文章编号:1004-0609(2015)02-0344-07

连续变断面循环挤压对TC4合金组织的影响

李 洁,刘莹莹,王庆娟,尤雪磊,王 坤

(西安建筑科技大学 冶金工程学院,西安 710055)

摘 要:研究连续变断面循环挤压变形道次、变形温度、变形速度对TC4合金组织的影响。结果表明:在临近再结晶温度变形时,随着变形道次的增加,晶粒的细化程度随之增加;而在较高温度变形时,随着变形道次的增加,晶粒的细化程度先增大后减小,且6道次的细化效果较佳。随着变形温度的升高,由于再结晶的作用,晶粒的细化程度先增大再减小,且在800 ℃变形时,细化效果较佳;提高变形速度有利于晶粒的细化,但当变形速度过高时,组织分布的均匀性较差。当TC4合金在800 ℃以2 mm/s经6道次变形后,初生α相尺寸由14 μm细化至2~ 3 μm左右,且组织分布较均匀。

关键词:TC4合金;连续变断面循环挤压;显微组织;晶粒细化

中图分类号:TG146.2 文献标志码:A

Effect of continuous variable cross-section recycling extrusion on microstructure of TC4 alloy

LI Jie, LIU Ying-ying, WANG Qing-juan, YOU Xue-lei, WANG Kun

(School of Metallurgical Engineering, Xi’an University of Architecture & Technology, Xi’an 710055, China)

Abstract: The TC4 titanium alloy was deformed by continuous variable cross-section recycling extrusion (CVCE), and the effects of deformation loop, temperature and speed on the microstructure were investigated. The results show that, near the recrystallization temperature, the grain size of the alloy decreases rapidly with increasing deformation loop. However, when deformed at higher temperature, the refinement degree of the grain increases firstly, and then decreases with the increase of deformation loops, and the refinement effect of 6 loops is better. Moreover, with the increase of deformation temperature, the grain size decreases firstly, and then increases due to recrystallization, and the refinement effect is better as the specimen is deformed at 800 ℃. The higher deformation speed is beneficial to refine the grain, but too high deformation speed is unfavourable for the distribution uniformity of microstructure. When the specimen is deformed at 800 ℃ and 2 mm/s for 6 loops, the size of the primary α phase reduces from 14 μm to 2-3 μm, and the microstructure distributes homogeneously.

Key words: TC4 alloy; continuous variable cross-section recycling extrusion; microstructure; grain refinement

连续变断面循环挤压法是近几年提出的一种大塑性变形法[1](Continuous variable cross-section recycled extrusion, CVCE),这种工艺是利用挤压和镦粗交替变形所产生的累积应变量与动态再结晶共同作用细化晶粒,以提高材料的综合性能[2-5]。连续变断面循环挤压法的最大优点如下:当高径比较大的圆柱试样镦粗时不会出现鼓形及压缩失稳现象;可以制备大规格块体细晶材料,且操作简单、模具成本低[3];具有实现工业生产和应用的可能性。目前,采用连续变断面循环挤压技术已成功制备出纯铝和镁合金细晶材料,如1A85纯铝室温经过4循环挤压后,得到1 μm细晶[4],AZ31镁合金在350℃经6循环挤压后,晶粒从13.3 μm细化至4 μm左右[5]。

钛合金具有密度小、比强度高、耐腐蚀等优良性能,被广泛应用于航空、航天、航海和化工等各个领域。TC4合金属于α+β两相钛合金,其组织与性能的关系非常密切,不同的组织具有不同的性能。研究结果表明:钛合金经等通道转角挤压[6-7](Equal channel angular pressing, ECAP)、高压扭转[8](High pressure torsion, HPT)、累积轧制[9](Accumulative roll bonding, ARB)、多向锻造[10](Multiple forging, MF)等方法变形后均可获得等轴、细小和均匀的显微组织,并能显著提高材料的塑性。但是这些方法存在工艺复杂、成本高和效率低等问题,不利于工业化转变。因此,本文作者采用连续变断面循环挤压法对TC4合金进行变形,研究连续变断面循环挤压对TC4合金显微组织的影响,获得制备具有等轴、细小、均匀的TC4合金的较佳工艺参数,为提高该合金的组织性能提供一定的工艺技术及参数指导。

1 实验

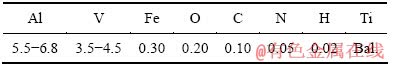

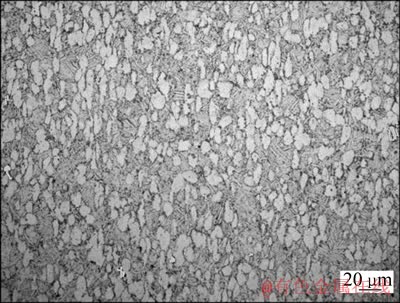

本研究所用原材料是由宝钛集团提供的d 20 mm的退火态TC4钛合金轧制棒材,相变温度为989 ℃,其化学成分和显微组织分别如表1和图1所示。

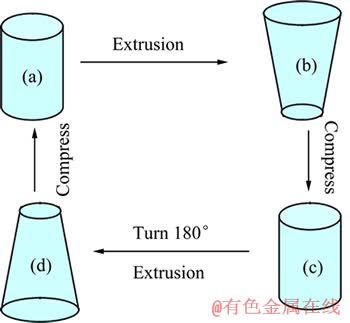

从图1可以看出,在β基体上分布着等轴的初生α相和片状的次生α相,其中初生α相的平均晶粒尺寸为14 μm。图2所示为连续变断面循环挤压法的工艺流程图。连续变断面循环挤压工艺是将圆柱体试样放入模腔中挤压成圆台体,再将圆台体镦粗成圆柱体,然后将试样变形量较小的一端朝下放入锥模进行挤压以及镦粗,完成一个道次的变形。通过多道次循环变形累积的应变量来获取大的塑性变形。

表1 TC4钛合金化学成分

Table 1 Chemical composition of TC4 titanium alloy (mass fraction, %)

图1 未经变形试样的原始显微组织

Fig. 1 Initial microstructure of specimen before deformation

根据TC4合金的塑性和模具型腔的尺寸,采用线切割将TC4棒材加工成d 20 mm×26 mm的圆柱状试样,随后采用YJ32-160B1型四柱液压机对试样进行连续变断面循环挤压变形。变形时,采用两台电阻式加热炉分别对试样和模具进行加热,其中挤压模具的加热温度为500 ℃。考虑到TC4合金的再结晶温度为700~800 ℃,故选取变形温度为700、750、800和850 ℃;挤压道次为3、6、8和12;挤压速度为0.5、2和5 mm/s。在连续变断面循环挤压的每两个工序之间,将试样加热10 min进行退火,以降低残余应力,提高材料的塑性,当试样达到所要求的变形循环道次后水冷。

图2 CVCE工艺流程图

Fig. 2 Process flow of CVCE

分别采用280、600、800、1200和2000号的砂纸对试样依次进行打磨、抛光,酒精清洗后,对试样表面进行腐蚀,腐蚀液为HF、NO3和H2O的混合液,且V(HF):V(HNO3):V(H2O)=1:3:7,腐蚀时间2~3min。然后采用OLYMPUS光学金相显微镜观察式样沿径向的显微组织。采用JD-1型双喷减薄机制样,电解双喷抛光液为HClO4、C2H5OH和H3OH的混合液,且V(HClO4):V(C2H5OH):V(H3OH)=1:2:7,喷射电压为40 V,并用液氮冷却,对试样进行减薄至穿孔制得透射电镜试样。采用Tecani G2 F30型透射电子显微镜观察试样的组织形貌及位错组态变化。

2 结果与分析

2.1 变形道次的影响

图3所示为在750 ℃以2 mm/s经不同道次变形后TC4合金的显微组织。由图3可以看出,经过3道次变形后,组织中保留有大量的次生α相,初生α相也无明显变化(见图3(a));经过6道次或8道次变形后,次生α相破碎程度增大,初生α相的晶界模糊(见图3(b)和(c));经过12道次变形后,次生α相晶粒均匀细小,初生α相破碎程度增大,且晶粒可细化至3 μm(见图3(d))。

在挤压工序时,试样边部的晶粒不仅沿轴向产生了延伸变形,由于摩擦力的存在,还产生了剪切变形,这些均有利于晶粒被拉长,拉长程度更大的晶粒会被破碎而呈现出等轴状;镦粗时,在压应力和切应力的共同作用下,组织中形成大量的剪切和滑移,导致被拉长的组织破碎成等轴状组织,从而有效地细化晶粒。这种挤压—镦粗工艺累似于反复揉压,使得晶粒发生充分破碎和断裂。随着挤压道次的增加,大量位错的增殖及位错之间的相互缠结,形成了位错胞,而且变形量越大,位错胞就越多且越小,晶粒细化程度就越好[11]。因此,当循环道次为12时,晶粒更加细小,且组织分布更加均匀。

图4所示为在800 ℃以2 mm/s经不同道次变形后TC4合金的显微组织。由图4可以看出,经3道次变形后,初生α相的尺寸为7~13 μm,且片状次生α相的破碎效果较差(见图4(a));经6道次变形后,次生α相完全破碎,初生α相的尺寸为2~3 μm ,且显微组织均匀,晶粒细化效果显著(见图4(b));与6道次相比,8道次的初生α相晶粒尺寸和形态无明显变化(见图4(c));但经12道次变形后,初生α相的尺寸为4~12 μm,不仅组织有所粗化,其分布的均匀性也变差(见图4(d))。其原因是当变形量低于6道次时,随着变形道次的增加,累积应变量不断增加,材料发生强烈变形,从而产生大量位错和剧烈的晶界扭曲,增大再结晶驱动力,促进晶粒细化[12]。当变形道次为6~8时,累积变形量达到一定程度,位错密度基本不再变化,所以晶粒尺寸基本不变。但当变形道次大于8时,晶粒尺寸已细化到了极限,此外由于变形时的反复加热,晶界扩散和迁移能力增强,导致再结晶晶粒发生合并长大,故12道次的晶粒细化效果较差[13]。

图3 在750 ℃以2 mm/s经不同道次变形后试样的显微组织

Fig. 3 Microstructures of specimens deformed at 750 ℃ with 2 mm/s for different loops

图4 在800 ℃以2 mm/s经不同道次变形后试样的显微组织

Fig. 4 Microstructures of specimen deformed at 800 ℃ and 2 mm/s for different loops

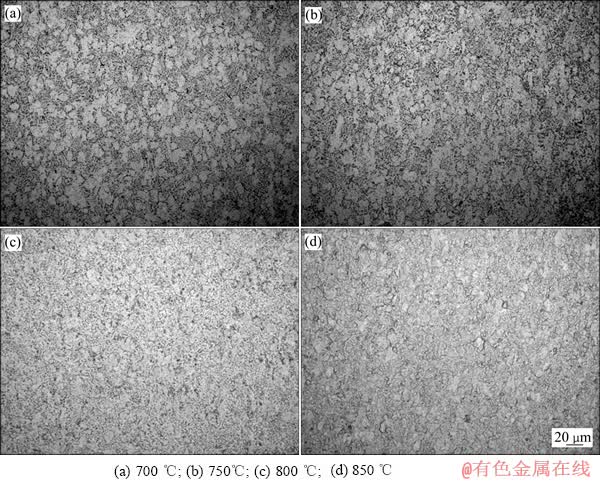

2.2 变形温度的影响

图5所示为在不同温度以2 mm/s经6道次变形后TC4合金的显微组织。由图5可以看出,当挤压温度为700和750 ℃时,晶粒细化不均匀,且存在大量次生α相,仍然保留变形组织(见图5(a)和(b));当变形温度为800 ℃时,初生α相的晶粒尺寸为2~3 μm,细化效果显著,且组织分布均匀(见图5(c));当变形温度继续升高至850 ℃时,初生α相的晶粒尺寸由2~3 μm增至4~6 μm(见图5(d))。

当挤压温度为700和750 ℃时,仍然保留变形组织,其原因是由于坯料和模具之间发生热量交换,导致实际的变形温度可能低于再结晶温度,从而保留了变形组织的形貌。但是,当变形温度升高至800 ℃ 时,晶粒的细化效果显著,这是由于随着温度的提高,位错活动性提高,从而导致晶间切变抗力降低,金属的塑性得到提高,同时变形所需的激活能降低,晶粒容易发生回复和再结晶,因此,提高变形温度有利于挤压的进行和晶粒的细化。但当变形温度过高时(高于800 ℃),位错的湮灭速度将大于增殖速度,导致位错密度减小,再结晶形核能减小,细化效果反而变差[14]。

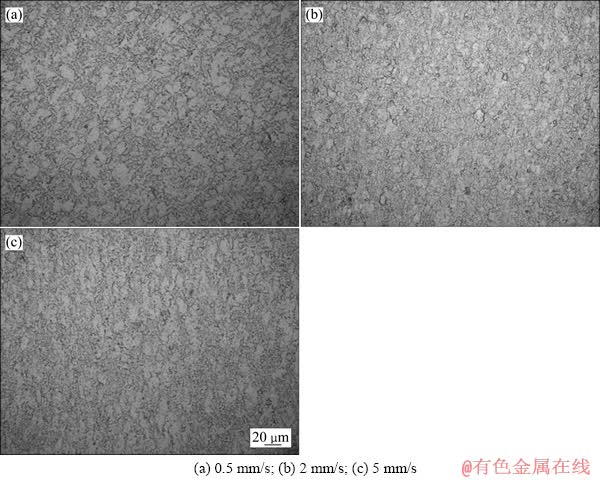

2.3 变形速度的影响

图6所示为在850 ℃以不同速度经6道次变形后TC4合金的显微组织。由图6可以看出,变形速度为0.5 mm/s时,其显微组织中存在大量的初生α相和次生α相,基本上仍然保留变形组织,晶粒细化效果较差(见图6(a));当变形速度为2 mm/s时,次生α相完全被破碎,初生α相平均晶粒度为5 μm,且组织的均匀性较好,等轴化程度高(见图6(b));当变形速度增大到5 mm/s时,初生α相的晶粒尺寸为4~8 μm,次生α相的破碎效果较佳,但组织的均匀性相对较差(见图6(c))。

当变形速度为0.5 mm/s时,由于变形速度过低,试样在变形时温度下降明显,材料的塑性下降,导致细化效果较差;变形速度为2 mm/s时,组织细化效果较好,且组织分布的均匀性较好,这与挤压模腔相接触的坯料表层受模具冷却作用较小,同时,变形过程中材料与模具摩擦引起热效应,致使坯料表层的温降较小,温度场分布相对均匀,且材料在变形过程中的回复和动态再结晶时间较长有关。TC4合金属于难变形材料,随着变形速度的增大,晶格畸变能随之增大,位错密度也随之增大,晶粒的细化效果较佳。但是,随着挤压速度继续增大至5 mm/s时,材料的易变形区变形剧烈,产生大量的变形热,且来不及向坯料的表层传递热量,导致温度场的不均匀性增大;此外,由于变形速度较大,达到同样的变形所需的时间也较短,使得动态回复和动态再结晶不充分,这些都使得组织的均匀性降低[15-16]。

综上所述,当TC4合金在700~850 ℃以0.5~5 mm/s进行3~12循环变形时, 晶粒细化效果最佳的一组工艺参数为800 ℃、2 mm/s、6道次,可将晶粒从14 μm细化至2~3 μm,且组织分布的均匀性较好。

图5 在不同温度以2mm/s经6道次变形后试样的显微组织

Fig. 5 Microstructures of specimen deformed at different temperatures and 2 mm/s for 6 loops

图6 在850 ℃以不同速度经6道次变形后试样的显微组织

Fig. 6 Microstructures of specimens deformed at 850 ℃ and different speeds for 6 loops: (a) 0.5 mm/s; (b) 2 mm/s; (c) 5 mm/s

图7所示为TC4合金在此工艺参数下变形后的TEM像。由图7可以得出与从光学组织得到的同样的结果:平均晶粒尺寸为2 μm。

图7 在800 ℃时以2 mm/s经6道次变形后试样的TEM像

Fig. 7 TEM image of specimen deformed at 800 ℃ and 2 mm/s for 6 loops

3 结论

1)在临近再结晶温度变形时,随着变形量的增加,晶粒的细化程度增加;在较高温度变形时,随着变形量的增加,晶粒的细化程度呈先增大后减小的趋势,6道次的细化效果较佳。

2) 随着变形温度的升高,晶粒的细化程度先增大再减小,且变形温度为800 ℃时,细化效果较佳。虽然提高变形速度有利于晶粒的细化,但变形速度过高时组织分布的均匀性较差。

3) TC4合金在800 ℃以2 mm/s经6道次变形后,初生α晶粒尺寸由14 μm细化至2~3 μm,且组织分布均匀。

REFERENCES

[1] AZUSHIMA A, KOPP R, KORHONEN A,YANG D Y, MICARI F, LAHOTI G D, GROCHE P, YANAGIMOTO J, TSUJI N, ROSOCHOWSKI A, YANAGIDA A. Severe plastic deformation (SPD) processes for metals[J]. CIRP Annals- Manufacturing Technology, 2008, 57(2): 716-735.

[2] 刘长瑞, 王庆娟, 王快社. 连续变断面循环挤压制备细晶材料的方法及装置: 中国, CN100386466C[P]. 2008-05-07.

LIU Chang-rui, WANG Qing-juan, WANG Kuai-she. Method and apparatus for preparing fine-grained material: China, CN100386466C[P]. 2008-05-07.

[3] 刘长瑞, 王庆娟, 杜仲泽, 王快社, 陈 明. 连续变断面循环挤压制备细晶材料的新方法研究[J]. 稀有金属材料与工程, 2009, 38(S1): s257-s260.

LIU Chang-rui, WANG Qing-juan, DU Zhong-ze, WANG Kuai-she, CHEN Ming. Technology of producing refined grain materials by continuous variable cross-section recycled extrusion[J]. Rare Metal Materials and Engineering, 2009, 38(S1): s257-s260.

[4] 张 娟, 刘长瑞, 王庆娟, 王快社, 马正强. 纯铝1A85 连续变断面循环挤压过程的组织演变[J]. 材料科学与工程学报, 2010, 28(6): 930-933.

ZHANG Juan, LIU Chang-rui, WANG Qing-juan, WANG Kuai-she, MA Zheng-qiang. Structural evolution of pure aluminum 1A85 during continuous variable cross-Section recycled extrusion[J]. Journal of Materials Science & Engineering, 2010, 28(6): 930-933.

[5] 刘长瑞, 任红霞, 王庆娟. 连续变断面循环挤压AZ31镁合金的组织与性能[J]. 轻合金加工技术, 2009, 37(7): 34-37.

LIU Chang-rui, REN Hong-xia, WANG Qing-juan. Microstructure and properties of AZ31 magnesium alloy by continuous variable cross-section recycled extrusion[J]. Light Alloy Fabrication Technology, 2009, 37(7): 34-37.

[6] SEMENOVA I P, RAAB G I, SAITOVA L R, VALIEV R Z. The effect of equal-channel angular pressing on the structure and mechanical behavior of Ti-6Al-4V alloy[J]. Materials Science and Engineering A, 2004, 387/389: 805-808.

[7] SONG Jie, WANG Li-ming, ZHANG Xiao-ning, SUN Xiao-gang, JIANG Hong, FAN Zhi-guo, XIE Chao-ying, WU M H. Effects of second phases on mechanical properties and martensitic transformations of ECAPed TiNi and Ti-Mo based shape memory alloys[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(8): 1839-1848.

[8] ISLAMGALIEV R K, KAZYHANOV V U, SHESTAKOVA L O, SHARAFUTDINOV A V, VALIEV R Z. Microstructure and mechanical properties of titanium (Grade 4) processed by high-pressure torsion[J]. Materials Science and Engineering A, 2008, 493(1): 190-194.

[9] RADUCANU D, VASILESCU E, COJOCARU V D, CINCA I, DROB P, VASILESCU C, DROB S I. Mechanical and corrosion resistance of a new nanostructured Ti-Zr-Ta-Nb alloy[J]. Journal of the Mechanical Behavior of Biomedical Materials, 2011, 4(7): 1421-1430.

[10] 徐 烽, 颜银标. 多向锻造法细化钛及钛合金晶粒的研究现状[J]. 钛工业进展, 2012, 29(2): 15-18.

XU Feng, YAN Yin-biao. The research situation of refining titanium and titanium alloys by using multi-direction forging[J]. Titanium Industry Progress, 2012, 29(2): 15-18.

[11] 杨西荣, 赵西成, 付文杰. 钛及钛合金ECAP变形研究进展[J]. 材料导报, 2010, 24(3): 96-100.

YANG Xi-rong, ZHAO Xi-cheng, FU Wen-jie. Review on UFG titanium and its alloys processed by ECAP[J]. Materials Review, 2010, 24(3): 96-100.

[12] 康志新, 彭勇辉, 赖晓明, 李元元, 赵海东, 张卫文. 剧塑性变形制备超细晶/纳米晶结构金属材料的研究现状和应用展望[J]. 中国有色金属学报, 2010, 20(4): 587-598.

KANG Zhi-xin, PENG Yong-hui, LAI Xiao-ming, LI Yuan-yuan, ZHAO Hai-dong, ZHANG Wei-wen. Research status and application prospect of ultrafine grained and/or nano-crystalline metallic materials processed by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 587-598.

[13] 张 郑, 王经涛, 赵西成. 7475铝合金ECAP的晶粒细化极限[J]. 中国有色金属学报, 2004, 14(5): 741-745.

ZHANG Zheng, WANG Jing-tao, ZHAO Xi-cheng. Microstructure and grain refinement limit of 7475 aluminum alloy after equal-channel angular pressing[J]. The Chinese Journal of Nonferrous Metals, 2004, 14(5): 741-745.

[14] KIM I, KIM J, SHIN D H, LEE C S, HWANG S K. Effects of equal channel angular pressing temperature on deformation structures of pure Ti[J]. Materials Science and Engineering A, 2003, 342(1): 302-310.

[15] 张忠明, 王锦程, 唐文亭, 郭学锋, 杨根仓. 等通道转角挤压(ECAP)工艺的研究现状[J]. 铸造技术, 2004, 25(1): 10-12.

ZHANG Zhong-ming, WANG Jin-cheng, TANG Wen-ting, GUO Xue-feng, YANG Geng-cang. Status of equal Channel angular pressing (ECAP)[J]. Foundry Technology, 2004, 25(1): 10-12.

[16] PARK K T, KWON H J, KIM W J, KIM Y S. Microstructural characteristics and thermal stability of ultrafine grained 6061 Al alloy fabricated by accumulative roll bonding process[J]. Materials Science and Engineering A, 2001, 316(1/2): 145-152.

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51101116)

收稿日期:2014-07-21;修订日期:2014-11-14

通信作者:刘莹莹,副教授,博士;电话:029-82205097;E-mail: wfllyy7779@163.com