J. Cent. South Univ. Technol. (2010) 17: 906-910

DOI: 10.1007/s11771-010-0575-4

Cooperative effect of surface alloying and laser texturing on tribological performance of lubricated surfaces

WAN Yi(万轶)1, XIONG Dang-sheng(熊党生)2, LI Jian-liang(李建亮)2

1. Jincheng College, Nanjing University of Aeronautics and Astronautics, Nanjing 211156, China;

2. Department of Materials Science and Engineering,

Nanjing University of Science and Technology, Nanjing 210094, China

? Central South University Press and Springer-Verlag Berlin Heidelberg 2010

Abstract: The cooperative effect of laser surface texturing (LST) and double glow plasma surface alloying on tribological performance of lubricated sliding contacts was investigated. A Nd:YAG laser was used to generate microdimples on steel surfaces. Dimples with the diameter of 150 μm and the depth of 30-35 μm distributed circumferentially on the disc surface. The alloying element Cr was sputtered to the laser texturing steel surface by double glow plasma technique. A deep diffusion layer with a thickness of 30 μm and a high hardness of HV900 was formed in this alloy. Tribological experiments of three types of samples (smooth, texturing and texturing + alloying) were conducted with a ring-on-disc tribometer to simulate the face seal. It is found that, in comparison with smooth steel surfaces, the laser texturing samples significantly reduce the friction coefficient. Moreover, the lower wear rate of the sample treated with the two surface techniques is observed.

Key words: laser surface texturing; double glow plasma surface alloying technology; carbon steel; tribological performance; lubricated surface

1 Introduction

The reduction of friction of tribological components is considered to be necessary from a point of view of saving energy, prolonging durability, improving efficiency and protecting environment for future engine systems. Lubrication of sliding surfaces is the most important to life and operation for engine machine, and good surface quality is beneficial to lubrication [1-4]. Laser surface texturing, as a means for enhancing tribological performance of contact components, has gained an increasing interest for years, including in piston ring/cylinder in engine, mechanical seals and sliding bearings, slider and hard disc [5-9]. Hydrodynamic lubricating theory indicates that the microstructures artificially distributed on the bearing surface may affect lubricating state and load carrying capacity [8-10]. The cavities or grooves on a flat surface have several effects, such as acting as an oil reservoir to transport or retaining oil when lubricant breaks down, and entrapping wear particles to reduce abrasion and plough in the sliding contact [11-14].

In recent years, various smart surface engineering and multilayered composite coating technologies have been developed significantly, which now become an intergral part of advanced machining and manufacturing applications under a wide range of tribological conditions [15-16]. Double glow discharge plasma is one of the surface hardening processes widely used for improving wear properties of steel and alloy components due to its beneficial features such as good reproducibility, low distortion of the treated parts and low energy-consuming [17-18]. The desired alloying elements are sputtered by the source electrode, traveling towards the substrate. Subsequently, the alloying elements diffuse into the surface of the substrate, forming a functionally graded surface in which the concentration of the alloying elements is gradually changed in the depth direction. Some of the phases in coatings can favorably react with additives in oils to provide low friction, while other phases can provide high hardness and low wear. The focus of this work was to investigate the cooperative effects of laser surface texturing and double glow plasma surface alloying to achieve not only low friction and wear but also high hardness in face seals.

2 Experimental

2.1 Laser surface texturing

The annealed AISI 1045 steel disc with HRC30 was used as the substrate with 48 mm in diameter and polished to an average roughness (Ra) less than 0.05 μm. The ring was constructed from T8 tool steel with HRC 55-58, internal and external diameters of 32 and 46 mm, respectively, and surface roughness of about 0.1 μm. All the samples were 8 mm in thickness. A pulsed Nd:YAG laser with a wavelength of 1 064 nm and a pulse width of 450 ns was used to induce dimples on the disc surface. Ten pulses were used to make a dimple. The structure and topography of laser texturing dimples were observed using an optical microscope and white-light interferometric surface mapping microscope.

2.2 Double glow plasma surface alloying

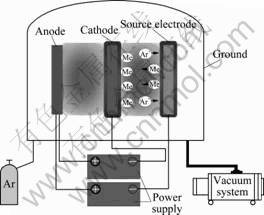

After surface texturing, the specimen surface was ground by 1200# SiC sand paper to remove the raised rims induced by laser ablation and then degreased with acetone. A double glow plasma surface alloying device, shown in Fig.1, was used to sputter Cr. The Cr plate (d 130 mm×5 mm) was used as the source electrode material for supplying the alloying element. Laser texturing steel disc was used as substrate materials. The processing parameters were: source electrode voltage, 950 V; substrate voltage, 450 V; working pressure, 40 Pa; parallel distance between the source electrode and the substrate, 20 mm; and treatment time, 3 h. The phase structure identification on the alloyed surface was conducted on a D8 X-ray diffractometer, and the hardness on the cross-section was measured with HX-1000 micro-hardness instrument made by Harbin Measure Manufactory, Heilongjiang Province, China.

Fig.1 Schematic diagram of double glow plasma surface alloying installation

2.3 Friction testing methods and test conditions

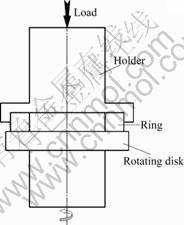

Friction tests were carried out on a ring-on-disc tribological tester MG-2000 made by Xuanhua Beilun Balance Manifactory, Hebei Province, China, as shown in Fig.2.

The upper ring was fixed into a metallic holder, which was loaded vertically to laser texturing disc. The bottom disc was driven by a motor to a rotational speed.

Fig.2 Schematic diagram of ring-on-disc tribological tester

The average diameter of the frictional track on the samples was about 40 mm. Before tests, all the samples were cleaned in an acetone bath ultrasonically for 3 min. The steel disc was smeared with a mineral base oil with viscosity (h) of 0.013 6 Pa?s at the beginning, then mounted onto a centrifuge at a rotational speed of 400 r/min for 1 min to spin off the excessive oil, keeping a thin oil film on disc. Tests were performed at a load of 100 N and an initial speed of 200 r/min (corresponding to linear sliding speed of 0.4 m/s). The speed was increased with a stepwise manner of 100 r/min after a sliding distance of 500 m. The tests stopped when the friction coefficient suddenly increased. The mass loss (?m) of disc after test was measured by an analytical balance with a precision of 0.1 mg. Wear rate (ω) related to load (P), sample density (ρ) and sliding distance (L) was obtained from ω=Δm/(ρPL). All the discs were cleaned by ultrasonic bath for 3 min before and after friction test and then measured three times for an average value.

3 Results

3.1 Topography of surface texturing

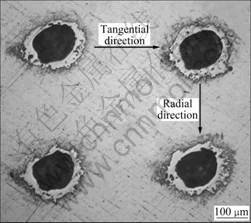

The optical image of the laser texturing AISI 1045 steel disc is shown in Fig.3. It is clear that dimples distribute circumferentially. The diameter of the dimple (d) is about 150 μm, the tangential distance (l) is 500 μm and the radial interval (D) is 400 μm. The dimple area ratio (r) is obtained from r=πd 2/(4lD), which is found to be about 8.8%.

During the laser texturing process, metal materials absorbing laser energy are ejected out of the surface as a result of plastic deformation. For the high energy density, ablation area is formed rapidly and melt materials around the dimples are the typical features of laser-induced microstructures. The circular area surrounding the dimple is called the heat-affected zone.

Fig.3 Optical image of laser texturing AISI 1045 steel disc

3.2 Microstructure and phase formation on texturing sample after surface alloying process

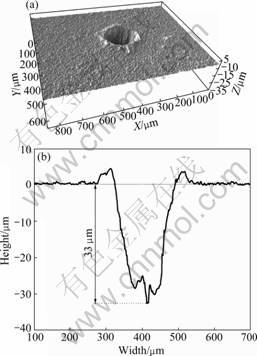

Fig.4 illustrates the topographys on the laser texturing steel surface after the double glow plasma surface alloying process. It can be seen that the alloyed layer is rather compact and smooth. The dimple is cone- shaped with a depth of about 30 μm. Compared with the laser texturing substrate, the depth of dimple is reduced slightly.

Fig.4 White-light interferometric 3D profile (a) and cross- section profile (b) of laser texturing dimple after double glow plasma surface alloying process

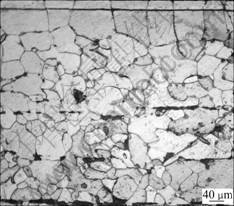

A typical microstructure of Cr-alloyed layer on the cross-section of the specimen, etched with 4% HNO3 of alcohol solution, is shown in Fig.5. It is clear that the alloying layer is composed of columnar grains that are connected with the substrate, forming an obvious boundary between the surface alloying layer and the substrate. It is well known that Cr is the element of diminishing the γ area. When Cr is diffused into AISI 1045 carbon steel surface to reach a critical transform value, γ-Fe will transform to α-Fe, causing a Cr alloying layer formed in the substrate. While the phase structure of Cr alloying layer is maintained during cooling and kept as α-solid solution till room temperature, the phase transforming from γ-Fe to α-Fe just takes place in the substrate [19-20]. So, there is a mis-arranged region of atomic arrangement at the interface, leading to a boundary between the alloying layer and the substrate. The interface between the alloying layer and the substrate with no porosity is found to be metallurgical combination.

Fig.5 Microstructure of surface alloying layer on cross-section of AISI 1045 steel

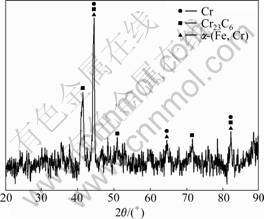

Carbide layer is formed on the surface of the sample, identified by XRD, as shown in Fig.6. Some carbides on the surface layer mainly are Cr23C6+α-phases.

3.3 Hardness

Fig.7 shows the gradually distributed micro- hardness on the cross-section of Cr alloying layer by

Fig.6 XRD pattern of surface alloying layer on steel

Fig.7 Hardness distribution on cross-section of Cr alloying layer

HX-1000 micro-hardness instrument with 0.5 N load employed. The hardness on the surface layer is quite high, approximately HV900. The reason for the increase is that there are lots of uniform fine carbides, which are enhanced by phases with better wear resistance distributed on the matrix. Overally, the hardness of the alloyed layer is larger than that in the substrate.

3.4 Tribological behavior

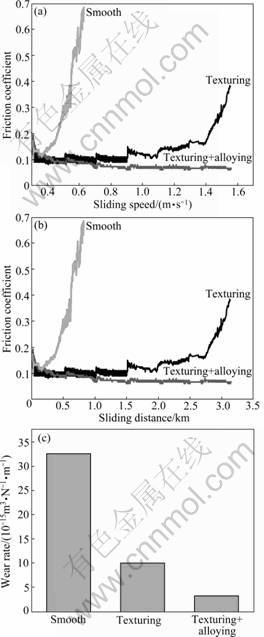

Figs.8(a) and (b) show the friction coefficients of three types of samples at a load of 100 N and a continuous sliding speed. For the smooth specimen, friction coefficient increases to above 0.3 quickly after a sliding distance of 500 m. For texturing and texturing+ alloying discs, a similar friction trend can be observed. After the sliding speed exceeds 1.4 m/s, the friction of texturing sample suddenly increases. Throughout the same sliding distance (about 3.2 km), the texturing+ alloying disc shows a low and steady friction coefficient, 20%-50% lower than that of the texturing disc. With increasing the sliding speed continuously, the friction coefficient decreases in a manner of stepwise as to reach the lowest point of 0.067, which implies that the lubrication shifts towards the mixed lubrication regime.

Fig.8(c) shows that the smooth disc has the largest wear rate among the three types, and many ploughs are found on the smooth steel surface. The texturing+ alloying disc displays the smallest value for better wearable performance resulting from the higher hardness of surface Cr alloying layer.

4 Discussion

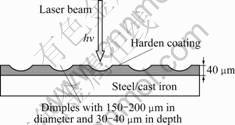

Laser texturing tribological surfaces have been developed significantly in recent years. Such surfaces can provide lower friction and wear under hydrodynamic and mixed-boundary lubricated sliding conditions. In order to assess the two surface processing technologies, a sketch map is established to show the cooperative effect of laser texturing and surface Cr alloying on the tribological properties during the lubricating process, as shown in Fig.9.

Fig.8 Friction and wear properties of three discs at load of 100 N: (a) Friction coefficient vs sliding speed; (b) Friction coefficient vs sliding distance; (c) Wear rate

Fig.9 Sketch map of cooperative effect of laser texturing and double glow plasma surface alloying technology

In this test, all the surfaces of texturing and texturing+alloying samples were ground by 1200# SiC sand paper to remove the raised rims. For the low dimple density about 8.8%, although there are small differences of the contact pressure and surface roughness between smooth and texturing discs, such effect is considered to be miner on the sliding contact surfaces. The positive effect of the dimples is to act as oil-reservoirs assisting the formation of a lubricating film, which pulls the lubricant into the contact area due to viscous flow and trap wear debris to reduce wear in sliding contact region at the sliding interfaces.

The aim of double glow plasma surface alloying in the present experiment is to employ Cr to react with carbon in steel substrate, resulting in high hardness Cr-C phase such as Cr23C6. It is expected that the depth of Cr-C layer is large enough to improve the anti-wear and corrosion ability. The intersectional distribution of soft and hard phases in matrix can improve the wear-resistance ability [19]. With the integration of the laser texturing for improving the lubricating state from boundary to hydrodynamic regime and the double glow plasma surface alloying technology for enhancing the anti-wear ability of sliding surfaces, further improvements in tribological performance can be achieved by texturing+alloying sample compared with the laser texturing one. In future, the cooperative use of surface engineering approaches and lower viscosity oils with reduced sulfur and phosphorus may be feasible to meet the increasingly more stringent tribological conditions.

5 Conclusions

(1) Dimples with 150 μm in diameter and 30 μm in depth are generated in AISI 1045 steel surfaces with a pulsed Nd:YAG laser. The laser texturing is an effective way to reduce friction coefficient under similar operating conditions compared with smooth one.

(2) The Cr-alloyed layer on laser texturing steel is characterized by 30 μm in depth and a hardness up to HV 900 using a double glow plasma surface alloying technology, which mainly consists of Cr23C6+α-phases.

(3) With the integration of the laser texturing and double glow plasma surface alloying techniques, further improvements of friction properties are observed, compared with the laser texturing one, which can improve the lubricating state from boundary to mixed lubrication and enhance the anti-wear ability of the contact surfaces.

References

[1] VOEVODIN A A, ZABINSKI J S. Laser surface texturing for adaptive solid lubrication [J]. Wear, 2006, 261: 1285-1292.

[2] WAN Yi, XIONG Dang-sheng. Study of laser surface texturing for improving tribological properties [J]. Tribology, 2006, 26(6): 603- 607. (in Chinese)

[3] ERDEMIR A. Review of engineered tribological interfaces for improved boundary lubrication [J]. Tribology International, 2005, 38: 249-256.

[4] KAWASEGI N, SUGIMORI H, MORIMOTO H, MORITA N, HORI I. Development of cutting tools with microscale and nanoscale textures to improve frictional behavior [J]. Precision Engineering, 2009, 33: 248-254.

[5] ZUM GAHR K H, WAHL R, WAUTHIER K. Experimental study of the effect of microtexturing on oil lubricated ceramic/steel friction pairs [J]. Wear, 2009, 267: 1241-1251.

[6] ANDERSSON P, KOSKINEN J, VARJUS S, GERBIG Y, HAEFKE H, GEORGIOU S, ZHMUD B, BUSS W. Microlubrication effect by laser-textured steel surfaces [J]. Wear, 2007, 262: 369-379.

[7] LIU Ying-ying, XIA Chang-qing, PENG Xiao-min. Effect of heat treatment on microstructures and mechanical properties of Al-6Zn- 2Mg-1.5Cu-0.4Er alloy [J]. Journal of Central South University of Technology, 2010, 17(1): 24-27.

[8] ETSION I, SHER E. Improving fuel efficiency with laser surface textured piston rings [J]. Tribology International, 2009, 42: 542-547.

[9] WAN Yi, XIONG Dang-sheng. The effect of laser surface texturing on frictional performance of face seal [J]. Journal of Materials Processing Technology, 2008, 197: 96-100.

[10] KOVALCHENKO A, AJAYI O, ERDEMIRA A, FENSKE G, ETSION I. The effect of laser surface texturing on transitions in lubrication regimes during unidirectional sliding contact [J]. Tribology International, 2005, 38: 219-225.

[11] WANG Xiao-lei, LIU Wei, ZHOU Fei, ZHU Di. Preliminary investigation of the effect of dimple size on friction in line contacts [J]. Tribology International, 2009, 42: 1118-1123.

[12] NAKATA K, YAMAUCHI W, AKAMATSU K, USHIO M. Plasma nitriding behavior of low carbon binary alloy steels [J]. Surface and Coatings Technology, 2003, 174/175: 1206-1210.

[13] RAPOPORT L, MOSHKOVICH A, PERFILYEV V, GEDANKEN A, KOLTYPIN Y, SOMINSKI E, HALPERIN G, ETSION I. Wear life and adhesion of solid lubricant films on laser-textured steel surfaces [J]. Wear, 2009, 267: 1203-1207.

[14] RYK G, KLIGERMAN Y, ETSION I. Experimental investigation of partial laser surface texturing for piston rings friction reduction [J]. Tribology Transaction, 2005, 48: 583-588.

[15] PODGORNIK B, JACOBSON S, HOGMARK S. Influence of EP and AW additives on the tribological behaviour of hard low friction coatings [J]. Surface and Coatings Technology, 2003, 165: 168-175.

[16] LI Zhong-hou, LIU Sha-sha, CHEN Zhi-yong. Study on plasma discharge parameters in double-glow plasma surface alloying furnace [J]. Vacuum, 2009, 83: 801-804.

[17] ZHU Xiao-lin, YAO Zheng-jun, GU Xue-dong, CONG Wei, ZHANG Ping-ze. Microstructure and corrosion resistance of Fe-Al intermetallic coating on 45 steel synthesized by double glow plasma surface alloying technology [J]. Transactions of Nonferrous Metals Society of China, 2009, 19(2): 143-148.

[18] WAN Yi, XIONG Dang-sheng, WANG Jun. Tribological properties of dimpled surface alloying layer on carbon steel [J]. Journal of Wuhan University of Technology: Materials Science, 2009, 24(2): 218-222.

[19] XU Jin-yong, LIU Yan-ping, WANG Jian-zhong, LIU Xiao-yun, GAO Yuan, XU Zhong. A study on double glow plasma surface metallurgy Mo-Cr high speed steel of carbon steel [J]. Surface and Coatings Technology, 2007, 201: 5093-5096.

[20] GAO Yuan, GAO Qing, XU Jin-yong, LIAO Hong-yi, XU Zhong. Morphology and composition of plasma alloying of Cr-Mo layer [J]. Surface and Coatings Technology, 2007, 201: 5526-5528.

(Edited by CHEN Wei-ping)

Foundation item: Project(2007046) supported by High Technology Research Project of Jiangsu Province, China

Received date: 2009-10-29; Accepted date: 2010-03-22

Corresponding author: WAN Yi, PhD; Tel: +86-25-87190167; E-mail: wan2721@163.com