方法适合于各种具有空间啮合线的齿轮传动啮合效率的计算与分析。

参考文献:

[1] 赵韩, 吴其林, 黄康, 等. 国内齿轮研究现状及问题研究[J]. 机械工程学报, 2013, 49(19): 11-20.

ZHAO Han, WU Qilin, HUANG Kang, et al. Status and problem research on gear study[J]. Journal of Mechanical Engineering, 2013, 49(19): 11-20.

[2] 王志, 刘建炜, 刘锐, 等. 面齿轮传动国内研究进展[J]. 机械设计与制造, 2012(3): 219-220.

WANG Zhi, LIU Jianwei, LIU Rui, et al. Face gear drive and its research developments in domestic[J]. Machinery Design and Manufacture, 2012(3): 219-220.

[3] LITVIN F L, WANG J C, BOSSLER R B, et al. Application of face-gear drives in helicopter transmissions[J]. Journal of Mechanical Design, 1994, 116(3): 672-676.

[4] LITVIN F L, ZHANG Y, WANG J C, et al. Design and geometry of face-gear drives[J]. Journal of Mechanical Design, 1992, 114(4): 642-647.

[5] LITVIN F L, FUENTES A. Gear geometry and applied theory[M]. London: Cambridge University Press, 2004: 508-546.

[6] 陈兴明. 含安装误差的修形直齿-面齿轮传动齿面接触分析的研究[D]. 长沙: 中南大学机电工程学院, 2012: 11-39.

CHEN Xingming. Tooth contact analysis of modified spur face gear drives with alignments errors[D]. Changsha: Centra South University. College of Mechanical and Electrical Engineering, 2012: 11-39.

[7] 何国旗, 严宏志, 胡威, 等. 面齿轮啮合过程中齿面接触分析[J]. 中南大学学报(自然科学版), 2013, 44(1): 95-100.

HE Guoqi, YAN Hongzhi, HU Wei, et al. Tooth contact analysis of face gear meshing[J]. Journal of Central South University (Science and Technology), 2013, 44(1): 95-100.

[8] 刘艳平. 直齿-面齿轮加载接触分析及弯曲应力和接触应力计算方法研究[D]. 长沙: 中南大学机电工程学院, 2012: 23-46.

LIU Yanping. The loaded tooth contact analysis and bending stress and contact stress calculating method research of face-gear drive with spur involute pinion[D]. Changsha: Cental South University. College of Mechanical and Electrical Engineering, 2012: 23-46.

[9] LITVIN F L, GONZALEZ P I, FUENTES A, et al. Design, generation and stress analysis of face-gear drive with helical pinion[J]. Computer Methods in Applied Mechanics and Engineering, 2005, 194(36): 3870-3901.

[10] TANG Jinyuan, YIN Feng, CHEN Xingming. The principle of profile modified face-gear grinding based on disk wheel[J]. Mechanism and Machine Theory, 2013, 70: 1-15.

[11] 彭先龙, 方宗德, 苏进展, 等. 应用大碟形刀具加工面齿轮的理论分析[J]. 哈尔滨工业大学学报, 2013, 45(5): 80-85.

PENG Xianlong, FANG Zongde, SU Jinshan, et al. Theory analysis for application of disk tool of long radius in face gear machining[J]. Journal of Harbin Institute of Technology, 2013, 45(5): 80-85.

[12] HU Zehua, TANG Jinyuan, CHEN Siyu, et al. Effect of mesh stiffness on the dynamic response of face gear transmission system[J]. Journal of Mechanical Design, 2013, 135(7): 1-7.

[13] HU Zehua, TANG Jinyuan, CHEN Siyu. Periodic and chaotic dynamic responses of face gear transmission system[J]. Advanced Materials Research, 2014, 834(15): 1273-1280.

[14] 胡泽华. 基于接触特性的面齿轮传动动力学特性分析[D]. 长沙: 中南大学机电工程学院, 2014: 18-77.

HU Zehua. Dynamic analysis of face gear drive based on meshing characteristics[D]. Changsha: Centra South University. College of Mechanical and Electrical Engineering, 2014: 18-77.

[15] 李晓贞, 朱如鹏, 李政民卿, 等. 非正交面齿轮传动系统的耦合振动分析[J]. 中南大学学报(自然科学版), 2013, 44(6): 2274-2280.

LI Xiaozhen, ZHU Rupeng, LI Zhengminqing, et al. Analysis of coupled vibration of face gear drive with non-orthogonal intersection[J]. Journal of Central South University (Science and Technology), 2013, 44(6): 2274-2280.

[16] 靳广虎, 朱如鹏, 鲍和云. 正交面齿轮传动系统的非线性振动特性[J]. 中南大学学报(自然科学版), 2010, 41(5): 1808-1813.

JIN Guanghu, ZHU Rupeng, BAO Heyun. Nonlinear dynamical characteristics of face gear transmission system[J]. Journal of Central South University (Science and Technology), 2010, 41(5): 1808-1813.

[17] PETRY-JOHNSON T T, ANDERSON N E, CHASE D R, et al. An experimental investigation of spur gear efficiency[J]. Journal of Mechanical Design, 2008, 130(6): 1-10.

[18] HANDSCHUH R F, KILMAIN C J. Preliminary comparison of experimental and analytical efficiency results of high-speed helical gear trains[C]//ASME 2003 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference. Chicago: American Society of Mechanical Engineers, 2003: 949-955.

[19] 刘白, 汪大鹏. 齿轮传动效率的试验研究[J]. 机械工程学报, 2001, 37(1): 109-112.

LIU Bai, WANG Dapeng. Experiment study on gear drive efficiency[J]. Chinese Journal of Mechanical Engineering, 2001, 37(1): 109-112.

[20] XU H, ANDERSON N E, MADDOCK D G, et al. Prediction of mechanical efficiency of parallel-axis gear pairs[J]. Journal of Mechanical Design, 2007, 129(1): 58-68.

[21] 姚建初, 陈义保, 周济, 等. 齿轮传动啮合效率计算方法的研究[J]. 机械工程学报, 2001, 37(11): 18-21.

YAO Jianchu, CHEN Yibao, ZHOU Ji, et al. Study on a method for calculating gear meshing efficiency[J]. Journal of Mechanical Design, 2001, 37(11): 18-21.

[22] 王成, 方宗德, 贾海涛. 斜齿轮滑动摩擦功率损失的计算[J]. 燕山大学学报, 2009, 33(2): 99-108.

WANG Cheng, FANG Zongde, JIA Haitao. Calculation of sliding friction power losses on helical gears[J]. Journal of Yanshan University, 2009, 33(2): 99-108.

[23] 王成, 高常青, 崔焕勇. 基于啮合效率下斜齿圆柱齿轮设计参数的选择[J]. 燕山大学学报, 2012, 36(2): 126-130.

WANG Cheng, GAO Changqing, CUI Huanyong. Selection of design parameters of helical gear based on meshing efficiency[J]. Journal of Yanshan University, 2012, 36(2): 126-130.

[24] 王成, 高常青, 贾海涛. 基于人字齿轮啮合特性的滑动摩擦功率损失[J]. 中南大学学报(自然科学版), 2012, 43(6): 2173-2178.

WANG Cheng, GAO Changqing, JIA Haitao. Power losses of sliding friction based on meshing characteristics of double helical gears[J]. Journal of Central South University (Science and Technology), 2012, 43(6): 2173-2178.

[25] 王成, 崔焕勇, 张清萍, 等. 齿轮啮合效率的理论研究进展[J]. 济南大学学报(自然科学版), 2015, 29(3): 229-235.

WANG Cheng, CUI Huanyong, ZHANG Qingping, et al. Theoretical research progress of gear meshing efficiency[J]. Journal of University of Jinan (Science and Technology), 2015, 29(3): 229-235.

(编辑 陈爱华)

收稿日期:2015-02-13;修回日期:2015-04-20

基金项目(Foundation item):国家重点基础研究发展计划(“973”计划)项目(2011CB706800);国家自然科学基金资助项目(51304562,51275530)(Project (2011CB706800) supported by the National Program on Key Basic Research Project; Projects (51304562, 51275530) supported by the National Natural Science Foundation of China)

通信作者:唐进元,博士,教授,从事齿轮传动设计及数字化制备的研究;E-mail:jytangcsu_312@163.com