Bonding strength in carbon steel sandwich panels under condition of diffusion-rolling with small reduction①

来源期刊:中南大学学报(英文版)2005年第4期

论文作者:刘靖 韩静涛 付定梅

文章页码:393 - 395

Key words:bonding assistant coat; diffusion-rolling; steel sandwich panels; bonding strength

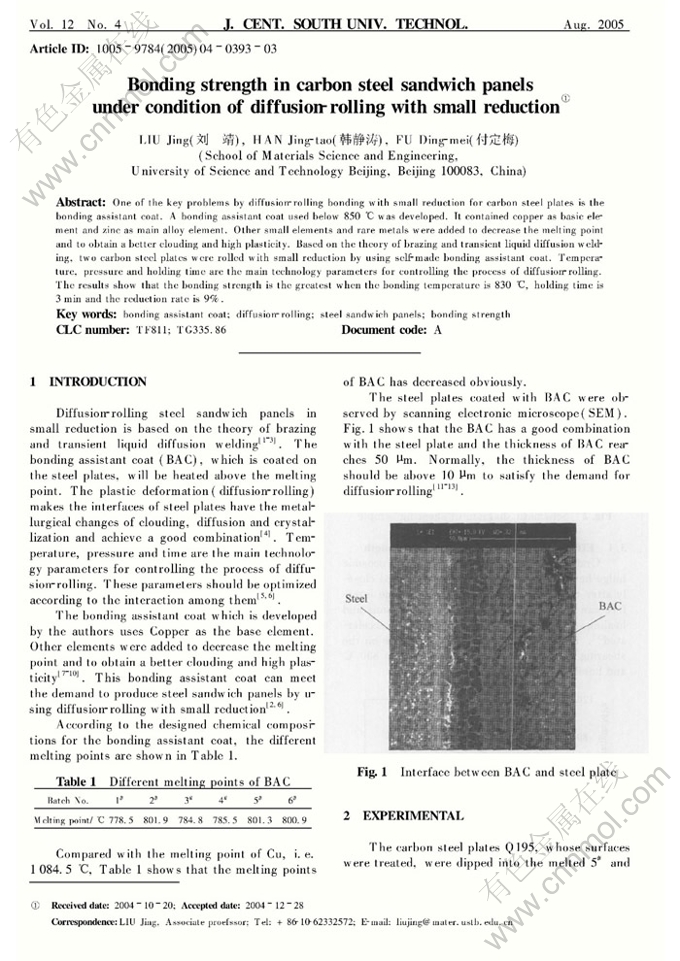

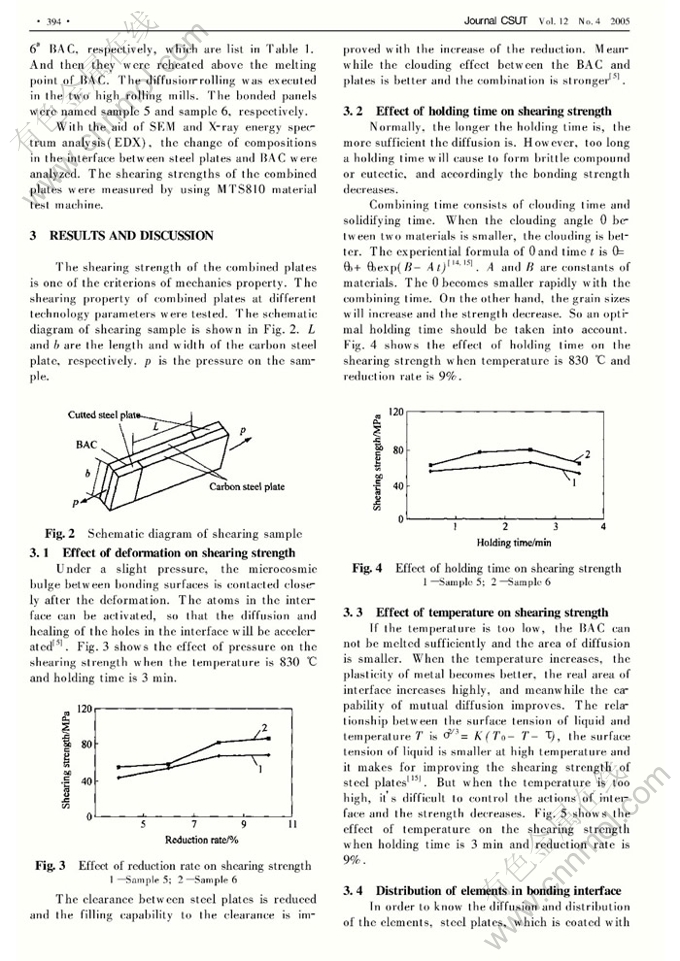

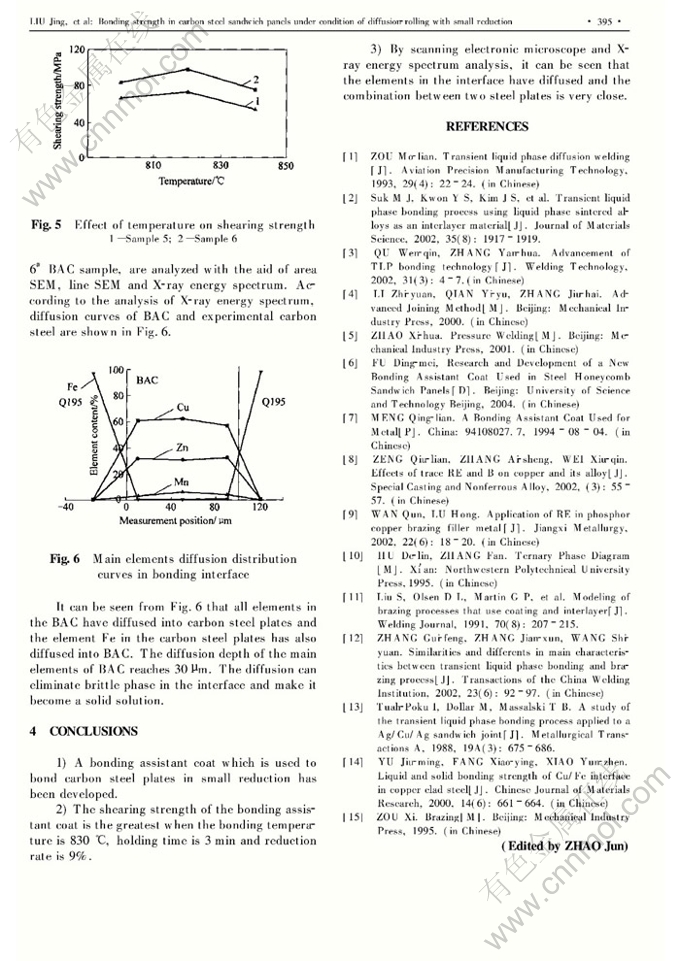

Abstract: One of the key problems by diffusion-rolling bonding with small reduction for carbon steel plates is the bonding assistant coat. A bonding assistant coat used below 850℃was developed. It contained copper as basic element and zinc as main alloy element. Other small elements and rare metals were added to decrease the melting point and to obtain a better clouding and high plasticity. Based on the theory of brazing and transient liquid diffusion welding, two carbon steel plates were rolled with small reduction by using self-made bonding assistant coat. Temperature, pressure and holding time are the main technology parameters for controlling the process of diffusion-rolling. The results show that the bonding strength is the greatest when the bonding temperature is 830℃, holding time is 3 min and the reduction rate is 9%.