Preparation and mechanical properties of TLCP/UP/GF in-situ hybrid composites

YU Xian-bao(于贤保)1, 2, WEI Chun(韦 春)1, 2, LU Shao-rong(陆绍荣)1, 2, YU Jing-hong(虞锦洪)1, 2,

XU Deng(徐 灯)1, 2, LU Chi-hua(卢炽华)1, 2

1. Department of Material and Chemical Engineering, Guilin University of Technology,Guilin 541004, China;

2. Key Laboratory of Nonferrous Materials and New Processing Technology, Ministry of Education, Guilin University of Technology, Guilin 541004, China

Received 10 April 2006; accepted 25 April 2006

Abstract: One kind of novel reactive thermotropic liquid crystalline polymer-methacryloyl copolymer (LCMC) containing polyester mesogenic units was synthesized. Its structure, morphology and properties were investigated systemically by Ubbelohde viscometer, differential scanning calorimetry (DSC), Fourier transform infrared spectroscopy (FTIR), wide-angle X-ray diffractometry (WAXD) and polarizing optical microscopy (POM). The results indicate that it is one kind of nematic thermotropic liquid crystal polymer (TLCP). The impact strength, bending strength and the morphologies of impact fracture surface of LCMC, unsaturated polyester (UP) and glass fiber (GF) in-situ hybrid composites were studied by Izod impact tester, universal testing machine and scanning electron microscopy (SEM), respectively. The results show that the impact and bending strength of composites containing LCMC are improved, especially the composites containing 5% LCMC increases most obviously. These results with SEM results reveal that LCMC plays an important role in the improvement of interfacial adhesive between matrix and fiber.

Key words: thermotropic liquid crystalline polymer; in-situ hybrid composite; unsaturated polyester; mechanical properties

1 Introduction

Unsaturated polyester resins (UPs) as one kind of thermosetting material, play an important role in the development of all kinds of composites because of their cheap price, light mass and versatility [1-3]. They are used in a very wide range of products for our daily life, for example, some structure parts of automobile, coating materials, engineering materials, construction and electrical application, and they are the most commonly used matrix materials for fiber-reinforced plastics [4-8], but they have some weak points, such as high sensitive to hydrolysis, brittle [9, 10]. Usually, the cured unmodified UPs have low strength and elongation at break, and are subjective to stress cracking and brittle fracture, while in-situ composites and in-situ hybrid composites are two ways to improve the performance of materials [11, 12].

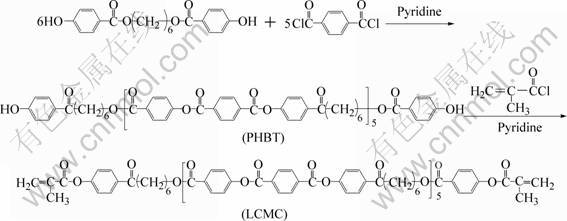

In this paper, in order to improve the mechanical properties of unsaturated polyester by the addition of TLCP, one kind of reactive TLCP was synthesized through the reaction between liquid crystalline polyester, polyhexamethylene-bis-(4-oxybenzoates)-terephthaloyl (PHBT), with the monomer of methacryloyl chloride (See Scheme 1). It was hoped that the double bond on the chains of LCMC might take part in the curing reaction with unsaturated bonds in UP after curing and thus improve the mechanical performances of UP.

2 Experimental

2.1 Materials

Methyl 4-hydroxybenzoate (AR), 1,6-hexandiol (AR), methacryloyl chloride (AR) and terephthaloyl dichloride(AR) were bought from supplier and used without further purification. The hexamethylene bis (4-hydroxybenzote) was synthesized according to Ref. [13] by molten-state transesterification of methyl 4-hydroxybenzoate and 1,6-hexandiol. UPS (molecular structure is shown is Scheme 2), GF (length: 5-6 mm,

Scheme 1 Synthesis route of LCMC

Scheme 2 Molecular structure of UP diameter: 10-13 μm) and other inorganic fillers were commercial products kindly provided by Guilin Special Plastics Plant, China.

2.2 Synthesis of PHBT

Bis(4-hydroxybenzote) (0.12 mol) and terephthaloyl dichloride (0.1 mol) were dissolved in 1,1,2,2-tetra- chloroethane (250 mL) and then about ten-droplet pyridine was added dropwise. The mixture was stirred at 160 ℃ for more than 10 h after the reaction, the mixture was poured into a beaker with 95% methanol, filtered, washed with water, and eventually put into vacuum oven at 80 ℃. The yield was 93.5 %, and the melting point of the product measured by DSC was 225.8 ℃.

2.3 Synthesis of PHBT

Bis(4-hydroxybenzote)(0.12 mol) and terephthaloyl dichloride (0.1 mol) were dissolved in 1,1,2,2-tetra- chloroethane (250 mL) and then about ten-droplet pyridine was added dropwise. The mixture was stirred at 160 ℃ for more than 10 h after the reaction, the mixture was poured into a beaker with 95% methanol, filtered, washed with water, and eventually put into vacuum oven at 80 ℃. The yield was 93.5 %, and the melting point of the product measured by DSC was 225.8 ℃.

2.4 Synthesis of LCMC

PHBT (10 mmol), methacryloyl chloride (25 mmol) were dissolved in 1,1,2,2-tetrachloroethane (150 mL) and then a minimum amount of pyridine was added dropwise. The mixture was stirred at 150 ℃ for 12 h, and then the products was poured in methanol, filtered, eventually dried in vacuum oven at 70 ℃. The yield was 90%, and the melting point characterized by DSC was 226.4 ℃.

2.5 Preparation of LCMC/UP/GF in-situ hybrid composites

TLCP, UP, GF, curing agent(styrene) and other fillers(zinc stearate, calcium carbonate, aluminum hydroxide) were simultaneously introduced into a mixing plastic mill, the ratios of TLCP were 0, 2.5, 5, 7.5, 10, 15% respectively. All kinds of specimens will be produced by compression-molding under a pressure of 10 MPa at 160 ℃ for 4 min for the consequent testing.

2.6 Characterization

The Intrinsic viscosities of the polymers were determined by an Ubbelohde viscometer with 1,1,2,2- tetrachloroethane as a solvent at 25℃.The DSC measurements were carried out by means of a Netzsch differential scanning calorimeter (model DSC-204), heated from 50 to 350 ℃ with 10K/min heating rate, in a nitrogen atmosphere. Infrared spectra were recorded on Nicolet 470 Fourier transform infrared spectroscopy. Phase transition and optical anisotropies were observed by Olympus BH-2 polarizing microscope equipped with a heating stage. The wide-angle X-ray diffraction instrument (WAXD) was BRUKER-AXS D8ADVANCE with copper and a wavelength of 1.540 ? , the scanning 2θ angle ranged between 3? and 30? with a step scanning rate of 4(?)/min.

The impact behavior of the specimens with dimension of 120 mm×10 mm×4 mm was determined using Izod impact machine(model JC-25) at room temperature; the bending strength was tested by Shimadzu universal testing machine (mode AG-201) with test rate of 2 mm/min.

3 Results and discussion

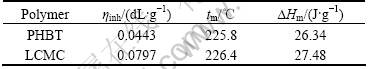

As both PHBT and LCMC are insoluble in the usual organic solvent, their intrinsic viscosities, ηinh, have to be measured in 1,1,2,2-tetrachloroethane. From Table 1, it is seen that the ηinh of LCMC is 0.079 7 dL/g, significantly higher than the value of PHBT(0.044 3 dL/g). Clearly, it can be attributed to the relative molecular mass increase as a result of the reaction between PHBT and methacryloyl chloride.

Table 1 Intrinsic viscosity and thermal properties of polymers

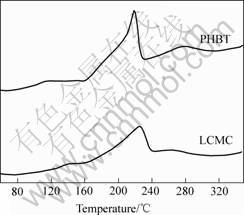

Fig.1 shows the DSC thermograms of PHBT and LCMC, from the heating curves, it can be seen that two endotherms at 225.8 and 226.4 ℃(listed in Table 1, respectively. The melting temperature of LCMC is higher than that of PHBT, due to the relative molecular mass of LCMC is higher than that of PHBT. Besides, the clearing temperature of the nematic phase and the cold crystallization transition of LCMC are not detected by DSC clearly.

Fig.1 DSC thermograms of PHBT and LCMC

The IR spectra of PHBT and LCMC are shown in Fig.2. For PHBT, the peak at 3 409 cm-1 is assigned to terminal O—H stretching of phenol groups, and the absorption at 1 716 cm-1 results from ester groups adjacent to benzene rings. The results agree with the results reported by TAN et al [14]. For LCMC, it can be seen clearly that the peak at 3 409 cm-1 disappears compared with PHBT, showing that the O—H has fully reacted with methacryloyl chloride.

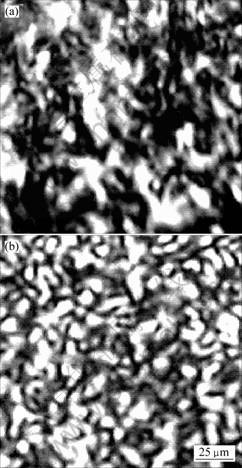

Fig.3 shows the optical micrographs of PHBT and LCMC measured under a polarizing optical microscope. The results indicate that they are highly birefringent and liquid crystalline. A threaded nematic texture is observed in two cases, especially in LCMC. PHBT starts to melt and to form bright regions at a temperature higher than 220 ℃, and LCMC at higher than 228 ℃. The liquid

Fig.2 FTIR spectra of PHBT and LCMC

Fig.3 Polarizing optical micrographs of PHBT(a) and LCMC(b) at 250 ℃

crystalline phase domain of PHBT and LCMC detected by POM are 220-271 ℃ and 228-290 ℃, respectively.

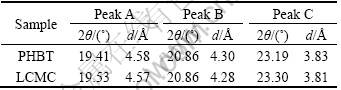

The WAXD measurement plots are shown in Fig.4 and some parameters are summarized in Table 2. It can be seen that both PHBT and LCMC have one group of low intensity diffraction peaks located at the range of 19-25°of 2θ angle. These indicate that there are some crystal parts in these two kinds of polymers except the amorphous parts. We can also see that the position of diffraction peaks and interplanar spacing (d) values of two polymers are similar, illustrating that the two polymers attribute to one crystal systems. The d values of LCMC are smaller than these values of PHBT due to the crystal degree increase little because of the introduction of methacryloyl group. These results agree well with the results analyzed by POM.

Fig.4 WAXD curves of PHBT and LCMC

Table 2 WAXD results of PHBT and LCMC

It is understood that the mechanical properties of composites are determined by the compatibility and the interfacial adhesion between the TLCP domains and the polymer matrix[15]. Thus, the measurement of mechanical properties of composites can provide information about the compatibility of TLCP/UP. The impact strength, bending strength and blending modules are listed in Table 3. It can be found that the impact strength of composites with LCMC is higher than that without LCMC and the impact strength value of composite with 5% LCMC is 5.7 MPa, 3.1 MPa higher than that of composites without LCMC(2.6 MPa), increased by about 114%. The values of bending strength, modules of composites indicate the addition of LCMC can improve the mechanical properties of composites, too. The bending strength and modules of composites containing 5% LCMC are increased by 56.6% and 29.5%, respectively. The results attribute to the improvement of compatibility of LCMC /UP because of the crosslink reaction between LCMC and UP and the reinforcement of LCP fibril formed in the process.

Table 3 Mechanical properties of composites

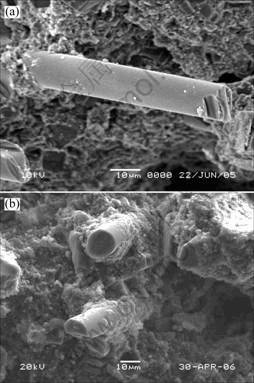

Fig.5 shows the SEM micrographs of the impact fracture surfaces of compression-molding specimens of composites. The fracture surfaces show remarkable difference between the composites with LCMC and that without LCMC. It is obvious that, the surface of glass fiber in composites is clear and free of any links to the unsaturated polyester matrix (Fig.5(a)). In contrast, in the composites containing 5% LCMC (Fig.5 (b)), there is much unsaturated polyester matrix linked to the fiber surface. It can be also found that the length of drawn glass fiber from matrix of composites without LCMC is longer than that containing 5% LCMC. These result from

Fig. 5 SEM micrographs of impact fracture surfaces of composites: (a) 0%TLCP; (b) 5%TLCP

the improvement of interfacial adhesion of fiber- unsaturated polyester. It also indicates that the fracture energy of composites has been improved with the addition of LCMC. This result agrees well with the results reported by PARK and JIN [16] and IBARRA and PA?OS [17].

4 Conclusions

One kind of reactive nematic thermotropic liquid crystalline polymer is synthesized successfully, which is used to improve the UP/GF composites. The impact strength and bending strength of composites with the LCMC are improved obviously, especially for the composites containing 5% LCMC, the impact and bending strength increase most. The addition of LCMC can improve the interfacial adhesion of matrix and GF, and then the mechanical properties are improved.

References

[1] LU M G, SHIM M J, KIM S W. Curing behavior of an unsaturated polyester system analyzed byAvrami equation [J]. Thermochim Acta, 1998, 323: 37-42.

[2] DE LA CABA K, GUERRERO P, ECEIZA A, et al. Kinetic and rheological studies of two unsaturated polyester resins cured at different temperatures [J]. Eur Polym J, 1997, 33 (1): 19-23.

[3] YU Xian-bao YU, FU Yu, XU Deng, et al. Effects of TLCP contents on the thermal and mechanical properties of TLCP/UP/GF in situ hybrid composites [A]. Proceedings of 2005 International Conference on Advanced Fibers and Polymer Materials [C]. Shanghai, 2005. 474-477.

[4] ZETTERLUND P B, GOSDEN R G, JOHNSON A F. New aspects of unsaturated polyester resin synthesis Part I: Modeling and simulation of reactant sequence length distributions in stepwise polymerization [J]. Polym Int, 2003, 52: 104-112.

[5] MESSORI M, TOSELLI M, POLATI F, TONELLI C, et al. Unsaturated polyester resins modified with poly (e-caprolactone)- perfluoropolyethers block copolymers [J]. Polymer, 2001, 42: 9877-9885.

[6] SANCHEZ E M S, ZAVAGLIA C A C, FELISBERTI M I. Unsaturated polyester resins: influence of the styrene concentration on the miscibility and mechanical properties [J].Polymer, 2000, 41: 765-769.

[7] MASEGOSA R M, NAVA D, GARCIA S, et al. Thermal behavior of unsaturated polyester resins +poly (3-octylthiophene) [J]. Thermochim Acta, 2002, 385: 85-94.

[8] LEE G W, EE N J, JANG J, et al. Effect of surface modification on the resin-transfer moulding (RTM) of glass-fibre/unsaturated- polyester composites [J].Compos Sci Technol, 2002, 62:9-16.

[9] VELETTE L, HSU C P. Polyurethane and unsaturated polyester hybrid networks; 2.Influence of hard domain on mechanical properties [J].Polymer, 1999, 40: 2059-2070.

[10] NAVA D, SALOM C, PROLONGO M G, et al. Thermal properties and interactions on blends of poly (e-caprolactone) with unsaturated polyester resin [J]. J Mate Proecess Tech, 2003, 143-144: 171-177.

[11] KISS G. In-situ composites: Blends of isotropic polymers and thermotropic liquid crystalline polymers [J]. Polym Eng Sci, 1987, 27(6): 410-423.

[12] HE Jia-song, ZHANG Hong-zhi, WANG Yu-li, et al. In-situ hybrid composites containing reinforcements at two orders of magnitude [J]. Polymer, 1997, 38(16): 4279-4283.

[13] TAN Song-ting, WEI Chun, WANG Yong, et al. Synthesis and characterization of liquid crystalline polymer and epoxy block copolymer [J]. Acta Polym Sin, 2002, 2: 249-252. (In Chinese)

[14] TAN Song-ting, WEI Chun, WANG Xia-yu, et al. Blends of liquid crystalline polyester-polyurethane and epoxy: Preparation and properties [J]. J Appl Polym Sci, 2003, 88: 783-787.

[15] LIU Hua, LIAO Kin. Tensile behavior and morphology studies of glass-fiber-reinforced polymeric in situ hybrid composites [J]. J Appl Polym Sci, 2004, 94: 211-221.

[16] PARK S J, JIN J S. Effect of silane coupling agent on interphase and performance of glass fibers/unsaturated polyester composites [J]. J Colloid Interface Sci, 2001, 242: 174-179.

[17] IBARRA L, PA?OS D. Dynamic properties of thermoplastic butadiene-styrene (SBS) and oxidized short carbon fiber composite materials [J]. J Appl Polym Sci, 1998, 67:1819-1826.

(Edited by YUAN Sai-qian)

Foundation item: Project(50473060) supported by the National Natural Science Foundation of China

Corresponding author: WEI Chun; Tel: +86-773-5896671; Fax: +86-773-5896671; E-mail: glweichun@glite.edu.cn