DOI: 10.11817/j.ysxb.1004.0609.2020-39455

预拉伸变形量对7055铝合金厚板表面残余应力的影响

范 宁1, 2, 3,熊柏青1, 3,李志辉1, 3,闫宏伟1, 2, 3,张永安1, 2, 3,李锡武1, 2, 3,温 凯1, 2, 3

(1. 有研科技集团有限公司 有色金属材料制备加工国家重点实验室,北京 100088;

2. 有研工程技术研究院有限公司,北京 101407;3. 北京有色金属研究总院,北京 100088)

摘 要:为了系统性地研究预拉伸变形量对淬火残余应力的消减规律,采用基于cosα法的μ-X360s型X射线残余应力分析仪,表征7055铝合金厚板经不同预拉伸变形量(0%、0.5%、1.2%、1.5%、2.5%、3.3%、3.9%)的表面残余应力水平,并通过基于sin2Ψ法的X射线衍射法和钻孔法验证测试结果。结果表明:7055铝合金厚板经过固溶淬火处理后,残余应力水平较高,轧向分应力略小于横向分应力,在厚板边缘区域残余应力水平波动较大,波动区域大约在距边部27mm的位置。当预拉伸变形量为1.5%时,轧向分应力的明显减小,继续增大拉伸量,残余应力稳定在-60~-70 MPa;而当预拉伸变形量大约为1.5%时,横向分应力由压应力状态转变为拉应力状态;经超过2.5%的预拉伸变形后,残余应力稳定在20~30 MPa。

关键词:7055铝合金厚板;淬火;预拉伸;残余应力;X射线衍射法

文章编号:1004-0609(2020)-02-0301-07 中图分类号:TG146.21 文献标志码:A

7055铝合金是一种可热处理强化的超高强变形铝合金,目前已广泛应用于航空航天等重要领域[1]。7055铝合金厚板通过在高温固溶处理后淬火处理来获得过饱和固溶体,从而在后续的时效过程中析出细小弥散的强化相以提高合金的力学性能[2-3]。然而在淬火过程中,铝合金厚板的表层和心部之间存在较高的温度梯度,从而产生较大的淬火残余应力[4-5],在后续的机加工过程中可能发生严重的变形甚至开裂,同时也影响铝合金构件的疲劳性能、抗应力腐蚀等性能[6]。

淬火完成后,一般还需进行预拉伸、预压缩、振动时效或热处理时效等工艺消减淬火残余应力[7-9]。无论从消除工艺角度还是生产实际考虑,预拉伸已被广泛应用于超大规格铝合金厚板淬火残余应力的消除。TANNER等[10]的研究结果表明,对7010铝合金厚板施加2%的拉伸量,可消除大部分残余应力;KARABIN等[11]解释了预拉伸消除残余应力的机理;而LUO 等[12]、WU等[13]、LIAO等[14]以及龚海[15]利用有限元模拟,分析了铝合金厚板淬火-预拉伸残余应力分布特点和演变规律。ZHANG等[16]建立了铝合金预拉伸板残余应力场分层模型,研究了厚板沿厚度方向力学性能不均匀对预拉伸消除残余应力的影响。

当前研究存在的主要问题是缺少利用实验测试手段来系统性地表征铝合金经过不同预拉伸变形量后的残余应力水平和分布,缺乏预拉伸对残余应力消减规律的实验数据支撑。本研究采用基于cosα法的X射线衍射法,表征了7055铝合金厚板经过不同预拉伸变形量后的表面残余应力分布,分析了预拉伸态铝合金厚板残余应力的分布水平,探明了不同预拉伸变形量对7055铝合金厚板淬火残余应力的消减规律。

1 实验

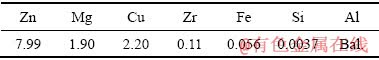

实验材料选择尺寸规格为400 mm×60 mm×27 mm(L向×LT向×ST向)的7055-H112铝合金厚板,合金成分如表1所示。

表1 7055铝合金合金成分

Table 1 Chemical composition of 7055 aluminum alloy (mass fraction, %)

图1所示为实验厚板尺寸示意图及照片。经过475 ℃、2 h的固溶处理后,在30 ℃的水中进行淬火,转移过程不超过3 s。厚板两端由细铁丝牵引,沿厚度方向浸入淬火池。淬火过程无任何搅拌,且冷却水量充足,保证淬火过程的一致性。淬火完成后,在万能拉伸机上进行预拉伸实验,如图2所示。两端夹持区均为60 mm,夹持力为602.8 kN,拉伸速率为5 mm/min。除去夹持区,厚板变形区长度为260 mm,预拉伸完成卸载后,再次测量变形区长度,拉伸率的计算式如下:

(1)

(1)

式中:l0为预拉伸前变形区的长度;l为预拉伸后变形区的长度。

最终确定拉伸率分别为0.5%、1.2%、1.5%、2.5%、3.3%、3.9%。

图1 淬火-预拉伸板示意图及照片

Fig. 1 Schematic diagram(a) and photos(b) of quenched- prestretched plate

图2 预拉伸实验装置图

Fig. 2 Diagram of pre-stretching equipment

铝合金厚板表面残余应力测试设备选择日本Pulstec公司制造的μ-X360s型X射线残余应力分析仪。该设备基于cosα法,采用全二维探测器,单角度入射即可获得完整的Debye-Scherrer环,对于铝合金等晶粒粗大或存在织构的材料,通过添加振荡单元,可以高精度地拟合计算残余应力[17]。设备渗透深度约为10 μm,准直器直径为1 mm。选用靶材为标准Cr靶。测点分布如图1所示,同一测点分别测试轧向分应力(σR)和横向分应力(σT)。除应力分布均匀区外,重点测试厚板表面沿L方向和LT方向靠近边缘或夹持区的应力波动区域,在厚板同一表面每隔3 mm取一个测点,共9个测点。此外,在每块厚板的中心位置取两个测点,分别使用基于sin2Ψ法的X射线衍射法和钻孔法测试,验证测试结果。

2 结果与讨论

2.1 测试方法对比

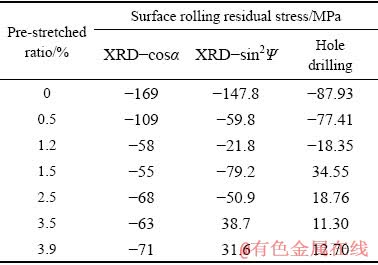

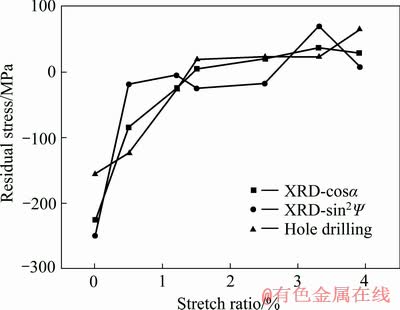

对基于cosα法的X射线衍射法、基于sin2Ψ法的X射线衍射法和钻孔法在表面中心点的测试结果进行对比验证。表2和3所示分别为3种测试方法表征不同预拉伸变形量的7055铝合金厚板表面中心点轧向和横向残余应力水平。由表2和3可知,3种测试方法均能有效的表征预拉伸对淬火残余应力的消减规律,即施加一定变形量的预拉伸,淬火残余应力明显得到了消减,而继续增大预拉伸变形量,残余应力的变化不大。横向对比3种测试方法可以看出,测试结果的绝对数值略有偏差。造成这种差异的原因可能是3种测试方法的测试原理和空间分辨率不同。基于sin2Ψ法的X射线衍射法在测试过程中需要改变晶面衍射方位角Ψ,分别测定对应的衍射角2θ,然后通过sin2Ψ-2θ拟合曲线的斜率计算残余应力值。基于cosα法的X射线衍射法无需改变入射角,通过分析Debye-Scherrer环来计算残余应力值。这两种原理的X射线衍射法在铝合金中的测试深度约为表面10 μm。钻孔法属于机械释放方法,在材料表面钻一个直径1.5 mm×2 mm的圆孔,通过捕捉圆孔周围的应变来计算该圆孔的应力值。而且,钻孔法对人为操作影响较为敏感,测试过程中微小的失误就会使结果出现较大偏差。

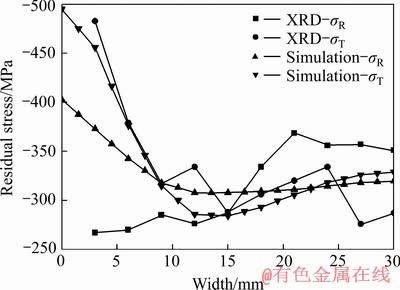

2.2 淬火残余应力

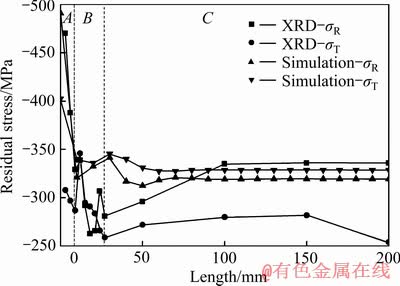

7055铝合金厚板沿L方向表面淬火残余应力分布如图5所示。在应力分布均匀区域,轧向分应力在(-169±30) MPa之间,横向分应力在(-225±28) MPa之间,整体来看,轧向分应力小于横向分应力。

表2 3种测试方法表征不同预拉伸变形量的7055铝合金厚板表面轧向分应力

Table 2 Surface rolling residual stress of 7055 aluminum alloy plate with different pre-stretched ratios by three measuring methods

图3 3种测试方法表征不同预拉伸变形量的7055铝合金厚板表面轧向分应力

Fig. 3 Surface rolling residual stress of 7055 aluminum alloy plate with different pre-stretched ratios by three measuring methods

表3 3种测试方法表征不同预拉伸变形量的7055铝合金厚板表面横向分应力

Table 3 Surface transverse residual stress of 7055 aluminum alloy plate with different pre-stretched ratios by three measuring methods

图4 3种测试方法表征不同预拉伸变形量的7055铝合金厚板表面横向分应力

Fig. 4 Surface transverse residual stress of 7055 aluminum alloy plate with different pre-stretched ratios by three measuring methods

由图5可知,淬火态的7055铝合金厚板表面存在明显的残余压应力,根据残余应力的自平衡性可知,厚板心部呈现拉应力状态。淬火时,厚板的边角处首先快速冷却,低温状态屈服强度高,不易发生塑性变形,因此,厚板整体的几何形状基本确定;而表面的冷却速率比心部快,因此表面先发生变形,此时既有弹性变形,也有塑性变形;对应的厚板心部还处在高温状态,不会产生较大的应变,内外塑性变形不均匀导致表面呈现拉应力状态,心部呈现压应力状态。随着淬火的继续进行,表面材料温度已经比较低,屈服强度高,所以变形仅存在弹性变形的形式。心部开始冷却收缩,发生塑性变形,因此心部呈现拉应力状态,受限于厚板整体的几何尺寸,表面呈现压应力状态。随着厚板心部温度的下降,屈服强度升高,不再发生塑性变形。最终,残余应力以弹性变形能的形式储存在铝合金厚板内,整个厚板在表面呈现出残余压应力、心部呈现出残余拉应力的状态。

图5 7055铝合金厚板沿L方向表面淬火残余应力分布

Fig. 5 Surface residual stress distribution of 7055 aluminum alloy plate along L direction (σR—Rolling residual stress; σT—Transverse residual stress)

此外,通过靠近边缘区域的测试结果可以看出,该区域的轧向分应力波动明显,而横向分应力波动较小。在淬火起始阶段,0~10 mm的边缘区域(A区域)首先冷却,材料在低温状态下屈服强度高,后续由温度梯度引起的变形不足以诱发塑性变形,此时的变形基本为弹性变形。随着淬火的进行,材料各处温度基本一致,温度梯度消失,边缘区域的变形发生回弹,因此残余应力水平较低。在距离边缘10~27 mm的区域(B区域),在淬火中期仍会发生一定的塑性变形,回弹后该位置存在一定的残余应力。在距离边缘27 mm以上的区域(C区域),塑性变形量较大,回弹后的残余应力也较高且分布基本均匀。从边缘到中心处,轧向塑性变形逐渐增大,横向塑性变形相对较小,因此会出现轧向分应力波动大、横向分应力波动小的现象。

图6所示为7055铝合金厚板沿LT方向表面淬火残余应力分布,同理可得出类似的结论,沿LT方向分布的残余应力,其横向分应力波动较大、轧向残余应力波动较小。

2.3 预拉伸对残余应力水平的影响

图6 7055铝合金厚板沿LT方向表面淬火残余应力分布

Fig. 6 Surface residual stress distribution of 7055 aluminum alloy plate along LT direction (σR—Rolling residual stress; σT—Transverse residual stress)

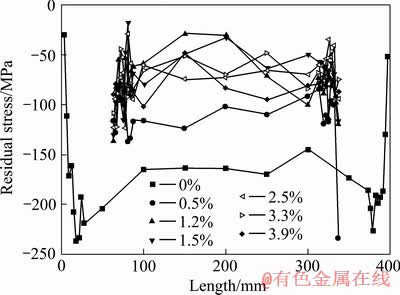

图7 不同预拉伸变形量的7055铝合金厚板表面轧向分应力沿L方向分布

Fig. 7 Surface rolling residual stress distribution of 7055 aluminum alloy plate with different pre-stretched ratios along L direction

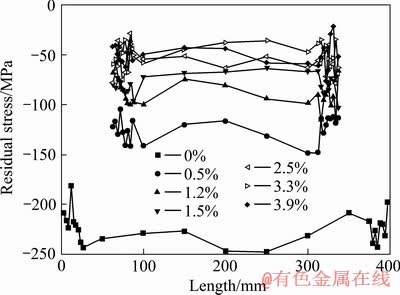

图8 不同预拉伸变形量的7055铝合金厚板表面横向分应力沿L方向分布

Fig. 8 Surface transverse residual stress distribution of 7055 aluminum alloy plate with different pre-stretched ratios along L direction

图7所示为不同预拉伸变形量的7055铝合金厚板表面轧向分应力沿L方向分布。7055铝合金厚板淬火态的表面轧向残余应力为(-169±30) MPa,经过0.5%的预拉伸变形后,残余应力降低到(-109±16) MPa,应力削减率为35.50%;经过1.5%的预拉伸变形后,残余应力水平降到(-55±29) MPa,应力削减率为67.46%。继续增加拉伸量,轧向残余应力基本保持不变。图8所示为不同预拉伸变形量的7055铝合金厚板表面横向分应力沿L方向分布,7055铝合金厚板淬火态的表面横向残余应力水平为(-211±28) MPa,经过0.5%的预拉伸变形后,残余应力水平降低到(-84±22) MPa,应力削减率为60.19%;经过1.5%的预拉伸变形后,表面残余应力状态由压应力转变为拉应力;经过2.5%的预拉伸变形后,残余应力水平大约为20~30 MPa,且继续增加预拉伸量,横向残余应力基本保持不变。说明淬火态7055铝合金厚板经过预拉伸处理后,可以有效地消减淬火残余应力,但当预拉伸变形量增加到一定值时,继续增大预拉伸变形量,厚板的残余应力水平变化不大。

铝合金厚板在预拉伸过程中沿轧制方向拉伸,同时横向也会产生一定程度的收缩。因为预拉伸会导致晶粒间原来的平衡状态被破坏,晶粒发生移动或转动,晶内位错发生滑移,由此引发塑性变形,晶粒平衡状态的改变会引起原有应力平衡状态的剧烈变化。整个厚板通过预拉伸来协调各部分的塑性变形程度,使变形状态尽量趋于一致,卸载回弹后,把厚板的残余应力水平控制在一个较低的水平。

铝合金厚板在热轧过程中会产生大量的轧制织构,但在表层或近表层的区域,除轧制织构外,还存在大量的剪切织构。此外,热轧还会导致表层的晶粒细化,呈扁平状,从表层到心部,晶粒尺寸增大。在淬火过程中,心部由于冷却速度缓慢,发生脱溶析出,导致厚板沿厚度方向的微观组织和力学性能具有一定的差异。这种由于晶粒、织构、微观组织和力学性能等不均匀性的综合作用使超大规格铝合金厚板具有严重的各向异性,在预拉伸过程中不同位置的塑性变形程度不同,导致在整个厚板内部仍然存在一定水平的残余应力,而且继续增加拉伸量,对整体残余应力的削减效果不大。

一般地,可以通过测试结果的标准偏差值来表征数据的波动性。图9所示为不同拉伸率的7055铝合金厚板表面残余应力标准偏差。由图9可以看出,未经过预拉伸的厚板,残余应力分布波动较大,表面轧向分应力和横向分应力的标准偏差均大于40。经过预拉伸变形后,标准偏差明显降低,说明厚板的残余应力分布趋于均匀一致,而且随着预拉伸变形量的增加,厚板的标准偏差逐渐降低。说明预拉伸工艺不但可以消减残余应力水平,还可以有效地减弱残余应力分布的不均匀性。

图9 不同预拉伸变形量的7055铝合金厚板表面残余应力标准偏差

Fig. 9 Standard deviation for surface residual stress of 7055 aluminum alloy plate with different pre-stretched ratios

3 结论

1) 7055铝合金厚板淬火后表面残余应力为压应力状态,在本试验条件下,表面横向分应力略大于表面轧向分应力。

2) 在距离边缘位置大约27mm的区域,存在应力波动现象,沿L方向靠近边缘的区域,轧向分应力波动较大,而沿LT方向靠近边缘的区域,横向分应力波动较大。

3) 预拉伸工艺通过协调厚板各部分塑性变形行为的方式达到消减淬火残余应力的效果,并且可以减弱残余应力分布的不均匀性。

4) 当预拉伸变形量达到一定的数值后,继续增加拉伸量,对厚板残余应力的影响不大,残余应力消减效果的极值主要取决于厚板不同位置微观组织和力学性能不均匀程度。

REFERENCES

[1] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[2] 熊柏青, 李锡武, 张永安, 李志辉, 王 峰, 刘红伟. 高强韧低淬火敏感性7XXX系铝合金的发展[J]. 中国材料进展, 2014, 33(2):114-119.

XIONG Bai-qing, LI Xi-wu, ZHANG Yong-an, LI Zhi-hui, WANG Feng, LIU Hong-wei. Development of 7XXX series aluminum alloy with high strength high toughness and low quench sensitivity[J]. Materials China, 2014, 33(2): 114-119.

[3] LI Pei-yue, XIONG Bai-qing, ZHANG Yong-an, LI Zhi-hui, ZHU Bao-hong, WANG Feng, LIU Hong-wei. Quench sensitivity and microstructure character of high strength AA7050[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 268-274.

[4] ROBINSON J S, TANNER D A, TRUMAN C E. 50th anniversary article: The origin and management of residual stress in heat-treatable aluminium alloys[J]. Strain, 2014, 50(3): 185-207.

[5] 王祝堂. 铝合金厚板淬火残余应力及其控制[J]. 铝加工, 2013(4): 4-11.

WANG Zhu-tang. Residual stress in quenched aluminum alloy plate and its controlling[J]. Aluminium Fabrication, 2013(4): 4-11.

[6] JI Peng-fei, YANG Zhong-yu, ZHANG Jin, ZHENG Lin, VINCENT J, VINCENT K. Residual stress distribution and microstructure in the friction stir weld of 7075 aluminum alloy[J]. Journal of Materials Science, 2015, 50(22): 7262-7270.

[7] TANNER D A, ROBINSON J S. Reducing residual stress in 2014 aluminium alloy die forgings[J]. Materials & Design, 2008, 29(7): 1489-1496.

[8] VARDANJANI M J, GHAYOUR M, HOMAMI R M. Analysis of the vibrational stress relief for reducing the residual stresses caused by machining[J]. Experimental Techniques, 2016, 40(2):705-713.

[9] KOC M, CULP J, ALTAN T. Prediction of residual stresses in quenched aluminum blocks and their reduction through cold working processes[J]. Journal of Materials Processing Technology, 2006, 174(1/3): 342-354.

[10] TANNER D A, ROBINSON J S. Modeling stress reduction techniques of cold compression and stretching in wrought aluminium alloy products[J]. Finite Elements in Analysis & Design, 2003, 39(5): 369-386.

[11] KARABIN M E, BARLAT F, BECKER R. A simplified analysis of the effect of microstructure gradient on the stress relief of aluminum plates and extrusions[J]. International Journal of Mechanical Sciences, 2003, 45(9): 1483-1503.

[12] 罗家元, 朱才朝, 李大峰, 钟 渝, 李 云. 7075铝合金拉伸残余应力数值模拟及实验测试[J]. 重庆大学学报, 2011, 34(9): 33-38.

LUO Jia-yuan, ZHU Cai-chao, LI Da-feng, ZHONG Yu, LI Yun. Numerical simulation and experimental investigation of residual stress in the stretching process of the 7075 aluminum alloy[J]. Journal of Chongqing University, 2011, 34(9): 33-38.

[13] 吴运新, 龚 海, 廖 凯. 铝合金预拉伸板残余应力场的评估模型[J]. 华南理工大学学报(自然科学版), 2011, 39(1): 90-94.

WU Yun-xin, GONG Hai, LIAO Kai. Evaluation model of residual stress field of aluminum alloy pre-stretched plate[J]. Journal of South China University of Technology (Natural Science Edition), 2011, 39(1): 90-94.

[14] 廖 凯. 铝合金厚板淬火-预拉伸内应力形成机理及其测试方法研究[D]. 长沙: 中南大学, 2010.

LIAO Kai. Research on mechanism and measurement method of quenching-prestretching stress in aluminum alloy thick plate[D]. Changsha: Central South University, 2010.

[15] 龚 海. 铝合金厚板内应力演变规律及残余应力场评估模型研究[D]. 长沙: 中南大学, 2011.

GONG Hai. Research on evolution and evaluation model of residual stress in aluminum alloy thick plate[D]. Changsha: Central South University, 2011.

[16] ZHANG Shu-yuan, WU Yun-xin, GONG Hai. A modeling of residual stress in stretched aluminum alloy plate[J]. Journal of Materials Processing Technology, 2012, 212(11): 2463-2473.

[17] MIYAZAKI T, MARUYAMA Y, FUJIMOTO Y, SASAKI T. Improvement of X-ray stress measurement from a Debye-Scherrer ring by oscillation of the X-ray incident angle[J]. Powder Diffraction, 2015, 30(3): 250-255.

Influence of pre-stretched ratio on surface residual stress of 7055 aluminum alloy thick plate

FAN Ning1, 2, 3, XIONG Bai-qing1, 3, LI Zhi-hui1, 3, YAN Hong-wei1, 2, 3, ZHANG Yong-an1, 2, 3, LI Xi-wu1, 2, 3, WEN Kai1, 2, 3

(1. State Key Laboratory of Nonferrous Metals and Processes, GRINM Group Co., LTD., Beijing 100088, China;

2. GRIMAT Engineering Institute Co., LTD., Beijing 101407, China;

3. General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: In order to systematically study the reduction rule of quenched residual stress caused by pre-stretched systematically, the surface residual stresses of 7055 aluminum alloy thick plate with different pre-strectched ratios (0%, 0.5%, 1.2%, 1.5%, 2.5%, 3.3%, 3.9%) were characterized by the μ-X360s X-ray residual stress analyzer based on cosα method, and the measured results were verified by X-ray diffractometry based on sin2Ψ method and hole drilling method. The results show that the residual stress of 7055 aluminum alloy thick plate is relatively high than that of the alloy after solution-quenched treatment, the rolling residual stress is slightly less than the transverse residual stress. The residual stress fluctuates greatly at the edge area of thick plate, and the fluctuation area is about 27 mm away from the edge. When the pre-stretched ratio is 1.5%, the rolling residual stress decreases obviously. The residual stress is stable at -60- -70 MPa with increasing the pre-stretched ratio. When the pre-stretched ratio is about 1.5%, the transverse residual stress changes from compressive stress to tensile stress, and when the pre-stretched ratio is more than 2.5%, the residual stress is stable at 20-30 MPa.

Key words: 7055 aluminum alloy thick plate; quench; pre-stretch; residual stress; X-ray diffraction method

Foundation item: Projects(2016YFB0300803, 2016YFB0300903) supported by the National Basic Research Development Program of China

Received date: 2019-01-10; Accepted date: 2019-09-02

Corresponding author: LI Zhi-hui; Tel: +86-10-60662655; E-mail: lzh@grinm.com

(编辑 龙怀中)

基金项目:国家重点研究发展计划资助项目(2016YFB0300803,2016YFB0300903)

收稿日期:2019-01-10;修订日期:2019-09-02

通信作者:李志辉,教授,博士;电话:010-60662655;E-mail:lzh@grinm.com