文章编号:1004-0609(2016)-07-1538-09

高压辊磨对邦铺钼铜矿石选择性碎解作用及机制

侯 英1,印万忠2,于光涛3,杨 春3,盖 壮3,赵通林1,肖丽聪1

(1. 辽宁科技大学 矿业工程学院,鞍山 114051;

2. 福州大学 紫金矿业学院,福州 350108;

3. 鞍钢集团 弓长岭矿业公司,辽阳 111008)

摘 要:对邦铺钼铜矿石进行高压辊磨(HPGR)和颚式破碎(JC),然后对两种产品进行磨矿—浮选试验,采用扫描电镜(SEM)研究矿石的高压辊粉碎特性,采用单体解离度分析仪(MLA)研究磨矿产品的解离特性,并从药剂用量等方面研究矿石的最佳磨矿细度和浮选工艺条件。结果表明:高压辊磨—球磨—浮选工艺适宜的磨矿细度为粒度小于0.074 mm的颗粒含量为65%,颚式破碎—球磨—浮选工艺适宜的磨矿细度为粒度小于0.074 mm的颗粒含量为75%;在适宜磨矿细度和药剂制度下,高压辊磨—球磨较颚式破碎—球磨浮选效果好,钼粗精矿钼品位提高0.83%,钼回收率提高1.05%;铜粗精矿铜品位提高0.23%,铜回收率提高2.66%;高压辊磨对邦铺钼铜矿石发生选择性粉碎现象。球磨对高压辊磨产品发生选择性解离现象,提出“矿石高压辊选择性粉碎—球磨选择性解离—浮选”技术方案。

关键词:高压辊磨机;颚式破碎机;选择性磨矿;选择性解离;浮选

中图分类号:TD 952 文献标志码:A

高压辊磨机是一种新型高效的破碎设备,具有单位破碎能耗和钢耗低、处理能力大、占地面积少等特点[1]。经高压辊磨机粉碎的产品,粒度细,分布均匀[2-3]。粉碎产品内部可产生大量微裂纹,能够有效降低Bond球磨功指数,节能效果明显[4]。

OZCAN等[5]从操作条件和循环负荷上研究高压辊磨机的粉碎性能。翁兴媛等[6]从磨矿技术效率和Bond 球磨功指数等能耗方面研究贫赤铁矿石的磨矿特性。MEER[7]研究了高压辊磨机的给矿对产品质量和磨机操作和物料含水率的影响。袁致涛等[8]对攀西钒钛磁铁矿进行了高压辊磨超细粉碎,高压辊磨产品内部产生的晶内裂纹和解离裂纹比颚式破碎产品的多,其Bond球磨功指数比颚式破碎产品的低14.05%,节能效果显著。刘磊等[9]对高压辊磨产品和圆锥破碎产品的磨矿技术效率进行对比研究,相对于圆锥产品,辊压产品个别粒级分布的“双峰”特征更加明显,提出一种高压辊磨机超细碎-分级磨矿新工艺,大幅降低一段磨机的入磨量,提高磨矿技术效率,减弱整体磨矿过程中的过粉碎。

德国的Krupp研究中心利用美国及南美洲的氧化铜矿在高压辊磨机上进行开发性试验,得到了提高铜浸取回收率5%~15%的显著效果[10];德国的Krupp公司在美国西部对高压辊磨机粉碎的不同粒度的金矿石进行了浸取试验,取得了使堆浸金矿回收率由60%提高到75%~80%显著的经济效益效益[10];易南概等[11]研究了不同粉碎方式对金矿石氰化浸出效果的影响,证实高压辊磨工艺不仅可以提高矿石的解离程度,而且还可以使金矿石的铁污染大大减少,提高氰化浸出率1%~3%;OLIVEIRA等[12]应用硫氧化微生物对巴西铜矿石进行酸性浸出试验,证据表明,高压辊磨工艺比颚式破碎工艺的浸出效果更高效;朱德庆等[13]采用高压辊磨技术预处理镜铁矿,通过优化高压辊磨闭路流程的循环负荷,巴西镜铁矿的表面形状及比表面积得到改善,成球性得到明显提高;唐远等[14]针对颚式破碎和高压辊磨两种不同破碎方式下进行细粒级金矿石的全泥氰化浸出试验,试样经高压辊磨机处理后对金的浸出有利,最终比常规颚破产品的浸出率提高约3.7%~6.6%,浸出剂减少约9%~10%。

刘磊[15]针对贫赤铁矿石开展了高压辊磨机粉碎和分选研究,与颚式破碎分选相比,精矿产率提高1.56%,回收率提高5.18%;印万忠等[16]针对紫金山铜金矿石进行高压辊碎磨浮选试验研究,与颚式破碎磨矿浮选相比,铜的回收率提高5.95%;印万忠等[17]针对邦铺钼铜矿石的高压辊磨产品进行了可磨性和浮选试验,高压辊磨产品Bond 球磨功指数至少降低9.05%,并且可以放粗高压辊磨产品的磨矿细度。

许多学者针对高压辊磨工艺可以提高后续球磨处理能力进行了大量的试验研究和论述,但是针对为何可以提高球磨机处理能力,以及针对磨矿产品是否可以放到更粗,针对放粗产品磨矿细度的机理没有进行深入地研究,也没有对高压辊粉碎特性、磨矿特性和浮选特性之间的关系进行深入地分析。

本文作者对邦铺钼铜矿石进行高压辊磨和颚式破碎,并对产品的粉碎特性进行粒级金属分布分析,采用SEM对产品表面的微裂纹进行表征;然后对两种产品进行了球磨—浮选试验,找到最佳的磨矿细度,应用MLA分析磨矿产品的单体解离度,并对比分析高压辊磨产品和颚式破碎产品磨矿后的浮选结果。

1 实验

1.1 实验原料

试验原料为邦铺钼铜矿石的细碎产品。试样的主要化学成分分析见表1,试样的X射线衍射分析见图1。钼和铜的物相分析见表2和3。

由表1可知,原矿的化学多元素分析结果表明,有回收价值的金属元素为钼和铜。

由图1可知,邦铺钼铜矿石含有的矿物为石英(SiO2)、辉钼矿(MoS2)、钼华(MoO3)、铜蓝(CuS)、辉铜矿(Cu2S)、赤铜矿(Cu2O)、黑铜矿(CuO)、黄铜矿(CuFeS2)、黄铁矿(FeS2)、铁锂云母(KLiFeAl(AlSi3)O10(F, OH))、钾长石(KAlSi3O8)和钠长石(NaAlSi3O8)等。

由表2可知,钼物相分析结果表明,硫化钼中的钼占总钼的99.06%,氧化钼中的钼仅占0.94%,钼的氧化程度较低,对选钼有利。

由表3可知,铜物相分析结果表明,该钼铜矿中的铜大部分为硫化铜,其中原生铜占有率为37.35%,次生硫化铜占有率为46.69%,次生现象较严重,且铜矿物的氧化率为15.96%,氧化程度较高。

表1 化学多元素分析结果

Table 1 Chemical analytical result of mineral samples (mass fraction, %)

图1 邦铺钼铜矿石的XRD谱

Fig. 1 XRD pattern of Mo-Cu ore from Bangpu

表2 原矿钼物相分析结果

Table 2 Results of phase analysis of molybdenum

表3 原矿铜物相分析结果

Table 3 Results of phase analysis of copper

1.2 实验方法

高压辊磨试验选用成都利君实业股份有限公司生产的CLM-25-10型高压辊磨机,压辊直径 250 mm,压辊宽度100 mm,辊面压力0~7 N/mm2,辊面速度0~0.52 m/s,工作辊间距2~7 mm。

设置高压辊磨机的工作参数,设定辊面压力5.5 N/mm2,辊面速度0.21 m/s,工作辊间距3 mm,无压启动设备,将物料堆满料仓,加压后迅速打开下料口使物料落入两压辊之间,试验完成后对粉碎产品进行打散,应用3.2 mm的筛子进行筛分,筛上产品返回高压辊磨机进行辊压,筛下产品混匀、缩分、取样。

颚式破碎试验选用武汉洛克粉磨设备制造有限公司生产的RK/PEF-60 mm×100型颚式破碎机,给料口尺寸60×100 mm,排料粒度0.1~15.1 mm。

设置颚式破碎机的工作参数,排料口宽度3 mm,无给料情况下启动设备,给入物料进行粉碎试验,试验完成后应用3.2 mm的筛子进行筛分,筛上产品返回颚式破碎机进行破碎,筛下产品混匀、缩分、取样。

磨矿试验选用XMQ型锥形球磨机,每次实验中球磨机给矿量m=500 g,磨矿浓度c=70%,充填率φ=22.36%,磨机转速n=100 r/min,磨机容积V=6.25 L。

浮选试验在1.5LXFD-Ⅲ型单槽浮选机里进行,每次取500 g矿样,加214.3 mL水后进行磨矿,磨矿后在浮选机中调浆3 min,浮选机转速为2800 r/min,然后依次加入抑制剂、活化剂、捕收剂等浮选药剂进行浮选。

X射线衍射分析采用 PW3040/60型X射线衍射仪,扫描电镜分析采用日立S-3500n 型扫描电镜,单体解离度测定采用澳大利亚FEI公司生产的MLA-650型号的MLA分析系统。

2 结果及讨论

2.1 粒级金属分布

对高压辊磨产品和颚式破碎产品进行粒级金属分布分析。粒级金属分布分析结果如表4和5所列。

由表4和表5可以看出,在0.9~3.2 mm粒级范围内,高压辊磨产品中Mo的分布率低7.40%,Cu的分布率低10.48%;在小于0.045 mm粒级范围内,Mo的分布率高6.77%,Cu的分布率高11.59%。

选择性破碎[18-20]和选择性磨矿[21-23]是基于矿石中不同矿物的物理性质差异,通过对破碎和磨矿方式的选择及调整破碎和磨矿条件,增大矿物破碎和磨矿行为的差异,以实现不同矿物在碎磨产品不同粒级中的相对富集。

由品位和粒级金属分布分析可以得出:在0.9~3.2 mm粒级范围内,高压辊磨产品的Mo和Cu品位和分布率都较颚式破碎产品低;在小于0.18 mm粒级范围内,高压辊磨产品中Mo和Cu的分布率都不同程度的比颚式破碎产品的高。针对上述分析,高压辊磨机对邦铺钼铜矿石发生了选择性粉碎。

表4 高压辊磨产品的粒级金属分布分析结果

Table 4 Metal distribution of product crushed by HPGR

表5 颚式破碎产品的粒级金属分布分析结果

Table 5 Metal distribution of product crushed by JC

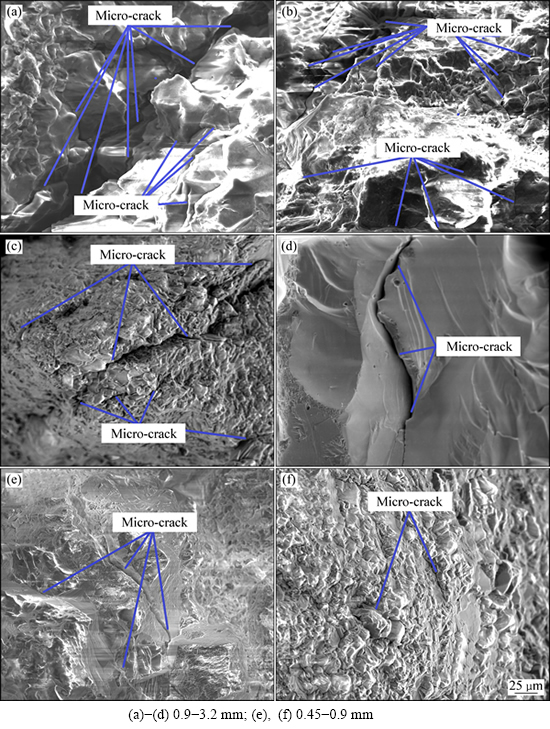

2.2 产品的表面微裂纹对比

采用SEM对不同粒级高压辊磨产品和颚式碎磨产品的表面微裂纹进行表征[24],可以直观地分析产品表面的微裂纹,如图2所示。

对比图2中(a)、(b)和(c)、(d)可以看出,在0.9~3.2 mm粒级时,高压辊磨产品的微裂纹数量远远高于颚式破碎产品微裂纹的数量;由图2中(e)和(f)对比可以看出,在0.45~0.9 mm时,高压辊磨产品的微裂纹数量稍高于颚式破碎产品微裂纹的数量。微裂纹包括晶内裂纹(矿物颗粒内部的裂纹)和解离裂纹(矿石颗粒中不同矿物间的裂纹)[25],晶内裂纹会降低后续磨矿过程的能耗,解离裂纹会增加后续磨矿过程中矿物的单体解离度。

图2 高压辊磨产品与颚式破碎产品不同粒径表面的微裂纹

Fig. 2 Micro-cracks of products crushed by HPGR ((a), (b), (e)) and products crushed by JC ((c), (d), (f)):

2.3 磨矿细度条件试验结果

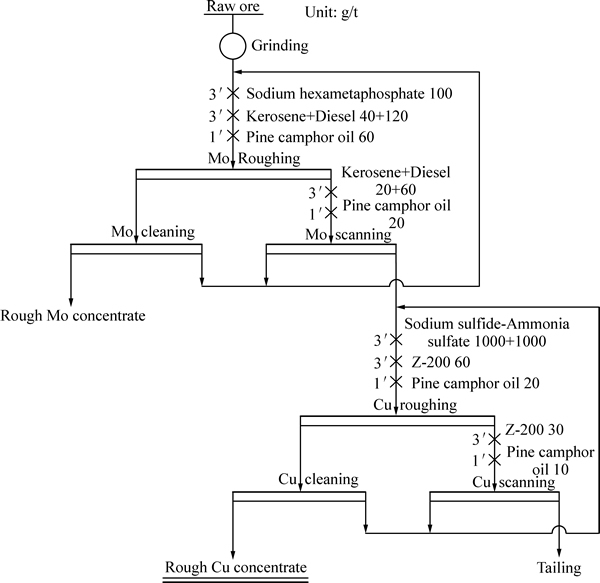

针对邦铺钼铜矿石的矿石性质,并根据钼铜矿石可选性文献综述的研究[26-27],选择“钼铜等可浮—钼铜分离—铜硫混合浮选—铜硫分离”工艺流程处理邦铺钼铜矿石。

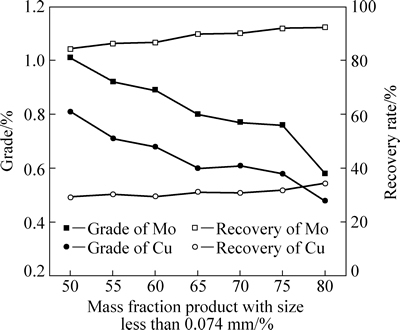

磨矿细度条件试验工艺流程和药剂制度如图3所示,磨矿细度试验结果如图4和5所示。

由图4可以看出,精矿中Mo的品位随着磨矿细度的增加而逐渐降低,而Mo的回收了逐渐升高,在磨矿细度小于0.074 mm的含量大于65%时回收率升高缓慢,而品位下降较快,综合考虑,选择高压辊磨产品磨矿细度小于0.074 mm的含量占65%时比较适宜,此时精矿的钼品位为0.81%,回收率为92.42%。

图3 磨矿细度试验工艺流程图

Fig. 3 Process flow diagram of grinding fineness

图4 高压辊磨产品的磨矿细度试验结果

Fig. 4 Experiment results of grinding fineness of product crushed by HPGR

由图5可以看出,精矿中Mo的回收率随着磨矿细度的增加而逐渐升高,而Mo的品位逐渐降低,在磨矿细度小于0.074 mm的含量大于75%时品位迅速下降,综合考虑,选择高压辊磨产品磨矿细度小于0.074 mm的含量占75%时比较适宜,此时精矿的钼品位为0.76%,回收率为91.75%。

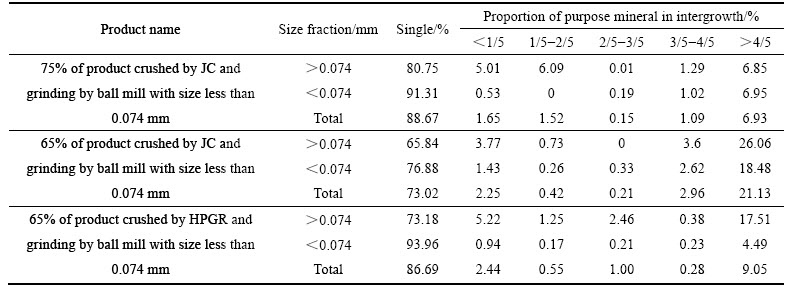

2.4 磨矿产品单体解离度结果

为了考察磨矿产品的单体解离情况,在颚式破碎产品磨矿细度小于0.074 mm的含量占75%、颚式破碎产品磨矿细度小于0.074 mm的含量占65%和高压辊磨产品磨矿细度小于0.074 mm的含量占65%情况下应用MLA对矿物的单体解离度进行了测定。试验结果如表6所列。

由表6中辉钼矿的单体解离结果可知,颚式破碎产品在磨矿细度小于0.074 mm的含量占75%和高压辊磨产品在磨矿细度小于0.074 mm的含量占65%时的解离效果较好,单体分别为87.67%和86.69%,单体和大于4/5的富连生体之和分别为95.60%和95.74%。颚式破碎产品在磨矿细度为小于0.074 mm含量占65%的解离效果稍差,单体分别为73.18%,单体和大于4/5的富连生体之和为94.15%。

图5 鄂式破碎产品的磨矿细度试验结果

Fig. 5 Experiment result of grinding fineness of product crushed by JC

表6 不同连生比例下辉钼矿的分配百分含量

Table 6 Percentage of molybdenite under different probabilities of intergrowth

2.5 闭路试验结果分析

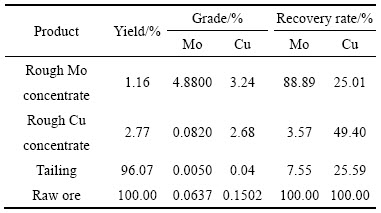

在颚式破碎产品在磨矿细度小于0.074 mm的含量占75%和高压辊磨产品在磨矿细度小于0.074 mm的含量占65%的情况下进行闭路试验,闭路试验工艺流程和药剂制度如图6所示,试验结果如表7和8所列。

由表7可知,颚式破碎产品在磨矿细度小于0.074 mm的含量占75%时进行闭路浮选,可以获得钼粗精矿钼品位为4.05%,钼回收率为87.84%,铜品位为3.04%,铜回收率为27.69%;铜粗精矿钼品位为0.10%,钼回收率为4.54%,铜品位为2.45%,铜回收率为46.74%。

由表8可知,高压辊磨产品在磨矿细度小于0.074 mm的含量占65%时进行闭路浮选,可以获得钼粗精矿钼品位为4.88%,钼回收率为88.89%,铜品位为3.24%,铜回收率为5.01%;铜粗精矿钼品位为0.082%,钼回收率为3.57%,铜品位为2.68%,铜回收率为49.40%。

高压辊磨产品在磨矿细度小于0.074 mm的含量占65%的情况下比颚式破碎产品在磨矿细度小于0.074 mm的含量占75%的情况下的闭路试验指标都有所提高,钼粗精矿钼品位提高0.83%,钼回收率提高1.05%;铜粗精矿铜品位提高0.23%,铜回收率提高2.66%。

分析高压辊磨工艺提高浮选指标的原因,一方面是高压辊磨产品进行磨矿后提高了单体解离度;另一方面是高压辊磨产品在放粗磨矿细度后改善了浮选环境,削弱了矿石的泥化对浮选的影响。

综上所述可知,高压辊磨工艺会对邦铺钼铜矿石发生选择性粉碎现象,球磨会对高压辊磨产品发生选择性解离现象,针对上述分析,提出“矿石高压辊选择性粉碎—球磨选择性解离—浮选”技术方案。

图6 闭路试验工艺流程图

Fig. 6 Process flow diagram of closed circuit test

表7 颚式破碎产品闭路试验结果

Table 7 Experiment results of closed circuit test of products crushed by JC

表8 高压辊磨产品闭路试验结果

Table 8 Experiment results of closed circuit test of products crushed by HPGR

3 结论

1) 由品位和粒级金属分布分析结果可知,高压辊磨对邦铺钼铜矿石发生了选择性粉碎。

2) 高压辊磨产品表面的微裂纹数量高于颚式破碎产品表面微裂纹的数量,在后续磨矿过程中,有利于降低高压辊磨产品的磨矿能耗和提高矿物的单体解离度。

3) 高压辊磨产品适宜的磨矿细度为小于0.074 mm的含量占65%,颚式破碎产品适宜的磨矿细度为小于0.074 mm的含量占75%,采用高压辊磨工艺可以放粗产品的磨矿细度。

4) 单体解离度结果表明,颚式破碎产品在磨矿细度小于0.074 mm的含量占75%和高压辊磨产品在磨矿细度小于0.074 mm的含量占65%时的解离效果较好,颚式破碎产品在磨矿细度为小于0.074 mm的含量占65%的解离效果稍差。

5) 高压辊磨产品在磨矿细度小于0.074 mm的含量占65%情况下的比颚式破碎产品在磨矿细度小于0.074 mm的含量占75%情况下的闭路试验指标都有所提高,钼粗精矿钼品位提高0.83%,钼回收率提高1.05%;铜粗精矿铜品位提高0.23%,铜回收率提高2.66%。

6) 提出“矿石高压辊选择性粉碎—球磨选择性解离—浮选”技术方案。

REFERENCES

[1] TAVARES L M. Particle weakening in high-pressure roll grinding[J]. Minerals Engineering 2005, 18(7): 651-657.

[2] TORRES M, CASALI A. A novel approach for the modeling of high-pressure grinding rolls[J]. Minerals Engineering, 2009, 22(13): 1137-1146.

[3] NAMIK A A, LEVENT E, HAKAN B. High pressure grinding rolls(HPGR) applications in the cement industry[J]. Minerals Engineering, 2006, 19(2): 130-139.

[4] KODALI P, DHAWAN N, DEPCI T, LIN C L, MILLER J D. Particle damage and exposure analysis in HPGR crushing of selected copper ores for column leaching[J]. Minerals Engineering, 2011, 24(13): 1478-1487.

[5] OZCAN O, AYDOGAN N A, BENZER H. Effect of operational parameters and recycling load on the high pressure grinding rolls(HPGR) performance[J]. International Journal of Mineral Processing, 2015, 136: 20-25.

[6] 翁兴媛, 杨启帆, 刘 磊, 曹进成. 不同破碎方式对鞍山式赤铁矿石磨矿特性的影响[J]. 金属矿山, 2015(3): 120-122.

WENG Xing-yuan, YANG Qi-fan, LIU Lei, CAO Jin-cheng. Effect of different broken way on grinding characteristics of Anshan-type hematite[J]. Metal Mine, 2015(3): 120-122.

[7] MEER F P. Pellet feed grinding by HPGR[J]. Minerals Engineering, 2015, 73: 21-30.

[8] 袁致涛, 郭小飞, 严 洋, 韩跃新. 攀西钒钛磁铁矿高压辊磨的产品特性[J]. 东北大学学报(自然科学版), 2012, 33(1): 124-127, 132.

YUAN Zhi-tao, GUO Xiao-fei, YAN Yang, HAN Yue-xin. Product characteristics of vanadium-titanium magnetite from Panxi by high pressure grinding roller[J]. Journal of Northeastern University(Natural Science), 2012, 33 (1): 124- 127, 132.

[9] 刘 磊, 曹进成, 吕 良, 郭珍旭, 岳铁兵. 不同破碎方式下磨矿技术效率[J]. 中国有色金属学报, 2015, 25(9): 2565-2574.

LIU Lei, CAO Jin-cheng, L Liang, GUO Zhen-xu, YUE Tie-bing. Grinding technical efficiencies in various comminution modes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2565-2574.

Liang, GUO Zhen-xu, YUE Tie-bing. Grinding technical efficiencies in various comminution modes[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2565-2574.

[10] 高 航, 方存光, 杨晓明, 徐小荷. 高压辊磨技术的发展及其在选矿业的应用前景[J]. 中国有色金属学报, 1998, 8(S2): s623-s626.

GAO Hang, FANG Cun-guang, YANG Xiao-ming, XU Xiao-he. Development of the technology of high pressure Grinding rolls and its application prospect in ore beneficiation[J]. The Chinese Journal of Nonferrous Metals, 1998, 8(S2): s623-s626.

[11] 易南概, 徐小荷. 粉碎方式对金矿石氰化浸出效果影响的实验研究[J]. 黄金, 1996(1): 32-35.

YI Nan-gai, XU Xiao-he. Experimental study of the influence of pulverizing mode on cyanide leaching of gold ore[J]. Gold, 1996(1): 32-35.

[12] OLIVEIRA D M, SOBRAL L G S, OLSON G J, OLSON S B. Acid leaching of a copper ore by sulphur-oxidizing microorganisms[J]. Hydrometallurgy, 2014, 147: 223-227.

[13] 朱德庆, 唐艳云, VINICIUS M, 潘 建, 翟 勇. 高压辊磨预处理强化巴西镜铁矿球团[J]. 北京科技大学学报, 2009, 31(1): 30-35.

ZHU De-qing, TANG Yan-yun, VINICIUS M, PAN Jian, ZHAI Yong. Improvement in pelletization of Brazilian specularite by high-pressure roller grinding[J]. Journal of University of Science and Technology Beijing, 2009, 31(1): 30-35.

[14] 唐 远, 印万忠, 迟晓鹏. 破碎方式对低品位金矿石全泥氰化的影响[J]. 中国有色金属学报, 2016, 26(2): 423-429.

TANG Yuan, YIN Wan-zhong, CHI Xiao-peng. Influence of comminuting methods on full-slime cyaniding of low grade gold ore[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(2): 423-429.

[15] 刘 磊. 贫赤铁矿石高压辊磨机粉碎-高效分选技术研究[D]. 沈阳: 东北大学, 2012: 135.

LIU Lei. High efficient separation of lean hematite ore comminuted by high-pressure grinding roller[D]. Shenyang: Northeastern University, 2012: 135.

[16] 印万忠, 吴 凯, 王纪镇, 林 涛, 张千新. 破碎方式对紫金山铜金矿石可磨性及浮选的影响[J]. 福州大学学报(自然科学版), 2014, 42(2): 321-326.

YIN Wan-zhong, WU Kai, WANG Ji-zhen, LIN Tao, ZHANG Qian-xin. Effect of different comminuting process on grindability and flotation of Zijinshan Cu-Au ore[J]. Journal of Fuzhou University(Natural Science Edition), 2014, 42(2): 321-326.

[17] 印万忠, 侯 英, 丁亚卓, 姚 金, 王余莲, 罗溪梅, 孙大勇. 破碎方式对邦铺钼铜矿石可磨性及钼浮选的影响[J]. 金属矿山, 2013(2): 86-89.

YIN Wan-zhong, HOU Ying, DING Ya-zhuo, YAO Jin, WANG Yu-lian, LUO Xi-mei, SUN Da-yong. Effect of Different Comminuting process on grindability and molybdenum flotation of Bangpu Mo-Cu ore[J]. Metal Mine, 2013(2): 86-89.

[18] STEPANOV Y V, POPOVA N K, SHESTOPEROVA A V, GILYAZETDINOV R R, TSAREV N V. Effectiveness of selective crushing for coking batch[J]. Coke and Chemistry, 2010, 53 (7): 247-249.

[19] EREMIN A Y, KUKOLEV Y B, GILYAZETDINOV R R, MAKHORTOVA L A, STEPANOV Y B, TSAREV N V. Selective crushing with pneumatic separation at unit 3 in NTMK coal-preparation shop 1. Quality of concentrates[J]. Coke and Chemistry, 2008, 51(7): 247-255.

[20] EREMIN A Y, KUKOLEV Y B, GILYAZETDINOV R R, MAKHORTOVA L A, STEPANOV Y V, TSAREV N V. Efficiency of selective crushing with pneumatic separation for the third unit in the OAO NTMK coal-preparation shop 2. Equipment and operating conditions[J]. Coke and Chemistry, 2008, 51(11): 434-439.

[21] YUSUPOV T S, KIRILLOVA E A, DENISOV G A. Dressing of quartz-feldspar ores on the basis of selective grinding and mechanical activation[J]. Journal of Mining Science, 2003, 39(2): 174-177.

[22] 曾桂忠, 鲁顺利, 段希祥. 磨机因素对选择性磨矿的影响分析[J]. 矿山机械, 2008(1): 55-57.

ZENG Gui-zhong, LU Shun-li, DUAN Xi-xiang. Analyzing influence of factor of a tube mill on selectively grinding[J]. Mining & Processing Equipment, 2008(1): 55-57.

[23] 段希祥. 碎矿与磨矿[M]. 第2版. 北京: 冶金工业出版社, 2006: 179-180, 202-206.

Duan Xi-xiang. Crushing and grinding[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2006: 179-180, 202-206.

[24] 侯 英, 丁亚卓, 印万忠, 姚 金, 罗溪梅, 王余莲, 孙大勇. 邦铺钼铜矿石高压辊磨后物料的特性[J]. 中南大学学报(自然科学版), 2013, 44(12): 4781-4786.

HOU Ying, DING Ya-zhuo, YIN Wan-zhong, YAO Jin, LUO Xi-mei, WANG Yu-lian, SUN Da-yong. Product characteristics of Mo-Cu ore from Bangpu by high pressure grinding rolls[J]. Journal of Central South University(Natural Science), 2013, 44(12): 4781-4786.

[25] 陈友晴. Westerly花岗岩试样单轴压缩破坏瞬时微裂纹观察[J]. 岩石力学与工程学报, 2008, 27(12) : 2440-2448.

CHEN You-qing. Observation of micro-cracks patterns in Westerly granite specimens stressed immediately before failure by uniaxial compressive loading[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(12): 2440-2448.

[26] 周 峰, 孙春宝, 刘洪均, 古志君, 米丽平, 王 越. 某低品位铜钼矿低碱度浮选工艺研究[J]. 金属矿山, 2011(3): 80-83.

ZHOU Feng, SUN Chun-bao, LIU Hong-jun, GU Zhi-jun, MI Li-ping, WANG Yue. Investigation on the low alkalinity flotation process for a low grade copper-molybdenum ore[J]. Metal Mine, 2011(3): 80-83.

[27] 呼振峰. 西藏某铜钼矿选矿工艺研究[J]. 有色金属(选矿部分), 2011(6): 13-16.

HU Zhen-feng. Study on mineral processing technology for certain Cu-Mo ore in Tibet[J]. Nonferrous Metals(Mineral Processing Section), 2011(6): 13-16.

Effect and mechanism of selective crushing and liberation of Mo-Cu ore from Bangpu crushed by high pressure grinding rolls

HOU Ying1, YIN Wan-zhong2, YU Guang-tao3, YANG Chun3, GAI Zhuang3, ZHAO Tong-lin1, XIAO Li-cong1

(1. School of Mining Engineering, University of Science and Technology Liaoning, Anshan 114051, China;

2. College of Zijin Mining, Fuzhou University, Fuzhou 350108, China;

3. Gongchangling Mining Co.,Ltd, Anshan Steel Group, Liaoyang 111008, China)

Abstract: Mo-Cu ore from Bangpu was crushed by high pressure grinding rolls(HPGR) and jaw crusher(JC), and grinding-flotation test of the product crushed by different crushing processes was carried out. Crushing characteristics of HPGR of ore was studied by scanning electron microscopy(SEM), dissociation character of grinding product was studied by mineral liberation analyzer(MLA), and the best grinding fineness and flotation process conditions were studied from the reagent dosage and other aspects. The results show that the best grinding fineness of the product with size less than 0.074 mm crushed by HPGR and JC are 65% and 75%, respectively. The floatation effect of the grinding product crushed by HPGR are better than that crushed by JC, and the molybdenum grade, molybdenum recovery of molybdenum rougher concentrate, copper grade, copper recovery of copper rougher concentrate of HPGR products when the grinding fineness less than 0.074 mm content is 65% comparing with JC products when the grinding fineness less than 0.074 mm content is 75%, respectively, high 0.83%, high 1.03%, low 0.02%, high 2.66%. The phenomenon of selective combinations occurs when crushed by HPGR, and the phenomenon of selective dissociation occurs when the product crushed by HPGR is grinding. The “HPGR selective crushing-selective dissociation of the product was grinding by ball milling-flotation” technical scheme was put forward.

Key words: high pressure grinding rolls; jaw crusher; selective grinding; selective dissociation; flotation

Foundation item: Project(51374079) supported by the National Natural Science Foundation of China

Received date: 2015-04-19; Accepted date: 2016-05-17

Corresponding author: YIN Wang-zhong; Tel: +86-24-83673958; E-mail: yinwanzhong@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51374079)

收稿日期:2015-04-19;修订日期:2016-05-17

通信作者:印万忠,教授,博士;电话:024-83673958;E-mail:yinwanzhong@163.com