Characterization and technology of fast reducing roasting for fine iron materials

来源期刊:中南大学学报(英文版)2012年第8期

论文作者:罗立群 黄红 余永富

文章页码:2272 - 2278

Key words:iron material; reducing roasting; thermal decomposition; X-ray diffraction; magnetic property

Abstract: The features of the techniques of fast reducing roasting (FRR) and conventional magnetic roasting, as well as tremendous demands of iron ores in iron and steel industry of China, were briefly described. The test equipment suitable for FRR of fine-grained materials was introduced. Weakly magnetic materials with grain size of <0.30 mm were converted into strongly magnetic materials by FRR for several to dozens of seconds. In a weakly reducing atmosphere and at 740-800 ℃, refractory powder iron material (<0.30 mm) which is rich in specularite, limonite and Mg-Mn siderite was subjected to FRR for a few seconds to 60 s. Concentrate with iron grade of 55.67%-55.21%, high contents of Mg and Mn in the ore is obtained and the yield of magnetic separation reaches 81.66%-86.57%. The results of X-ray diffraction (XRD) analysis and magnetism detection of the material before and after FRR indicate that weakly magnetic material is mainly converted into strongly magnetic material Fe3O4 with specific saturation magnetic moment. The efficiency of FRR is consistent with TFe recovery of magnetic separation; meantime, the specific saturation magnetic moment increases from 33 to 42 times after FRR. Calculations show that speeds of flash magnetic roasting are obtained from several dozen to two or three hundred times, compared with rotary kiln or shaft furnace. This indicates that it is practicable to use the fast reducing roasting technique to improve the comprehensive utilization of iron ore resources.

J. Cent. South Univ. (2012) 19: 2272-2278

DOI: 10.1007/s11771-012-1271-3![]()

LUO Li-qun(罗立群)1, 2, HUANG Hong(黄红)3, YU Yong-fu(余永富)1

1. School of Resources and Environmental Engineering, Wuhan University of Technology, Wuhan 430070, China;

2. School of Chemical Engineering, University of Queensland, Brisbane, QLD 4072, Australia;

3. Library of West Campus, Wuhan University of Technology, Wuhan 430070, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2012

Abstract: The features of the techniques of fast reducing roasting (FRR) and conventional magnetic roasting, as well as tremendous demands of iron ores in iron and steel industry of China, were briefly described. The test equipment suitable for FRR of fine-grained materials was introduced. Weakly magnetic materials with grain size of <0.30 mm were converted into strongly magnetic materials by FRR for several to dozens of seconds. In a weakly reducing atmosphere and at 740-800 ℃, refractory powder iron material (<0.30 mm) which is rich in specularite, limonite and Mg-Mn siderite was subjected to FRR for a few seconds to 60 s. Concentrate with iron grade of 55.67%-55.21%, high contents of Mg and Mn in the ore is obtained and the yield of magnetic separation reaches 81.66%-86.57%. The results of X-ray diffraction (XRD) analysis and magnetism detection of the material before and after FRR indicate that weakly magnetic material is mainly converted into strongly magnetic material Fe3O4 with specific saturation magnetic moment. The efficiency of FRR is consistent with TFe recovery of magnetic separation; meantime, the specific saturation magnetic moment increases from 33 to 42 times after FRR. Calculations show that speeds of flash magnetic roasting are obtained from several dozen to two or three hundred times, compared with rotary kiln or shaft furnace. This indicates that it is practicable to use the fast reducing roasting technique to improve the comprehensive utilization of iron ore resources.

Key words: iron material; reducing roasting; thermal decomposition; X-ray diffraction; magnetic property

1 Introduction

Stepping into the 21st century, China has been trying to build a moderately prosperous and resource- saving society in an all-round way, which greatly stimulated the development of iron and steel industry. Crude steel production in China reached 625×106 t in 2010. However, the domestic production of iron ore is seriously deficient, with a self-sufficient rate less than 50%. The annual iron ore import reaches 619×106 t. Moreover, the price of imported iron ore keeps high. Therefore, it is urgent to develop new beneficiating technology to improve the utilization efficiency of domestic iron ore resources in China [1-3].

Magnetic roasting technique, mainly aiming at refractory weakly-magnetic materials, is a physico- chemical process in which the weakly magnetic material is turned into strongly magnetic material by magnetic roasting. The conventional magnetic roasting techniques and equipment for iron materials, e.g. reduction roasting of lump ore by shaft furnace (>15 mm), reduction roasting by rotary kiln (15-0 mm) and fluidized-bed roasting, can only treat coarse-grained or rich-in-coarse- particle materials, with long roasting time, slow and non-uniform reduction and dissatisfactory continuous treating efficiency [4-5]. In commercial production, the material used in magnetic roasting process is block ore. Therefore, powder ore must be subjected to agglomeration process before magnetic roasting and to high-power-consumption grinding operation after roasting. The process circuit is very complicated. When the grain size of the material is large, the ore particles have less surface contacting with reductant. The reduction process goes slowly, thereby resulting in insufficient reduction or over-reduction. The quality of the roasted ores is not high in general.

At present, China has hundreds of millions of tons of low-grade refractory strongly-magnetic concentrates, middlings and associated weakly-magnetic materials that are not effectively utilized every year [6-7]. The grain size of the materials is very small, generally 0.2-0.3 mm, and the smaller the grain size, the larger the specific area, and the higher the reactivity. If magnetic roasting can be conducted directly under fluid bed condition to realize FRR, the magnetic reaction rate and roasting efficiency can be greatly promoted [8-10]. The complicated and high-power-consumption agglomeration process and grinding operation can be left out to simplify the process circuit and make the power consumption and production cost decrease. This accords with the characteristics of iron ore resources and iron ore production in China. However, there is few report about the reduction roasting technique and furnace for low-grade fine powdered materials (<0.3 mm) [11-12]. It is necessary to make pioneering and deep-going studies on them in theory and practice. The aim of this work is to investigate the well-known refractory hematite—Jiuquan Jingtieshan Iron Mine in China using the new technique of FRR and independently-designed equipment in order to gain break-through achievements.

2 Experimental

2.1 Test samples

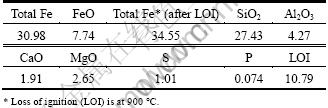

The samples used in this work were ground material, called crude ore (JY), obtained by grinding the fine ore (0-15 mm) from Jingtieshan Huashugou Iron Mine of Jiuquan Iron and Steel (Group) Co., Ltd. (JISC) with industrial grinder and the concentrates (JZ) from crude ore roughing and scavenging. In the iron ore of JISC, the grade of useful elements is low, the disseminated size of industrial minerals is very small, and the content of gangue is high. The ore has a complex structure, with banded, block and disseminated structures. The recoverable iron minerals in the ore are weakly magnetic specularite, Mg-Mn siderite and limonite, with a ratio of 2.4:1:1.4. The iron grade of the fine ore is generally 29%-31%. The gangue minerals are mainly jasperite, quartz, barite and ferrodolomite. The wall rock is phyllite, most of which is ferrous-phyllite. The minerals differ from each other in their crushing, grinding and separation properties. Among the gangue, the jasperite and phyllite have a great impact on the separation results. It makes the fine ore of JISC difficult to be separated, resulting in low separation efficiency [13-14]. The results of chemical analysis, phase analysis of iron and magnetic property detection of primary minerals are listed in Tables 1, 2 and 3, respectively.

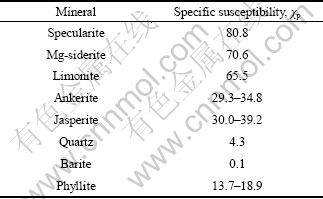

Table 1 Results of chemical analysis of iron ore samples (mass fraction, %)

Table 2 Results of phase analysis of iron (mass fraction, %)

Table 3 Results of magnetic property detection of primary minerals (10-9 m3/kg)

2.2 Test equipments

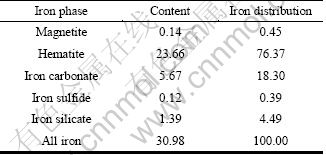

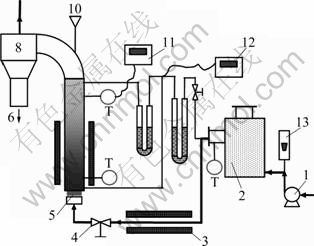

The equipment for FRR test is independently designed and made according to the process that the material is rapidly magnetized and converted under the conditions of fluid bed and magnetic reduction temperature and atmosphere. Two sets of test equipment have been designed and made. One is detecting equipment for parameters of cold FRR test. Another is reduction reaction equipment and speed detecting system for hot FRR test. The detecting equipment consists of reduction furnace, distribution plate, differential pressure gauge, fan and devices for feeding, discharging and adjusting. It is used for providing referential data for the hot test. The reduction reaction equipment and speed detecting system consist of reducing atmosphere generator, flash fluid-bed reduction furnace, electric heating and temperature controlling system, gas supplying and adjusting system, material adding and collecting system and measuring and controlling system. The block diagrams of the reduction reaction equipment and speed detecting system are shown in Fig. 1.

The parameters of the hot test equipment are as follows: inner diameter of reduction furnace, 50 mm; height of furnace body, 2 000 mm (heating belt height of 1 000 mm); temperature of hearth, ≤1 000 ℃ mm; time for magnetic roasting, 10 s (the shortest); error in temperature controlling of temperature detecting system, within ±5 ℃ [15]. Range of reducing atmosphere generator shown in Table 4 can obtain the requirements for atmosphere composition.

Fig. 1 Schematic diagrams of reduction reaction equipment and speed detecting system of FRR: 1-Air blower; 2-Gas producer furnace; 3-Tubular heater; 4-Cross-over valve; 5-Gas distribution panel; 6-Discharge hole; 7-Fast reactor; 8-Gas- solid separator; 9-Waste gas escapement; 10-Feed mouth; 11- Temperature centralized controls; 12-Differential pressure controls; 13-Flow capacity controls

Table 4 Atmosphere compositions of reducing atmosphere generator (volume fraction, %)

![]()

2.3 Test methods

The reducing atmosphere generator of the hot test equipment system uses coke or charcoal as fuel and air with certain pressure as gasification medium to produce reducing gases, mainly CO. The CO content (volume fraction) is controlled through adjusting air output. After the temperature of the reducing gas is adjusted by the electric heater, the gas with certain temperature goes into the fluid-bed FRR furnace so that the iron material to be reduced in the furnace is subjected to FRR to produce artificial magnetite. The magnetite is protected by inert gas with certain pressure and discharged through the collecting system, and then is quenched by water, thereby magnetically roasted sample is obtained.

Magnetic-tube concentrator is a magnetic analyzing device for wet analysis of the content of strongly magnetic minerals in ores. It is used to determine the feasibility of the ore by magnetic separation. The magnetic roasting product is separated with the magnetic-tube concentrator first, and then is subjected to chemical analysis and calculation to determine the content of mediumly and strongly magnetic minerals so as to evaluate the effect of the flash magnetic roasting. XRD is used to analyze the sample composition to ascertain the products of chemical reaction and even the intermediate phase and final phase of the roasting. Vibration sample magnetometer (VSM) is used to determine the specific susceptibility or magnetic moment of the sample to be roasted and the roasted artificial magnetite is used to verify the effect of the new FRR technique on the conversion of weakly magnetic minerals.

3 Results and discussion

3.1 Results of flash magnetic roasting of crude ore (JY) for different time

With respect to the related parameters of the cold test, tests of FRR for different time were conducted on the basis of running test. The crude ore (JY) used was in the size fraction of 0-0.25 mm. The conditions for the tests were as follows: differential pressures of gas inlet, 1 950-2 050 Pa; temperature of reaction chamber wall, 870-880 ℃; feed rate, 120 g/batch; flash fluidization reaction time, 60 s, 30 s, 10 s and “discharging as soon as charging” (about 3-5 s), respectively. The roasted material was subjected to magnetic analysis in magnetic-tube concentrator after being ground by ball mill. The field intensity was 80 kA/m. The feed rate was 50 g/batch.

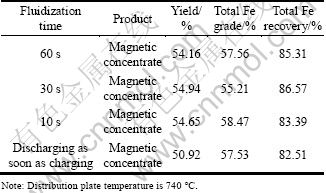

The temperature of the distribution plate during feeding was 740 ℃. The reaction atmosphere before and after the test was CO2/O2/CO with a ratio of 19.2/0.2/< 0.10-19.0/0.4/<0.10. The results of flash magnetic roasting of crude ore (JY) for different time are listed in Table 5.

Table 5 Results of flash magnetic roasting of crude ore (JY) for different time

The results indicate that it is possible to flashly magnetize the refractory powder iron material, JISC crude ore (with size fraction of 0-0.25 mm), to gain weakly magnetic separation concentrate by magnetically roasting the crude ore for different time ((3-5 s) to 60 s) under the conditions of weak reduction atmosphere and fluid bed roasting. The yield of magnetic product is 50.92%-54.94%; iron grade, 55.21%-58.47%; iron recovery, 86.57%-82.51%. This proves that the independently designed and patented hot flash magnetic roasting equipment is feasible. As JISC ore is complicated and refractory material (moreover with high contents of Mg and Mn), even it is treated by roasting and magnetic separation, the grade of the iron concentrate is only 55%-56% (the laboratory result is slightly higher, 57%-58%). The research literatures about JISC ore sample and year’s practices of JISC can give evidence for this.

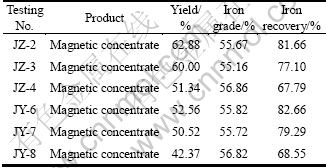

3.2 Results of flash magnetic roasting of middling (JZ) for different time

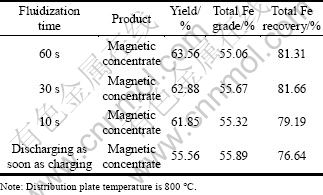

The conditions for the FRR test of JISC middling were as follows: differential pressure of gas inlet, 2 000- 2 150 Pa; temperature of reaction chamber wall, 930- 950 ℃; material size fraction, 0-0.30 mm; flash fluidization reaction time, 60 s, 30 s, 10 s and “discharging as soon as charging” (about 3-5 s) respectively; distribution plate temperature, 800 ℃. The reaction atmosphere before and after the test was CO2/O2/CO with a ratio of 18.6/0.2/<0.10-19.4/0.2/< 0.10. The results of flash magnetic roasting of middling (JZ) for different time are listed in Table 6.

Table 6 Results of flash magnetic roasting of middling (JY) for different time

The results indicate that it is also possible to realize flash magnetization of the refractory powder iron material, JISC middling (JZ) (with size fraction of 0- 0.25 mm), to obtain weakly magnetic separation concentrate by magnetically roasting the middling for different time ((3-5 s) to 60 s) under the conditions of weak reduction atmosphere and fluid bed roasting. The yield of magnetic product is 55.56%-63.56%; iron grade, 55.06%-55.89%; iron recovery, 76.64%-81.66%. This proves that the independently designed and patented hot flash magnetic roasting equipment is feasible.

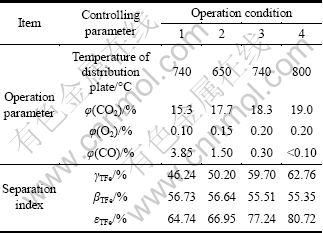

3.3 Results of comprehensive tests for different flash magnetization time at different temperatures

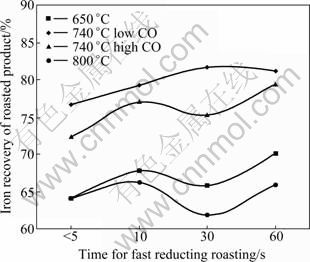

In order to fully grasp the rule of material magnetization during FRR, comprehensive tests of the JISC middlings were made under different roasting conditions. The differential pressure of gas inlet adopted was 1 950-2 150 Pa. The material size was 0-0.30 mm. The results of FRR under the conditions of different temperatures of distribution plate, different reduction atmospheres and different reduction time are shown in Fig. 2. The results of comprehensive FRR of middling (JZ) under different conditions are listed in Table 7.

Fig. 2 Results of FRR under conditions of different temperatures and time

Table 7 Results of FRR of middling (JZ) under different conditions

It is known that the results of the FRR of iron materials are better under the conditions of distribution plate temperature of 650-800 ℃ and CO volume content of 0-4.5%. The iron recovery increases with the rise of the distribution plate temperature, with descending amplitude. When the distribution plate temperature rises from 650 ℃ to 740 ℃, the iron recovery increased by 10%-12%; from 740 ℃ to 800 ℃, 4%-6%. The iron recovery increases with the decrease of CO content in the reducing atmosphere. When the material is charged while the distribution plate temperature is 650 ℃, CO content is 3.2%-4.5%; the iron recovery is only 61.75%- 66.09%. When CO content is 0-0.6%, the iron recovery reaches 72.38%-79.43%, increased by 11%-13%. During the magnetic roasting time from “discharging as soon as charging” to 60 s, the iron recovery increases, by 3%-5% in general (referring to Tables 5 and 6). The results indicate that the amplitude of increase in iron recovery has less influence than the distribution plate temperature and CO content. It is in the “flash period of time” in the magnetic roasting process when the material is magnetized. The magnetizing rate in the early magnetization stage is not as same as that in the later stage. The magnetization is affected by chemical reaction in the early stage, but by diffusion control in the later stage. Since there were various types of iron minerals in the iron material, the mechanisms of controlling magnetizing rate are likely different.

3.4 Analysis of flash magnetic roasting products

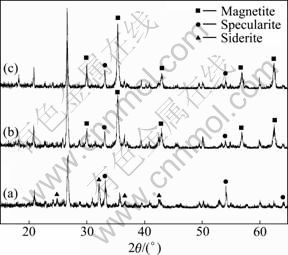

XRD was adopted to investigate the change of the iron minerals and the production of strongly magnetic matter after the FRR of the samples. The results of XRD analysis of before-roasting sample of crude ore (JY) and after-roasting samples of JY-6 and JZ-2 (Table 8) are shown in Fig. 3.

Table 8 Results of separation of determination samples by magnetic-tube concentrator

Fig. 3 XRD spectra of samples before and after flash magnetic roasting: (a) Sample before FRR; (b) Sample JY-6 after FRR; (c) Sample JZ-2 after FRR

The results indicate that for the weakly magnetic material before being roasted, the main characteristic peaks of iron minerals are: siderite, d=2.781 9, d=3.574 7, d=1.724 4; hematite (JISC’s sample is specularite), α-Fe2O3, d=2.692 9, d=1.692 2, d=3.674 3; limonite’s FeOOH peak is not obvious, but dolomite’s peak is visible, e.g. d=2.884 8, where d is the crystal plane spacing. For the crude ore sample, there is no characteristic peak of strongly magnetic iron mineral, indicating that there is no or little strongly magnetic iron mineral in the sample. After being subjected to FRR, both of the crude ore and middling samples show clear characteristic peaks of strongly magnetic iron mineral. Moreover, the characteristic peak of magnetite is sharp and high, as shown in Fig. 3, d=2.534 7, d=2.972 2, d= 2.101 8. This indicates that a lot of strongly magnetic matters with high degree of crystallization are produced in the process of flash magnetic roasting. However, the characteristic peak of strongly magnetic γ-Fe2O3 does not appear, indicating that the weakly magnetic iron mineral is reduced and almost converted into strongly magnetic Fe3O4 in the FRR process.

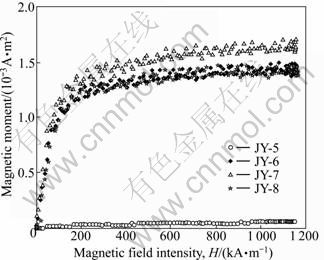

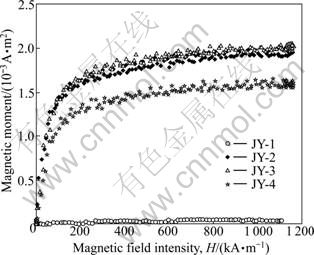

3.5 Change in magnetic property before and after FRR

Magnetic moment is an important physicochemical parameter to judge the magnetism strength of minerals [16-17]. Under the condition of certain magnetic strength, the larger the magnetic moment is, the higher the specific susceptibility is, and the easier the material is beneficiated. VSM can be used to determine the relation between the magnetic moment and field intensity of the sample to reveal the rule of change in magnetism of the material subjected to FRR.

In order to clearly reveal the notable change and change rule of the magnetic properties of the material before and after FRR, the test samples with certain differential iron recovery after FRR were chosen for magnetic property determination in Table 8. The magnetic property curves for the crude ore (JY) and middling (JZ) before and after FRR are shown in Figs. 4 and 5, respectively.

Fig. 4 Magnetic property curve for crude ore (JY)

Fig. 5 Magnetic property curve for middling (JZ)

After FRR, the magnetic moments of both of the crude ore (JY) and middling (JZ) are greatly increased as well as their specific susceptibilities. The samples show characteristics of strongly magnetic mineral. The increase of the magnetic moment is consistent with the separation results of magnetic-tube concentrator. The larger the saturated magnetic moment of the sample is, the higher the iron recovery of the magnetic separation after FRR is. There is a certain relation between these two. The weakly magnetic material is mainly converted into Fe3O4 with large specific saturated magnetic moment and high specific susceptibility. The iron recovery is in direct proportion to the magnetic moment.

It can be known from the results of magnetic property determination that after being roasted, the weakly magnetic material has a specific saturated magnetic moment 33-42 times higher than that before the roasting. It can also be found that when the roasted crude ore and middling have same iron recoveries of weakly magnetic separation, their saturated magnetic moments are different, which is related to the types and contents of weakly magnetic iron minerals in the materials.

3.6 Comparison of results of FRR

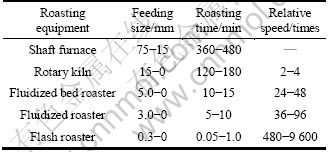

Since the magnetic roasting is conducted under high temperature condition, the rate of roasting reaction has a direct influence on the power consumption. If the material stays in the high temperature reaction zone for a long time, it is quite natural that more power will be consumed. Reducing the dwelling time of the material in the high temperature zone can lower down the power consumption. The materials treated by different magnetic roasting equipments have different grain sizes so that they require different magnetization time. In order to explain the flashness of the magnetic roasting of fine materials and realize power saving and cost reducing, the feeding size and roasting time of the iron materials in different magnetic roasting equipments are listed in Table 9. It is known that if the magnetic roasting of fine materials (e.g. <0.30 mm middling used in this work) realizes flash magnetization, the magnetization rate of the material will be greatly promoted. During the magnetic roasting, the fine material is in a high-speed fluidized state so that its magnetization rate is several or tens of times faster than that in fluid bed roasting. The magnetization of the material is finished in an instant. The flash magnetic roasting of the material is realized thereby.

Table 9 Feeding size and roasting time in different equipments of shaft furnace

4 Conclusions

1) According to the occurrence mode (poor, fine and complicated) and the processing features of the domestic iron ore resources, a brief discussion is made on the technological characteristics of FRR technique and conventional magnetic roasting techniques. It is suggested to use the new technique of FRR to improve the utilization efficiency of iron ore resources.

2) An introduction is made to the independently designed reduction reaction equipment and speed detecting system for FRR test of fine materials. A description is made on the methods and results of the tests of domestic low-grade refractory iron ores using the equipment and coke as fuel. It is the first time that FRR is realized.

3) In a weakly reducing atmosphere and at 740- 800 ℃, the refractory powder iron materials (<0.30 mm) which is rich in specularite, limonite and Mg-Mn siderite, JISC’s crude ore and middling, are subjected to flash magnetic roasting for a few seconds to 60 s, achieving an iron grade of 55.21%-58.47% (due to high contents of Mg and Mn in the ore) and iron recovery of 82.51%- 86.57%. The results of FRR are good.

4) The results of XRD analysis and magnetic property determination before and after FRR indicate that the weakly magnetic material is mainly converted into strongly magnetic Fe3O4 with large specific saturated magnetic moment and high specific susceptibility. After being roasted, the weakly magnetic material has a specific saturated magnetic moment 33-42 times higher than that before the roasting. Therefore, it is feasible to use the new technique of FRR to improve the utilization efficiency of iron ore resources.

Acknowledgements

The author gracefully acknowledges the School of Chemical Engineering, University of Queensland, for the intellectual condition and environment.

References

[1] LUO Li-qun, ZHANG Jing-sheng. Analysis of the ironmaking raw materials market in China [J]. Journal of Wuhan University of Technology, 2005, 27(9): 67-69. (in Chinese)

[2] CHENK J L. Recent status of fluidized bed technologies for producing iron input materials for steelmaking [J]. Particuology, 2011, 9(1): 14-21.

[3] LUO Li-qun, ZHANG Jing-sheng. Film-magnetic separation technique to strengthen the separation of complicated weak-magnetic minerals [C]// International Conference of Iron Ore 2005. Fremantle, Australia, 2005: 371-378.

[4] YU Yong-fu. Development trends of iron mines and status and problems of beneficiation technology in China [J]. Mining and Metallurgical Engineering, 2006, 26(1): 21-25. (in Chinese)

[5] CUI Z, LIU Q, ETSELL T H. Magnetic properties of ilmenite, hematite and oilsand minerals [J]. Minerals Engineering, 2002, 15(12): 1121-1129.

[6] ZHANG Jing-sheng, LUO Li-qun. Actuality of magnetic separation technique [J]. Mining and Metallurgical Engineering, 2005, 25(3): 25-29. (in Chinese)

[7] LUO Li-qun, ZHANG Jing-sheng, GAO Yuan-yang. Research on dry cooling magnetic roasting technology for siderite ore [J]. Metal Mine, 2004, (10): 28-31, 35. (in Chinese)

[8] ?I?EK B, BILGES?, ?ENELTA A M, PAMUK V. Desulphurization of coals by flash pyrolysis followed by magnetic separation [J]. Fuel Processing Technology, 1996, 46(2): 133-142.

[9] SRINIVASAM N S, STAFFANSSON L I. A theoretical analysis of the fluidized-bed process for the reduction of iron ores [J]. Chemical Engineering Science, 1990, 45(15): 1253-1265.

[10] SRINIVASAM N S. Reduction of iron oxides by carbon in a circulating fluidized bed reactor [J]. Powder Technology, 2002, 124(1/2): 28-39.

[11] CAVANAGH P E. Autogenous roasting of iron ore [P]. US Patent 5 244 494, 1993.

[12] YOUSSEF M A, MORSI M B. Reduction roast and magnetic separation of oxidized iron ores for production of blast furnace feed [J]. Canada Metallurgical Quarterly, 1998, 37(5): 419-428.

[13] LUO Li-qun, ZHANG Jing-sheng, YU Yong-fu. New technology and magnetic property of fast reducing roasting for fine iron bearing materials [C]// The 5th International Congress on the Science and Technology of Ironmaking (2009). Shanghai, China, 2009: 488-493.

[14] LIU Q F. Study on pro-concentration technique to Jingtieshan ore in Jiuquan iron and steel (group) Co. Ltd [D]. Xi’an: College of Metallurgical Engineering, Xi’an University of Architecture and Technology, 2003. (in Chinese)

[15] LUO Li-qun, ZHANG Jing-sheng, YU Yong-fu. Flash magnetic roasting and microstructure characteristics & phase transformation of iron minerals [J].Journal of Central South University: Science and Technology, 2009, 40(5): 1172-1177. (in Chinese)

[16] SUR S K. Measurement of magnetic susceptibility and magnetic moment of paramagnetic molecules in solution by high-field Fourier transform NMR spectroscopy [J]. Journal of Magnetic Resonance, 1989, 82(1): 169-173.

[17] BERTINI I, LUCHINAT C, PARRIGI G. Magnetic susceptibility in paramagnetic NMR [J]. Progress in Nuclear Magnetic Resonance Spectroscopy, 2002, 40(3): 249-273.

(Edited by DENG Lü-xiang)

Foundation item: Project(20070497048) supported by China Scholarship Council, Ministry of Education of China

Received date: 2011-07-10; Accepted date: 2012-02-01

Corresponding author: LUO Li-qun, Associate Professor, PhD; Tel: +86-27-62857276; E-mail: lqluollq@hotmail.com