文章编号:1004-0609(2008)05-0946-06

铜火法冶炼热动力学系统实测数据EMD处理

鄂加强,王春华,龚金科,李 娟,彭 雨,朱 浩

(湖南大学 机械与汽车工程学院,长沙 410082)

摘 要:为提高铜火法冶炼热动力学系统热工关键参数控制精度,针对热工关键参数信号的瞬时非线性特点,将热工关键参数信号EMD分解,并通过能量特征提取有用的IMF分量,去掉主要干扰因素所对应的IMF的影响,再将剩余IMF分量进行重构得到关键热工参数信号的真实趋势。铜精炼过程重油流量数据EMD处理以及铜锍吹炼过程氧化空气压力数据EMD处理实例表明,重油输送管路压降振荡脉动是引起重油流量信号无规则波动的主要原因,而压降振荡是引起铜锍吹炼过程氧化空气压力信号振荡的主要原因,去掉相关IMF分量所对应的干扰因素,重构后的信号能反映参数信号的真实波动趋势。本文所提出的方法用于分析非线性不确定的铜火法冶炼热动力学系统关键热工参数信号变化的真实趋势具有较好的效果。

关键词:铜火法冶炼;热动力学系统;经验模态分解方法;本征模函数

中图分类号:TF 811 文献标识码:A

Process on measurement data from copper pyrometallurgical

heat dynamical system by using of EMD method

E Jia-qiang, WANG Chun-hua, GONG Jin-ke, LI Juan, PENG Yu, ZHU Hao

(College of Mechanical and Automotive Engineering, Hunan University, Changsha 410082, China)

Abstract: In order to improve control accuracy of key parameters about heat engineering from copper pyrometallurgical heat dynamical system, a new method for recognition of specific frequency band was put forward by using of power spectrum of its intrinsic mode function components based on the instantaneous nonlinear characteristic of key parameters about heat engineering. By using of empirical mode decomposition, instantaneous key parameters signals about heat engineering are decomposed into a series of IMFs, each of which covers a specific frequency band, which means corresponding disturbance factor. Then useful IMFs are selected as features to reconstruct key parameters signals about heat engineering which present true trend for key parameters signals about heat engineering. The application examples that the main reason for the fluctuation of the signals of the heavy oil flow is the pulsating of the signals of the heavy oil transmission pipeline pressure drop, the main reason leading to the oscillation of the signals of the air pressure is the fluctuation of the pressure drop. And removing the affecting factors of IMFs, reconstructed signals can be expressed as exact description of fluctuation value. The proposed method is reasonable to process non-linear key parameters signal about heat engineering from copper pyrometallurgical heat dynamical system.

Key words: copper pyrometallurgical; heat dynamical system; empirical mode decomposition; intrinsic mode function

包括闪速熔炼[1-3]、转炉吹炼[4-5]以及阳极精炼[6-8]等工艺流程在内的铜火法冶炼热动力学系统,是一个具有非常复杂的高温、多相物理化学变化和非线性作用机制的宏观复杂系统,具有多变量、非线性、强耦合、大滞后等特点。铜火法冶炼热动力学系统热工关键参数控制精度直接影响整个铜火法冶炼热动力学系统的生产效率、产品质量以及与操作安全[5-8]。在铜火法冶炼热动力学系统热工关键参数实际测试系统中,采集到的信号又不可避免地受到白噪声、局部高频化噪声等干扰。当采用傅里叶滤波算法[9]去噪声时,在滤除高斯白噪声的同时也会滤除信号中十分重要的高频信息;当采用样条拟合方法[10]去噪声时,可以较好地抑制高斯白噪声,但同时会将无关信息引入铜火法冶炼热动力学系统的燃料流量、助燃空气压力(绝对压力和相对压力) 时间序列、物料及产品成分时间序列信号、炉温时间序列等信号中;小波变换极大模算法的主要缺点是准确度不高[11-12],而经验模态分解(Empirical Mode Decomposition,EMD) 方法是由Huang等发展的一种新的数据分析方法[13-15],该方法能有效地去除高斯白噪声对采集信号的干扰,而且不删除采集信号中的有用信息,不引入无关信息,消噪效果好,目前尚未见到铜火法冶炼热动力学系统实测数据EMD处理的相关文献报道。采用EMD方法去除铜火法冶炼热动力学系统各种噪声,对认识铜火法冶炼热动力学系统复杂现象背后所隐藏的本质规律显得十分的重要,具有很大的学术价值与广阔的工程应用前景。

1 铜火法冶炼热动力学系统实测数据EMD方法

1.1 非平稳信号的经验模态分解条件

IMF方法的本质是通过特征时间尺度获得IMF,然后再由IMF来分解时间序列数据。在HHT中描述信号的基本量是瞬时频率(Instantaneous frequency,IF),这是与其他信号处理方法的本质区别,而瞬时频率对每一个IMF 都有实际意义。

IMF分量要满足以下条件:①整个数据序列的极大极小值数目与过零点数目相等或最多相差1个;②数据序列的任意一点由极大值所确定的包络与由极小值所确定的包络均值始终为零。

这2个条件使分解得到的所有IMF分量是窄带信号。而且这种分解应满足假设:①信号至少有1个极大值和1个极小值;②特征时间尺度是由极值间的时间间隔所确定;③如果数据中没有极值点,而只有拐点,可通过一阶或多阶微分得到极值点,再通过分解、积分的方法获得IMF分量。

1.2 EMD端点问题的处理

EMD中的关键一步就是采用3次样条曲线求上下包络的平均值,3次样条曲线具有光滑的一次微分和连续的一次微分特点。由于所分析信号的长度有限,信号的两端点不能确定是极值,因此,在进行3次样条插值时,必然使得信号的上下包络在信号的两端附近严重扭曲。对于信号的高频分量,由于时间尺度小,极值间的距离小,端部的边缘效应仅局限在信号两端很小的部分。但对于低频分量,由于时间尺度大,极值间的距离大,端部的边缘效应就传播到信号的内部,特别是原始信号数据集比较短时,会严重影响EMD的质量,使得分解出的IMF分量无实际物理意义。

基于3次样条插值的特点,当原始信号的两端点不是极值点时,若能够根据端点以内极值点序列的规律得到该序列在端点处的近似值,则可以防止对极值点进行样条插值得到的包络线出现极大的摆动。取出原极值点序列最左端1/3的极值点,根据该数据的间距均值和左端点的幅值,定出左端点需增加的极值点位置和幅值。同理,可定出右端点需增加的极值点位置和幅值,当所构成的新的极大值和极小值数据集的最大间距比原始信号的小时,以近似的左端点处增加的极值点为起始点,向左进行数据对称延拓;以近似的右端点处增加的极值点为起始点,向右进行数据对称延拓。将得到的新的数据作为一个整体进行经验模态分解,需要指出的是,所取的结果只是中间部分。虽然该方法只是求出左右端的近似值,对近似极值点进行对称延拓,但延拓的目的不是为了给出准确的原序列以外的数据,而是提供一种条件,使得包络完全由端点以内的数据确定。

1.3 铜火法冶炼热动力学系统实测数据EMD过程

1) 找出信号所有的局部极值点,用3次样条线将所有的局部极大值点和局部极小值点连接起来形成上下包络线,上下包络线应包含所有的数据点。2条包络线的平均值记为m1,数据X与m1之差为h1:

如果h1(t)满足IMF的定义,那么h1(t)是一个IMF,h1(t)就是X(t)的第一个分量。

2) 如果h1不满足IMF的定义,就把h1(t)作为原始数据,重复以上步骤,得到:

判断h11(t)是否满足IMF的定义,若不满足,则重新循环k次,得到h1k(t) = h1(k-1)(t)-m1k(t),使m1k(t)满足IMF的定义,记c1 = h1k。

3) 将c1从数据X中分离出来,得到:

再把r1(t)作为新的原始数据,重复以上步骤,得到第二个满足IMF的分量c2,重复循环下去,得到:

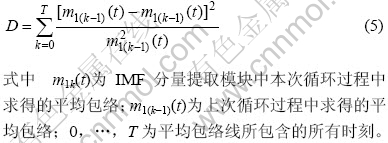

为了判断所处理信号不再含有IMF分量,一般采取IMF分量结束循环条件。IMF分量满足条件②过于苛刻,会删除掉具有物理意义的幅度波动,因此,为了保证每一个IMF具有幅度和频率调制的物理意义,把条件②转化为比较容易实现的数量标准D。该标准由式(5)给出:

理想的D应该在0.2~0.3之间。满足上述2个条件的IMF分量,既是进一步进行Hilbert变换的基础,又保证了每个分量蕴含必要的物理意义。

直到rn(t)成为一个单调函数不能从中提取满足IMF的分量时,循环结束。这样,原始数据可以由IMF分量和最后残量之和表示为

可见,可以把铜火法冶炼热动力学系统热工关键参数的任何一个信号X(t)分解为n个IMF和1个残量rn之和,其中分量c1,c2,…,cn分别包含了信号从高到低不同频率段的成分,而且不是等带宽的。EMD方法是一个自适应的信号分解方法,这是它优于小波包分析的地方。

2 铜火法冶炼热动力学系统实测数据EMD处理实例

2.1 铜精炼过程重油流量数据EMD处理

铜精炼过程重油流量数据来源于某大型铜冶炼厂350 t铜精炼炉氧化精炼过程重油流量实测数据,采样周期为0.5 s,重油流量约420 t/h。椭圆齿轮重油流量计所获得信号是噪声和真实重油流量的混合信号,通过EMD分解得到的IMF1~IMF7分量如图1所示,IMF1~IMF7代表着从低阶IMF分量(即高频段成分占主要部分) 向高阶IMF分量(即低频段成分占主要部分)的自适应变化,逐次把铜精炼炉氧化精炼过程重油流量脉动信号的频率分量从高到低分解出来。由于EMD分解方法本身的特点,其基底函数是自适应的,因此,不会像传统的信号分析方法那样受到先验基底函数的影响,所得到的IMF1~IMF7分量是信号直接和真实的反映。

图1 重油流量信号及其IMF1~IMF7分量

Fig.1 Heavy oil flux signal and its IMF1~IMF7 components

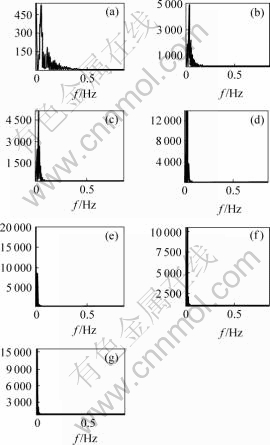

由图2所示的铜精炼炉氧化精炼过程重油流量信号的IMF1~IMF 8分量的频谱可知:①IMF1分量信号频率集中在0.05~0.25 Hz,混叠有机械振动所引起重油流量信号同步振荡的干扰成分的影响;②粗铜熔液搅拌会引起重油流量信号波动,这种重油流量信号波动的主要成分集中0.02~0.06 Hz,IMF2代表这部分信号的主要成分;③重油输送管路压降振荡也会引起重油流量信号无规则波动。据分析,该影响因素成分主要集中在0.005~0.02 Hz,所以,IMF3~IMF5代表这部分信号的主要能量,IMF6中有时也会重叠相关压降振荡的干扰成分;④EMD分解后的余量R8和具体干扰因素内在关联性以及是否影响重油流量信号,还有待于进一步研究。

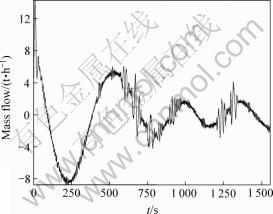

EMD分析结果表明,重油输送管路压降振荡脉动是引起重油流量信号无规则波动的主要原因,故先将重油流量信号进行EMD分解,再去掉IMF3~IMF6相关成分所对应的干扰因素,对IMF1,IMF2和IMF7信号进行重构,得到如图3所示的真实重油流量图。

图2 重油流量信号的IMF1~IMF7分量的功率谱

Fig.2 Spectrum of IMF1~IMF7 of heavy oil flux signal: (a) IMF 1; (b) IMF 2; (c) IMF 3; (d) IMF 4; (e) IMF 5; (f) IMF 6; (g) IMF 7

图3 重油流量信号IMF分量重构后真实重油流量

Fig.3 True signal of heavy oil flux based on reconstruction IMF components of heavy oil flux signal

重构后的信号能反映重油流量的真实波动趋势。开始采集时,重油流量信号在-10~10 t/h波动,经过约 600 s过渡时间后,重油流量信号逐渐平稳,在-3~3 t/h小范围内变化并趋向于平稳,这和实际运行情况吻合。

2.2 铜锍吹炼过程氧化空气压力数据EMD处理

铜锍吹炼过程氧化空气压力数据来源于某大型铜冶炼厂的P-S转炉铜锍吹炼过程氧化空气压力数据实测数据,采样周期为0.5 s,氧化空气压力约为115 kPa。铜锍吹炼过程氧化空气压力传感器所获得信号是噪声和真实氧化空气压力的混合信号,通过EMD分解得到的IMF1~IMF6分量如图4所示,IMF1~IMF6代表从低阶IMF分量(即高频段成分占主要部分) 向高阶IMF分量(即低频段成分占主要部分)的自适应变化,逐次把铜锍吹炼过程氧化空气压力信号的频率分量从高到低分解出来。

图4 氧化空气压力及其IMF1~IMF6分量

Fig.4 Air pressure signal and its IMF1~IMF6 components

根据图4所示的铜锍吹炼过程氧化空气压力信号的IMF1~IMF6分量的频谱可知:①IMF1分量代表铜锍吹炼过程氧化空气密度的不稳定性引起氧化空气 压力的周期性波动,信号频率集中在0.03~0.20 Hz;②铜锍吹炼过程铜锍熔液氧化程度以及氧化过程的释热强度振荡也会引起压力波动,其压力波动的主要成分集中0.01~0.03 Hz,IMF2代表这部分信号的主要成分;③氧化空气管路上压降振荡会引起氧化空气压力无规则波动。据分析该影响因素成分主要集中在0.006~0.020 Hz,所以,IMF3~IMF5代表这部分信号的主要能量;④EMD分解后的余量R7和具体干扰因素内在关联性,及是否影响氧化空气压力信号波动,还有待于进一步研究。

图5 氧化空气压力IMF1~IMF6分量的功率谱

Fig.5 Spectrum of IMF1~IMF6 of air pressure signal: (a) IMF 1; (b) IMF 2; (c) IMF 3; (d) IMF 4; (e) IMF 5; (f) IMF 6

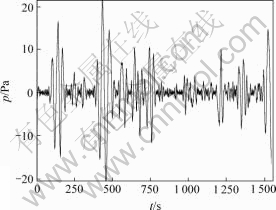

EMD分析结果表明,压降振荡是引起铜锍吹炼过程氧化空气压力信号振荡的主要原因。考虑先将铜锍吹炼过程氧化空气压力信号进行EMD分解,再去掉IMF3~IMF5相关成分所对应的干扰因素,对IMF1,IMF2和IMF6信号进行重构,得到如图6所示的真实氧化空气压力曲线。重构后的信号能反映铜锍吹炼过程氧化空气压力信号的真实波动趋势。

图6 氧化空气压力信号IMF分量重构后真实氧化空气压力

Fig.6 True signal of air pressure based on reconstruction IMF components of air pressure signal

由图6可知,在100~200 s,400~800 s以及1 500~ 1 550 s,铜锍吹炼过程氧化空气压力信号在-20~20 Pa波动,氧化空气压力信号变化趋势比较明显,这主要是铜锍吹炼过程氧化空气剧烈搅拌以及急剧的氧化反应所致。在其他时间段内,铜锍吹炼过程氧化空气压力信号波动幅度基本上为-5~5 Pa。这与实际运行情况吻合。

3 结论

1) 根据铜火法冶炼热动力学系统噪声的特点,利用经验模态分解方法对铜火法冶炼热动力学系统实测数据进行了分析,明确铜火法冶炼热动力学系统的一些关键热工参数信号复杂的组成成分,为研究铜火法冶炼热动力学系统非线性特性以及建立新的非线性模型提供理论依据。

2) 铜精炼过程重油流量数据EMD处理以及铜锍吹炼过程氧化空气压力数据EMD处理实例表明,EMD方法能将铜精炼过程重油流量信号以及铜锍吹炼过程氧化空气压力信号分解为多个IMF分量,去掉干扰因素所对应的IMF分量后,对剩余的IMF分量进行信号重构,可得到真实反映铜精炼过程重油流量以及铜锍吹炼过程氧化空气压力变化趋势的信号。

REFERENCES

[1] 梅 炽, 陈 卓, 任鸿九, 张卫华, 吴 军. 闪速炉反应塔炉膛内形的数值模拟与在线显示[J]. 中国有色金属学报, 2001, 11(4): 716-720.

MEI Chi, CHEN Zhuo, REN Hong-jiu, ZHANG Wei-hua, WU Jun. Numerical simulation and on-line display of freeze profile of reaction shaft in flash smelting furnace[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 716-720.

[2] GUI Wei-hua, WANG Ling-yun, YANG Chun-hua, XIE Yong-fang, PENG Xiao-bo. Intelligent prediction model of matte grade in copper flash smelting process[J]. Trans Nonferrous Met Soc China, 2007, 17(5): 1075-1081.

[3] SANCHEZ C V M, VALERA G J A, FLORES P P, PEREZ T M. Copper flash smelting mass balance calculations using genetic algorithms[J]. Joumal of the Minerals Metals and Material Society, 2004, 56(11): 178-179.

[4] GEORGALLI G A, EKSTEEN J J, REUTER M A. An integrated thermochemical-systems approach to the prediction of matte composition dynamics in an Ausmelt nickel-copper matte converter[J]. Minerals Engineering, 2002, 15(11): 909-917.

[5] MOSKALYK R R, ALFANTAZI A M. Review of copper pyrometallurgical practice: today and tomorrow[J]. Minerals Engineering, 2003(16): 893-919.

[6] 鄂加强. 铜精炼过程优化建模与智能控制[M]. 长沙: 湖南大学出版社, 2006.

E Jia-qiang. Optimal modeling and intelligent control about copper refining process[M]. Changsha: Hunan University Press, 2006.

[7] 鄂加强, 王耀南, 梅 炽, 龚金科. 铜精炼过程液化气消耗泛函混沌优化器的设计[J]. 中国有色金属学报, 2006, 16(2): 370-376.

E Jia-qiang, WANG Yao-nan, MEI Chi, GONG Jin-ke. Design on functional chaos optimizer about consumption of liquefied petroleum gas in copper refining process[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(2): 370-376.

[8] E J Q, WANG Y N, MEI Ch, GONG J K. Chaos behavior of crude copper composition time series from the copper convertor and the predicable time scale[J]. Nonlinear Analysis: Real World Applications, 2006, 7(4): 651-661.

[9] Alsdorf. Noise reduction in seismic data using Fourier correlation coefficient filtering[J]. Geophysics, 1997, 62(5): 1617-1627.

[10] 吴先良, 焦 丹, 王良之, 彭仲秋. 从目标瞬态响应中提取极点的样条拟合及有理逼近方法[J]. 中国科学技术大学学报, 1996, 26(4): 528-533.

WU Xian-liang, JIAO Dan, Wang Liang-zhi, PENG Zhong-qiu. A method for singularity extraction from targets transient response with spline functions and rational approximation[J]. Journal of China University of Science and Technology, 1996, 26(4): 528-533.

[11] 焦 丹, 徐善驾, 吴先良, 李世雄. 采用频域紧支集正交小波基消除瞬态散射回波中的高斯白噪声干扰[J]. 电子学报, 1999, 27(6): 120-122.

JIAO Dan, XU Shan-jia, WU Xian-liang, LI Shi-xiong. Recovery of signal from transient scattered response contaminated by gaussian white noise based on orthogonal bases of compactly supported wavelets in frequency domain[J]. Acta Electronica Sinica, 1999, 27(6): 120-122.

[12] MENDES Jr O, DOMINGUES M O, da COSTA A M, AL?CIA L, de GONZALEZ C. Wavelet analysis applied to magnetograms: Singularity detections related to geomagnetic storms[J]. Journal of Atmospheric and Solar-Terrestrial Physics, 2005, 67(17/18): 1827-1836.

[13] HUANG N E, SHEN Z, LONG S R, et al. The empirical mode decomposition and the Hilbert spectrum for nonlinear and non-stationary time series analysis[J]. Proc R soc Lond A, 1998, 454: 903-995.

[14] LOH C H. Application of the empirical mode decomposition- Hilbert spectrum method to identify near-fault ground-motion characteristics and structural responses[J]. Bulletin of the Seismological Society of America, 2001(91): 1339-1357.

[15] ECHEVERRIA J C. Application of empirical mode decomposition to heart rate variability analysis[J]. Medical & Biological Engineering & Computing, 2001, 39: 471-479.

基金项目:湖南省自然科学基金资助项目(06JJ50103)

收稿日期:2007-09-10;修订日期:2007-12-26

通讯作者:王春华,电话:0731-8821750;E-mail: wchhx1987@163.com

(编辑 陈爱华)