文章编号:1004-0609(2013)10-2730-08

往复挤压镁合金再结晶组织表征

杨文朋1,郭学锋1,任 昉2,梁世何1

(1. 河南理工大学 材料科学与工程学院,焦作 454000;

2. 河南理工大学 经济管理学院,焦作 454000)

摘 要:利用往复挤压在300~360 ℃细化铸态Mg-6Zn-1Y-1Ce合金组织,研究其组织演变和挤压参数对再结晶组织的影响。结果表明:往复挤压合金横截面边缘存在不均匀环,由靠近筒壁的细晶环和粗晶环组成,其宽度随着挤压温度提高而减小;细晶环是由边缘区域与挤压筒壁摩擦而发生第二轮再结晶所致,粗晶环是由再结晶晶粒长大所致;合金晶粒度由变形速率和温度决定,经340 ℃挤压合金晶粒最细,平均粒径8.2 μm。除边缘外,往复挤压过程中合金在挤压阶段发生一次再结晶,墩粗过程和后续多道次挤压变形都是通过晶界滑移实现。因此,随着挤压道次的增加,保温时间随之延长,晶粒随之被粗化。

关键词:镁合金;往复挤压;再结晶;挤压参数

中图分类号:TG146.2 文献标志码:A

Characterization of recrystallized microstructure of reciprocating extruded magnesium alloy

YANG Wen-peng1, GUO Xue-feng1, REN Fang2, LIANG Shi-he1

(1. School of Materials Science and Engineering, Henan Polytechnic University, Jiaozuo 454000, China;

2. School of Economic and Management, Henan Polytechnic University, Jiaozuo 454000, China)

Abstract: The microstructure of as-cast Mg-6Zn-1Y-1Ce alloy was refined by reciprocating extrusion (REX) at the temperature range of 300-360 ℃, the microstructural evolution and the effect of extrusion parameters on recrystallized microstructure were investigated. The results show that the as-REXed alloys have an inhomogeneous ring on cross section, which consists of a fine-grain ring and a coarse-grain ring on the periphery. The width of the ring decreases with increasing the extrusion temperature. The fine-grain ring is attributed to the secondary recrystallization occurring because of friction between the periphery of sample and container wall, the coarse-grain ring is attributed to grain growth followed recrystallization. The grain size of REXed alloy is determined by deformation rate and temperature, a minimum grain size of 8.2 μm is obtained at 340 ℃. During REX process, recrystallization occurs only once during extrusion except for the periphery, the deformation processes during upsetting and subsequent multi-pass REX are achieved by grain boundary sliding. Therefore, with increasing REX passes, the holding-time is prolonged and grains coarsen.

Key words: magnesium alloy; reciprocating extrusion; recrystallization; extrusion parameter

镁合金是目前可应用的最轻的金属基结构材料,在汽车和航空航天工业使用量日益增多[1-2]。由于镁合金铸造性能好,大部分镁结构件是通过压铸方式生产[3]。然而铸造镁合金组织粗大、强度低、塑性差,产品形状尺寸和应用范围受到很大限制。与铸造镁合金相比,经过塑性加工的变形镁合金组织细小,具有优异的力学性能,更适用于制作大结构件并满足结构多样化的要求,显示出巨大的发展潜力[4]。往复挤压是集挤压和墩粗为一体的大塑性变形工艺,材料经过反复挤压和墩粗后可以获得足够大的应变量而没有破裂危险,变形后材料能恢复到原始尺寸,适合制备组织均匀的大块细晶合金[5]。长期以来,往复挤压被认为是最好的细化组织工艺之一,合金经过往复挤压后组织明显细化,强度和伸长率均有大幅提高[6-9]。虽然关于往复挤压合金组织和性能已有大量报道,然而已报道的文献[6-8]中,研究者通常将往复挤压合金直接正挤压出棒材进行研究,而单独的往复挤压组织和挤压参数对组织的影响鲜有关报道,因此限制了往复挤压工艺的进一步发展。本文作者以高强度Mg-6Zn- 1Y-1Ce合金[10]为对象,观察其往复挤压后的组织特征,分析合金在往复挤压过程中组织演变规律和变形机制,研究挤压道次和温度对合金组织的影响,为往复挤压工艺的优化和细晶镁合金的制备提供参考。

1 试验

使用纯Mg、纯Zn、Mg-47%Y和Mg-90%Ce中间合金颗粒在Ar+SF6气体保护环境中制备Mg-6Zn-1Y-1Ce合金,将熔体浇铸到d 52 mm的石墨模具中获得铸锭。将铸锭加工成d 50 mm的坯料用于挤压。往复挤压详细工艺见文献[5],在本研究中,挤压筒直径d0=50 mm,挤压颈直径dm=14 mm,每个挤压道次合金获得的真应变Δe=5.09 (Δe=4 ln(d0/dm)[5])。挤压温度范围为300~360 ℃,挤压前将坯料和挤压模具在挤压温度下保温60 min,使材料整体温度均匀。在1.28 MN压力下进行挤压,挤压过程中温度波动±5 ℃,各温度下挤压杆运动速度v和等效应变速率 (

( =

= [11],其中,

[11],其中, 是正挤压的等效应变速率;φ是凹模半角,为60°)列于表1。

是正挤压的等效应变速率;φ是凹模半角,为60°)列于表1。

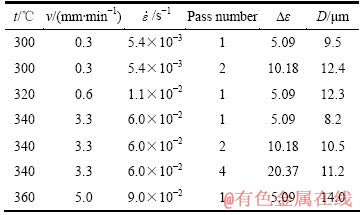

表1 往复挤压参数和晶粒尺寸

Table 1 REX parameters and grain sizes

金相试样经过打磨、抛光后腐蚀。使用Nikon Epiphot型光学显微镜(OM)观察组织,平均晶粒度使用截线法测量。

2 结果与分析

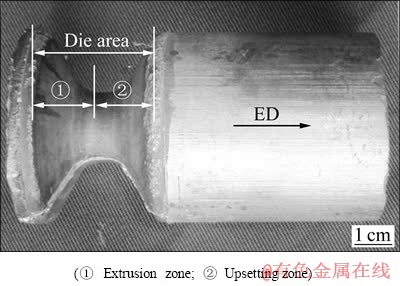

往复挤压试样表面光滑、有金属光泽且无裂纹、褶皱等缺陷。由于合金在墩粗后恢复到原始直径,所以附带凹模区(包括挤压区和墩粗区)的往复挤压试样呈杯状,实物照片如图1所示。

图1 往复挤压试样照片

Fig. 1 Photo of REXed sample

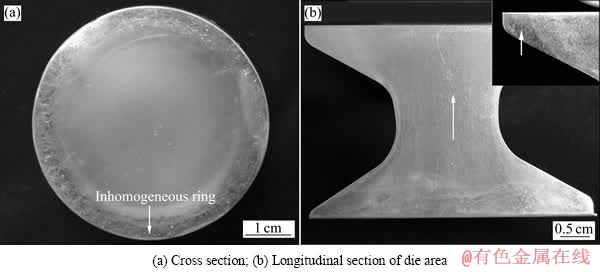

为研究往复挤压过程中组织演变规律,以300 ℃经1道次挤压合金为例进行剖析。图2所示为试样横截面和凹模区纵截面典型宏观组织。从横截面组织(见图2(a))可看出,试样边缘存在宽度约5 mm的环状不均匀组织,随着与边缘距离增加,合金组织逐渐均匀,宏观上很难分辨出组织差别。合金在挤压区(见图2(b))的变形与正挤压相似,经过颈缩变形后即被墩粗,可隐约看出挤压流线分布。在挤压筒和凹模交界处(见图2(b)中插图)存在不均匀组织,该区域宽度约为5 mm,与横截面(见图2(a))不均匀环对应。随着向中心区域 过渡,组织趋于均匀。

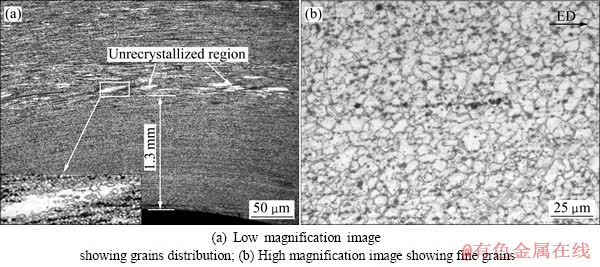

图3所示为凹模区纵截面显微组织。由图3(a)可知,试样凹模区组织与正挤压合金相似,在靠近凹模一侧,挤压流线以凹模为轮廓弯曲,随着与对称轴距离减小,弯曲的弧线逐渐转变为平直。在靠近凹模的区域,合金发生了充分的动态再结晶,组织由均匀细小的等轴晶组成(见图3(b)),平均尺寸为8.7 μm。在距离凹模细颈处约1.3 mm处有许多亮白色区域,这些区域是未发生再结晶的区域,沿挤压方向被拉长且边界呈锯齿状(见图3(a)插图)。对凹模颈缩边缘区域 和中心区域组织分析发现,各区域再结晶晶粒尺寸无差别。

图2 往复挤压试样宏观组织

Fig. 2 Macrostructures of REXed sample

图3 300 ℃往复挤压试样凹模区纵截面组织

Fig. 3 Longitudinal section microstructures of die area of REXed sample processed at 300 ℃

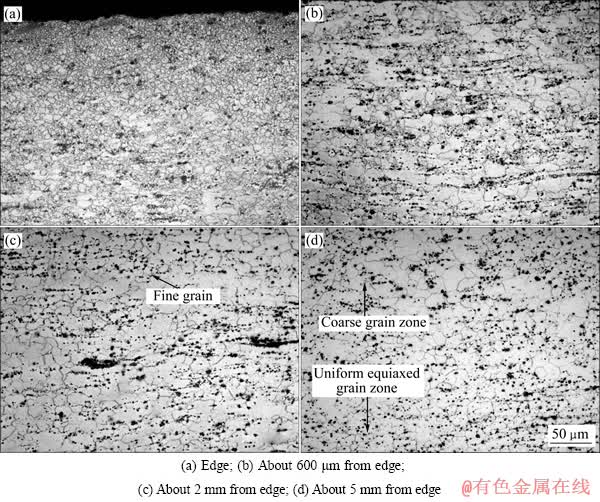

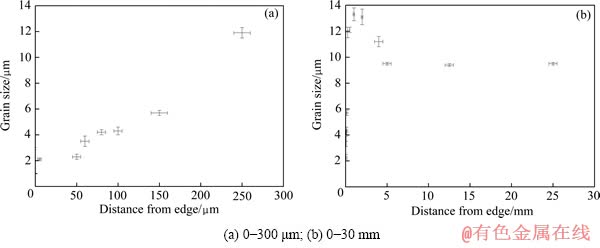

图4所示为试样横截面从边缘到中心区域的组织演变,图5所示为晶粒尺寸随着与边缘距离增加的变化图。由图4(a)和5(a)可知,靠近边缘区域存在一层细小的等轴晶区,晶区宽度约为100 μm,紧靠挤压筒壁处晶粒平均尺寸约为2.1 μm。随着与边缘距离增 加,晶粒逐渐粗化,距离边界100 μm处,晶粒平均尺寸约为4.3 μm,距离边界250 μm处,平均晶粒尺寸已达11.9 μm。另一方面,随着与边缘距离的增加,组织中细小晶粒体积分数逐渐减小,粗大晶粒体积分数逐渐增加。在距边缘约为600~870 μm之间区域中(见图4(b)),大部分的晶粒为粗晶,粗大晶粒之间还夹杂着许多细小等轴晶,如图4(b)中箭头所示,该区域内平均晶粒尺寸约为13.0 μm。当距离边缘超过1 mm时,组织基本上由粗晶组成,很难发现细小等轴晶。在距离边缘1~4 mm的区域中,组织基本上由相对均匀的粗晶组成,在不均匀环的中心区域(距离边缘约2 mm)(见图4(c)),平均晶粒尺寸约为13.3 μm。在距离边界5 mm区域中,粗晶逐渐向均匀细小的等轴晶组织转变。图4(d)所示为粗晶和均匀等轴晶过渡区域典型组织。在均匀等轴晶区域,合金晶粒尺寸变化不大,平均晶粒尺寸约为(9.5±0.2) μm,整个试样各区域晶粒尺寸随着距边缘距离的变化如图5(b)所示。

研究表明,各挤压温度下试样均存在不均匀环,而且不均匀环是由靠近挤压筒壁的细晶环和粗晶环组成;随着挤压温度升高,环宽度变窄,320、340和360 ℃挤压试样不均匀环宽度分别约为1.6 mm、580 μm和540 μm,细晶环宽度均在30 μm左右,主要是粗晶环宽度随着温度增加而减小。

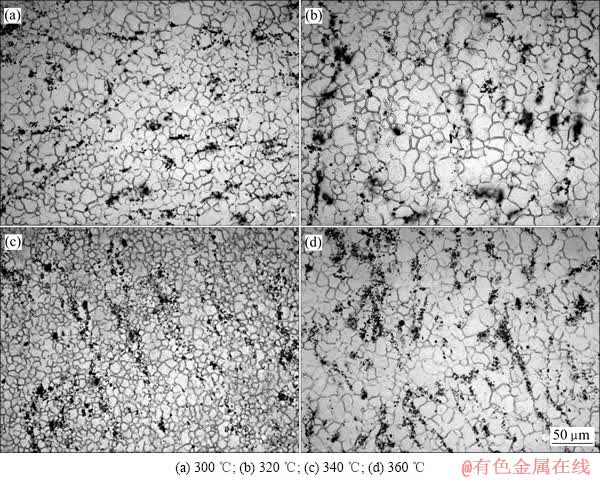

图6所示为300~360 ℃挤压试样金相组织。由图6可知,各温度下合金均发生了充分的再结晶,组织由均匀的等轴晶组成,平均晶粒尺寸见表1。从总体来看,随着挤压温度的提高,晶粒尺寸随之增加。340 ℃挤压合金晶粒最小,平均晶粒尺寸约为8.2 μm。经往复挤压后,破碎的第二相颗粒仍呈网状分布,而且随着挤压温度的提高,均匀度并无明显改善。

图4 300 ℃往复挤压试样横截面组织演变

Fig. 4 Microstructural evolutions of cross section of REXed sample processed at 300 ℃

图5 距边缘距离与晶粒尺寸之间的关系

Fig. 5 Relationship between distance from edge and grain size

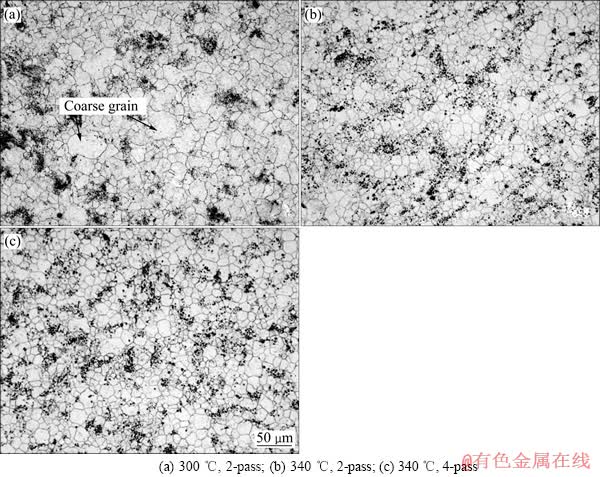

结合以上观察结果,在研究挤压道次对合金组织影响时,将温度确定为300 ℃和340 ℃。图7所示为经300 ℃和340 ℃多道次挤压试样组织。由图7(a)可知,300 ℃下经2道次挤压试样晶粒平均尺寸为12.4 μm,而且还可以观察到少许尺寸约为40 μm的粗大晶粒,如箭头所示。在340 ℃经2和4道次挤压试样晶粒平均尺寸分别为10.5 μm 和11.2 μm,最大晶粒小于28 μm。从图7可以看到,经过挤压后,破碎的第二相颗粒具有网状分布特征,随着挤压道次的增加,颗粒分布的均匀度略有提高。

图6 不同温度往复挤压试样横截面组织

Fig. 6 Cross section microstructures of REXed samples at various temperatures

图7 300 ℃和340 ℃经2道次和4道次挤压试样横截面组织

Fig. 7 Cross section microstructures of REXed samples at 300 ℃and 340 ℃ for 2-pass and 4-pass

3 讨论

3.1 变形机制

通常认为[12-14],往复挤压过程中合金会发生多次再结晶,即在挤压过程合金会发生第一次再结晶,在墩粗过程中合金在正应力和剪切应力作用下,再结晶晶粒内位错不断增殖,位错和空位密度会有大幅升高,当贮能达到临界值时,再次发生再结晶。然而,通过组织分析,作者认为在墩粗过程合金并未发生第二轮动态再结晶,其主要原因如下:

1) 300 ℃挤压合金组织中未再结晶区域具有锯齿状边界,再结晶机制为晶界弓出形核的动态再结晶机制[15](旋转动态再结晶机制也会产生类似的组织特征,但旋转动态再结晶只在具有粗大再结晶晶粒组织和较强基面纤维织构的镁合金轧制变形时才能观察到,而且未再结晶区域没有明显被拉长的现象[16]),若合金在墩粗过程中发生了新一轮的再结晶,在组织中可观察到晶界弓出形核现象,即原始晶粒(上轮再结晶晶粒)周围会存在一些细小晶粒。由于挤压后马上退模并取出试样,所以在靠近凹模的区域再结晶晶粒受温度影响较小,即使再结晶晶粒有所长大,也可以发现一定数量的细晶。然而,组织观察表明,往复挤压合金墩粗后的晶粒尺寸和形貌与颈缩处相比无变化(见图3),墩粗区并未发现再次再结晶的细晶。

2) 往复挤压过程的计算机模拟结果表明[17],材料在中心区域流变速度最快,而在墩粗一侧,靠近挤压筒内壁,材料的运动速度最慢。以彩泥为原料模拟往复挤压过程发现[18],在墩粗一侧中心区域,虽然材料的流变速度最快,但是其变形量较小,而且局部区域、尤其是最中心区域垂直于挤压方向并不存在流动性;相对地,在靠近挤压筒内侧,虽然材料的流动速度较慢,但变形量较大,可观察到材料沿挤压方向明显地被拉长。当材料获得的变形量较小时,在塑性变形过程中,位错密度较低,材料获得的贮能就较小,所以,很难发生再一轮再结晶。而接触挤压筒壁的区域,则会再次发生再结晶。

3) 研究表明,在250~300 ℃范围内,镁合金晶界滑移激活能与晶界扩散激活能接近;在320~400 ℃范围内,镁合金晶界滑移激活能与晶格扩散激活能接近[19-21]。对于晶粒尺寸小于10 μm的镁合金,当变形温度较高时,原子自由能较大;当晶界滑移的激活能稍高于晶界扩散或/和晶格扩散激活能时,晶界会发生相对滑移。在300 ℃往复挤压时,当合金通过挤压颈缩区时,大部分区域已经发生动态再结晶,形成了约为8.7 μm的细小等轴晶。因此,在随后的墩粗过程中,细小的晶粒完全可以通过晶界滑移来实现。由于在墩粗过程中,材料的等效应变速率为2.7×10-3 s-1,即使在塑性变形过程中产生位错,位错也有充足的时间通过滑移或攀移至晶界,并被晶界吸收。

通过以上分析可知,在往复挤压过程中,实质上合金绝大部分只经历了一轮动态再结晶。对于挤压过程中未发生再结晶的区域,在墩粗过程中很难如细晶一样通过晶界滑移实现塑性变形,这些区域在后续变形过程会积累大量位错,并发生再结晶。所以墩粗后的试样很难发现未再结晶区域。

3.2 不均匀环

往复挤压合金横截面存在不均匀环,包括细晶环和粗晶环。对凹模区组织(见图3(a))分析可知,靠近凹模的区域再结晶最充分,组织由均匀细小的等轴晶组成,而不均匀环是在凹模区末端和挤压筒接触区域才开始出现(见图3(b)),因此,可以确定不均匀环是在墩粗最后阶段形成的。合金经墩粗充型后,随着挤压杆的推移,基本不发生塑性变形,由于整个挤压装置在继续加热,所以靠近挤压筒的区域温度较高,晶粒长大较明显,则会形成粗晶环。

细晶区的产生归因于合金与挤压筒之间的摩擦力作用。由于摩擦力作用,外层金属受到的剪切力较大,获得应变较大,从而发生了第二次再结晶。随着与边缘距离增加,材料受到的剪切力逐渐减弱,变形量逐渐减小,只有部分区域发生第二次再结晶,所以图4(b)中粗晶之间夹杂的细小晶粒为第二轮再结晶晶粒。并且随着向中心距离的推移,细小等轴晶的数量和面积分数逐渐减少。

由于摩擦力所致的细晶区宽度基本不变,所以不均匀环的宽度主要由粗晶区域决定。当挤压温度较低时,合金变形速率较慢(见表1),晶粒粗化区域受温度影响较大,环较宽,反之亦然。

3.3 晶粒度及挤压温度对组织的影响

Mg-6Zn-1Y-1Ce合金在300、340和370 ℃经正挤压后晶粒的平均尺寸分别为2.7、3.3和11.2 μm[10]。挤压比相同时,经过1道次往复挤压合金获得的真应变是正挤压的2倍,然而,300 ℃和340 ℃往复挤压合金晶粒平均尺寸分别为9.5 μm和12.3 μm。可见,应变量对晶粒度没有直接联系。一般而言,再结晶晶粒尺寸D由形核率N和生长速度v决定[22]:

(1)

(1)

形核率与应变速率有关,应变速率较大时,变形过程中产生的位错没有充足的时间抵消或被吸收,位错密度较高,再结晶形核率较大。再结晶晶粒生长速度与温度有关,温度提高,晶界扩散和晶界迁移能力增强,晶粒容易长大而导致晶粒粗化。因此,正挤压和往复挤压合金的晶粒尺寸差距主要是受应变速率的影响。其结果可用综合温度和应变速率的Zener- Hollomon参数方程进行描述[23]:

(2)

(2)

(3)

(3)

式中:Q为变形激活能;R为摩尔气体常数;T为变形温度;k和b均为常数。由式(2)和(3)可知,当挤压温度和应变速率确定时,合金的晶粒尺寸也是确定的。由于往复挤压时挤压的同时还受到墩粗反作用力的影响,所以合金变形速率非常小(表1)。(例如,300 ℃正挤压的应变速率约为往复挤压的30倍,分别0.16 s-1[10]和5.4×10-3 s-1)。当挤压力、温度和挤压比相同时,往复挤压合金晶粒受温度的影响而粗化,细化效果逊于正挤压合金的。

经300 ℃和320 ℃挤压时,挤压杆的运动速度分别为0.3 mm/min和0.6 mm/min,再结晶细晶有充足的生长时间,因此,最终晶粒大小可看作是该温度下平衡晶粒尺寸,与正挤压组织相比,差距很大。

当温度升高时,挤压速度明显提高,再结晶晶粒长大受温度影响程度降低,因此,340 ℃挤压合金晶粒比300 ℃和320 ℃时挤压合金的更细小。360 ℃时,晶界在高温驱动下迁移速度很快,再结晶晶粒迅速长大而粗化;同时,由于挤压速度提高,再结晶晶粒受温度影响很小,所以,360 ℃往复挤压合金晶粒大小与370 ℃正挤压合金晶粒大小接近。

3.4 挤压道次对组织的影响

通常认为,挤压道次增加再结晶次数也会增加,晶粒会越来越细[7-9, 13]。然而,对300 ℃和340 ℃不同挤压道次组织观察表明,晶粒随着挤压道次的增加而粗化。根据3.1节分析可知,合金只在通过凹模时经历一轮动态再结晶,而墩粗的充型过程是细晶通过晶界滑移实现的。如果合金在第2道次挤压时经历第二轮再结晶,则晶粒会更加细小,即使在高温下晶粒有所长大,晶粒也小于1道次挤压合金。因此,后续的往复挤压过程实质上也是细晶通过晶界滑移实现的。整个过程中晶粒长大是持续的,随着挤压道次增加晶粒会粗化。在多道次的挤压过程中,细晶会不断吸收位错或通过旋转以有利于合金的塑性变形,因此晶粒长大较缓慢。然而,如果挤压时等效应变速率过低,晶粒长大将成为主要的控制机制。例如,300 ℃挤压速度很慢,挤压时间过长,晶粒严重粗化,而且存在异常长大的粗晶(见图7(a))。

由以上分析可知,通过增加挤压道次来增加应变量不但不会使组织细化,反而由于长时间保温会使组织粗化。若要获得细晶组织,往复挤压需在较低温度和较快的应变速率下进行。

4 结论

1) 合金在往复挤压的挤压阶段发生一次再结晶,而墩粗过程是通过晶界滑移实现的。

2) 往复挤压试样横截面边缘存在不均匀环,不均匀环由靠近筒壁的细晶环和粗晶环组成,细晶环的形成归因于边缘区域与筒壁摩擦而发生第二轮再结晶,粗晶环归因于晶粒长大,不均匀环的宽度随挤压温度提高而减小。

3) 往复挤压合金再结晶晶粒尺寸与应变量无关,由变形速率和温度决定,要获得细晶粒组织,应采取合适的温度和变形速率。1.28×106 N挤压时,在340 ℃挤压试样晶粒最细,为8.2 μm。

4) 后续多道次挤压过程也是细晶通过晶界滑移实现的,随着挤压道次增加,保温时间增加,晶粒粗化。

REFERENCES

[1] ANYANWU IA, GOKAN Y, NOZAWA S, KAMADO S, KOJIMA Y, TAKEDA S, ISHIDA T. Heat resistant magnesium alloys for automotive powertrain applications[J]. Materials Science Forum, 2003, 419/422(I): 445-450.

[2] FROES F. Advanced metals for aerospace and automotive use[J]. Materials Science and Engineering A, 1994, 184(2): 119-133.

[3] FRIEDRICH HE, MORDIKE BL. Magnesium technology: Metallurgy, design data, applications[M]. Berlin Heidelberg: Springer Verlag, 2006: 144-218.

[4] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究、开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chi, MA Zheng-qing. Research, development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[5] ZRNIK J, DOBATKIN S,  I. Processing of metals by severe plastic deformation (SPD)—Structure and mechanical properties respond[J]. Metalurgija, 2008, 47(3): 211-216.

I. Processing of metals by severe plastic deformation (SPD)—Structure and mechanical properties respond[J]. Metalurgija, 2008, 47(3): 211-216.

[6] GUO X, SHECHTMAN D. Reciprocating extrusion of rapidly solidified Mg-6Zn-1Y-0.6Ce-0.6Zr alloy[J]. Journal of Materials Processing Technology, 2007, 187/188: 640-644.

[7] 郭学锋, 杨文朋, 宋佩维. 往复挤压Mg-4Al-2Si合金的高温拉伸性能[J]. 中国有色金属学报, 2010, 20(6): 1032-1038.

GUO Xue-feng, YANG Wen-peng, SONG Pei-wei. Elevated temperature tensile properties of Mg-4Al-2Si alloy prepared by reciprocating extrusion[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(6): 1032-1038.

[8] LEE S, CHEN YL, WANG H, YANG C F, YEH J W. On mechanical properties and superplasticity of Mg-15Al-1Zn alloys processed by reciprocating extrusion[J]. Materials Science and Engineering A, 2007, 464(1/2): 76-84.

[9] CHEN Y J, WANG Q D, ROVEN H J, LIU M P, KARLSEN M, YU Y D, HJELEN J. Network-shaped fine-grained microstructure and high ductility of magnesium alloy fabricated by cyclic extrusion compression[J]. Scripta Materialia, 2008, 58(4): 311-314.

[10] YANG Wen-peng, GUO Xue-feng. A high strength Mg-6Zn- 1Y-1Ce alloy prepared by hot extrusion[J]. Journal of Wuhan University of Technology, 2012, 28(2): 389-395.

[11] DIETER GE. Mechanical metallurgy[M]. Singapore: McGraw-Hill Book Company, 1988: 625-629.

[12] JIANG T, GUO XF, MA G. Microstructures and properties of reciprocating extruded as-cast ZK60 magnesium alloy[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(S1): s396-s399.

[13] LIN J, WANG Q, PENG L, ROVEN H J. Microstructure and high tensile ductility of ZK60 magnesium alloy processed by cyclic extrusion and compression[J]. Journal of Alloys and Compounds, 2009, 476(1/2): 441-445.

[14] 徐春杰, 郭学锋, 郑水云, 张忠明. 往复挤压高韧Mg-Zn-Y合金[J]. 材料工程, 2007(7): 16-20.

XU Chun-jie, GUO Xue-feng, ZHENG Shui-yun, ZHANG Zhong-ming. Mg-Zn-Y alloy with high elongation properties by reciprocating extrusion[J]. Journal of Materials Engineering, 2007(7): 16-20.

[15] AL-SAMMAN T, LI X, CHOWDHURY SG. Orientation dependent slip and twinning during compression and tension of strongly textured magnesium AZ31 alloy[J]. Materials Science and Engineering A, 2010, 527(15): 3450-3463.

[16] DEL VALLE JA,  MT, RUANO OA. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 68-78.

MT, RUANO OA. Texture evolution during large-strain hot rolling of the Mg AZ61 alloy[J]. Materials Science and Engineering A, 2003, 355(1/2): 68-78.

[17] 叶永南, 刘 君, 郭学锋, 徐春杰, 张忠明. 热力耦合数值模拟往复挤压AZ31成形过程[J]. 兵器材料科学与工程, 2007, 30(6): 10-13.

YE Yong-nan, LIU Jun, GUO Xue-feng, XU Chun-jie, ZHANG Zhong-ming. Numerical simulation on reciprocating extrusion of AZ31 alloy by thermal-mechanical coupling method[J]. Ordnance Material Science and Engineering, 2007, 30(6): 10-13.

[18] 郭学锋. 细晶镁合金制备方法及组织与性能[M]. 北京: 冶金工业出版社, 2010: 263-265.

GUO Xue-feng. Refined Mg alloys and their microstructures and properties[M]. Beijing: Metallurgical Industry Press, 2010: 263-265.

[19] CHUVIL’DEEV V, NIEH T, GRYAZNOV M, KOPYLOV V I, SYSOEV A N. Superplasticity and internal friction in microcrystalline AZ91 and ZK60 magnesium alloys processed by equal-channel angular pressing[J]. Journal of Alloys and Compounds, 2004, 378(1/2): 253-257.

[20] BUSSIBA A, BENARTZY A, SHTECHMAN A, LFERGAN S, KUPIEC M. Grain refinement of AZ31 and ZK60 Mg alloys—towards superplasticity studies[J]. Materials Science and Engineering A, 2001, 302(1): 56-62.

[21] CHEN T, MOHAMED FA, MECARTNEY ML. Threshold stress superplastic behavior and dislocation activity in a three- phase alumina-zirconia-mullite composite[J]. Acta Materialia, 2006, 54(17): 4415-4426.

[22] 毛卫民. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 56-69.

MAO Wei-min. Recrystallization and grain growth of metals[M]. Beijing: Metallurgical Industry Press, 1994: 56-69.

[23] ZENER C, HOLLOMON JH. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

(编辑 李艳红)

基金项目:河南省教育厅自然科学基金(2010A4300008);中国博士后科学基金资助项目(2013M541973);河南省高等学校矿业工程材料重点学科开放实验室开放基金(KLMEM2012)

收稿日期:2012-11-12;修订日期:2013-02-25

通信作者:郭学锋,教授,博士;电话:0391-3986958;E-mail: guoxuef@gmail.com