文章编号:1004-0609(2010)06-1046-07

浇注温度对自孕育铸造法制备AM60镁合金半固态浆料的影响(Ⅰ)

李元东1, 2,杨 建1,马 颖1, 2,曲俊峰1,张 鹏1

(1. 兰州理工大学 甘肃省有色金属新材料省部共建国家重点实验室,兰州 730050;

2. 兰州理工大学 有色金属合金及加工教育部重点实验室,兰州 730050)

摘 要:采用新型的自孕育法制备AM60镁合金半固态浆料,研究浇注温度对自孕育法制备AM60镁合金半固态浆料的影响。结果表明:随着浇注温度的降低,组织中发达和粗大的树枝晶逐渐减少;在接近液相线温度时出现小块状或蔷薇状晶粒,晶粒的尺寸逐渐减小;分布逐渐趋向正态分布,且存在一个合适的温度加工区间,即630 ~ 680 ℃,对应的晶粒尺寸为58.4~63.1 μm。加入的孕育剂在熔体中起到内冷铁作用,加快熔体的冷却速率,使熔体快速到达半固态区间。采用自孕育法制浆时,合金熔体中晶核主要来源于熔体中的高熔点质点(Al8Mn5)、孕育形核和晶粒游离与增殖。

关键词:镁合金;AM60镁合金;半固态浆料;自孕育法;浇注温度;凝固过程

中图分类号:TG249,TG146.2 文献标志码:A

Effect of pouring temperature on AM60 Mg alloy semi-solid slurry prepared by self-inoculation method (Ⅰ)

LI Yuan-dong1, 2, YANG Jian1, MA Ying1, 2, QU Jun-feng1, ZHANG Peng1

(1. State Key Laboratory of Gansu Advanced Non-ferrous Metal Materials,Lanzhou University of Technology, Lanzhou 730050, China;

2. Key Laboratory of Non-ferrous Metal Alloys and Processing, Ministry of Education,Lanzhou University of Technology, Lanzhou 730050, China)

Abstract: The semi-solid slurry of AM60 Mg alloy was prepared by a novel self-inoculation method(SIM). The effect of pouring temperature on the semi-solid slurry prepared by self-inoculation method was investigated. The results show that the coarser dendrite reduces with the decrease of pouring temperature. A small block or rosette grain is obtained when the pouring temperature is near-liquidus. Meanwhile, the grain size also decreases, and it becomes approximately normally distributed. An ideal temperature process interval/window has to be required between 630 ℃ and 680 ℃, and the grain size is 58.4-63.1 μm correspondingly. The added inoculants are as internal chill in AM60 melt, which accelerates the cooling rate of the melt, as a result, the melt is cooled down to semi-solid range rapidly. The nuclei are from high melting point phases in the melt (such as Al8Mn5), inoculants, and the grain of the free and the proliferation.

Key words: Mg alloy; AM60 Mg alloy; semi-solid state slurry; self-inoculation method; pouring temperature

近年来,随着半固态浆料制备技术的不断创新,技术越来越趋向于简捷方便,使得后续成形设备简单,加工成本降低。这些技术的共同特点就是利用铸造凝固组织控制技术和原理,控制形核与抑制树枝晶生长改变材料凝固行为,使之获得理想的半固态浆料。因此可以认为,理论上首先要在合金熔体中形成足够多的晶核,并且能够稳定存在;其次要比较好地满足球形晶生长的界面稳定性条件。国外一些学者提出液-液混合,固-液混合和半固态-半固态混合等新兴的制备方法,并成功制备出细晶的变形铝合金[1-3]。国内学者也进行相关研究,陈振华[4]在喷射沉积、快速凝固等技术的基础上提出一种新的材料制备工艺固-液混合铸造。

总的来说,为了获得半固态非枝晶组织,工艺上通过控制凝固条件来实现:1) 热学条件,如低温浇注;2) 孕育处理,如传统孕育或变质处理,悬浮铸造及固液混合;3) 动态结晶,如倾斜冷却板法及其改进技 术[5-7]、振动(机械、超声波)法等。且技术的发展逐渐趋向多种技术的结合,如前所述,CRP技术[8]就是低温浇注和动态结晶的结合,固-液混合技术[4]就是孕育处理和搅拌技术的结合。在低温浇注、液-液混合法、固-液混合法、悬浮铸造[9]及斜板冷却法的基础上,作者提出了自孕育法的概念。所谓自孕育法(Self-inoculation method,简称SIM法)就是指将两个一定成分、质量和温度的合金的固-液相(或液相和半固态)、半固态-半固态(或固相)混合,再经过一定角度的导流器,利用两个合金液(体)的不同性质,如温度、表面张力和组织等,在混合后使得合金液中瞬间形成大量晶核(一次自孕育),同时通过导流器产生紊流,促进晶粒增殖,加强自孕育效果(二次自孕育),抑制晶粒长大,获得具有非枝晶初生固相的固-液混合浆料,然后进行各种后续热加工,如流变成形或触变成形。自孕育法铸造中,加入的孕育剂为小金属块,没有特殊的形状要求,所以不要特别加工,导流器可以起到倾斜板的作用,破碎枝晶,孕育剂又起到激冷作用,可以促进熔体形核并抑制其长大,从而得到理想的组织。自孕育法技术工艺简单,生产成本低,适合各种合金,可以成形复杂铸件,还可以直接与冷室压铸机相连,进行半固态成形,而不需要安装其他特殊装置。本文作者主要研究浇注温度对自孕育铸造法制备AM60镁合金半固态浆料的影响。

1 实验

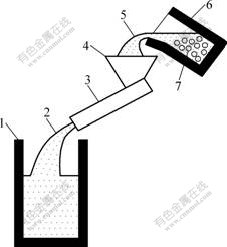

图1所示为自行设计的自孕育法铸造工艺示意图。本研究采用商用AM60镁合金铸锭,其液相线温度为618 ℃,共晶温度为433 ℃,其成分如表1所列。

图1 自孕育法铸造工艺的示意图

Fig.1 Schematic diagram of self-inoculation method: 1—Mould; 2, 5—Melt; 3—Cooling channel; 4—Pouring cup; 6—Crucible; 7—Inoculant

表1 AM60合金的化学成分

Table 1 Chemical composition of AM60 alloy(mass fraction, %)

将镁合金AM60锭料在井式坩锅电阻炉中熔炼,待金属全部熔化后,开始测温。当熔体温度达到720~725 ℃后(热电偶测定),用1.5%~2% C2Cl6(质量分数)进行精炼除气,调整金属液温度为710~720 ℃时浇注成d15 mm×150 mm棒料,然后加工成5 mm×5 mm×5 mm金属块作为孕育剂。同前面的熔炼工艺,在一定的熔体温度(720、680、650、630 ℃)下,孕育剂加入量为5% (质量分数)、颗粒尺寸为5 mm×5 mm×5 mm、加入方式为直接加入到同种成分AM60镁合金的熔体中(见图1),浇注成d15 mm×150 mm的试样。

把上述制备的试样进行制样、固溶处理后测定其晶粒尺寸与分布,采用MEF-3光学显微镜观察其组织形貌。

2 结果

根据AM60合金液相线温度,选取4种浇注温度,即720、680、650、630 ℃。图2所示为不同浇注温度下自孕育法浇注坯料的铸态组织。由图2(a)可以看出,组织中具有明显的树枝晶结构,同时有部分块状晶粒和一些等轴晶存在;在图2(b)和(c)中没有看到明显的树枝晶,二次枝晶臂不明显,一次枝晶臂比较粗;图2(d)中显微组织没有树枝晶,晶粒呈小块状或蔷薇状。由此得出,随着浇注温度的降低,组织中粗大的树枝晶在减少,在接近液相线温度时出现了小块状或蔷薇状晶粒,且晶粒的尺寸在减小。

图2 不同浇注温度下自孕育法浇注坯料的铸态显微组织

Fig.2 As-cast microstructures of AM60 alloys produced by self-inoculation method at different pouring temperatures: (a) 720 ℃; (b) 680 ℃; (c) 650 ℃; (d) 630 ℃

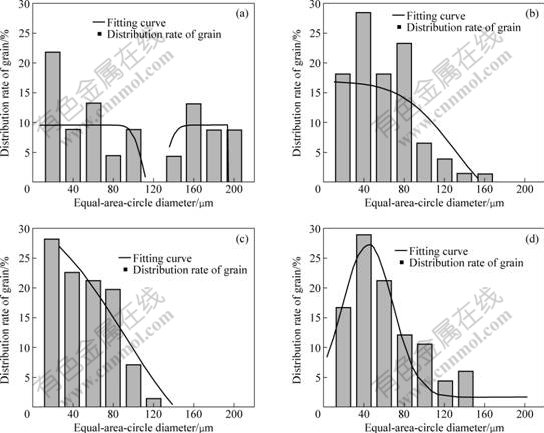

为了测定晶粒尺寸,本研究采用等面积圆直径表征每个晶粒的大小和平均晶粒尺寸,测定前先对铸态坯料进行固溶处理。图3所示为自孕育法制备坯料经固溶处理后的组织。不同浇注温度条件下坯料的晶粒尺寸分布如图4所示。由图4可以看出,720 ℃浇注时,晶粒尺寸分布极不均匀,尺寸在140~200 μm的晶粒与小于100 μm的晶粒比例相当。而从图4(b)、(c)和(d)中可以看出,尺寸为40~80 μm晶粒所占比例越来越大。随着浇注温度的降低,小尺寸晶粒逐渐增多,大尺寸晶粒减少,且分布逐渐趋向正态分布。

图3 不同浇注温度下自孕育法浇注坯料固溶处理后的显微组织

Fig.3 Microstructures of AM60 alloys produced by self-inoculation method after solid solution treatment at different pouring temperatures: (a) 720 ℃; (b) 680 ℃; (c) 650 ℃; (d) 630 ℃

图4 不同浇注温度自孕育法浇注坯料的晶粒尺寸分布

Fig.4 Grain size distributions of AM60 alloys produced by self-inoculation method at different pouring temperatures: (a) 720 ℃; (b) 680 ℃; (c) 650 ℃; (d) 630 ℃

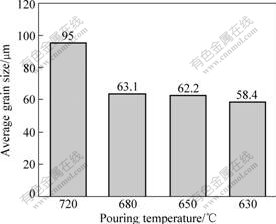

图5所示为不同浇注温度条件下坯料的平均晶粒尺寸。由图5可看出,对不同浇注温度条件下坯料的晶粒尺寸取平均值后发现,随着浇注温度的降低,坯料的平均晶粒尺寸显著减小。浇注温度为720、680、650、630 ℃对应的晶粒平均等面积圆直径分别为95、63.1、62.2、58.4 μm。

图5 不同浇注温度下自孕育法浇注坯料的平均晶粒尺寸

Fig.5 Average grain sizes of AM60 alloy samples produced by self-inoculation method at different pouring temperatures

综合上述实验,浇注温度越低,晶粒尺寸越小且细小晶粒在组织中所占比例越来越大。当浇注温度为630 ℃时,晶粒尺寸最小,但是由于此时熔体过热度太小,只有18 ℃左右,加之孕育剂的降温作用,导致在后期熔体温度过低,流动性差,大量金属熔体凝固在导流器中,从而大量浪费材料。因此,浇注温度不易太低,选择650 ℃为较合适的浇注温度。

3 分析与讨论

3.1 浇注温度的影响

从自孕育法铸造的工艺过程来说,当浇注温度过高时,熔体过热度太高,加入一定量的孕育剂,孕育剂全部被重熔,从而不能起到有效的作用,再经导流器时主要是枝晶断裂机制起作用[6],由于温度高,同时导流器的直径小,层流的液面厚度大,不能很好地散热,致使初期形成的粗大树枝晶不能被剪断。当进入到铸型中时,温度仍然很高,致使熔体有充分时间形核、长大,形成大的树枝晶。随着浇注温度的降低,熔体本身过热度降低,当加入一定量的孕育剂时,瞬间在熔体中形成很多晶核,这样在经导流器时,又有激冷作用,所以不易生成粗大的树枝晶。在剪切力的作用下,一些细小的树枝晶就被破碎,这些破碎的枝晶在熔体中又可以充当晶核,从而使熔体组织形成不规则的晶粒。当浇注温度很低时,加入孕育剂会进一步降温,使操作变得困难,因此存在一个合适的温度处理区间或窗口。

当高温金属熔体沿导流器浇注到铸型中时,在流动过程中受到导流器的激冷作用,以非均匀形核方式大量形核并长大为枝晶状,由于合金熔体中枝晶间、枝晶与合金熔体间相互碰撞、摩擦、冲刷和剪切等物理冶金作用,初生相的枝晶很容易被折断、破碎,形成短枝晶和球状晶,即主要是枝晶断裂机制。而当熔体流经导流器末端时,由于金属液温度的降低程度加大, 熔体黏度增大,熔体内部枝晶之间的相对运动速度降低而发生相互之间的粘连, 又形成形态不规则非枝晶,最终形成近球状晶粒[10],即枝晶熟化机制。

当合金熔体刚进入铸型时,由于铸型温度低,使得接触型壁的熔体瞬间凝固,在凝固收缩的作用下,铸型型壁与熔体间形成界面气隙[11],阻碍熔体中的热量由铸型型壁向外传导,降低了熔体凝固前沿的过冷度。如果此时合金熔体温度很高,熔体就有充足的时间形核、长大,从而形成发达的树枝晶。

3.2 孕育剂的影响

经典凝固理论认为,合金熔体的凝固方式有两种:自发形核和非自发形核。实际中的合金凝固大都是非自发形核。一些学者对合金熔体结构提出假设[12],金属熔体是由具有金属原子和一定数量的不同种类的原子团共同组成的。这些原子团能够保持一定尺寸和结构的稳定性,且对合金熔体温度很敏感。在一定温度下,某一类型的原子团数量占优势。当合金熔体温度升高时,原子团向小尺度原子团趋势变化。反之,当合金熔体的温度降低时,原子团则向大尺度原子团的方向发展。这些熔体中稳定存在的原子团是金属凝固时临界晶核的“准晶胚”, 大尺度的原子团越多,相同凝固条件下的临界晶核的“准晶胚”越多,凝固组织越细小;反之,则凝固组织粗化。

加入的孕育剂在熔体中起到内冷铁作用,加快熔体的冷却速率,使熔体快速到达半固态区间;同时,激冷作用使熔体中瞬间产生大量晶核,增加了熔体的形核率。根据金属凝固学原理可知,在液体中存在着相起伏。相起伏的尺寸超过临界值时,就可以作为晶胚进而转变为晶核,液体温度越低,相起伏尺寸越大,数量越多。在自孕育法中,撒入的孕育剂使熔体内温度快速降低,变成过冷熔体,此时熔体中大尺寸相起伏数量增加,从而增加了晶核,达到晶核增殖效果,使晶粒细化。晶核在后期长大时,由于凝固过程固-液界面的溶质扩散,导致相近的晶粒的扩散场重叠,减小凝固前端的温度梯度,因此不会形成枝晶。加入孕育剂后熔体温度较低,此时熔体黏度大,流经导流器时受到的剪切力就大,使得型壁间产生大量的枝晶碎片,从而增加了更多的游离晶核进入到熔体中。这些游离晶在流动过程中会受到各个方向上的剪切力,晶粒在各个方向上生长的机率一致,所以晶粒最终趋向于蔷薇状或近球状。

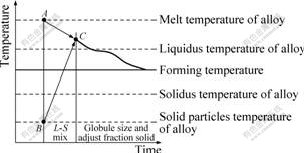

3.3 自孕育铸造法凝固过程

图6所示为自孕育法铸造中液-固混合凝固过程示意图。由图6可看出,当高温的熔体与低温的固体混合后,两者的温度迅速趋于一致,接近液相线温度。再经过导流器时温度再继续降低,并低于液相线温度。因此可以认为,当把两个一定成分和温度的合金混合在一起时会发生: 1) 混合后的合金经过传导和对流使热量重新分配,最后达到热平衡;2) 通过界面的质量扩散达到化学平衡;3) 合金混合时,两种母合金内部的已有晶核为对方提供形核基底,并在导流器内的流动过程中发生晶粒增殖,抑制晶粒生长。

图6 自孕育法液-固混合凝固过程示意图

Fig.6 Schematic diagram of liquid-solid mixing solidification by self-inoculation method

宏观上看,晶粒长大是晶粒界面向液相中逐渐推移的过程[13]。从微观角度观察,晶核长大就是原子逐个地由液相中扩散到晶体表面,按照晶体点阵规律,逐个占据合适的位置与晶体稳定的结合。晶体长大的条件是:1) 液相不断地向固相中提供原子,这就要求熔体中液相温度不能太低,合适的温度才能保证金属原子有足够的扩散能力;2) 晶体表面能够牢固地接收这些原子,根据热力学条件,晶体长大时体积自由能的降低应该大于晶体表面能的增加。在通常情况下,晶核界面结构、温度场分布、结晶时潜热释放和散热状况决定晶体长大方式和长大速度。采用自孕育法铸造AM60半固态浆料时,由于在孕育剂和导流器的作用下,熔体温度在液相线附近,大量的晶核在加孕育剂时已经形成,所以此时晶核的长大方式主要依靠固-液界面的性质以及前沿的过冷情况。

根据金属凝固原理[14]可知,在凝固过程中,金属熔体中固-液界面为“粗糙”界面,即凝固过程中固-液界面只有50%位置为固相原子所占有,形成很多“晶芽”,“晶芽”是否伸向液相中生长与凝固界面前沿的过冷状况相关。而界面前沿的过冷与液固界面前沿中液相的成分变化相关。

ATSUMI [15]认为,结晶首先在冷的铸型壁上形成,由于溶质再分配和枝晶根部元素扩散不畅导致根部产生颈缩,此处如遇温度起伏或液流冲击极易断开成为游离晶。同时,这些游离晶遇到高温则再溶解,遇到低温再长大,长大时也可能产生颈缩,再遇到高温熔断成碎晶,再遇到低温时又长大,完成增殖过程。

就自孕育法凝固过程中晶核的来源而言,主要有3部分:1) 熔体中的高熔点质点。当合金熔体没有冷却到液相线时,就存在一些高熔点相,这些相在后续凝固时可以充当晶核,如AM60镁合金中的Al8Mn5相。2) 孕育形核。加入孕育剂后熔体内的温度场均匀,熔体温度降低,在熔体中形成大量的晶核或“准固相原子团簇”,这些“准固相原子团簇”为后续结晶提供条件。3) 晶粒游离与增殖。熔体经导流器流入铸型过程温度快速降低,熔体中存在的“准固相原子团簇”迅速地发展为游离晶核。同时,在导流器器壁和熔体接触面上大量形核,长大成头部大、根部小的晶核,在熔体流动的剪切力作用下脱落,游离入熔体中,导致晶粒游离与增殖。

4 结论

1) 随着浇注温度的降低,组织中发达、粗大的树枝晶在减少,在接近液相线温度时出现小块状或蔷薇状晶粒,且晶粒的尺寸不断减小。在650、630 ℃浇注所得铸态组织较好,但在630 ℃浇注时,熔体的可操作性差。所以,存在一个合适的温度加工区间,即650~ 680 ℃。

2) 随着浇注温度的降低,小尺寸晶粒逐渐增多,大尺寸晶粒减少,且分布逐渐趋向正态分布。浇注温度720、680、650、630 ℃对应的晶粒平均等面积圆直径分别为95、63.1、62.2、58.4 μm。

3) 加入的孕育剂在熔体中起到内冷铁作用,加快熔体的冷却速率,使熔体快速到达半固态区间。同时,激冷作用使熔体中瞬间产生大量晶核,增加了熔体的形核率。流经导流器时在剪切力的作用下,使得型壁间产生大量的枝晶碎片,晶粒最终趋向于蔷薇状或近球状。

4) 自孕育法合金熔体中晶核主要来源于熔体中的高熔点质点(Al8Mn5)、孕育形核和晶粒游离与增殖。

REFERENCES

[1] LANGFORD G, APELIAN D. Diffusion solidification[J]. Journal of Metals, 1980(9): 28-33.

[2] LANGFORD G, CUNNINGHAM R E. Steel casting by diffusion solidification[J]. Metallurgical Transactions B, 1978, 9(3): 5-19.

[3] SAHA D. Novel processing methods and mechanisms to control the cast microstructure in Al based alloys-390 and wrought alloys[D]. Worcester: Worcester Polytechnic Institute, 2005.

[4] 陈振华. Al-Si 合金固液混合铸造[J]. 中国有色金属学报, 2000, 10(3): 349-352.

CHEN Zhen-hua. Solid-liquid mixing casting of Al-Si alloy[J]. The Chinese Journal of Nonferrous Metals, 2000, 10(3): 349-352.

[5] 杨小容, 毛卫民, 高 冲. 采用蛇形管通道浇注法制备半固态浆料[J]. 中国有色金属学报, 2009, 19(5): 869-873.

YANG Xiao-rong, MAO Wei-min, GAO Chong. Preparation of semi-solid feedstock by serpentine pipe pouring[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(5): 869-873.

[6] 管仁国, 李江委, 李喜坤, 石 路, 陈礼清. AZ91D 镁合金波浪型倾斜板振动技术触变成形[J]. 中国有色金属学报, 2007, 17(11): 1798-1802.

GUAN Ren-guo, LI Jiang-wei, LI Xi-kun, SHI Lu, CHEN Li-qing. Thixoforming of AZ91D magnesium alloy by vibrating wavelike sloping plate process[J]. The Chinese Journal of Nonferrous Metals, 2007, 17(11): 1798-1802.

[7] 张小立, 谢水生, 李廷举, 杨浩强, 金俊泽. 阻尼冷却管法制备A356 铝合金半固态浆料的研究[J]. 稀有金属材料与工程, 2007, 36(5): 915-919.

ZHANG Xiao-li, XIE Shui-sheng, LI Ting-ju, YANG Hao-qiang, JIN Jun-ze. A356 aluminum alloy semisolid slurry prepared by damper cooling tube process[J]. Rare Metal Materials and Engineering, 2007, 36(5): 915-919.

[8] FINDON M M. Semi-solid slurry formation via liquid metal mixing[D]. Worcester: Worcester Polytechnic Institute, 2003.

[9] 任 政, 张兴国, 房灿峰, 郝 海. 电磁-悬浮铸造对变形镁合金晶粒细化的影响[J]. 材料研究学报, 2007, 21(5): 491-495.

REN Zheng, ZHANG Xing-guo, FANG Can-feng, HAO Hai. Effect of electromagnetic suspension casting on grain refinement for wrought magnesium alloy[J]. Chinese Journal of Materials Research, 2007, 21(5): 491-495.

[10] 李润娟, 蒋业华, 周荣锋, 周 荣. 半固态高铬铸铁球状先共晶奥氏体的形成[J]. 铸造, 2006, 55(2): 156-159.

LI Run-juan, JIANG Ye-hua, ZHOU Rong-feng, ZHOU Rong. Formation of spherical pro-eutectic austenite grains in semi-solid high chromium cast iron[J]. Foundry, 2006, 55(2): 156-159.

[11] 马建超, 杨院生, 童文辉. 熔体过热对AlSi304不锈钢亚快速凝固薄带组织的影响[J]. 金属学报, 2007, 43(8): 879-882.

MA Jian-chao, YANG Yuan-sheng, TONG Wen-hui. Effect of melt superheating on the subrapidly solidified microstructure of aisi 304 austenitic stainless steel strip[J]. Acta Metallurgica Sinica, 2007, 43(8): 879-882.

[12] 王 冰, 王建中, 曹丽云, 齐锦刚, 苍大强. 过热度对电脉冲孕育处理Al-5%Cu 合金凝固组织的影响[J]. 热加工工艺, 2007, 36(13): 61-63.

WANG Bing, WANG Jian-zhong, CAO Li-yun, QI Jin-gang, CANG Da-qiang. Influence of superheat degree on structure of Al-5%Cu alloy by electric pulse modification[J]. Hot Working Technology, 2007, 36(13): 61-63.

[13] 李 超. 金属学原理[M]. 哈尔滨: 哈尔滨工业大学出版社, 1996.

LI Chao. Principles of metallography[M]. Harbin: Harbin Institute of Technology Press, 1996.

[14] 胡汉起. 金属凝固原理[M]. 北京: 机械工业出版社, 2000.

HU Han-qi. Metal solidification theory[M]. Beijing: China Machine Press, 2000.

[15] ATSUMI O. Solidification: The separation theory and its practical applications[M]. Berlin: Springer-Verlag, 1987.

________________________________

基金项目:国家重点基础研究计划资助项目(2007CB613700);甘肃省国际科技合作计划资助项目(090WCGA894);兰州理工大学博士科研启动基金资助项目(SB01200701)

收稿日期:2009-08-25;修订日期:2009-12-25

通信作者:李元东,副教授,博士;电话:0931-2976795;E-mail:liyd_lut@163.com

(编辑 李艳红)