文章编号:1004-0609(2009)04-0613-06

预置横向挤压载荷法防止铝合金薄板焊接热裂纹

周广涛,刘雪松,杨建国,闫德俊,方洪渊

(现代焊接生产技术国家重点实验室,哈尔滨工业大学 150001)

摘 要:提出采用横向预置挤压载荷进行随焊同步防止铝合金薄板焊接热裂纹的新方法。对处于脆性温度区间的焊缝金属施加一适当的横向挤压载荷,可以减小焊缝金属凝固收缩时产生的横向拉伸应力和应变,使其总应变被限制在最低延性值范围内,改变了热裂纹产生的力学条件。建立横向预置压应力模型、采用弹塑性有限元方法阐明横向预置应力法防止热裂纹的原理,在自制的装置上对常规焊和横向预置压应力工艺条件下焊接试件裂纹率进行比较分析。鱼骨状裂纹试验结果表明:在加载宽度一定时,随着预置载荷的增加,在焊缝处产生的挤压应力也随之增加,裂纹率和裂纹长度逐渐降低,当横向预置压应力达到一定数值(0.3σ0.2)后,能够完全防止焊接热裂纹的产生。

关键词:预置横向挤压载荷;焊接热裂纹;裂纹率;数值模拟

中图分类号:TG115.28 文献标识码: A

Transverse compressive pre-stress method for controlling welding hot cracking of aluminum thin-plate

2ZHOU Guang-tao, LIU Xue-song, YANG Jian-guo, YAN De-jun, FANG Hong-yuan

(3National Key Laboratory of Advanced Welding Production Technology, Harbin Institute of Technology,

Harbin 150001, China)

Abstract: A new technique was presented to prevent welding hot cracking of aluminum thin plate by employing transverse compressive pre-load(TCPL)during welding. A proper transverse compressive load that is applied to the weld metal in brittle temperature range (BTR) can reduce the transverse tensile stress and strain when the weld metal is contracted during its solidifying so as to limit its total strain below the minimum plastic value, and the mechanical condition of welding hot cracking is changed. The model of TCPL was established and the principle of preventing welding hot cracking was illuminated by means of elasto-plastic finite element method. The cracking rates of conventional welding and welding with transverse compressive pre-stress were compared with each other. The experimental results of fish-bone samples show that with the TCPL increasing, the compressive stress in weld increases and the cracking length and cracking rate are reduced when the load region has a given value. When TCPL reaches a certain value (0.3σ0.2), the cracking is prevented completely.

Key words: transverse pre-stress; welding hot cracking; cracking rate; numerical simulation

高强铝合金焊接热裂敏感倾向大,易产生凝固裂纹,在薄板结构焊接时尤为显著。凝固裂纹是由于焊缝凝固过程中处于脆性温度区间的焊缝金属承受拉伸应力而产生的,因此,焊接热裂纹是冶金因素和力学因素共同作用的结果[1-3]。

从冶金角度控制焊接热裂纹主要是引入与母材异质的填充材料,设法改善焊缝金属的抗裂性,但由此产生的焊缝可能会影响接头部分力学性能,这也表明单从冶金角度来控制焊接热裂纹具有一定局限性 的[4-5],而从力学角度防止焊接热裂纹的实质就是调整和改善焊接时应力和应变分布情况,即采取适当措施使处于脆性温度区间的焊缝或热影响区金属承受一种外加压缩应变,以抵消焊接冷却过程中凝固收缩和热收缩及外部应力造成的致裂拉伸应变。从力学角度防止焊接热裂纹的方法主要集中在:随焊锤击法[6]、局部加热法、局部冷却及碾压法[7-12]等。

本文作者提出采用横向预置压应力法来防止热裂纹,即通过在焊接过程中施加垂直于焊缝方向的横向挤压载荷来减小焊缝金属在脆性温度区间内由于焊缝金属凝固收缩而承受的拉伸应变。这样既可达到控制热裂纹的目的,获得优质焊接接头,又能够弥补冶金方法的局限性[13-17]。与其他力学方法相比,该方法设备简单、可行性好,而且外力作用位置远离熔池,电弧稳定不受干扰,属于自然成形,接头表面外观优良,属于随焊操作,控制性强。本文作者通过数值模拟计算和焊接试验相结合的手段,探讨该方法下的温度场、应变场的演变以及对裂纹率的影响规律。

1 横向预置应力法模型及机理

1.1 横向预置压应力法模型

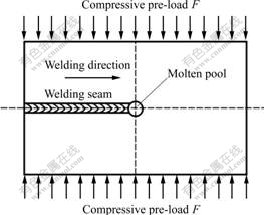

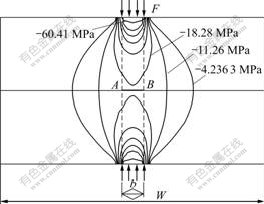

横向预置压应力法控制焊接热裂纹模型如图1所示,从图中可以看出,在垂直于焊缝方向(横向)给焊接工件的板宽端边施加一横向挤压载荷F,在工件中预先产生挤压应变场,施加载荷要达到一定的数值,其数值低于材料的屈服强度σ0.2,并保证薄板不出现压曲失稳,然后进行焊接,横向预置载荷作用于焊接过程的始终,该压应变场数值应能满足抵消焊接时冷却过程中处于脆性温度区间的焊缝金属承受的拉伸应力及应变。

图1 横向预置压应力法模型

Fig.1 Model of transverse compressive pre-stress

1.2 横向预置压应力法控制热裂纹机理

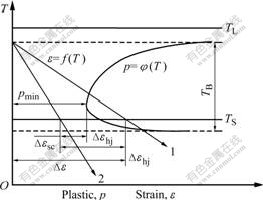

结晶裂纹的产生在于焊缝中存在液态薄膜和在焊缝凝固过程中受到拉伸应力共同作用的结果。图2所示为拉伸应力与脆性温度区间内被焊金属塑性变化之间的关系。其中横坐标ε表示拉伸应力产生的应变;ε为处于脆性温度区间TB内焊缝金属的塑性,p是温度的函数。当焊缝金属凝固结晶出现液态薄膜时,存在一个最小的塑性值,这是材料本身固有属性,能表征材料的抵抗热裂纹的能力,不同材料具有不同的pmin。

图2 热裂纹产生条件及防止机理

Fig.2 Hot cracking production condition and prevention mechanism

如果拉伸应力产生的拉伸应变随温度按线2变化,在焊缝塑性最小的固相线TS附近,此时产生的应变量低于pmin,焊缝仍然具有相当于Δεsc塑性储备量,且Δεsc>0,这种情况下不会产生热裂纹。当拉伸应变按照曲线1变化时,此时产生应变量为Δε,该数值超过焊缝金属在脆性温度区间所具有的最低塑性pmin,即Δε>pmin,此时液态薄膜就会被拉开,产生热裂纹。

对于拉伸应力产生的应变超过材料在脆性温度区间的最低塑性储备的情况,对该时刻焊缝金属施加一恰当的横向挤压应变Δεhj,则

Δεsc=pmin-(Δε+Δεhj) (1)

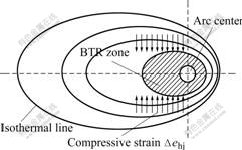

式中 Δεhj是外加载荷产生的挤压应变,即Δεhj<0;因此,只要保证Δεhj足够大,Δεsc就能恒大于零,焊缝金属保持一定的塑性储备,不会产生热裂纹,如图3所示。

图3 横向挤压应变施加位置

Fig.3 Acting position for transverse compression strain

材料的力学性能是随温度变化的,对于铝合金,屈服强度随着温度的升高而降低,接近液态温度TS时,几乎为零,失去了强度,而在固相线温度与液相线温度之间时,金属呈现“糊状”,屈服强度非常低,很容易发生屈服,很小的外力就可以使其产生塑性应变。脆性温度区间位于电弧周围很窄的区域内,热裂纹主要在该区域产生。横向预置挤压载荷法控制热裂纹的出发点就是对BTR区的金属产生挤压应力和应变,外加载荷达到焊缝中心的数值要足以克服该温度的屈服强度并使其产生塑性挤压应变。由于焊接是个不均匀加热过程,使得材料的各部分力学状态分布也极其不均匀,但只要施加的横向挤压力大于一定数值,就能满足控制热裂纹产生的条件。

2 横向预置应力的数值模拟

2.1 横向预置压应力产生的应力场

采用弹塑性有限元方法、利用Marc软件对横向预置压应力在工件中产生的应力分布情况进行了数值模拟。尺寸为180 mm×100 mm×2 mm,模型如图4所示。材料采用YL12CZ,其力学性能参数弹性模量E为71 GPa,屈服极限σ0.2为315 MPa。

图4 有限元模型及网格划分

Fig.4 FEM model and mesh genenration

为了解应力场的形成,采用局部加载,分析加载位置、范围和产生的应力分布之间的关系,横向挤压载荷为0.2σ0.2,加载宽度为18 mm,占整个板宽(W)的10%。图5所示为该条件下在工件中产生的预先应力分布情况,假想AB处为热裂纹产生位置,预置载荷F在AB处产生的挤压应力pAB小于F,从等力线分布可以看出,作用于一定宽度范围的横向预置载荷F在要控制的焊缝区域产生了压缩应力场,加载中心位置AB处压应力最大,向两侧逐渐减弱,而控制热裂纹起主要作用的就是pAB。预置应力的加载宽度为b。

图5 加载宽度为10%W时产生的应力场

Fig.5 Stress fields generated in condition of 10%W

2.2 加载宽度和载荷对横向预置压应力产生的应力场影响

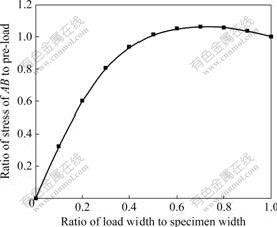

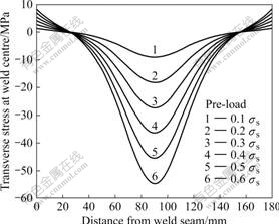

随着加载宽度的增加,到达AB处的预置压应力逐渐增加,图6所示为加载宽度b与AB处产生的最大压应力之间的变化关系。从数值模拟结果来看,加载宽超过60%W(板宽)以后,在AB处就能得到与预置载荷F等值的应力,即没有传递损失,这一点对于定量地控制热裂纹有利,只要知道致使热裂纹产生的拉应力,便可以恰当地施加挤压载荷,不需要中间量的换算。图7所示为加载宽度一定时,不同预置载荷在整个焊缝长度上产生的应力,曲线1为F=0.1σ0.2载荷情况,随着横向预置载荷的增加,到达焊缝能处的压应力逐渐增大。

图6 加载宽度对AB处压应力影响

Fig.6 Effects of load width on stress of position AB

图7 不同预置载荷对AB处应力的影响

Fig.7 Effects of different pre-load on transverse stress of position AB

3 横向预置应力法焊接试验

3.1 试验材料及其焊接参数

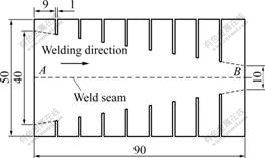

本试验采用LY12CZ板材。为了研究焊接热裂纹情况,试板加工成鱼骨状可变拘束试样,试板尺寸为90 mm×50 mm×2 mm。试板两侧采用线切割加工方式,割出如图8所示的切口,切口宽度和间距分别为1和9 mm,切口长度由短到长依次递增。切口越长,则该处的拘束度也越小。所以,从A端到B端拘束度逐渐减小,焊接方向是从A到B。

图8 鱼骨状试件尺寸

Fig.8 Size of fish-bone specimen (Unit: mm)

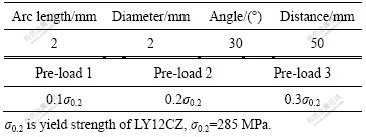

焊接方法采用TIG焊接,焊接电流I=50 A、焊接电压U=16 V、焊接速度v=5 mm/s、氩气流量为12 L/min,本焊接试验外载荷参数如表1所列。

表1 预置载荷工艺参数

Table 1 Processing parameters of pre-load

3.2 横向预置应力的施加原则与实现装置

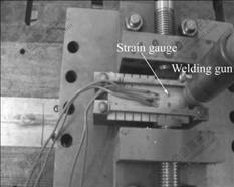

在焊接前对试件施加横向挤压载荷,预置应力的施加要保持在弹性范围内,挤压载荷的大小分别取0.1σ0.2、0.2σ0.2和0.3σ0.2。σ0.2为材料室温状态下的屈服极限,施加预置应力的数值是通过静态应变仪测 出。利用数值模拟的方法,模拟试件在指定外加载荷作用下各处产生的应变,然后在特定的位置处粘贴电阻应变片,即可读出对应的应变,根据虎克定律折算出应力值。加载区域为距起弧端14 mm,加载宽度为36 mm。因为起弧端最容易产生热裂纹,所以加载区域离起弧处距离近一些。如果在此处能控制住裂纹的产生,那么对其他位置则更加有效,预置应力装置机构实物如图9所示,焊接实验在此机构上完成。

图9 预置应力试验设备实物图

Fig.9 Transverse pre-stress experiment equipment

3.3 试验结果

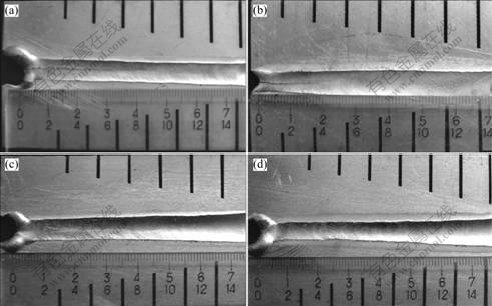

试验对比了常规焊和预置应力两种情况下裂纹的外观,如图10所示。从常规焊与预置应力焊焊缝成形照片可以看出,在相同焊接参数下,常规焊的裂纹长度明显比预置应力焊的长。如图10(a)所示,在常规焊接条件下,裂纹长度很大,约为45 mm,几乎达到试件长度的一半;如图10(b)所示,当施加的横向载荷为0.1σ0.2载荷时,裂纹长度明显减小,为19 mm;当施加的横向载荷为0.2σ0.2时,裂纹长度约为3 mm;当施加的横向载荷为0.3σ0.2时,裂纹已经消失,如图10(c)和(d)所示。为了说明该方法的效果,实验中以裂纹率Lcr%作为热裂纹倾向评定指标,裂纹率可表示为裂纹长度和裂纹总长度的比值,图中表明,常规焊的宏观裂纹率为36%,预置应力0.2σs时宏观裂纹率2.8%,0.3σs时为零,裂纹完全消失,裂纹率和裂纹长度都随预置应力的增加而显著降低。

图10 焊缝裂纹外观

Fig.10 Appearance comparison of welding cracking: (a) Without pre-load; (b) Pre-load=0.1σs; (c) Pre-load=0.2σs; (d) Pre-load=0.3σs

4 分析与讨论

当焊缝金属凝固时,成分较纯的金属熔点较高,首先凝固形成树枝晶的主干,大部分合金元素和杂质保留在液体中;随着温度的进一步降低,液态金属量越来越少而杂质浓度越来越高,被排挤到焊缝中心的晶界上,形成了低熔点的液态薄膜;此时液态杂质薄膜和固体金属共存,这个共存的温度范围称为脆性温度区间。脆性温度区间是热裂纹出现的最敏感温度范围,如果焊缝金属在脆性温度区间内受到拉伸应力的作用,晶间的液态薄膜就可能被拉开,导致裂纹的出现,因此,减小拉应力甚至消除拉应力就可以防止热裂纹产生。由于铝合金热裂纹一般出现在焊逢中截面上,主要是横向拉伸应力导致的,这样,施加的横向挤压预置应力便能补偿抵消致裂拉伸应变。

对热裂纹的控制取决于横向预置载荷的数值,载荷过小,则在焊缝处产生的挤压应力不足以克服焊缝金属凝固收缩所承受的拉伸应力,无法消除热裂纹的产生;随着载荷的增加,焊缝处承受的压缩应力逐渐增加,使得液态薄膜受到挤压,失去产生热裂纹的力学条件。当温度降到低于BTR温度以下时,材料恢复强度、弹性和塑性,屈服强度和弹性模量提高,能承受更多拉伸应力发生塑性应变,从而避开热裂纹产生的敏感温度区间,防止热裂纹的出现。但是横向预置载荷也不能过大,过大会造成严重横向收缩,不利于焊接成型。该预置载荷应低于该材料的失稳临界应 力,可以根据试验结果得出。由于焊缝金属在脆性温度区间的屈服强度极低,所需的外力只要克服掉它承受的拉伸应力就可以使其产生压缩应变,促使“糊状”的金属愈合,在力学上防止了热裂纹的产生。从试验结果看,当横向预置压载荷达到0.3σ0.2时,热裂纹完全消失,说明在0~0.3σ0.2之间存在一个临界数值,达到该值便可控制热裂纹,实现定量的控制,不需要中间量的转化。横向预置挤压载荷法防止焊接热裂纹取得了良好效果。但由于材料在高温时最低延性值不易测定,所以临界止裂载荷难以确定,这也是本试验进一步研究的内容。

5 结论

1) 横向预置挤压载荷通过在焊缝位置对处于BTR的金属产生横向挤压应力,克服因其凝固收缩受到的拉伸应力,从而防止热裂纹产生。

2) 在加载宽度一定时,随着横向挤压载荷的增加,在焊缝处产生的挤压应力也随之增大,但数值均小于外加载荷量;在载荷量一定时,随着加载宽度的增加,在焊缝处产生的最大压应力提高,在加载宽度超过整个板长的60%时,达到焊缝中心的压应力数值与外加载荷相当。

3) 随着横向预置应力的增加,裂纹长度和裂纹率显著降低,0.3σ0.2的横向压应力就可以避免产生焊接热裂纹。

REFERENCES

[1] RADAJ D. 焊接热效应: 温度场、残余应力、变形[M]. 熊第京, 译. 北京: 机械工业出版社, 1997: 328-330.

RADAJ D. Heat effects of welding: temperature fields, residual stress, distortion[M]. XIONG Di-jing, transl. Beijing: China Machine Press, 1997: 328-330.

[2] 刘伟平, 田锡唐, 张修智. 一种防止高强铝合金焊接热裂纹产生的新方法[J]. 焊接学报, 1995, 16(2): 106-110.

LIU Wei-ping, TIAN Xi-tang, ZHANG Xiu-zhi. A new method for prevention of weld hot cracking[J]. Transactions of The China Welding Institution, 1995, 16(2): 106-110.

[3] BORLAND J C. Fundamentals of solidification cracking in welds(Part2)[J]. Welding and Metal Fabrication, 1979, 3: 100-107.

[4] KARLSSON L. Mathematical models approximating butt welding process cause and prevention of hot cracking[C]// Proceedings of IIW International Conference on Advances in Welding and Allied Technologies, Ⅱ W-X-806-76. Tokyo, 2006: 59-68.

[5] 陈 晓, 陈颜堂, 王 蕾. 大线能量低焊接裂纹敏感性钢的显微组织[J]. 中国有色金属学报, 2004, 14(S1): 811-812.

CHEN Xiao, CHEN Yan-tang, WANG Lei. Microstructure of large heat input welding steel low susceptivity to weld cracking [J]. The Chinese Journal of Nonferrous Metal, 2004, 14(S1): 811-812.

[6] 方洪渊, 董志波, 徐文立. 随焊锤击防止薄板焊接热裂纹的工艺研究[J]. 焊接, 2002(3): 17-19.

FANG Hong-yuan, DONG Zhi-bo, XU Wen-li. Process of avoiding welding hot cracking of thin plate with trailing peening [J]. Welding & Joining, 2002(3): 17-19.

[7] 田锡唐, 郭绍庆, 徐文立. 随焊激冷对LY12CZ 铝合金焊接热裂纹倾向影响的研究[J]. 航材料工艺, 1998, 28(5): 48-52.

TIAN Xi-tang, GUO Shao-qing, XU Wen-li. Effect of follow-up rapid cooling on welding hot cracking susceptibility of LY12CZ aluminum alloy[J]. Aerospace Materials & Technology, 1998, 28(5): 48-52.

[8] CICALA E, DUFFET G, ANDRZEJEWSKI H. Hot cracking in Al-Mg-Si alloy laser welding-operating parameters and their effects[J]. Mater Sci Eng A, 2005, 395: 1-9.

[9] ZIVKOVIC D, ANZULOVIC B. The fatigue of 5083 aluminium alloy welds with the shot-peened crater hot-cracks[J]. Materials and Design, 2005, 26: 247-250.

[10] HO S K, WHITE R N, LUCAS I. A vision system for automated crack detection in welds[J]. Measurement Science and Technology, 1990, 1(3): 287.

[11] ANKARA A, ARI H B. Determination of hot crack susceptibility in various kinds of steels[J]. Material and Design, 1996, 17(5/6): 261-265.

[12] 周鹏展, 钟 掘, 贺地求. 7A52铝合金厚板搅拌摩擦焊[J], 中国有色金属学报, 2006, 16(6): 964-969.

ZHOU Peng-zhan, ZHONG Jue, HE Di-qiu. Friction stir welding on thick plate of 7A52 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(6): 964-969.

[13] LIU Gang, WANG Li-liang, YUAN Shi-jian. Compressive formability of 7075 aluminum alloy rings under hydrostatic pressure[J]. Trans Nonferrous Met Soc China, 2006, 16(5): 1103-1109.

[14] LI Jing, YIN Yan-sheng, LIU Ying-cai, MA Lai-peng. Fractal analysis of crack paths in Al2O3-TiC-4%Co composites[J]. Trans Nonferrous Met Soc China, 2006, 16(4): 795-799.

[15] LIU Ren-pei, DONG Zu-jue, PAN Yong-ming. Solidification crack susceptibility of aluminum alloy weld metals[J]. Trans Nonferrous Met Soc China, 2006, 16(1): 110-116.

[16] ZACHARIA T. Dynamic stresses in weld metal hot cracking[J]. Welding Journal, 1994, 7: 164s-172s.

[17] DUDAS J H, COLLINS F R. Preventing weld cracking in high strength aluminum alloys[J]. Welding Journal, 1966, 45(6): 241-249.

收稿日期:2008-11-23;修订日期:2008-12-28

通讯作者:方洪渊,教授;电话:0451-86418715;E-mail: zhougt_hit@sina.com

(编辑 何学锋)