Cu-Ni-Al粉末合金的烧结膨胀行为及其机理

冯颖,李益民,何浩,曾昭易

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:以Cu,Ni和Al元素粉为原料,采用模压法制备Cu-Ni-Al粉末合金,对其烧结行为和膨胀机理进行研究。实验结果表明:Cu-10Ni-1.25Al合金在600~800 ℃温度区间内发生烧结膨胀,相对密度显著降低,孔隙率明显增加。结合差热分析、EDAX能谱分析以及微观组织观察发现,Al与Cu和Ni在600 ℃左右发生反应并产生富Al液相,引起膨胀速率和膨胀量增大;富Al液相沿Cu颗粒表面流动,并在原液相产生位置留下孔洞;同时,Al在Cu和Ni中的溶解度远高于Cu和Ni在Al中的溶解度,引起元素原子间的不等量扩散,使富Al液相最终渗透进入Cu颗粒内部,造成固-液界面间的物质迁移,导致固相颗粒体积长大和试样的整体膨胀。

关键词:Cu-Ni-Al粉末合金;烧结行为;膨胀机理

中图分类号:TF 124 文献标志码:A 文章编号:1672-7207(2010)01-0108-06

Sintering expansion behavior and expansion mechanism of Cu-Ni-Al powder alloy

FENG Ying, LI Yi-min, HE Hao, ZENG Zhao-yi

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Cu-10Ni-1.25Al alloy was prepared by compression molding with Cu, Ni and Al powder. The sintering behavior and expansion mechanism of Cu-Ni-Al system powder alloy were investigated. The results show that considerable expansion occurs after being sintered at 600-800 ℃, accompanied by the decrease of density and increase of porosity. The measurements including differential thermal analysis, EDAX X-ray analysis and metallographic observation were conducted, and it is proved that the compacts perform the larger and faster expansion after the appearance of Al-rich melt which forms by the reaction of Al with Cu and Ni at 600 ℃. Al-rich melt penetrates into the grain boundaries of Cu particles and leaves pores at the prior Al particle sites. Because of a large solubility of Al in the Cu and Ni, Al-rich melt is finally absorbed into the solid as a result of unbalanced diffusion between components, leading to the net mass flow between the solid/liquid interfaces, which brings about the solid particle grain growth and the increase in the volume of the specimen as a whole.

Key words: Cu-Ni-Al powder alloy; sintering behavior; expansion mechanism

Cu-Ni白铜合金具有良好的导电性和导热性,较强的耐腐蚀性和较高的延展性,是制备医疗、化工器械及各种精密仪器的重要材料,广泛应用于造船、石油、化工等领域。Cu-Ni合金的强度等力学性能较低,但通过添加合金元素,可以在保持耐腐蚀性的同时,明显提高材料的力学性能[1]。如Cu-Ni-Al白铜合金中,添加Al元素能显著提高白铜的强度与抗蚀性,对合金起强化作用[2]。但是,铜基粉末合金中加入Al,会引起烧结过程中样品发生膨胀[3],使烧结[4]较难控制。一些学者在研究Cu-Al[5-6]体系的烧结过程时发现,合金出现了体积增大、相对密度降低的烧结膨胀现象。Mitani等[7]对不同Al含量的Cu-Al合金进行了烧结实验研究,发现了膨胀现象,膨胀的温度点稍高于共晶反应发生的温度点。Lee等[8]通过分析发现,Cu-Al合金在烧结过程中产生了瞬时液相,液相的流动对烧结体中孔隙结构和成分均匀化过程产生重要影响。Schaffer等[9]认为Al-Cu系合金的烧结膨胀是液相扩散进入固相颗粒内部,导致固相颗粒体积增大所致。一般来说,液相的产生可以有效地强化烧结过程,得到接近全致密的产品。但是在对Cu-Al,Cu-Sn,Al-Zn和Fe-Cu等合金体系[10-16]的研究中发现,液相的存在也会导致发生烧结膨胀和相对密度下降。German 等[17-20]认为烧结膨胀的发生,与材料的元素组成有关。当形成液相的低熔点合金元素在固相元素中有较高的溶解度时,液相会最终消失,导致孔洞出现、膨胀发生。目前,对Cu-Ni-Al粉末合金烧结行为的研究尚未见报道。为此,本文作者以Cu-10Ni-1.25Al成分的粉末合金为研究对象,结合烧结过程中试样尺寸变化以及微观结构观察,分析Cu-Ni-Al体系材料的烧结行为,探讨铝白铜材料的烧结膨胀机理。

1 实验

1.1 试样制备

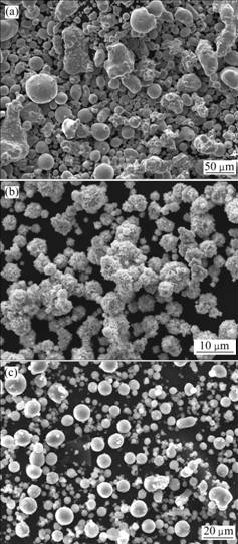

实验原料采用Cu,Ni和Al元素粉末,主要性能见表1,粉末形貌见图1。

表1 原料粉末的性能

Table 1 Characteristics of experimental powders

(a) Cu粉;(b) Ni粉;(c) Al粉

图1 原料粉末的SEM形貌

Fig.1 SEM morphologies of experimental powders

制备Cu-10Ni和Cu-10Ni-1.25Al(质量分数,%)2种成分合金作对比实验。将粉末按照质量分数比配制成混料,利用标准拉伸模具压制成拉伸样条,样条长为36 mm,压制压力为400 MPa。实验选取500~1 000 ℃区间内的不同烧结温度,保温时间均为2 h,保护气氛为氢气。另外,在膨胀发生温度对Cu-10Ni- 1.25Al合金淬火,研究膨胀机理。

1.2 检测分析

用游标卡尺测量烧结后样品的长度,按下式计算尺寸变化率:

式中:l0和l分别为烧结前、后样品的长度。用排水法测量烧结样品的密度;用真空浸渍法测量烧结后的开孔率;在Polyvar-met金相显微镜上观察微观组织;在差式扫描量热仪上对粉末合金进行差热分析;用日本JEOL JSM-6360LV扫描电镜进行形貌观察及能谱分析。

2 结果与讨论

2.1 样品尺寸、相对密度及孔隙率的变化

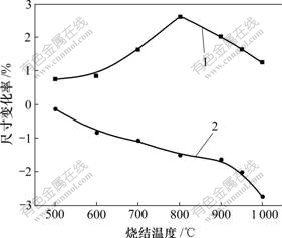

Cu-10Ni和Cu-10Ni-1.25Al合金的尺寸变化率与烧结温度的关系如图2所示。可以看出:Cu-10Ni的样品尺寸在各烧结温度下均呈收缩趋势,收缩率随温度的升高而增大,表现为传统的烧结致密化过程。而Cu-10Ni-1.25Al合金在低温阶段出现尺寸长大的异常膨胀现象。在600 ℃以下,合金膨胀速率较慢,膨胀量较小;在600~800 ℃,膨胀量和膨胀速率随温度的升高而增大,膨胀量在800 ℃达到最大;继续升高温度,烧结由膨胀转入收缩。

1—Cu-10Ni-1.25Al; 2—Cu-10Ni

图2 Cu-10Ni 和Cu-10Ni-1.25Al合金尺寸变化率与烧结温度的关系

Fig.2 Relationships between dimensional change and sintering temperature for Cu-10Ni and Cu-10Ni-1.25Al alloy

通过对比可见:添加Al元素导致铝白铜在低温阶段出现了烧结膨胀。其中,600 ℃以下的微量膨胀是合金元素间发生不等量原子扩散的结果。Al的熔点为660 ℃,与Cu和Ni 的熔点差距较大。低熔点金属有较低的表面能和较高的自扩散率,因此,不同扩散速率产生不等量扩散,引起孔隙增大和烧结样品的体积增大。另外,在600 ℃左右烧结时,合金内开始产生液相,导致烧结膨胀的反致密化现象出现。

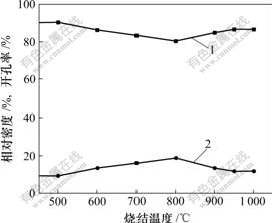

图3所示为铝白铜合金的相对密度及开孔率随烧结温度的变化。可以看到:在500~800 ℃之间时,烧结膨胀发生,相对密度下降,开孔率增加;在800 ℃时,相对密度降至最低,开孔率最大;当高于800 ℃后,随着温度的继续升高,相对密度增大,开孔率降低。

1—相对密度;2—开孔率

图3 Cu-10Ni-1.25Al合金相对密度和开孔率随烧结温度的变化

Fig.3 Variations of relative density and open porosity on sintering temperature for Cu-10Ni-1.25Al alloy

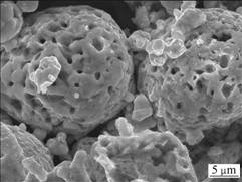

图4所示为Cu-10Ni-1.25Al合金烧结膨胀后的SEM像。由图可以看到合金内的连通孔隙结构。证明了孔洞伴随膨胀产生,引起烧结体密度下降。

图4 Cu-10Ni-1.25Al合金烧结膨胀后的SEM像

Fig.4 SEM image of Cu-10Ni-1.25Al alloy after sintering expansion

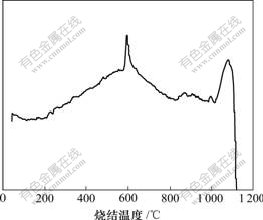

2.2 热分析

图5所示为Cu-10Ni-1.25Al合金的差热分析结果。可见:600 ℃左右有放热峰出现,却未观察到Al的熔化吸热峰。这是由于Al的熔化潜热为10.5 kJ/mol,而Ni与Al和Cu与Al的反应生成热分别可达到-72 kJ/mol[21]和-20 kJ/mol[22]。因此,放热峰的出现表明Al与Cu和Ni在合金化扩散过程中发生了反应,放出大量的热。结合Cu-Al,Ni-Al及Cu-Ni-Al相图[23]分析,反应发生在偏Al成分区域,并有富Al液相产生,从而改变了合金的烧结行为,导致反致密化过程出现。

图5 Cu-10Ni-1.25Al合金的DTA曲线

Fig.5 DTA curve of Cu-10Ni-1.25Al alloy

2.3 膨胀机理分析

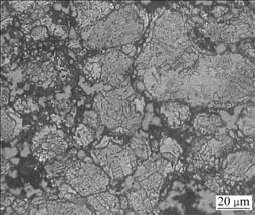

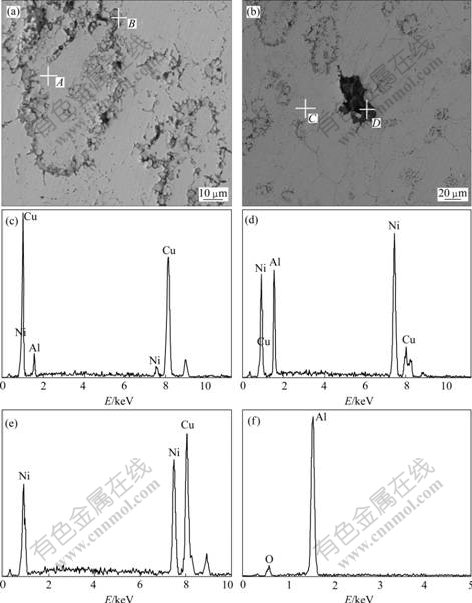

图6所示为Cu-10Ni-1.25Al合金于600 ℃淬火后的微观组织。可以看到:放热反应后出现的液相包覆在较大的Cu颗粒周围,使Cu颗粒之间处于“被隔离”状态。对该组织进行微区EDAX分析,结果如图7所示。经分析发现:包裹在颗粒表面的液相中,Al含量明显高于周围基体含量(如B点所示);同时,在原Al颗粒位置有孔洞留下,如D点所示。这表明富Al液相产生之后,在毛细管力作用以及润湿性的影响下,沿固相颗粒(尤其是粒度较大的Cu颗粒)表面流动并侵入颗粒接触部位,导致固相颗粒间距增大。同时,液相扩展且在其产生位置留下孔洞,引起烧结体孔隙率上升,相对密度下降,反致密化过程出现。

图6 Cu-10Ni-1.25Al合金于600 ℃淬火后的显微组织

Fig.6 Microstructure of Cu-10Ni-1.25Al alloy quenched at 600 ℃

(a), (b) 淬火样品的SEM像;(c) A点的EDAX谱;(d) B点的EDAX谱;(e) C点的EDAX谱;(f) D点的EDAX谱

图7 Cu-10Ni-1.25Al合金于600 ℃淬火后的EDAX谱

Fig.7 EDAX energy spectra of Cu-10Ni-1.25Al alloy quenched at 600 ℃

根据German[17]的反致密化理论,液相存在的烧结过程中,固-液间溶解度失配是导致烧结膨胀发生的主要原因。在Cu-Ni-Al体系中,Al在Cu和Ni中的溶解度远高于Cu和Ni在Al中的溶解度,使得富Al液相最终固溶于基体。元素间的溶解度不匹配决定了烧结体的膨胀反致密化。

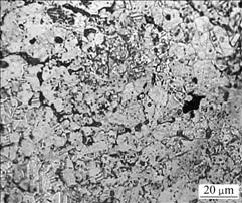

图8所示为900 ℃烧结后合金的显微组织。可以看到:此时合金化过程已经完成,组织显示为均匀的固溶体。但是,在较大的Cu颗粒周围发现有微小孔洞存在。这是由于富Al液相的较大溶解度,促使Al原子通过液相扩散进入Cu颗粒内部,液相固溶形成Cu固溶体。液相扩散后在其存在位置留下孔洞,导致孔隙率增加。Al原子扩散并固溶于Cu后,引起Cu的晶格畸变和晶格常数增大。合金元素间的不等量扩散,导致固-液间的物质迁移,引起固相颗粒的体积长大和样品的体积膨胀,因而产生了烧结膨胀。

图8 Cu-10Ni-1.25Al合金900 ℃烧结后的显微组织

Fig.8 Microstructure of Cu-10Ni-1.25Al specimens sintered at 900 ℃

3 结论

(1) Al的加入可影响Cu-Ni-Al体系合金的烧结行为,导致烧结膨胀的出现。Cu-10Ni-1.25Al 合金的烧结膨胀发生在600~800 ℃,烧结膨胀引起合金尺寸长大、相对密度下降以及孔隙率增加。

(2) Cu-Ni-Al合金的烧结膨胀发生在富Al液相产生之后。液相在固相中有较大的溶解度,使得液相向固相颗粒表面流动并最终扩散进入固相颗粒内部。

(3) Cu-Ni-Al体系的烧结膨胀机理是:由于液相对固相的扩散和渗透,在原液相产生位置留下孔洞;同时,物质迁移引起固相颗粒体积长大,孔隙率增加,导致膨胀发生。

参考文献:

[1] Shropshire B H, Kim K, Lin S T, et al. Copper P/M in thermal management[J]. The International Journal of Powder Metallurgy, 2003, 39(4): 47-50.

[2] 赵祖德, 姚良均, 郭鸿运, 等. 铜及铜合金材料手册[M]. 北京: 科学出版社, 1993: 421-426.

ZHAO Zu-de, YAO Liang-jun, GUO Hong-yun, et al. Handbook of copper and copper alloy[M]. Beijing: Science Press, 1993: 421-426.

[3] Itin V I, Savitskii A P K, Savitskii V, et al. Sintering in Cu-A1 powders[J]. Izvestiya VUZ Fizika, 1965(2): 139-144.

[4] 果世驹. 粉末烧结理论[M]. 北京: 冶金工业出版社, 1998: 93-96.

GUO Shi-ju. Theory of powder sintering[M]. Beijing: Metallurgical Industry Press, 1998: 93-96.

[5] 张承忠, 孙秋霞, 张洪绪. 铜-铝系合金粉末压坯烧结机理[J]. 东北工学院学报, 1989, 10(5): 561-564.

ZHANG Cheng-zhong, SUN Qiu-xia, ZHANG Hong-xu. Sintering mechanism of Cu-Al system powder billet[J]. Journal of Northeast University of Technology, 1989, 10(5): 561-564.

[6] 田素贵, 邵会孟, 邵桂春. Cu-Al粉末合金的烧结行为[J]. 沈阳工业大学学报, 1995, 17(4): 15-19.

TIAN Su-gui, SHAO Hui-meng, SHAO Gui-chun. Sintering behavior of Cu-Al powder alloy[J]. Journal of Shenyang Polytechnic University, 1995, 17(4): 15-19.

[7] Mitani H, Yokota M. Exothermic reaction of Cu-Al binary mixed powder compacts during vacuum sintering[J]. J Jap Inst Metals, 1970, 34(9): 902-907.

[8] Lee D J, Yoon D N. Transient liquid phase sintering of Cu-Al alloy[J]. Powder Metallurgy International, 1988, 20(5): 15-17.

[9] Schaffer G B, Sercomble T B, Lumley R N. Liquid phase sintering of aluminium alloys[J]. Materials Chemistry and Physics, 2001, 67(1/3): 85-91.

[10] Reyburn B, Corbin S. Monitoring transient liquid phase sintering of copper-tin by thermal analysis[J]. Int J Powder Metall, 2000, 36(5): 57-68.

[11] Savitskii A P, Burtsev N N, Martsunova L S. Volume changes experimented by Al-Zn compacts during liquid-phase sintering[J]. Soviet Powder Metallurgy and Metal Ceramics, 1982, 21(10): 760-764.

[12] 王才德, 汪建昌. Fe-Cu粉末压坯烧结膨胀机理[J]. 粉末冶金材料科学与工程, 1996, 1(1): 25-29.

WANG Cai-de, WANG Jian-chang. Mechanism of sintering expansion of Fe-Cu powder compacts[J]. Materials Science and Engineering of Powder Metallurgy, 1996, 1(1): 25-29.

[13] Pieczonka T, Kaysser W A, Petzow G. Transient liquid phase sintering of Fe-Cu-Ti compacts[J]. Journal of Materials Processing Technology, 1999, 92/93: 21-24.

[14] Kim Y C, Suk M J. Expansion behavior of iron-copper compact from (Fe-Cu) pre-alloyed powder[C]//2006 Powder Metallurgy World Congress and Exhibition, PM 2006. Stafa-Zuerich: Trans Tech Publication Ltd, 2007: 517-520.

[15] 朱远志, 尹志民, 李学谦. 一种烧结铁基合金Fe-Cr-Mo- Ni-Co-C的热致密化过程[J]. 中南大学学报: 自然科学版, 2006, 37(3): 455-460.

ZHU Yuan-zhi, YIN Zhi-min, LI Xue-qian. Hot densification of a sintered Fe-based alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(3): 455-460.

[16] Dewidar M M, Khalil K A, Lim J K. Processing and mechanical properties of porous 316L stainless steel for biomedical applications[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(3): 468-473.

[17] German R M. Liquid phase sintering[M]. New York: Plenum Press, 1985: 86-94.

[18] Liu J, Lal A, German R M. Densification and shape retention in supersolidus liquid phase sintering[J]. Acta Mater, 1999, 47(18): 4615-4626.

[19] German R M. Effect of green microstructure on densification and distortion in liquid-phase sintering[J]. Int J Refract Matals/Hard Mater, 2001, 19(3): 149-158.

[20] Savitskii A P, Burtsev N N. Compact growth in liquid-phase sintering[J]. Soviet Powder Metallurgy and Metal Ceramics, 1979, 18(2): 96-102.

[21] 夏冬生, 郭建亭, 李博, 等. NiAl(Co)系机械合金化的研究[J]. 金属学报, 1999, 35(3): 320-324.

XIA Dong-sheng, CUO Jian-ting, LI Bo, et al. Investigation on mechanical alloying of NiAl(Co)[J]. Acta Metallurgica Sinica, 1999, 35(3): 320-324.

[22] 张永刚, 韩雅芳, 陈国良, 等. 金属间化合物结构材料[M]. 北京: 国防工业出版社, 2001: 16-18.

ZHANG Yong-gang, HAN Ya-fang, CHEN Guo-liang, et al. Structural Intermetallics[M]. Beijing: National Defense Industry Press, 2001: 16-18.

[23] 田荣璋, 王祝堂. 铜合金及其加工手册[M]. 长沙: 中南大学出版社, 2002: 361-390.

TIAN Rong-zhang, WANG Zhu-tang. Handbook of copper alloy and processing[M]. Changsha: Central South University Press, 2002: 361-390.

收稿日期:2009-04-24;修回日期:2009-08-28

基金项目:国家高技术研究发展计划(“863”计划)项目(2007AA03Z114);国家自然科学基金创新群体资助项目(50721003)

通信作者:李益民(1971-),男,湖南郴州人,博士,教授,从事注射成形研究;电话:0731-88830693;E-mail: liyimin33@yahoo.com.cn

(编辑 陈爱华)