DOI: 10.11817/j.issn.1672-7207.2018.12.006

超声塑化工艺参数对聚合物熔体流动性能的影响

蒋炳炎,刘弢,吴旺青,张英平,邹洋,周啸天

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:为了测试超声塑化的聚合物熔体流动性能,采用自行研制的阿基米德螺旋模具进行超声塑化微注射成型充填实验,通过充填长度表征聚合物的流动性能。以聚甲基丙烯酸甲酯(PMMA,无定型)、聚丙烯(PP,半结晶型)、聚酰胺66(PA66,结晶型)这3种不同类型的聚合物为对象,采用单因素实验法分别研究超声振幅、塑化时间、塑化压力、保压时间、保压压力、模芯温度等关键工艺参数对聚合物充填长度的影响规律。研究结果表明:提高超声振幅、延长塑化时间、增大塑化压力、提高模芯温度均能显著提高聚合物的流动性能,在相同条件下,这3种聚合物的充填长度L关系为LPA66>LPP>LPMMA;当保压时间从2 s提高到6 s时,这3种聚合物充填长度分别提高24.3%,21.1%和24.1%;充填长度与保压压力呈线性增长关系。研究结果可为建立超声塑化的聚合物流动性测试标准提供参考。

关键词:超声塑化;微注射成型;聚合物;流动性

中图分类号:TQ320.66 文献标志码:A 文章编号:1672-7207(2018)12-2939-07

Effect of process parameters on fluidity of polymer melt plasticized by ultrasound

JIANG Bingyan, LIU Tao, WU Wangqing, ZHANG Yingping, ZOU Yang, ZHOU Xiaotian

(State Key Laboratory of High-Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: In order to test the fluidity of polymer melt plasticized by ultrasound, the ultrasonic plasticization filling experiment with self-designed spiral mold was conducted, and the fluidity was characterized by filling length. Three types of polymer material, i.e., PMMA, PP and PA66, were used as the research objects. These experiments were made to explore the influence of factors on ultrasonic amplitude, ultrasonic time, plasticization pressure, holding time, holding pressure, mold core temperature and filling length. The results show that fluidity of polymers increases with the increase of amplitude, ultrasonic time, plasticization pressure and mold core temperature, and the length relationship of the three polymers at the same condition is LPA66>LPP>LPMMA. The holding time increases from 2 s to 6 s, and the filling length of three kinds of polymers increase by 24.3%, 21.1% and 24.1%, respectively. And there is linear relationship between the holding pressure and filling length.The results provide reference for the establishment of ultrasonic plasticization polymer fluidity test standard.

Key words: ultrasonic plasticization; microinjection mold; polymer; fluidity

采用螺杆塑化微注射成型方式成型聚合物微细制件时,经常会发生充填不完全、表面凹陷、应力开裂等缺陷,这制约了聚合物微细制件向高精密的方向发展[1-2]。而近年来提出的超声塑化微注射成型技术可以有效解决这些问题[3]。超声塑化微注射成型技术装备简单,易于操作,能耗低,节省材料,且具有极高的成型效率[4],是微注射成型技术发展的一个重要方向。在超声塑化过程中,高频超声振动使聚合物颗粒之间剧烈摩擦,产生大量热量使聚合物颗粒熔融[5-7]。高频周期性的超声振动会对聚合物熔体产生剪切作用,导致相互纠缠的聚合物分子链解缠,且沿着熔体流动方向取向,从而降低了聚合物熔体的黏度[8]。CHEN等[9]通过实验研究发现超声对聚丙烯熔体黏度存在物理和化学2个方面的影响,其中,物理影响包括提高分子链运动活性、促进解缠,化学影响包括化学键断裂、相对分子质量降低等,且物理影响程度大于化学影响程度。KIM等[10]发现随着超声作用时间延长,低相对分子质量聚丙烯和高相对分子质量聚丙烯的黏度均逐渐下降,但后者下降程度更大。MICHAELI等[11]采用超声塑化方式成型微拉伸试验件,发现超声振幅及保压压力对制件填充率有影响。SACRIST N等[12]在此基础上对微拉伸试验件成型实验进行进一步研究,发现采用大振幅、中等塑化压力时聚乳酸具有更强的充填能力。张胜[13]采用自制的测试装置测试了不同聚合物在超声作用下的熔融指数,同样发现提高超声振幅有利于提高聚合物熔体流动性能,但因熔融指数测试要求模具温度高于聚合物熔融温度,聚合物塑化的主要能量来源是外部加热,而并非是超声振动。为了更好地优化超声塑化加工工艺及模具设计,需要采用合适的流动性测试方法测试聚合物流动性能。高压毛细管流变仪、旋转流变仪、熔融指数仪是常见聚合物流动性测试仪器,但这些仪器都无法直接测试超声塑化的聚合物,也难以体现微尺度效应下的聚合物充填性能。采用阿基米德螺旋模具进行聚合物流动性测试是一种行之有效的方法[14],它的优势在于可更加直观地反映聚合物在流道中的流动性能及充填性能,且结构简单,易于实现。蒋炳炎等[15]设计了一种螺旋测试模具,实验证明该模具能够有效测试聚合物及金属熔体流动性。王道宏等[16]采用螺旋模具对聚丙烯和聚乙烯这2种材料的熔体流动比进行测试,并分析了流动比与型腔轮廓特征的关系。但这些研究都是基于常规螺杆塑化的聚合物流动性测试,模具流道尺寸较大,与微注射成型主题不符,而当前又缺少微注射成型条件下的聚合物流动性测试方法与相关标准,为此,本文作者将该方法引入超声塑化聚合物流动性测试中,采用微流道阿基米德螺旋模具,通过单因素分析法研究超声振幅、塑化时间、塑化压力等关键工艺参数对聚合物熔体流动性能及充填性能的影响。

N等[12]在此基础上对微拉伸试验件成型实验进行进一步研究,发现采用大振幅、中等塑化压力时聚乳酸具有更强的充填能力。张胜[13]采用自制的测试装置测试了不同聚合物在超声作用下的熔融指数,同样发现提高超声振幅有利于提高聚合物熔体流动性能,但因熔融指数测试要求模具温度高于聚合物熔融温度,聚合物塑化的主要能量来源是外部加热,而并非是超声振动。为了更好地优化超声塑化加工工艺及模具设计,需要采用合适的流动性测试方法测试聚合物流动性能。高压毛细管流变仪、旋转流变仪、熔融指数仪是常见聚合物流动性测试仪器,但这些仪器都无法直接测试超声塑化的聚合物,也难以体现微尺度效应下的聚合物充填性能。采用阿基米德螺旋模具进行聚合物流动性测试是一种行之有效的方法[14],它的优势在于可更加直观地反映聚合物在流道中的流动性能及充填性能,且结构简单,易于实现。蒋炳炎等[15]设计了一种螺旋测试模具,实验证明该模具能够有效测试聚合物及金属熔体流动性。王道宏等[16]采用螺旋模具对聚丙烯和聚乙烯这2种材料的熔体流动比进行测试,并分析了流动比与型腔轮廓特征的关系。但这些研究都是基于常规螺杆塑化的聚合物流动性测试,模具流道尺寸较大,与微注射成型主题不符,而当前又缺少微注射成型条件下的聚合物流动性测试方法与相关标准,为此,本文作者将该方法引入超声塑化聚合物流动性测试中,采用微流道阿基米德螺旋模具,通过单因素分析法研究超声振幅、塑化时间、塑化压力等关键工艺参数对聚合物熔体流动性能及充填性能的影响。

1 实验

1.1 实验原理和方法

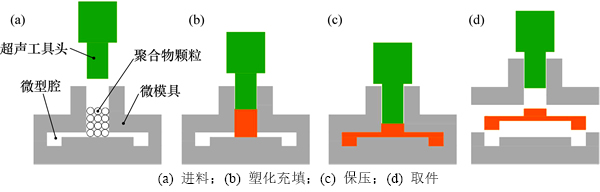

超声塑化微注射成型方式是利用高频超声振动使毫克级聚合物颗粒塑化并充填的一种成型方式。根据塑化与充填阶段的划分,可将其分为“先塑化后充填”和“边塑化边充填”2种。先塑化后充填方式的特点是塑化腔与型腔分离,聚合物先在超声作用下完全塑化后再打开阀门让熔体进行充填。边塑化边充填方式的特点是结构简单,塑化腔与型腔没有分隔开,在塑化过程中先塑化的熔体立刻充填到型腔中。目前的研究多采用边塑化边充填方式,本文研究也是基于这种成型方式进行。可进一步将超声塑化微注射成型过程划分为进料、塑化充填、保压和取件4个阶段,如图1所示。其中,在塑化充填阶段需开启超声,关闭超声后则立刻进入保压阶段。

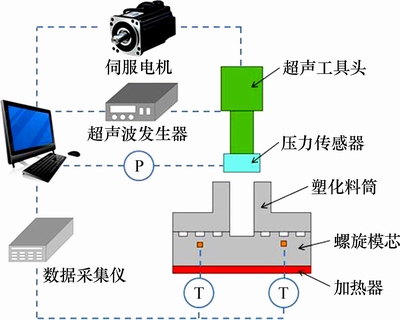

为了保证数据的准确性,需对实验中涉及的超声振幅、压力、温度等关键参数进行测试与校正。国家标准规定超声振幅是指连接换能器的加工头中心振动位移幅度的轴向分量[17]。采用超声振幅测量仪测试的工具头端面振幅是单边振幅,根据国家标准应该取其2倍。超声塑化聚合物流动性测试原理如图2所示。工具头由伺服电机驱动,通过设置伺服电机的转矩可以得到不同的工具头压力,但考虑到存在摩擦等因素,实际压力略小于理论值,采用压力传感器直接测试工具头端面压力可以得到给定电机转矩下的实际压力。实验中模芯由电阻加热片进行加热,采用数据采集仪连接热电偶可实时检测和记录模芯温度。

图1 超声塑化微注射成型过程示意图

Fig. 1 Schematic diagrams of ultrasonic plasticization microinjection molding process

图2 超声塑化聚合物流动性测试原理图

Fig. 2 Schematic diagram of polymer fluidity test in ultrasonic plasticization

本实验在超声塑化聚合物流动性测试平台上完 成[18]。实验采用自行设计的超声塑化聚合物流动性测试模具,其模芯上表面有阿基米德螺旋流道,如图3所示。流道中心线为阿基米德螺旋线,其方程为

(1)

(1)

式中:ρ为螺旋线上某点极径,mm;θ为极角。流道宽度为1.50 mm,流道深度为0.75 mm。

1.2 实验材料

实验材料采用3种不同类型的典型聚合物,材料主要性能参数见表1。

图3 阿基米德螺旋模芯

Fig. 3 Archimedes spiral mold core

1.3 实验方案

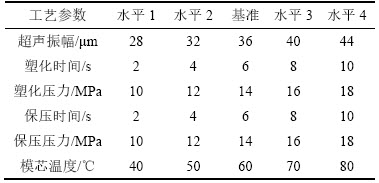

采用单因素实验法,依次研究超声振幅、塑化时间、保压时间、塑化压力、保压压力、模芯温度等不同工艺参数对聚合物螺旋制件充填长度的影响,各工艺参数取值如表2所示。

实验前需对材料PMMA和PA66进行干燥处理,PP吸湿性不强,可不用干燥。PMMA干燥温度为80 ℃,干燥时间为4 h;PA66干燥温度为100 ℃,干燥时间为4 h。实验时,先开启加热器对模芯进行加热,采用精密电子天平称取300 mg聚合物颗粒。待模芯温度稳定在设定温度时,将称取的聚合物倒入塑化料筒中,开启超声波发生器完成聚合物塑化及充填。开模后,取出螺旋制件,测量得到制件末端对应的角度,将角度转化为弧度并计算得到螺旋制件充填长度。螺旋长度计算公式为

(2)

(2)

式中:L为螺旋制件的长度,mm;θ为制件末端对应的极角,rad;5.2为流道入口处的过渡圆弧长度,mm。只有当聚合物充填长度超过10 mm时,才对超声塑化工艺具有实际参考价值,因此,当充填长度小于10 mm时,实验结果不予记录。

表1 实验材料性能参数[13]

Table 1 Performance parameters of experimental materials

表2 工艺参数取值水平

Table 2 Value of different precess parameters

2 实验结果分析

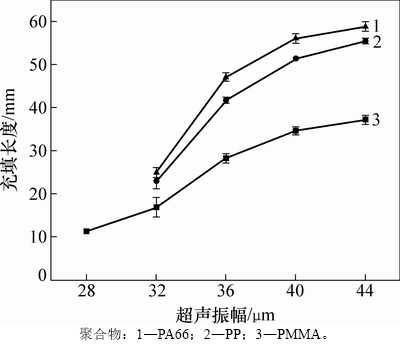

2.1 超声振幅对充填长度的影响

对于不同聚合物,超声振幅对螺旋制件充填长度的影响如图4所示。从图4可见:当超声振幅为28 μm时,PMMA已经可以塑化,充填长度为11.3 mm,但PP与PA66并未完成塑化,也无充填。由表1可知:PMMA的熔点最低,塑化所需的能量比PP和PA66的小,即振幅为28 μm的超声波足够使PMMA塑化,但不足以塑化PP和PA66。超声波波强计算公式如下:

(3)

(3)

式中:I为波强,也称为平均能流密度,即单位时间内、单位面积上通过的超声波能量,W/m2;ρ为介质密度,kg/m3;ω为圆频率;A为超声波振幅,μm;u为波速,m/s。当聚合物材料与超声波频率确定后,波强与超声振幅的平方呈正比关系,即超声振幅越大,超声波能量越大。

从图4可见:当超声振幅为32 μm时,PP和PA66充填长度分别为23.0 mm和25.1 mm;随着超声振幅持续增大,3种聚合物的充填长度均呈上升趋势;当超声振幅超过36 μm后,充填长度的增大幅度开始变缓,这是因为聚合物已经完全塑化。聚合物熔体在大振幅超声作用下持续剧烈振动,分子链运动活性增强,且分子链取向逐渐与流动方向相一致,熔体的黏度降低,流动性能加强,所以,充填长度仍能小幅增加。三者在相同条件下的充填长度关系为:LPA66>LPP>LPMMA(其中,LPA66,LPP和LPMMA分别为PA66,PP和PMMA的充填长度)。这说明在相同条件下,PA66熔体的流动性比PP和PMMA的好,而PMMA流动性最差,这一方面取决于这3种材料的本征流动特性,另一方面与材料的声阻抗有关。声阻抗反映了材料对声波能量的消耗能力,声阻抗越大,对超声的削弱程度也越大,所以,降低了超声对流动性能的影响。从表1可以看出PMMA的声阻抗比PP和PA66的高,所以,PMMA的流动性受超声改善的影响也最小。

图4 超声振幅对充填长度的影响

Fig. 4 Effect of ultrasonic amplitude on filling length

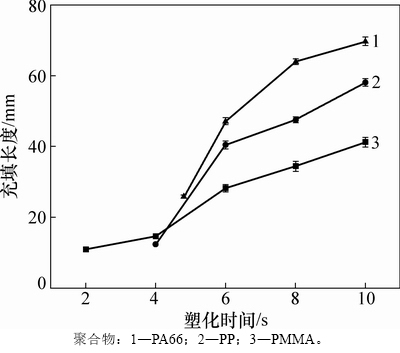

2.2 塑化时间对充填长度的影响

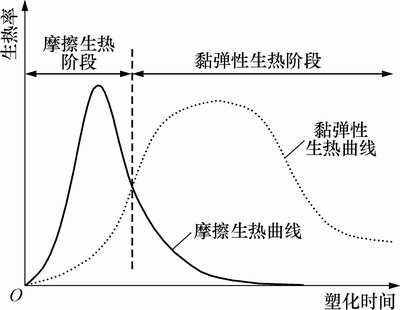

超声塑化的过程十分迅速,通常在几秒内即可完成塑化并充填。塑化时间对充填长度的影响如图5所示。从图5可见:PMMA在2 s时便已经充填10.9 mm,但PP与PA66均未开始塑化,这也与上述原因相一致,即PP与PA66塑化需要更多的能量;当塑化时间为4 s时,PP充填了12.5 mm。为探究PA66开始塑化的时间点,在塑化时间4~6 s内增加1组实验,以0.2 s为间隔。结果表明:当塑化时间为4.8 s时,PA66充填了25.9 mm;随着塑化时间的延长,这3种聚合物材料的充填长度均显著上升;当塑化时间从2 s延长到10 s时,PMMA充填长度提高了2.8倍;当塑化时间从4 s延长至10 s时,PP 充填长度提高了3.6倍;当塑化时间从4.8 s延长至10.0 s时,PA66充填长度提高了1.7倍。但这3种材料充填长度的增幅都随着塑化时间的延长而降低,这与超声塑化生热机理有关。超声塑化生热主要包括摩擦生热和黏弹性生热2个过程,如图6所示。当超声开启后,聚合物颗粒之间发生剧烈摩擦,并使颗粒界面处温度迅速上升,接触界面开始消融,摩擦生热作用逐渐减弱,随后,黏弹性生热占据主导作用,成为主要热量来源。当聚合物逐渐熔融后,黏弹性生热率也开始降低,但生热量仍能使聚合物维持在熔融状态[5-7]。塑化前期生热率较高,聚合物温度迅速上升,所以,聚合物充填长度增幅也较高。塑化后期生热率降低,聚合物温度逐渐稳定,但超声振动对熔体的剪切作用仍然存在,所以,塑化后期充填长度有所增加但增幅变缓。

图5 塑化时间对充填长度的影响

Fig. 5 Effect of ultrasonic time on filling length

图6 生热率与塑化时间的关系

Fig. 6 Relationship between heat generation rate and ultrasonic time

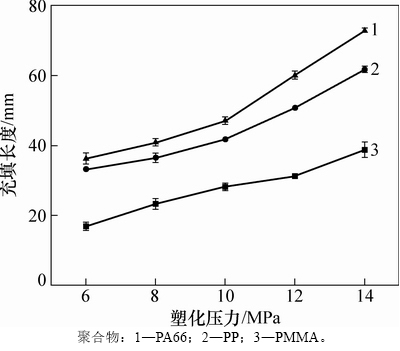

2.3 塑化压力对充填长度的影响

塑化压力是指工作时超声工具头直接作用在聚合物颗粒上的压力,它对3种聚合物的充填影响如图7所示。从图7可见:当塑化压力为6 MPa时,PMMA,PP和PA66的充填长度分别为17.1,33.2和36.4 mm;当塑化压力提高到14 MPa时,充填长度分别达到38.9,61.7和72.9 mm。塑化压力对超声塑化生热有直接影响,当工具头对聚合物颗粒压力作用增大时,聚合物颗粒变形越大,颗粒间的实际接触面积也随之增大,从而摩擦生热效率提高。随着塑化压力变大,超声工具头端面的负载变大,工具头克服负载阻力所做的功也越多,超声振动系统传递给聚合物的能量也越多。从超声波发生器的功率看,塑化压力越大,实际功率也越大。因为本实验采用的是边塑化边充填方式,所以,塑化压力也可看作是注射压力,提高塑化压力即提高注射压力,这与常规螺杆塑化时注射压力的影响类似,提高注射压力可以有效提高制件充填率。

图7 塑化压力对充填长度的影响

Fig. 7 Effect of plasticization pressure on filling length

2.4 保压过程对充填长度的影响

在注射成型保压阶段,熔融塑化后的聚合物熔体在保压压力作用下继续充填到模具型腔中。保压过程主要起熔体补偿和制件补缩的作用,且在一定程度上可以防止熔体回流,这在超声塑化微注射成型过程中同样适用。在超声塑化微注射成型过程中,保压阶段开始时间为超声作用停止时间,所以,保压过程对聚合物的塑化没有明显影响,但对于聚合物熔体的充填有一定影响。保压过程对充填长度的影响见图8。

从图8(a)可见:当保压时间从2 s延长到6 s时,PMMA,PP和PA66的充填长度分别提高24.3%,21.1%和24.1%;当保压时间从6 s延长到10 s时,3种聚合物的充填长度分别提高10.2%,5.0%和9.9%。在保压阶段,超声作用已经停止,没有了能量来源,聚合物熔体温度开始下降,所以,在保压前期对充填长度的影响比较大。随着时间的延长,聚合物冷却凝固,所以,保压后期的影响较小。延长保压时间能够产生更好的充填效果,但所需时间较长。因为超声塑化成型周期非常短,不应在保压阶段耗费过多时间,所以,保压时间设置不宜超过6 s。

从图8(b)可见:充填长度随着保压压力的增加近似呈线性增长,且对3种材料的影响规律基本一致。对3条曲线分别进行线性拟合,拟合方程为:

(4)

(4)

(5)

(5)

图8 保压过程对充填长度的影响

Fig. 8 Effect of holding process on filling length

(6)

(6)

将保压压力设置为0 MPa时,实验得到的PMMA,PP和PA66这3种材料充填长度分别为19.5,32.4和33.1 mm,实际值比理论值偏高但基本接近,偏差不超过10%,证明拟合方程可以较准确地反映充填长度与保压压力的关系。

2.5 模芯温度对充填长度的影响

聚合物在型腔中的充填结果除了受到塑化工艺参数及保压过程的影响外,还依赖于模芯温度。因为模芯温度低于熔体温度,所以,当聚合物熔体在模芯流道中流动时,熔体的能量向模芯传递,从而导致熔体温度降低,流动性下降。提高模芯温度可以有效减缓熔体能量丧失,提高充填长度。模芯温度对充填长度的影响如图9所示。从图9可见:当模芯温度从40 ℃升高到80 ℃时,PMMA,PP和PA66的充填长度分别提高200%,95%和61%,提高模芯温度对PMMA的充填影响最大。

图9 模芯温度对充填长度的影响

Fig. 9 Effect of mold core temperature on filling length

3 结论

1) 采用微流道阿基米德螺旋模具测试超声塑化的聚合物熔体流动性能具备可行性,且能够直接反映熔体在微流道中的充填性能,这为建立超声塑化聚合物流动性测试标准提供了实验基础,对规范超声塑化微注射成型工艺及模具设计及具有参考意义。

2) 提高超声振幅、塑化时间、塑化压力、模芯温度均能有效改善聚合物熔体流动性能,提高充填长度,其中,前3项可以增加超声塑化生热量,后1项可以减缓熔体能量的丧失。在相同条件下,3种聚合物的充填长度关系为:LPA66>LPP>LPMMA。

3) 保压时间和保压压力对充填长度的影响比超声振幅、塑化时间、塑化压力、模芯温度等参数的影响小。当保压时间从2 s提高到6 s时,PMMA,PP和PA66的充填长度增幅分别为24.3%,21.1%和24.1%;当保压时间从6 s提高到10 s时,PMMA,PP和PA66的充填长度增幅增幅分别为10.2%,5.0%和9.9%。充填长度随着保压压力呈线性增大,拟合方程能够很好地反映两者的关系。

参考文献:

[1] SHA B, DIMOV S, GRIFFITHS C, et al. Investigation of micro-injection moulding:factors affecting the replication quality[J]. Journal of Materials Processing Technology, 2007, 183(2/3): 284-296.

[2] LIN Huangya, YOUNG Wenbin. Analysis of the filling capability to the microstructures in micro-injection molding[J]. Applied Mathematical Modelling, 2009, 33(9): 3746-3755.

[3] YU A H W, CHI H L, JUNG P G, et al. Polymer micro-replication using ultrasonic vibration energy[J]. Journal of Micro/Nanolithography Mems & Moems, 2009, 8(2): 55-62.

[4] MICHAELI W, KAMPS T, HOPMANN C. Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection[J]. Microsystem Technologies, 2011, 17(2): 243-249.

[5] WU Wangqing, PENG Huajian, JIA Yunlong, et al. Characteristics and mechanisms of polymer interfacial friction heating in ultrasonic plasticization for micro injection molding[J]. Microsystem Technologies, 2017, 23(5): 1385-1392.

[6] JIANG Bingyan, PENG Huajian, WU Wangqing, et al. Numerical simulation and experimental investigation of the viscoelastic heating mechanism in ultrasonic plasticizing of amorphous polymers for micro injection molding[J]. Polymers, 2016, 8(5): 199-211.

[7] 贾云龙, 蒋炳炎, 彭华建, 等. 微注射成型超声塑化中黏弹性生热效应[J]. 中南大学学报(自然科学版), 2016, 47(9): 2976-2983.

JIA Yunlong, JIANG Bingyan, PENG Huajian, et al. Viscoelastic heating effect in ultrasonic plasticization for micro injection molding[J]. Journal of Central South University(Science and Technology), 2016, 47(9): 2976-2983.

[8] 于同敏, 包成, 黄晓超. 超声技术在聚合物成型加工中的应用研究进展[J]. 高分子材料科学与工程, 2012, 28(11): 173-177.

YU Tongmin, BAO Cheng, HUANG Xiaochao. Application evolution of ultrasonic technology in polymers processing[J]. Polymer Materials Science and Engineering, 2012, 28(11): 173-177.

[9] CHEN Jinyao, CHEN Yingzi, LI Huilin, et al. Physical and chemical effects of ultrasound vibration on polymer melt in extrusion[J]. Ultrasonics Sonochemistry, 2010, 17(1): 66-71.

[10] KIM H, LEE J W. Effect of ultrasonic wave on the degradation of polypropylene melt and morphology of its blend with polystyrene[J]. Polymer, 2002, 43(8): 2585-2589.

[11] MICHAELI W, KAMPS T, HOPMANN C. Manufacturing of polymer micro parts by ultrasonic plasticization and direct injection[J]. Microsystem Technologies, 2011, 17(2): 243-249.

[12] SACRIST N M, PLANT

N M, PLANT X, MORELL M, et al. Effects of ultrasonic vibration on the micro-molding processing of polylactide[J]. Ultrasonics Sonochemistry, 2014, 21(1): 376-386.

X, MORELL M, et al. Effects of ultrasonic vibration on the micro-molding processing of polylactide[J]. Ultrasonics Sonochemistry, 2014, 21(1): 376-386.

[13] 张胜. 聚合物超声塑化微注射成型设备塑化模块设计与研究[D]. 长沙: 中南大学机电工程学院, 2015: 44-53.

ZHANG Sheng. Design and research on plasticization module of ultrasonic plasticization micro-injection molding machine[D]. Changsha: Central South University. School of Mechanical and Electrical Engineering, 2015: 44-53.

[14] ASTM D3123—1998, Standard test method for spiral flow of low-pressure thermosetting molding compounds[S].

[15] 蒋炳炎, 谢磊, 彭华建. 一种螺旋流体流动性测试模具: 中国, CN1837776A[P]. [2006-09-27].

JIANG Bingyan, XIE Lei, PENG Huajian. A spiral mold to test fluidity of fluid: China, CN1837776A[P]. [2006-09-27].

[16] 王道宏, 蒋炳炎, 申瑞霞, 等. 注射成型螺旋模具中熔体流动比[J]. 中南大学学报(自然科学版), 2008, 39(6): 1251-1256.

WANG Daohong, JIANG Bingyan, SHEN Ruixia, et al. Melt flow ratio in spiral mold of injection molding[J]. Journal of Central South University(Science and Technology), 2008, 39(6): 1251-1256.

[17] GB/T 17252—1998, 声学-100 kHz以下超声压电换能器的特性和测量[S].

GB/T 17252—1998, Acoustics-characteristics and measurements of ultrasonic piezoelectric transducers up to 100 kHz[S].

[18] 蒋炳炎, 齐鹏程, 刘弢, 等. 一种超声塑化毛细管流变仪及黏度测试方法: 中国, CN106124362A[P]. [2016-06-07].

JIANG Bingyan, QI Pengcheng, LIU Tao, et al. Ultrasonic plasticization capillary rheometer and viscosity test method: China, CN106124362A[P]. [2016-06-07].

(编辑 陈灿华)

收稿日期:2018-01-05修回日期:2018-03-15

基金项目(Foundation item):国家自然科学基金资助项目(51575540);中南大学研究生创新项目(2017zzts401)(Project(51575540) supported by the National Natural Science Foundation of China; Project(2017zzts401) supported by the Graduate Innovation Program of Central South University)

通信作者:蒋炳炎,博士,教授,从事高分子材料紧密成型技术研究;E-mail:jby@csu.edu.cn