焊接热输入和后续热处理对AA7075-AA5086异种搅拌摩擦焊接头显微组织和力学性能的影响

来源期刊:中国有色金属学报(英文版)2017年第8期

论文作者:Jamshidi Aval HAMED

文章页码:1707 - 1715

关键词:搅拌摩擦焊;异种铝合金;热处理;热输入

Key words:friction stir welding; dissimilar aluminium alloys; heat treatment; heat input

摘 要:研究焊接热输入和后续热处理对时效硬化AA7075-T6合金和应变硬化AA5086-H32合金异种搅拌摩擦焊接接头显微组织和力学性能的影响。采用X射线残余应力分析、拉伸测试、光学金相分析以及透射电子显微分析研究工艺参数对焊接接头的影响。结果表明,与其他焊接接头相比,无散热片焊接的接头搅拌区更均匀。在所研究的自然时效时间范围内,焊接接头在快速冷却过程中高的固溶度将产生更大的驱动力,这也导致在自然时效过程中,AA7075的硬度增加。自然时效使AA7075搅拌区和热力影响区的残余应力减小10~25 MPa。该影响在无散热片焊接的接头中明显减小。此外,自然时效对接头强度无明显影响。

Abstract: The effects of welding heat input and post-weld heat treatment on the mechanical and microstructural aspects of dissimilar friction stir welds of age-hardened AA7075-T6 and strain hardenable AA5086-H32 aluminium alloys were investigated. X-ray diffraction (XRD) residual stress analysis and tensile testing together with optical metallography and transmission electron microscopy (TEM) were performed to assess the effects of process parameters on welded joints. It was discovered that joints produced without heat sink exhibited more homogeneous stir zones than other joints. Of the natural aging time studied, higher amount of solid solution during rapid cooling of welds produced higher driving force for increase in hardness in the AA7075 side during natural aging. Natural aging within stirring zone and thermo-mechanical affected zone of AA7075 side resulted in a 10 to 25 MPa reduction in the residual stress in these zones; its effect decreased considerably in the welds performed without heat sink. In addition, natural aging had no noticeable effect on the joint strength.

Trans. Nonferrous Met. Soc. China 27(2017) 1707-1715

Jamshidi Aval HAMED

Mechanical Engineering, Babol University of Technology, Shariati Avenue, Babol 484, Iran

Received 4 June 2016; accepted 17 October 2016

Abstract: The effects of welding heat input and post-weld heat treatment on the mechanical and microstructural aspects of dissimilar friction stir welds of age-hardened AA7075-T6 and strain hardenable AA5086-H32 aluminium alloys were investigated. X-ray diffraction (XRD) residual stress analysis and tensile testing together with optical metallography and transmission electron microscopy (TEM) were performed to assess the effects of process parameters on welded joints. It was discovered that joints produced without heat sink exhibited more homogeneous stir zones than other joints. Of the natural aging time studied, higher amount of solid solution during rapid cooling of welds produced higher driving force for increase in hardness in the AA7075 side during natural aging. Natural aging within stirring zone and thermo-mechanical affected zone of AA7075 side resulted in a 10 to 25 MPa reduction in the residual stress in these zones; its effect decreased considerably in the welds performed without heat sink. In addition, natural aging had no noticeable effect on the joint strength.

Key words: friction stir welding; dissimilar aluminium alloys; heat treatment; heat input

1 Introduction

The friction stir welding (FSW) technique, developed by The Welding Institute (TWI) in the United Kingdom [1], is a potentially attractive joining technique and has been extensively applied in aluminium alloys. The solid-state nature of FSW results in several conventional defects in fusion welding methods, such as porosity, solute redistribution, solidification cracking and liquation cracking. The low concentration of defects and the very tolerant variations in welding parameters and materials have resulted in the increased application of this technique in various industries, such as aerospace and automotive. The microstructure and properties of the final joint obtained by FSW are strictly dependent on the process parameters used, such as rotation and welding speed, geometric parameters of the tool, tool tilt, material thickness, alloy composition, heat sink. In this regard, some attempts have been made to study the dissimilar FSW of aluminium alloys, including AA5xxx and AA7xxx series in the literatures [2-7]. For example, ILANGOVAN et al [8] studied the microstructural evolution and tensile properties in the dissimilar friction stir welded AA6061-AA5086 joint. From their study, an improved hardness of HV 115 was obtained in the stir zone, which was higher than the hardness of the parent metal. However, higher grain boundary fraction and formation of brittle intermetallic phases at the weld were also reported to have improved the hardness. ACERRA et al [9] investigated the dissimilar FSW of AA2024-T4 and AA7075-T6 T-joints. AA2024-T4 blanks were utilized as skins and AA7075-T6 blanks were utilized as stringers. It was reported that a large tool shoulder diameter was required to produce a large amount of heat input and necessary forging action to fulfil the joint fillets during FSW of T-joints. DA SILVA et al [10] studied the effect of joining parameters on the microstructure, mechanical properties and material flow of dissimilar FSWed aluminium alloys AA2024-T3 and AA7075-T6. It was discovered that the minimum hardness value and fracture of joints occurred in the HAZ at the AA2024 side. They reported that there existed excessive movement of bulk material from the advancing side to the retreating side and vice versa underneath the tool shoulder; this was the key reason responsible for the lack of mixing. IPEKOGLU and  [11] investigated the effects of initial temper condition and post-weld heat treatment on the microstructure and mechanical properties of the dissimilar FSW of AA7075-O/6061-O and AA7075-T6/ 6061-T6 aluminium alloys. It was found that in the O-temper and T6 temper conditions, a hardness increase and decrease in the joint area were obtained, respectively. Moreover, they demonstrated that post-weld treatment improved the joint properties for both O and T6 joints. GUO et al [12] considered the effects of materials position and welding speed on the material flow, microstructure and mechanical property of FSWed AA6061 and AA7075 Al alloys. They reported the highest joint strength obtained when welding was conducted with the highest welding speed and AA6061 Al plates were fixed on the advancing side. PALANIVEL et al [13] examined the effect of tool rotational speed and pin profile on the microstructure and tensile strength of dissimilar friction stir welded AA5083 and AA6351 aluminium alloys. They found that the tool rotational speed and pin profile had effect on the joint strength due to variation in the behaviour of the material flow, change in microstructure and formation of macroscopic defects. SONG et al [14] studied the influences of welding speed and joint combination on defects features and mechanical properties of friction stir lap welded dissimilar AA2024-AA7075. They reported that the voids defect only appeared in joints with AA2024 alloy acting as the top sheet. Furthermore, they discovered that the lap shear strength generally increased with an increase in the welding speed. COLE et al [15] investigated the tool offset effect during friction stir welding of dissimilar aluminum alloys 6061-T6 and 7075-T6. They discovered that the tool offset into the retreating side due to the generation of lower average temperature increased the joint strength.

[11] investigated the effects of initial temper condition and post-weld heat treatment on the microstructure and mechanical properties of the dissimilar FSW of AA7075-O/6061-O and AA7075-T6/ 6061-T6 aluminium alloys. It was found that in the O-temper and T6 temper conditions, a hardness increase and decrease in the joint area were obtained, respectively. Moreover, they demonstrated that post-weld treatment improved the joint properties for both O and T6 joints. GUO et al [12] considered the effects of materials position and welding speed on the material flow, microstructure and mechanical property of FSWed AA6061 and AA7075 Al alloys. They reported the highest joint strength obtained when welding was conducted with the highest welding speed and AA6061 Al plates were fixed on the advancing side. PALANIVEL et al [13] examined the effect of tool rotational speed and pin profile on the microstructure and tensile strength of dissimilar friction stir welded AA5083 and AA6351 aluminium alloys. They found that the tool rotational speed and pin profile had effect on the joint strength due to variation in the behaviour of the material flow, change in microstructure and formation of macroscopic defects. SONG et al [14] studied the influences of welding speed and joint combination on defects features and mechanical properties of friction stir lap welded dissimilar AA2024-AA7075. They reported that the voids defect only appeared in joints with AA2024 alloy acting as the top sheet. Furthermore, they discovered that the lap shear strength generally increased with an increase in the welding speed. COLE et al [15] investigated the tool offset effect during friction stir welding of dissimilar aluminum alloys 6061-T6 and 7075-T6. They discovered that the tool offset into the retreating side due to the generation of lower average temperature increased the joint strength.

KASMAN et al [16] studied 5 mm-thick dissimilar friction stir welds between 5754 and 7075 aluminium alloys and discovered that defect-free joint was achieved in the case of a weld produced with 1000 r/min of tool rotational speed, 80 mm/min of welding speed, and 22 mm of tool shoulder diameter. Furthermore, they reported a decrease in the ultimate tensile strength with increasing welding speed or increasing tool rotational speed. SAEIDI et al [17] investigated the microstructure and mechanical behaviour of the dissimilar friction stir welded AA5083-AA7075 and developed a mathematical modelling to demonstrate a relationship between the friction stir welding parameters and the ultimate tensile strength of the joints. They reported that the maximum tensile strength of welded joints was achievable in rotational and traverse speeds of 500 r/min and 50 mm/min, respectively. SHOJAEEFARD et al [18] studied the microstructural and mechanical properties of 6 mm-thick dissimilar friction stir welded AA7075-O/ AA5083-O aluminium alloys and found out that joints fabricated using a tool rotational speed of 1400 r/min and traverse speed of 20 mm/min yielded higher strength. Moreover, they also reported that better recrystallized grains at low heat input resulted in the highest average microhardness values of joints.

AA5xxx and AA7xxx series alloys are used in industrial applications and joining of these two alloys are required in some of applications, while AA5xxx and AA7xxx alloys cannot be welded by conventional welding processes, such as fusion. FSW as a solid state welding process is capable of producing high-quality welds when optimized parameters are used. Significant researches in friction stir welding of aluminium alloys have been carried out over the last years and important advances have been achieved in this field. At present, to the authors’ knowledge, no study on the long-term aging effects on the mechanical property changes in the dissimilar friction stir welding of AA7075-T6 and AA5086-H32 with very interesting industrial applications has been reported in the open literature. The aims of this research were to study the effect of rotation and linear speed of tool and post-weld heat treatment on the microstructure formation and the precipitation distribution in the weld zone in dissimilar friction stir welding of AA7075-T6 and AA5086-H32. Accordingly, microstructural and mechanical testing, as well as residual stress measurement, were performed to estimate the effect of process parameters on welded material.

Table 1 Chemical compositions of alloys (mass fraction, %)

Table 2 Mechanical properties of base material from tensile tests

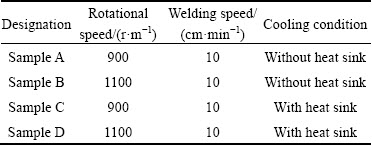

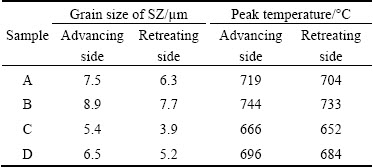

Table 3 Welding parameters used in experiments

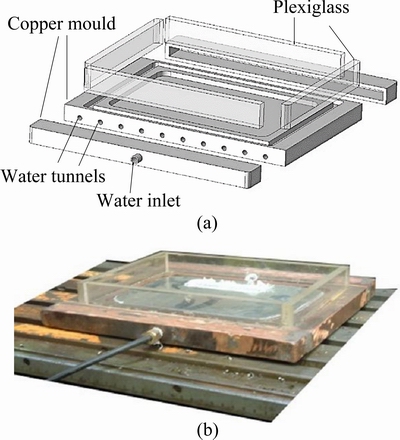

Fig. 1 Schematic of friction stir welding cooling system (a), cooling system consisting of copper mould and Plexiglas tank (b)

2 Experimental

In this study, aluminium alloy plates AA7075-T6 and AA5086-H32 of 4 mm in thickness were investigated. The compositions in mass fraction and mechanical properties of both alloys are presented in Tables 1 and 2. Welds were produced using a FSW machine in position control, with a tilt angle of 3°. The weld configuration consisted of the AA5086 alloy placed on the advancing side and the AA7075 alloy placed on the retreating side. The aluminium plates were cut in a rectangular shape having dimensions of 150 mm in length and 50 mm in width. To investigate the effect of welding heat input on the joint properties, the friction stir welding was carried out under different conditions. The tool rotational speeds of 700, 900, 1100, 1300 and 1500 r/min, and linear speeds of 6, 8 and 10 cm/min were applied in the experiments, but only the welds made by using rotating speed of 900 and 1100 r/min, and linear speed of 10 cm/min were satisfactory. The employed welding conditions are listed in Table 3. As shown in Fig. 1, a cooling system was designed to obtain rapid heat sinking during FSW. A thin copper mould and water were used for rapid cooling of the samples during FSW. Six tunnels were machined beneath the surface of the copper mould, thus allowing free immergence and flow through of water. Moreover, this cooling system was contained in a Plexiglas tank filled with a mixture of methanol and dry ice during the process in order to increase the cooling rate of FSWed material within the process. In addition, the temperature changes during and after FSW of various regions in the advancing and retreating sides of joints were measured using K-type thermocouples with a 0.25 mm-diameter wire. Single- pass friction stir butt welds were made using a tool made of H13 steel, with a concave shoulder 18 mm in diameter and threaded cylindrical pin. The pin length and diameter were 3.8 and 4 mm, respectively. The plunge rate during FSW was constant for all conditions, i.e., 1 mm/s. The penetration depth was set at 0.2 mm during all the tests.

To determine the microstructure of the joints, the transverse cross-sections of welded samples were prepared by standard metallographic procedures. The optical metallography was performed on polished samples using a reagent made of 0.5 mL HF, 15.5 mL HNO3, 84 mL H2O and 0.3 g Cr2O3 for AA5086 and a reagent made of 3 mL nitric acid (HNO3), 6 mL hydrofluoric acid (HF), 6 mL hydrochloric acid (HCl), and 150 mL H2O for AA7075. Transmission electron microscopy (TEM) samples were prepared by means of jet polishing, using a solution of 25% HNO3 in methanol. Apart from this, the linear intercept method based on ASTM: E112-13 was used to obtain the average grain size.

The Vickers micro-hardness of the joints was measured on a cross-section perpendicular to the welding direction of the plates, with a 100 g loading for 15 s. Tensile testing was conducted on the specimens with a 25 mm gage length and reduced section length and width of 32 and 6 mm which were prepared according to ASTM: E8M-13 standard at a constant cross-head speed of 1 mm/min. Three tensile tests were performed at each condition and the average engineering stress were compared. The longitudinal and transversal residual stress measurements were evaluated transversely to the weld direction by XRD technique using Cu Kα radiation, with the X-ray tube operated at 20 kV and 4 mA target current.

3 Results and discussion

Figure 2 shows the macrostructure of cross-section of the sound friction stir welded joints. The AA5086 alloy is on the left and the AA7075 alloy is on the right side in all images. Due to the mixing of two base materials, a semi-layered structure was observed in the stir zone of samples A and B. A comparison of the welded samples with and without heat sink showed that when weld was performed without heat sink (samples A and B), the mixing of materials was increased. This may be attributed to the higher heat generation and peak temperature in the samples, and more reduction of material flow stress (Table 4). It is also worth noting that, the stir zone of samples A and B was dominated by AA5086 and the amount of AA7075 increased in the stir zone with increasing tool rotational speed traveling speed, ratio (w/v). The tool rotational speed/traveling speed ratio is considered as a criteria of welding heat input.

Fig. 2 Macrostructure of welded samples

Table 4 Measured peak temperature and grain sizes of stir zone in advancing and retreating side of various samples

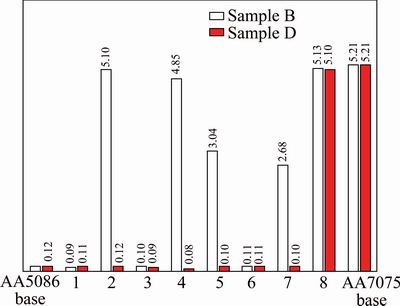

Furthermore, joints produced without heat sink (i.e., samples A and B) exhibited a stir zone which consisted of a higher amount of AA7075 than those produced with heat sink (i.e., samples C and D). The quantitative analysis of zinc in samples B and D on points specified in Figs. 2(b) and (d) are shown in Fig. 3. Comparing the results, it can be confirmed that in sample D, the zinc content near interface (regions 7, 8) suddenly changed. The zinc content of this region was related to AA5086 and AA7075 base material, respectively. Besides, the zinc content of regions 5 and 7 in sample B suggested that the zones were formed by a mixture of both materials. The zinc content between the two base materials may be related to the atomic diffusion at the interface of these joints due to severe plastic deformation and high peak temperature in the weld stir zone[19].

Fig. 3 Zinc content in samples B and D, measured in points indicated in Fig. 1

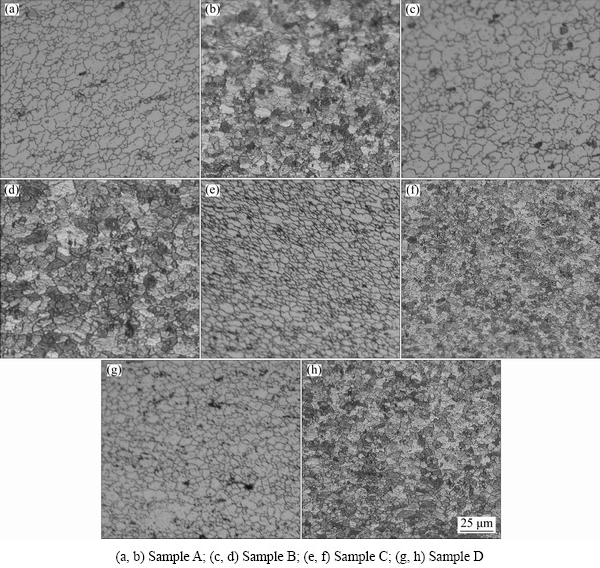

Figure 4 shows the influence of welding heat input and heat sink on the microstructure of the stir zone. Dynamic recrystallization of the stir zone resulted in the formation of fine equiaxed grains in both AA5086 and AA7075 sides. The average grain size of AA5086 and AA7075 based materials are approximately (87±0.7) μm and (75±0.5) μm, respectively. Table 4 and Fig. 4 indicate that the grain size of the stir zone on the AA5086 side was coarser than that of the AA7075 side, e.g., the grain sizes of stir zone in the AA5086 and AA7075 sides of sample A were 7.5 and 6.3 μm, respectively. This may be attributed to the lower temperature in the retreating side, lower deformation resistance of AA7075 than AA5086 [20] during increased temperature and smaller initial grain sizes of AA7075 than AA5086 [2]. It can be seen that grain size of the stir zone in welds made with heat sink was finer than that without heat sink in similar tool rotational speed/traveling speed ratio. This was due to higher heat flow and heat loss in welds performed under heat sink condition. In welds made with any of the heat sink condition, increasing rotational speed/traveling speed ratio resulted in coarser grain in the stir zone. The stir zone grain size changed significantly, depending on the heat input and strain caused by plastic deformation [16]. Although with increasing rotation speed, the plastic deformation was increased, it can be seen that strain stored in the stir zone only negligibly affected the evolution of the grain structure in the stir zone during FSW. Therefore, heat input was considered to be a very important factor in the stir zone grain size of these welds.

Fig. 4 Optical metallography images of stir zone

Fig. 5 Micro-hardness distributions at different aging periods

The micro-hardness distributions of samples A and C measured along the mid-thickness of joints at different aging periods after FSW are shown in Fig. 5. The base material AA7075-T6 and AA5086-H32 demonstrated average Vickers micro-hardness values of about HV 165 and HV 86, respectively. The hardness of stir zone varied according to the ratio mix of AA5086 and AA7075. According to Figs. 2(a) and (c), the right side and left side of stir zone (Retreating side and Advancing side) consisted of AA7075 and AA5086 alloys, respectively. Therefore, hardness value in the right side of the stir zone in sample A was related to AA7075 alloy. It is clear that a softened region consisting of the stir zone (SZ), thermo-mechanically affected zone (TMAZ) and heat affected zone (HAZ) was created in both FSW joints made with and without heat sink conditions. It can be seen that the minimum hardness value achieved on AA5086 side of joints and the significant hardness reduction began at TMAZ/HAZ interval of the advancing and retreating sides. The increase in micro-hardness value after 180 d of natural aging within the SZ and TMAZ of the AA7075 side in comparison to micro-hardness value of these zones in as-welded condition was noticeable. However, no obvious changes were observed in the SZ, TMAZ and HAZ of AA5086 side. The change in hardness in the AA7075 side of welded samples can be attributed to re-precipitation after natural aging. The softened region in welds performed with heat sink condition was remarkably narrowed, and the minimum hardness of AA5086 side increased but the minimum hardness of AA7075 side decreased in as-welded samples in comparison with the joints without heat sink. The hardness changes in FSWed age hardenable and non-age hardenable aluminium alloys was synthetically controlled by precipitate distribution, dislocation density, grain size and solid solution [21], which were all affected by heat sink condition employed in the present study. The rapid cooling made by heat sink resulted in finer stir zone grain in the AA5086 side and higher amount of solid solution in the AA7075 side. As can be seen in Fig. 5, higher amount of solid solution during rapid cooling of welds produced higher driving force for increasing hardness due to re-precipitation in the AA7075 side during natural aging. The increasing hardnesses of stir zone in the AA7075 side of samples A and C after 180 d of natural aging were HV 16 and HV 23, respectively. Figure 6 shows the TEM images of base material, SZ and TMAZ of AA7075 side of samples B and D as-welded and after 180 d of natural aging. In the Al-Zn-Mg-(Cu) system (7xxx alloys), the super- saturated solid solution (SS) decomposed as GP zones (MgZn) → intermediate precipitates (η′) → secondary precipitation (MgZn2) [22]. The precipitation of GP zones and η′ semi-coherent phases produced the highest strengths. The base material of AA7075 (Fig. 6(a)) presented a fine distribution of GP zones, according to selected area diffraction pattern (SADP) taken along [110] zone axis as shown in Fig. 6(h), and η′ precipitates 10 to 90 nm in size. In the TMAZ of both samples, the strengthening precipitates experienced a significant coarsening and decrease in density. The precipitates in the TMAZ of sample B had a diameter of 70 to 200 nm, much larger than the size observed in the BM (Fig. 6(b)). In the TMAZ of sample D, the extent of precipitate coarsening reduced because the maximum diameter of the precipitates was reached (i.e., 105 nm) (Fig. 6(c)). It appears that the diffusion of solute atoms from aluminium matrix to precipitates becomes lower in the TMAZ when heat sink is employed during FSW, which restricts the coarsening of precipitates. The TEM images of the stir zone of samples B and D (Figs. 6(d) and (e)) in as-welded condition shows that strengthening precipitates in base material were dissolved while the round η′ and precipitates of approximately 20 to 60 nm in size remained. As shown in Fig. 6(e), the density of precipitates in the stir zone of sample D was lower than that in sample B. This may be due to lower cooling rate in sample B which resulted in significant precipitates coarsening and dissolution. As seen, after natural aging, a large number of round type and rod shape precipitates re-precipitated onto the dislocations and undissolved precipitates. The density of precipitates in the stir zone of sample D due to higher driving force for natural aging was more than that in sample B. Considering the size and morphology of the precipitates, the re-precipitation of η′ was responsible for the increase in the micro-hardness in the stir zone after natural aging.

and η′ semi-coherent phases produced the highest strengths. The base material of AA7075 (Fig. 6(a)) presented a fine distribution of GP zones, according to selected area diffraction pattern (SADP) taken along [110] zone axis as shown in Fig. 6(h), and η′ precipitates 10 to 90 nm in size. In the TMAZ of both samples, the strengthening precipitates experienced a significant coarsening and decrease in density. The precipitates in the TMAZ of sample B had a diameter of 70 to 200 nm, much larger than the size observed in the BM (Fig. 6(b)). In the TMAZ of sample D, the extent of precipitate coarsening reduced because the maximum diameter of the precipitates was reached (i.e., 105 nm) (Fig. 6(c)). It appears that the diffusion of solute atoms from aluminium matrix to precipitates becomes lower in the TMAZ when heat sink is employed during FSW, which restricts the coarsening of precipitates. The TEM images of the stir zone of samples B and D (Figs. 6(d) and (e)) in as-welded condition shows that strengthening precipitates in base material were dissolved while the round η′ and precipitates of approximately 20 to 60 nm in size remained. As shown in Fig. 6(e), the density of precipitates in the stir zone of sample D was lower than that in sample B. This may be due to lower cooling rate in sample B which resulted in significant precipitates coarsening and dissolution. As seen, after natural aging, a large number of round type and rod shape precipitates re-precipitated onto the dislocations and undissolved precipitates. The density of precipitates in the stir zone of sample D due to higher driving force for natural aging was more than that in sample B. Considering the size and morphology of the precipitates, the re-precipitation of η′ was responsible for the increase in the micro-hardness in the stir zone after natural aging.

Fig. 6 TEM bright field images of different zones of AA7075 side in samples B and D

Figure 7 shows the residual stress profile of welded samples with the highest heat input with and without heat sink conditions, that is, samples D and B, respectively. As shown in Fig. 7, for both samples, the longitudinal residual stresses were tensile in the weld with the external regions subjected to compressive stresses. The overall behaviour of transversal residual stress was similar to the longitudinal residual stress, but the weld centre line was subjected to compressive stresses. The residual stress profiles of longitudinal and transverse direction were asymmetric and the maximum tensile residual stress occurred in the retreating side. The asymmetric nature of the friction stir welding process and different material properties of AA5086 and AA7075 resulted in asymmetric residual stress profile. It can be seen that sample B with higher amount of heat input than sample D welded under heat sink demonstrated the lower and more width tensile residual stress. The results of longitudinal residual stress measured in samples B and D after 1 and 180 d of natural aging are shown in Fig. 7(c). It can be seen that there existed noticeable decrease in the residual stress from 1 to 180 d of natural aging within SZ and TMAZ of AA7075 side. The residual stress in the AA5086 side did not show noticeable changes. The residual stress changes in the AA7075 side may be attributed to the microstructural modification during natural aging phenomena. This microstructural modification can cause stress relaxation. As seen, the decrease in the residual stress after 180 d of natural aging in sample B welded without heat sink was lower than that in sample D.

Fig. 7 Residual stresses profile of samples B and D

Figure 8 shows the effect of natural aging on transverse tensile test samples. All tensile specimens fractured in the TMAZ of the AA5086 side having a minimum hardness were observed. Although the strength of all samples continuously increased as the welding heat input decreased, the samples welded with heat sink demonstrated greater strength. It can be said that the greater strength of samples welded using heat sink was related to lower peak temperature and higher hardness of the joints made with heat sink. As seen, natural aging did not have noticeable effect on joint strength. A comparison of the microhardness profiles and tensile strengths indicated that there exited a correlation between the tensile strength and the minimum value in the microhardness profile. There was no change in the minimum hardness in the hardness profile with natural aging. This is not surprising since the hardness and strength in non-age hardenable AA5086 alloy were related to heat input and strain rate during FSW.

Fig. 8 Mechanical properties of welded samples according to results of tensile tests for different aging periods after welding: (a) Yield stress; (b) Tensile strength

4 Conclusions

1) In welds performed without heat sink, the stir zone was dominated by AA5086 and the amount of AA7075 increased in the stir zone as heat input increased. Also, joints produced without heat sink exhibited a stir zone which consisted of a higher amount of AA7075 than those produced with heat sink.

2) In each series of welds, the grain size of the stir zone on the AA5086 side was coarser than that of the AA7075 side. Furthermore, grain size of the stir zone in welds made with heat sink was finer than that without heat sink in similar welding parameters.

3) The softened region in welds performed with heat sink condition was remarkably narrowed, and the minimum hardness of AA5086 side increased but the minimum hardness of AA7075 side decreased in as-welded samples when compared with joints without heat sink. Coarsening and dissolution of the strengthening precipitates present in the AA7075 base metal resulted in softening in the weld zone of AA7075 side. Besides, reprecipitation of η′ precipitates resulted in increase of micro-hardness in the SZ of AA7075 side after natural aging.

4) In all welds, there was noticeable decrease in the residual stress from 1 to 180 d of natural aging within SZ and TMAZ of AA7075 side. However, the residual stress in the AA5086 side did not exhibit noticeable changes. The decrease in residual stress after 180 d natural aging in samples welded without heat sink was lower than that performed with heat sink.

5) The strength of all samples continuously increased as the welding heat input decreased. Besides, the samples welded with heat sink demonstrated greater strength. The tensile strength of welds was a function of minimum value in microhardness profile.

References

[1] THOMAS W M, NICHOLA E D, NEEDHAM E D, MURCH E D, TEMPLESMITH P, DAWES C J. Friction Stir Welding, International Patent Application No.PCT/GB92102203 and Great Britain Patent Application No. 9125978.81991 [P]. 1991-09-22.

[2] BALA SRINIVASAN P, DIETZEL W, ZETTLER R, DOS SANTOS J F, SIVAN V. Stress corrosion cracking susceptibility of friction stir welded AA7075-AA6056 dissimilar joint [J]. Materials Science and Engineering A, 2005, 392: 292-300.

[3] CAVALIERE P, PANELL F. Effect of tool position on the fatigue properties of dissimilar 2024-7075 sheets joined by friction stir welding [J]. Journal of Materials Processing Technology. 2008, 206: 249-255.

[4] STEUWER A, PEEL M J, WITHERS P J. Dissimilar friction stir welds in AA5083-AA6082: The effect of process parameters on residual stress [J]. Materials Science and Engineering A, 2006, 441: 187-196.

[5] CAVALIERE P, NOBILE R, PANELLA F W, SQUILLACE A. Mechanical and microstructural behaviour of 2024–7075 aluminium alloy sheets joined by friction stir welding [J]. International Journal of Machine Tools and Manufacture, 2006, 46: 588-594.

[6] KIM S, LEE C G, KIM S J. Fatigue crack propagation behavior of friction stir welded 5083-H32 and 6061-T651 aluminum alloys [J]. Materials Science and Engineering A, 2008, 478: 56-64.

[7] JAMSHIDI AVAL H. Influences of pin profile on the mechanical and microstructural behaviors in dissimilar friction stir welded AA6082– AA7075 butt Joint [J]. Materials and Design, 2015, 67: 413-421.

[8] ILANGOVAN M, RAJENDRA BOOPATHY S, BALASUBRAMANIAN V. Microstructure and tensile properties of friction stir welded dissimilar AA6061-AA5086 aluminium alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1080-1090.

[9] ACERRA F, BUFFA G, FRATINI L, TROIANO G. On the FSW of AA2024-T4 and AA7075-T6 T-joints: An industrial case study [J]. Int J Adv Manuf Technol, 2010, 48: 1149-1157.

[10] DA SILVA A A M, ARRUTI E, JANEIRO G, ALDANONDO E, ALVAREZ P, ECHEVERRIA A. Material flow and mechanical behaviour of dissimilar AA2024-T3 and AA7075-T6 aluminium alloys friction stir welds [J]. Materials and Design. 2011, 32: 2021-2027.

[11] IPEKOGLU G,  G. Effects of initial temper condition and postweld heat treatment on the properties of dissimilar friction-stir- welded joints between AA7075 and AA6061 aluminum alloys [J]. Metallurgical and Materials Transactions A, 2014, 45: 3074-3087.

G. Effects of initial temper condition and postweld heat treatment on the properties of dissimilar friction-stir- welded joints between AA7075 and AA6061 aluminum alloys [J]. Metallurgical and Materials Transactions A, 2014, 45: 3074-3087.

[12] GUO J F, CHEN H C, SUN C N, BI G, SUN Z, WEI J. Friction stir welding of dissimilar materials between AA6061 and AA7075 Al alloys effects of process parameters [J]. Materials and Design, 2014, 56: 185-192.

[13] PALANIVEL R, KOSHY MATHEWS P, MURUGAN N, DINAHARAN I. Effect of tool rotational speed and pin profile on microstructure and tensile strength of dissimilar friction stir welded AA5083-H111 and AA6351-T6 aluminum alloys [J]. Materials and Design, 2012, 40: 7-16.

[14] SONG You-bao, YANG Xin-qi, CUI Lei, HOU Xiao-peng, SHEN Zhi-kang, XU Yan. Defect features and mechanical properties of friction stir lap welded dissimilar AA2024–AA7075 aluminum alloy sheets [J]. Materials and Design, 2014, 55: 9-18.

[15] COLE E G, FEHREBACHER A, DUFFIE N A, ZINN M R, PFEFFERKORN F E, FERRIER N J. Weld temperature effects during friction stir welding of dissimilar aluminum alloys 6061-T6 and 7075-T6 [J]. Int J Adv Manuf Technol, 2014, 71: 643-652.

[16] KASMAN  YENIER Z. Analyzing dissimilar friction stir welding of AA5754/AA7075 [J]. Int J Adv Manuf Technol, 2014, 70: 145-156.

YENIER Z. Analyzing dissimilar friction stir welding of AA5754/AA7075 [J]. Int J Adv Manuf Technol, 2014, 70: 145-156.

[17] SAEIDI M, MANAFI B, BESHARATI GIVI M K, FARAJI G. Mathematical modeling and optimization of friction stir welding process parameters in AA5083 and AA7075 aluminum alloy joints [J]. Proceedings of the Institution of Mechanical Engineers (Part B) Journal of Engineering Manufacture, 2015, DOI: 10.1177/ 0954405415573697.

[18] SHOJAEEARD M H, BEHNAGH R A, AKBARI M, BESHARATI GIVI M K, FARHANI F. Modelling and Pareto optimization of mechanical properties of friction stir welded AA7075/AA5083 butt joints using neural network and particle swarm algorithm [J]. Materials and Design, 2013, 44: 190-198.

[19] SATO Y S, PARK S H C, MICHIUCHI M, KOKAWA H. Constitutional liquation during dissimilar friction stir welding of Al and Mg alloys [J]. Scripta Materialia, 2004, 50: 1233-1236.

[20] PRASAD Y V R K, SASIDHARA S. Hot working guide: A compendium of processing maps [M]. Metals Park: ASM International, 1997.

[21] LIU Hui-jie, ZHANG Hui-jie, HUANG Yong-xian, YU Lei. Mechanical properties of underwater friction stir welded 2219 aluminum alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20: 1387-1391.

[22] LORIMER G W, NICHOLSON R. Further results on the nucleation of precipitates in the Al-Zn-Mg system [J]. Acta Metallurgica, 1966, 14: 1009-13.

Jamshidi Aval HAMED

Mechanical Engineering, Babol University of Technology, Shariati Avenue, Babol 484, Iran

摘 要:研究焊接热输入和后续热处理对时效硬化AA7075-T6合金和应变硬化AA5086-H32合金异种搅拌摩擦焊接接头显微组织和力学性能的影响。采用X射线残余应力分析、拉伸测试、光学金相分析以及透射电子显微分析研究工艺参数对焊接接头的影响。结果表明,与其他焊接接头相比,无散热片焊接的接头搅拌区更均匀。在所研究的自然时效时间范围内,焊接接头在快速冷却过程中高的固溶度将产生更大的驱动力,这也导致在自然时效过程中,AA7075的硬度增加。自然时效使AA7075搅拌区和热力影响区的残余应力减小10~25 MPa。该影响在无散热片焊接的接头中明显减小。此外,自然时效对接头强度无明显影响。

关键词:搅拌摩擦焊;异种铝合金;热处理;热输入

(Edited by Yun-bin HE)

Corresponding author: Jamshidi Aval HAMED; E-mail: h.jamshidi@nit.ac.ir

DOI: 10.1016/S1003-6326(17)60193-6