DOI:10.19476/j.ysxb.1004.0609.2019.01.14

Mn元素对热浸镀Al-10Si-2Fe合金镀层显微组织的影响

吴广新1, 2, 3,张捷宇1, 2, 3

(1. 上海大学 省部共建高品质特殊钢冶金与制备国家重点实验室,上海 200072;

2. 上海大学 上海市现代冶金与材料制备重点实验室,上海 200072;

3. 上海大学 材料科学与工程学院,上海 200072)

摘 要:在高强钢热浸镀铝硅合金中,通常会有一定量Mn溶解到镀液中,对镀层凝固组织产生影响。本文研究了热浸镀用Al-10Si-2Fe合金中Mn元素对凝固组织及富铁相的影响规律。结果显示,随着Mn含量的增加,铝硅合金中富铁相形貌转变过程如下:针状→汉字状→星状→多边形。借助Pandat软件在热力学层面解释了Mn添加后铝硅合金中β-Al9Fe2Si2相向α-Al8(Fe,Mn)2Si相转变的原因。此外,给出了添加Mn后的渣量计算结果,认为铝硅熔液中最佳Mn含量(质量分数)应为0.8%~1.0%。

关键词:铝硅镀层,富铁相,渣量

文章编号:1004-0609(2019)-01-0122-09 中图分类号:TG178 文献标志码:A

硼钢Al-Si镀层是工业生产中常用的耐高温镀层,该镀层是Si含量(质量分数)为7%~11%的近共晶Al-Si合金[1]。该镀层具有优良的耐高温氧化性和耐蚀性,可以有效地防止钢板高温条件下的表面氧化和脱碳,并提升钢板的耐蚀性。在实际生产中,由于高温时硼钢在液锌中的溶解,Fe、Mn不可避免的扩散到铝硅镀液中,从而对后续的镀层凝固组织产生影响。

众所周知,在铝硅合金中,Fe是一种最常见的杂质元素,常温下在铝合金中的固溶度非常低,仅为0.05%[2-3],但有研究表明,680 ℃条件下,Fe在铝硅镀液中的溶解度可达3%[4]。因此Fe元素在凝固过程中常常被排斥到枝晶通道内,从而形成各种富铁金属间化合物,成为锌锅中的渣相。其中最常见的富铁金属间化合物主要有α-Fe、β-Fe相两种[5],α-Fe相一般为汉字状或骨骼状,有时还会以鱼骨状、星状、多边形状出现,β-Fe多为针状出现[6]。

针状的β-Fe(β-Al9Fe2Si2)相存在时对基体的割裂作用非常严重,容易产生应力集中,极大地影响了合金的力学性能[7]。而α-Al8Fe2Si富铁相一般呈现汉字状,基本上不会割裂基体,对合金的性能影响较小[8],所以在实际生产中要尽可能地减少乃至避免针状富铁相的出现。

消除针状富铁相有害作用的方法主要可以通过以下途径实现:一是设法降低Fe在铝合金中的含量,使得铝液中的Fe含量低于析出针状富铁相的临界值;二是改变富铁相在铝合金中的形貌,降低乃至避免β-Fe相的出现,从而降低富铁相对合金的力学性能的危害[9]。相对于去除铝熔液中的Fe来说,添加一些化学元素,如Mn、Cr、Sc和稀土元素等来改变合金中富铁相的形貌更为简单、经济[10-12]。其中Mn是高铁铝硅合金中最常用的中和元素,也是高强钢最常带入锌锅的元素,Mn元素的加入使针状铁相向汉字状、鱼骨状富铁相转变,能在一定能够程度上改善合金的力学性能[13-14]。

因此,作为整体研究的一部分,本实验以Mn作为中和元素,探究铝硅合金中富铁相形貌与Mn含量的关系,并从热力学角度探索了Mn含量对Al-10Si-2Fe合金中富铁相形貌的影响,为热浸镀铝硅过程提供基础理论。

1 实验

1.1 实验用材料与设备

实验仪器:井式电阻炉(意丰电炉,型号SG2-7.5-12);XQ-1金相镶嵌机;上海宇舟MP-1型抛光机;电子天平;烧杯、药匙、称量纸、玻璃棒若干;金相砂纸(600号、1000号、1500号、2000号)及抛光布若干;金刚石抛光膏(粒度2.5 μm和0.5 μm)。

实验原料:纯铝粒(纯度为99.99%);河北四通新材生产的铝硅合金锭(Al-15.1%Si)、铝锰合金(Al-20.28%Mn),铝铁合金(Al-9.67.%Fe)。

1.2 检测设备

金相试样用上海徕卡仪器有限公司生产的Leica DMI5000M型金相显微镜进行观测;铝硅合金样品的形貌借助VEGA-LMUH型扫描电子显微镜进行观测;X射线仪器为日本理学电机生产的D/max 2200V型X射线衍射仪。

1.3 实验方法

首先将实验中所用到的铁质坩埚钳、扒渣勺、浇铸模具、搅拌棒、氩气吹管等表面都涂上涂料并在烘箱中烘干备用,所用涂料的成分为:5%氧化锌,1.5%水玻璃,93.5%水。

之后将称量好的高纯铝以及Al-15.1%Si合金放入刚玉坩埚中,并加入1%的覆盖剂防止氧化,覆盖剂成分为50%NaCl和50%KCl。在井式炉中升温至750 ℃,待坩埚中合金完全熔化后依次加入相应量的Al-9.67%Fe合金 、Al-20.28%Mn合金,并保温30 min。等到加入的中间合金完全熔化后降温至720 ℃,通入高纯氩气进行精炼除气,精炼时间为1 min,之后扒去表面的浮渣。静置到炉内温度稳定至720 ℃,浇铸到如图1所示的预热铁模中,铸成尺寸为d30 mm×170 mm的铸锭,铁模预热温度为250 ℃。在各个试样距离底部15 mm处取样并经过打磨、抛光、腐蚀后制成金相试样,所用腐蚀液为0.5%HF溶液。

2 结果与讨论

2.1 Al-10Si-2Fe-xMn合金金相观测

图1 浇铸模具尺寸

Fig. 1 Sizes of casting model (Unit: mm)

图2 无Mn铝硅合金金相图

Fig. 2 LOM images of Al-Si alloy without Mn

图2所示为初始铝硅合金Al-10Si-2Fe合金的金相图,其中图2(b)所示为图2(a)中的局部放大图。从图2中可以看出,初始铝硅合金中主要有三种不同的相存在,白色的相为Al基体,主要以树枝状的形态存在。枝晶间为共晶组织,在共晶组织中存在的针状、颗粒状深灰色相为硅相。此外还存在着浅灰色的长针状富铁相,这种长针状的相为β-Al9Fe2Si2。针状的富铁相分布在共晶组织之上,会对合金基体产生严重的割裂作用。

图3所示为不同Mn添加量时铝硅合金样品的金相图。由图3可知,在添加了0.4%Mn后合金中有少量的针状富铁相开始向汉字状富铁相转变,但富铁相主要还是以针状的形态存在。由此可见,Mn的添加量过少,只对部分针状富铁相起到改变形貌的作用后就已经被完全消耗掉了。

当添加0.6%Mn时,合金中汉字状的富铁相数量有了明显的增加,但此时汉字状的富铁相周围还是有较多的针状富铁相存在,且结合后续XRD结果可知汉字状富铁相为α-Al8(Fe, Mn)2Si。

当添加0.8%Mn时,针状富铁相已经基本上都转化成为汉字状的富铁相,在低倍金相图中已经基本看不到针状富铁相(见图2(a)),但在高倍金相图中还是能够找到少量针状的富铁相存在(见图2(b))。

当添加1.0%Mn时,合金中针状富铁相已经完全转变成了汉字状的富铁相,此时在金相图中还可以看到一些星状的富铁相,可见部分富铁相的形貌又一次发生了改变。

图3 添加不同Mn含量后铝硅合金的金相图

Fig. 3 Metallographs of Al-Si alloy with different Mn contents

当添加的Mn含量达到1.6%时,合金中富铁相含量明显增多,而且此时富铁相除了汉字状之外,还有部分富铁相开始呈现规则的多边形状。这可能是由于Mn的添加提高了α-Al8(Fe, Mn)2Si相的结晶温度,从而加大了α-Al8(Fe, Mn)2Si与共晶Si结晶温度之间的差值,使得α-Al8(Fe, Mn)2Si相有足够的时间长大成为较大的多边形状富铁相,与他人的研究[15-16]相符。

之后,再提高Mn含量到2.2%和2.8%时,富铁相形貌没有明显的变化,主要还是由多边形状富铁相以及汉字状富铁相组成。

综上所述,Mn元素的添加能够有效地改变针状富铁相的形貌,并且随着合金中Mn含量的逐步增加,合金中的针状富铁相先转化为汉字状的富铁相,之后会有部分汉字状富铁相转变成星状的富铁相。随着Mn含量的进一步提高,星状富铁相消失,最终生成了多边形的富铁相。

2.2 Al-10Si-2Fe-xMn合金的物相分析

本实验取了Mn含量不同的各个合金试样进行了X射线衍射分析,图4所示为各个试样的XRD谱。由图4可知,在未添加Mn时合金中主要物相是Al、共晶Si以及β-Al9Fe2Si2;在添加了0.6%Mn时,XRD谱线上开始出现了Al8Fe2Si的峰,由此可见Mn的添加使得合金中部分β-Al9Fe2Si2发生了物相转变,生成了具有α-Al8Fe2Si晶体结构的Fe-Al-Si-Mn四元化合物;当Mn含量达到1.0%时,XRD谱线中已经没有Al9Fe2Si2相的峰形,此时合金中Al9Fe2Si2相含量很少或者已经全部转变成了Al8Fe2Si相。此后,再增加Mn含量时,合金中没有生成新的物相。

图4 不同Mn含量的铝硅合金XRD谱

Fig. 4 XRD patterns of Al-Si alloy with different Mn contents

2.3 Al-10Si-2Fe-xMn合金SEM及EDS检测

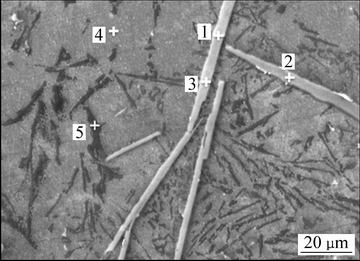

图5所示为未添加Mn元素时铝硅合金的SEM像,表1所列为图3中各个点的EDS结果。由图5可知,未添加Mn时铝硅合金主要是由浅灰色的Al基体、深灰色的共晶硅以及白色的针状富铁相组成,粗大的针状富铁相分布在铝硅共晶组织上。从EDS结果可知,图5中白色针状富铁相中n(Al):n(Fe):n(Si)约为66:19:14,结合表2可知该相比较符合Al9Fe2Si2的摩尔比及XRD结果,由此可以初步确定该针状相为β-Al9Fe2Si2(或者τ6-Al9Fe2Si2)。

图5 未添加Mn时铝硅合金的SEM像

Fig. 5 SEM image of Al-Si alloy without Mn addition

表1 未添加Mn时铝硅合金EDS结果

Table 1 EDS results of Al-Si alloy without Mn shown in Fig. 5

表2 常见的Fe-Al-Si相[17]

Table 2 Compositions of Fe-Al-Si phases[17]

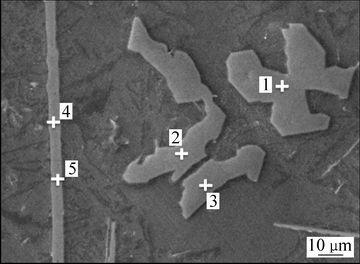

图6所示为添加0.4%Mn后铝硅合金的SEM像,表3所列为图6中各个点的EDS结果。根据图6和图3(a)可知,在添加0.4%Mn时,合金中富铁相开始由针状向汉字状开始转变,但主要还是以针状的形式存在。由EDS结果可知,此时针状的富铁相中已经开始固溶了少量的Mn元素,汉字状富铁相中固溶的Mn比针状富铁相中多,由此可见少量的Mn元素不能完全改变针状富铁相的形貌,只有足量的Mn原子固溶进了针状的Al9Fe2Si2中才能使富铁相呈现汉字状。

由于Mn原子与Fe原子在元素周期表排列相近,原子半径相似,Mn原子可以与Fe原子相互替代,故而可以将Al-Si-Mn-Fe四元化合物中Mn、FeT的摩尔分数看作是三元相Al-Fe-Si中Fe的摩尔分数。结合EDS结果及表2可知,图6中点1所在的汉字状富铁相的摩尔分数为71.09%,其成分可以看作是71.09%Al、17.67%Fe和11.24%Si,符合τ5-Al8(Fe,Mn)2Si中各原子的摩尔比,所以汉字状的富铁相可以看做是α-Al8(Fe, Mn)2Si。同理点2、点3所在富铁相也可以看做是α-Al8(Fe, Mn)2Si相。

图6 添加0.4%Mn时铝硅合金的SEM像

Fig. 6 SEM image of Al-Si alloy with 0.4%Mn

表3 添加0.4%Mn后铝硅合金EDS结果

Table 3 EDS results of Al-Si alloy with 0.4%Mn shown in Fig. 6

图7 添加1.0%Mn时铝硅合金的SEM像

Fig. 7 SEM image of Al-Si alloy with 1.0%Mn

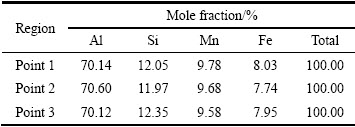

表4 添加1.0%Mn时铝硅合金EDS结果

Table 4 EDS results of Al-Si alloy with 1.0%Mn shown in Fig. 7

图7所示为添加1.0%Mn时的SEM像,结合图3(d)可知,此时针状富铁相完全转变成了汉字状富铁相,基本上没有针状富铁相的存在。根据EDS结果可知,汉字状的富铁相在成分上还是符合α-Al8(Fe, Mn)2Si相的摩尔比,但四元化合物中Mn含量有所上升。除此之外,当Mn添加量达到1.0%时,铝硅合金中还出现了星状的富铁相(即图7点1所在位置),由图7中点1的EDS结果可知,星状的富铁相成分与汉字状富铁相近似,并没有生成其他的含Mn化合物。

图8所示为添加2.2%Mn时的SEM像,此时铝硅合金中除了汉字状的富铁相外也有较多的多边形富铁相。由EDS结果(见表5)可知,多边形状富铁相也符合α-Al8(Fe, Mn)2Si的摩尔比,所以多边形富铁相仍为α-Al8(Fe, Mn)2Si。但多边形状富铁相中固溶的Mn含量比添加1.0%Mn时的又有所上升,达到了12.10%。

图8 添加2.2%Mn时铝硅合金的SEM像

Fig. 8 SEM image of Al-Si alloy with 2.2%Mn

表5 添加2.2%Mn时铝硅合金EDS结果

Table 5 EDS results of Al-Si alloy with 2.2%Mn shown in Fig. 8

综上所述,在Al-10Si-2Fe中添加Mn元素能够改变合金中富铁相的形貌,Mn的添加可以使铝硅合金中针状β-Al9Fe2Si2相逐渐转化为汉字状、多边形状的α-Al8(Fe, Mn)2Si相。虽然汉字状、星状、多变形状的富铁相形貌各不相同,富铁相中的Mn含量也有所不同,但成分都符合α-Al8(Fe, Mn)2Si相中各原子的摩尔比。

2.4 Al-10Si-2Fe-xMn合金凝固过程的热力学分析

Mn对铝硅合金中富铁相形貌的改变作用可能是因为Mn的添加使铝硅合金在凝固过程发生了相变,因此,为了更好地了解Mn元素对铝硅合金中富铁相的影响规律,本实验对铝硅合金的凝固过程进行热力学计算。

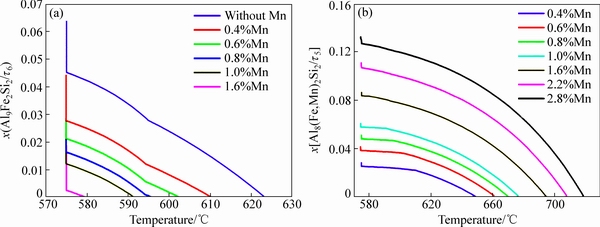

图9所示为借助Pandat软件[18]计算的不同Mn含量下合金中τ6-Al9Fe2Si2以及τ5-Al8(Fe, Mn)2Si相含量与温度的关系。由图9(a)可知,随着Mn含量的不断增加,合金中τ6-Al9Fe2Si2相的含量随之减少。由图9(b)可知,在Mn含量增加时,α-Al8(Fe, Mn)2Si相的含量也随之增加。由此可知,Mn的添加使得铝硅合金中的富铁相由τ6-Al9Fe2Si2相向转变为τ5-Al8(Fe, Mn)2Si相。

图9 不同Mn含量下Al9Fe2Si2/τ6、Al8(Fe, Mn)2Si/τ5相含量与温度的关系

Fig. 9 Relationships between mole fractions of Al9Fe2Si2/τ6 (a) and Al8(Fe, Mn)2Si/τ5 (b) and temperature at different Mn contents

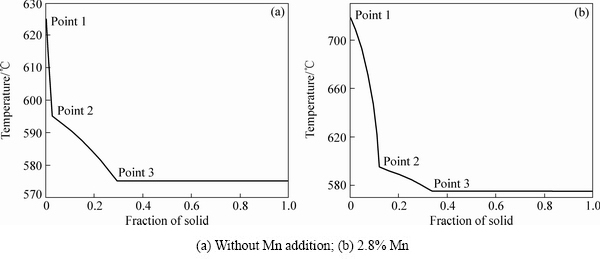

图10 不同Mn添加量时铝硅合金凝固路径图

Fig. 10 Calculated solidification path of Al-Si alloy with different Mn contents

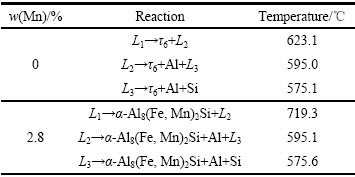

表6 无Mn和2.8%Mn时铝硅合金凝固路径结果

Table 6 Results of solidification path of Al-Si alloy without Mn and with 2.8% Mn shown in Fig. 10

为了更好地了解Mn添加对铝硅合金凝固过程的影响,随后又计算了Mn添加量为0、2.8%时铝硅合金的凝固路径,其结果如图10所示,表6所列为根据计算结果整理的各阶段物相转变过程。结合表6可知,当未添加Mn时,铝硅合金凝固过程中在623.1 ℃(见图10(a)中Point 1)先析出的是τ6-Al9Fe2Si2,之后随着温度降到595.0 ℃(见图10(a)中Point 2)后继续析出τ6以及α(Al),最后在共晶点575.1 ℃(见图10(a)中Point 3)发生共晶反应生成了τ6、Al、Si。当添加了2.8%Mn后合金中首先在719.3 ℃(见图10(b)中Point 1)时析出了α-Al8(Fe, Mn)2Si,之后在595.1 ℃(见图10(a)中Point 2)时继续析出了α-Al8(Fe, Mn)2Si以及α(Al),并最终在共晶点575.6 ℃(见图10(a)中Point 3)发生共晶反应生成了α-Al8(Fe, Mn)2Si、Al、Si。由此可见,Mn的添加在凝固过程起始阶段就抑制了τ6-Al9Fe2Si2相的析出[19],且Mn的添加会提高合金液相线的温度,使α-Al8(Fe, Mn)2Si相有足够的时间长大成为多边形状的富铁相[20],与前述实验现象吻合。

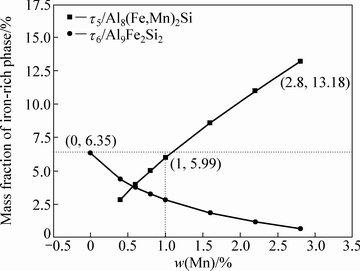

图11 铝硅合金中富铁相含量与Mn含量的关系

Fig. 11 Relationship between mass fraction of iron-rich phase and Mn content in Al-Si alloy

图11所示为铝硅合金中τ6-Al9Fe2Si2和τ5-Al8(Fe, Mn)2Si相与合金中Mn添加量的关系。从图11中可以看出,在未添加Mn时,富铁相含量约占合金总质量的6.35%,而当Mn含量为2.8%时,合金中τ5-Al8(Fe, Mn)2Si相所占的质量分数为13.18%,比未添加Mn时的τ6相所占的质量分数有了明显的增加,这说明了添加过量的Mn会导致富铁相的增加[21-23]。富铁相的增加会使铝硅合金的力学性能有所下降[24],同时富铁相的增加在热浸镀行业中来看即镀液中渣相的增加,而渣相的增加对于热浸镀工业生产来说有不利的影响。因此,结合镀液中渣量的问题来考虑,铝硅熔液中Mn的最佳添加量应为0.8%~1.0%。

3 结论

1) 在Al-10Si-2Fe中添加Mn元素能够改变合金中富铁相的形貌,Mn的添加可以铝硅合金中针状β-Al9Fe2Si2相转化为汉字状、多边形状的α-Al8(Fe, Mn)2Si相。实验中随着Mn元素含量的增加,铝硅合金中富铁相形貌转变过程如下:针状→汉字状→星状→多边形。虽然汉字状、星状、多变形状的富铁相形貌各不相同,富铁相中的Mn含量也有所不同,但成分都符合α-Al8(Fe, Mn)2Si中各原子的摩尔比。

2) 根据XRD结果可知,在Al-10Si-2Fe合金中添加Mn可以使β-Al9Fe2Si2转化成α-Al8Fe2Si相。在添加了0.6%Mn时,XRD谱线上开始出现Al8Fe2Si的峰;当Mn含量达到1.0%时,XRD谱线中已经没有Al9Fe2Si2相的峰形,此时铝硅合金中Al9Fe2Si2相含量很少或者已经完全转变成了Al8Fe2Si相。之后再提高Mn含量时,铝硅合金中没有生成新的物相,与EDS的结果吻合。

3) 结合热力学计算可知,Mn的添加能使τ6-Al9Fe2Si2相向τ5-Al8(Fe, Mn)2Si相转变。此外,从计算结果还可以看到,随着合金中Mn含量的提高,合金中最终的富铁相含量会比未添加Mn时的有明显的增加,这会增加锌锅渣相,对热浸镀过程不利。

REFERENCES

[1] GRAUER S J, CARON E, CHESTER N L, WELLS M A, DAUN K J. Investigation of melting in the Al–Si coating of a boron steel sheet by differential scanning calorimetry[J]. Journal of Materials Processing Technology, 2015, 216(4): 89-94.

[2] DINNIS C M, TAYLER J A, DAHLE A K. Interactions between iron, manganese, and the Al-Si eutectic in hypoeutectic Al-Si alloys[J]. Metallurgical and Materials Transactions A, 2006, 37(11): 3283-3291.

[3] 宋东福, 王顺成, 郑开宏. Mn/Fe摩尔比对A356铸造铝合金富铁相形态的影响[J]. 中国有色金属学报, 2015, 25(7): 1832-1838.

SONG Dong-fu, WANG Shun-cheng, ZHENG Kai-hong. Effects of Mn/Fe mole ratio on iron-rich phase morphology of A356 cast aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1832-1838.

[4] GUO M, GAO K, WANG W, WEI X. Microstructural evolution of Al-Si coating and its influence on high temperature tribological behavior of ultra-high strength steel against H13 steel[J]. Journal of Iron and Steel Research, International, 2017, 24(10): 1048-1058.

[5] ANNALISA F, MATTIA M, ELETTRA F, STEFANO P, GIAN G. On the influence of Mn and Mg additions on tensile properties, microstructure and quality index of the A356 aluminum foundry alloy[J]. Procedia Structural Integrity, 2016, 2: 2238-2245。

[6] BIDMESHKI C, ABOUEI V, SAGHAFIAN H. Effect of Mn addition on Fe-rich intermetallics morphology and dry sliding wear investigation of hypereutectic Al-17.5%Si alloys[J]. Journal of Materials Research and Technology, 2016, 5(3): 250-258.

[7] TAYLOR J A. Iron-containing intermetallic phases in Al-Si based casting alloys[J]. Procedia Materials Science, 2012, 1(8): 19-33.

[8] 印 飞, 杨江波, 孙宝德. 高含铁量铝硅合金中铁相的凝固行为与形貌控制[J]. 上海交通大学学报, 2002, 36(1): 43-46.

YIN Fei, YANG Jiang-bo, SUN Bao-de. Solidification behaviors and microstructure morphology of iron phase in Al-Si alloys with higher iron content[J]. Journal of Shanghai Jiao Tong University, 2002, 36(1): 43-46.

[9] 张 磊, 焦万丽, 尉海军, 姚广春. 锰结合预先热处理对铝硅合金中富铁相组织和力学性能的影响[J]. 中国有色金属学报, 2005, 15(3): 368-373.

ZHANG Lei, JIAO Wan-li, WEI Hai-jun, YAO Guang-chun. Influence of manganese and pre-heat treatment on microstructure and mechanical properties of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(3): 368-373.

[10] LI D, CUI C, WANG X, WANG Q, CHEN C, LIU S. Microstructure evolution and enhanced mechanical properties of eutectic Al–Si die cast alloy by combined alloying Mg and La[J]. Materials & Design, 2016, 90(5): 820-828.

[11] MARZOUK M, JAIN M, SHANKAR S. Effect of Sr-modification on the bendability of cast aluminum alloy A356 using digital image correlation method[J]. Materials Science and Engineering A, 2014, 598(5): 277-287.

[12] QIU C, MIAO S, LI X, Xia X, DING J, WANG Y. Synergistic effect of Sr and La on the microstructure and mechanical properties of A356 alloy[J]. Materials & Design, 2017, 114(6): 563-571.

[13] ZHAO Q, QIAO Z, CUI X, WU Y, LIU X. Optimizing microstructures of dilute Al-Fe-Si alloys designed with enhanced electrical conductivity and tensile strength[J]. Journal of Alloys and Compounds, 2015, 650(7): 768-776.

[14] TANG P, LI W, WANG K, DU J, CHEN X, ZHAO Y. Effect of Al-Ti-C master alloy addition on microstructures and mechanical properties of cast eutectic Al-Si-Fe-Cu alloy[J]. Materials & Design, 2017, 115(5): 147-157.

[15] KIM H Y, HAN S W, LEE H M. The influence of Mn and Cr on the tensile properties of A356–0.20Fe alloy[J]. Materials Letters, 2006, 60(15): 1880-1883.

[16] ZHANG Z, TEZUKA H, KOBAYASHI E, SATO T. Effects of the Mn/Fe ratio and cooling rate on the modification of Fe intermetallic compounds in cast A356 based alloy with different Fe contents[J]. Materials transactions, 2013, 54(8): 1484-1490.

[17] RAGHAVAN V. Al-Fe-Si (aluminum-iron-silicon)[J]. Journal of Phase Equilibria and Diffusion, 2011, 32(2): 140-142.

[18] CAO W, CHEN S L, ZHANG F, WU K, YANG Y, CHANG Y A. PANDAT software with PanEngine, PanOptimizer and PanPrecipitation for multi-component phase diagram calculation and materials property simulation[J]. Calphad, 2009, 33(2): 328-342.

[19] KIM H Y, PARK T Y, HAN S W, LEE H M. Effects of Mn on the crystal structure of α-Al(Mn,Fe)Si particles in A356 alloys[J]. Journal of Crystal Growth, 2006, 291(1): 207-211.

[20] GAO T, HU K, WANG L, ZHANG B, LIU X. Morphological evolution and strengthening behavior of α-Al(Fe,Mn)Si in Al-6Si-2Fe-xMn alloys[J]. Results in Physics, 2017, 7(3): 1051-1054.

[21] WANG M, XU W, HAN Q. Study of refinement and morphology change of AlFeSi phase in A380 alloy due to addition of Ca, Sr/Ca, Mn and Mn, Sr[J]. Materials Transactions, 2016, 57(9): 1509-1513.

[22] 黄晓锋, 冯 凯, 谢 锐. Mg及Mn元素对Al-Si合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2012, 22(8): 2196-2204.

HUANG Xiao-feng, FENG Kai, XIE Rui. Effects of Mg and Mn element on microstructure and mechanical properties of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2012, 22(8): 2196-2204.

[23] 马广辉, 李润霞, 白彦华, 李荣德. Si相对铸造Al-Si合金低温拉伸断裂行为的影响[J]. 中国有色金属学报, 2016, 26(8): 1615-1623.

MA Guang-hui, LI Rui-xia, BAI Yan-hua, LI De-rong. Effect of silicon phase on tensile fracture of Al-Si alloys at low temperature[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(8): 1615-1623.

[24] BASAK C, HARI B N. Morphological changes and segregation of β-Al9Fe2Si2 phase: A perspective from better recyclability of cast Al-Si alloys[J]. Materials & Design, 2016, 108(2): 277-288.

Influence of manganese on microstructure of hot-dip Al-10Si-2Fe alloy coating

WU Guang-xin1, 2, 3, ZHANG Jie-yu1, 2, 3

(1. State Key Laboratory of Advanced Special Steel, Shanghai University, Shanghai, 200072, China;

2. Shanghai Key Laboratory of Advanced Ferrometallurgy, Shanghai University, Shanghai 200072, China;

3. School of Materials Science and Engineering, Shanghai University, Shanghai 200072, China)

Abstract: During hot-dip Al-Si alloy coating process, there will be a certain amount of Mn dissolved into the bath, which affects the solidification microstructure of the coating. In this paper, the influence of Mn addition on solidification structure and iron-rich phase in Al-10Si-2Fe alloy for hot-dip coating was studied. The results show that with the increasing of Mn, the transformation sequence of iron-rich phase in aluminum silicon alloy is as follows: needle-like→Chinese-script→star-like→polygon. The thermodynamically reasons for the transformation of β-Al9Fe2Si2 phase to α-Al8(Fe, Mn)2Si phase in Al-Si alloy after Mn addition were explained by means of Pandat software. Moreover, the variation of slag content with Mn addition was also calculated, which shows that the optimal Mn content in Al-Si melt should be 0.8%-1.0%.

Key words: hot-dip; Al-10Si-2Fe coating; iron-rich phase, dross amount

Foundation item: Project(51674163) supported by the National Natural Science Foundation of China; Project(16ZR1412000) supported by the Science and Technology Committee of Shanghai, China

Received date: 2017-12-11; Accepted date: 2018-07-30

Corresponding author: WU Guang-xin; Tel: +86-21-66136567; E-mail: langes@shu.edu.cn

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51674163);上海市科委自然科学基金资助项目(16ZR1412000)

收稿日期:2017-12-11;修订日期:2018-07-30

通信作者:吴广新,研究员,博士;电话:021-66136567;E-mail:langes@shu.edu.cn