基于响应面法的钩尾框渐进热弯曲工艺多目标优化

夏玉峰,杨显红,郑晓凯,陈邦华

(重庆大学 材料科学与工程学院,重庆,400044)

摘要:根据某锻造厂生产某型号钩尾框弯曲工艺中出现弯曲载荷过大、根部拉伤以及平板根部变薄严重的问题,提出一种新型厚板渐进热弯曲工艺。以降低弯曲载荷、降低根部出现裂纹趋势以及保证钩尾框平板厚度合理为优化目标,并以凸模速度、副辊尺寸、辊与坯料间摩擦因素以及主副辊在高度和水平方向的距离为优化变量,采用正交实验与Design-expert软件进行响应面(RSM)拟合建模分析,得到3个目标量的二阶响应面模型,并通过数值模拟验证所建立的响应面模型准确性,其相对误差小于8%,可用于后续优化。生产实践结果表明,通过多目标优化后钩尾框新型渐进弯曲模结构可以把弯曲载荷力降低40%,能够有效降低根部出现裂纹趋势保证平板最小厚度。

关键词:厚板热弯曲;渐进弯曲;有限元模拟;响应面法;多目标优化

中图分类号:TG316 文献标志码:A 文章编号:1672-7207(2014)09-2977-08

Multi-object optimization of incremental hot bending process of hook tail frame based on RSM

XIA Yufeng, YANG Xianhong, ZHENG Xiaokai, CHEN Banghua

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: According to the issue that too large bending load, root injury and severe thinning of tablet root would emerge during the process of a certain type of hook tail frame produced by a forging factory, a novel thick plate incremental hot bending process was put forward. The optimization goal was to reduce the bending load and crack trend in the roots, and to ensure the thickness of hook tail frame. The punch velocity, the size of auxiliary roller, the friction factor between roller and billet, the distance of auxiliary roller in the direction of the height and level were the optimization variables. The orthogonal experiment and the design-expert software were made to analyse the response surface model (RSM) and the second order response surface model of three goals and optimal value were obtained. The production practice results show that through multi-objective optimization, the new incremental bending structure model of hook tail frame can reduce the forming load force by 40%, effectively lessen the trend of cracks on the roots and ensure the minimum thickness of plates.

Key words: plate hot bending; incremental bending; finite element simulation; response surface model (RSM); multi-object optimization

钩尾框作为火车上重要的连接部件,其使用寿命越来越受到关注[1]。大量的研究分析与实际使用数据表明,钩尾框主要失效是根部出现裂纹[2]。现行国内的主要工艺路线是锻造后弯曲搭焊来实现该产品的制造,通过生产实践发现钩尾框弯曲工序对钩尾框关键部位的成形起着至关重要的作用。针对钩尾框这一厚板热弯曲问题,Wang等[3]对比分析了Reissner和Mindlin理论,对于厚板弯曲的一般问题进行了研究,Frederic 等[4]对于应力边界条件对弯曲变形的影响进行了研究,张德智[5]采用物理分析和数学计算相结合方式,分析了板厚变化和应力应变中性层对弯曲工艺参数的影响,肖寒等[6]研究镁合金型材热弯曲成形前后微观组织和织构的演变规律。罗正章等[7]对钩尾框压弯过程进行模拟,分析压弯过程中锻件的温度场分布、应力-应变分布情况。付殿禹等[8]采用有限元模拟对17型钩尾框弯曲过程中出现裂纹、弯曲力过大、平板扭曲的问题进行单目标变量的优化分析。周杰等[9]提出折弯的思想并与数值模拟的方法相结合来以减小弯曲力、降低裂纹趋势,并做出了相应的分析与研究。以上研究都基本上是从单因素方面单目标来分析预测弯曲过程。而对于钩尾框这一厚板热弯曲载荷过大、根部出现裂纹以及根部变薄之间存在着耦合变量,单纯的基于某一性能的优化往往会导致另一性能的降低。因而,单目标优化方法或是基于某一性能的多目标优化方法,未能考虑三者的耦合关系[10]。鉴于此,本文作者针对某锻造厂生产的某型号的钩尾框弯曲工艺中出现的弯曲载荷过大、根部出现裂纹、平板局部变薄不合理的问题提出了“渐进弯曲”的新型厚板热弯曲工艺。在对该新型渐进弯曲模结构优化过程中采用了协同优化的响应面法作为优化方法。该方法是一种能够同时确保弯曲载荷合适、弯曲件根部不出现裂纹以及根部最小厚度合理的协同优化方法,其是一种典型的多学科设计方法[11],即可以把弯曲载荷过大、根部出现裂纹以及根部变薄的各个指标进行多目标的平衡和优化。

1 新型弯曲工艺建立

1.1 初始弯曲模型分析

本文所研究的Deform-3d仿真模型是基于工厂实际的模具结构而建立起来。其初始模具结构如图1(a)所示。数值模拟的相关参数设置为:锻件材料为AISI-1045(45钢);坯料与弯曲凸模和反顶装置的摩擦因数为0.3、坯料与辊摩擦因数为0.15;模具材料设置为刚性体;模具温度为常温;弯曲凸模的速度为12 mm/s;单元网格数为10 000;辊半径为60 mm。弯曲坯料初始温度为1 000 ℃;损伤判断模型同样采用软件自带的Cockcroft and Latham模型。流动应力模型选用软件自带的应力模型如式(1)所示。

(1)

(1)

通过模拟分析钩尾框弯曲载荷、最大损伤点损伤变化规律以及平板根部厚度变化情况,结果如图1(b)和1(c)所示。从图1可知,最大弯曲载荷为386 t、最大损伤值为0.54。钩尾框的弯曲过程属于热态厚板U型弯曲范畴,周杰等[9, 12]研究表明:钩尾框类弯曲中工艺参数对弯曲载荷的影响是通过对坯料产生弯矩来达到的,且弯曲载荷对其根部裂纹的产生以及变薄有着至关重要的影响,而对弯曲载荷研究显得至关重要。对图1(b)分析可知:初始时载荷急剧上升,这是由于弯曲初始时,钩尾框平板部分从水平位置要弯曲到垂直位置,平板的重心离弯曲凸模与坯料的接触点远,即所需要的弯曲力矩比较大,对应的根部损伤变大。当弯曲到达一定程度时弯曲载荷受平板因重力产生力距变小。弯曲载荷与根部变形有关,因而当弯曲件根部出现较大变形时,弯曲载荷急剧增加,损伤值也增加,即根部出现裂纹趋势增加,根部平板厚度变薄明显。

图1 初始弯曲模结构与数值模拟结果

Fig. 1 Initial bending mold structure and numerical simulation result

1.2 新型弯曲工艺提出

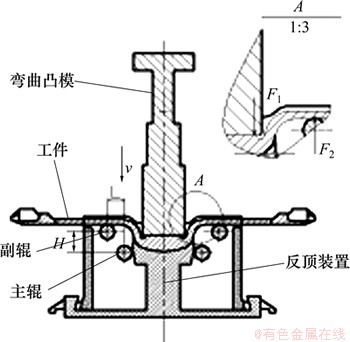

基于对初始弯曲分析可知:可以通过降低弯曲时所需的力矩来有效降低弯曲载荷,并保证弯曲件质量,鉴于此本文提出了在原有弯曲模结构上增加1对副辊来实现渐进弯曲的目的,其模具结构如图2所示。

图2 新型弯曲模结构图

Fig. 2 Graph of new bending mold structure

由于该弯曲模型是基于生产实践的基础上提出,锻造钩尾框初始温度由其生产工艺特点确定了,而弯曲工艺作为整体钩尾框成形工艺中的一部分,其温度受前面制坯、模锻工艺时间的影响,因而研究温度对弯曲工艺成型载荷与损伤的影响对于生产实际的应用意义不明显。根据生产实践得钩尾框弯曲工艺的温度基本维持在950~1 020 ℃范围,因而在优化时,弯曲件坯料温度取为1 000 ℃。本文在对其进行优化工艺时并没有考虑2个主辊之间的间隙、主辊的尺寸、坯料温度对工艺目标的影响。而主要针对副辊相对主辊的垂直方向的距离H、水平方向的距离L、坯料与主副辊之间的摩擦因素μ、弯曲凸模的速度V、副辊半径R这5个工艺参数对钩尾框质量的影响。

2 基于响应面方法优化

2.1 试验设计

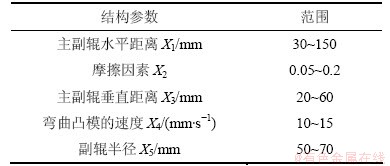

响应面法的使用必须先确定合理的因素以及相应的水平参数[13]。为了后续实验设计方便,现令主副辊水平距离L、摩擦因素μ、主副辊垂直距离H、弯曲凸模的速度v、副辊半径R、弯曲载荷、最大损伤值、根部最小厚度分别为X1,X2,X3,X4,X5,Y1,Y2和Y3。本文在生产实践的基础上借助数值模拟对5个因素进行单因素优化分析,确定各个因素合理范围,其范围如表1所示。

表1 结构参数优化范围

Table 1 Optimized scope of structural parameters

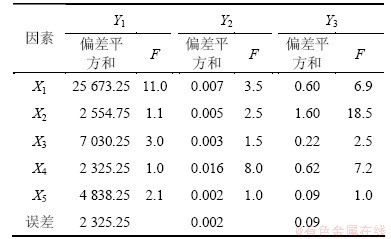

本文首先对5个因素进行了L16(54)的正交实验设计,以选出显著的因素;在方差分析中F值是F检验的统计量,其值越大则表明对应统计量的显著性水平越高。其方差分析的结果如表2所示。从表1可知:Y1的各个因素显著性影响关系为:X1>X3>X5>X2>X4,Y2各个因素显著性影响关系为:X4>X1>X2>X3>X5,Y3的各个因素显著性关系为:X2>X4>X1>X3>X5,综合对比各个因素与3个响应目标量显著性关系,最终选择X1,X2,X3,X4这4个因素量作为3个响应目标量的优化因素,其中X5取为50 mm。

表2 各种因素的方差分析结果

Table 2 Variance analysis results of different factors

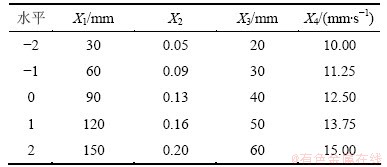

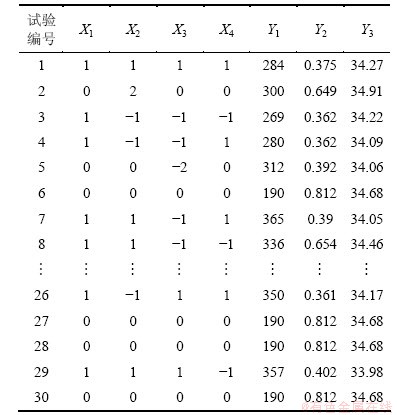

文中有优化变量4个,优化目标3个,因此二阶响应面模型的回归系数共有 个。为了得到合理的回归方程,每个因子所取的水平数为5,因而所要做的试验次数比较多,实现比较困难。为了解决这一矛盾,本文采用中心复合设计[14]来设计试验,并借助专业的设计软件Design-Expert v8.0完成了后续的响应面分析。在前面分析的基础上进行了4因素5水平的中心复合设计,共进行30次试验。因子水平如表3所示。部分实验方案及试验结果示于表4。

个。为了得到合理的回归方程,每个因子所取的水平数为5,因而所要做的试验次数比较多,实现比较困难。为了解决这一矛盾,本文采用中心复合设计[14]来设计试验,并借助专业的设计软件Design-Expert v8.0完成了后续的响应面分析。在前面分析的基础上进行了4因素5水平的中心复合设计,共进行30次试验。因子水平如表3所示。部分实验方案及试验结果示于表4。

表3 因子水平的中心复合设计

Table 3 Central composite design of factor levels

表4 部分试验方案及试验结果

Table 4 Part of test program and results

2.2 响应面模型与试验结果分析

采用二阶模型建立3个目标响应Y关于设计变量的预测模型。对于4因素试验,多项式模型表示如下:

(2)

(2)

采用式(2),应用最小二乘法对表4的数据进行回归分析,分别得到关于3个目标响应函数如下:

(3)

(3)

(4)

(4)

(5)

(5)

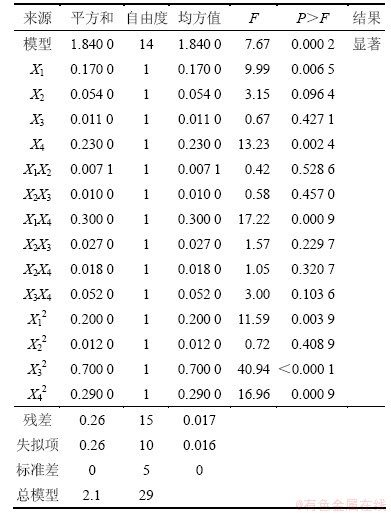

为了验证所建的响应面模型是否能真正反映响应面与设计因素间的统计规律,对式(3)~(5)进行方差分析。方差分析结果如表5~7所示。

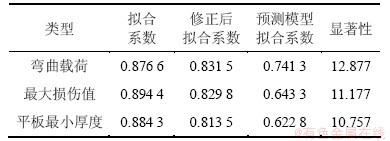

根据表5~7可知:3个模型的F分别为7.61,8.03和7.67,说明3种模型是显著的。相应的“P>F”值依次为0.000 2,0.000 1和0.000 2,远小于0.05,3种模型是非常显著的。除F检验之外,可通过S,R2和 来进一步检验构建预测模型的可靠性,通常R2和

来进一步检验构建预测模型的可靠性,通常R2和 越大,回归模型的拟合程度越好。从表8可知:3个模型R2分别为87.66%,89.44%和88.43%,说明该模型的预测精度较好。综上所述,3个预测模型可较好地描述所提出的Y关于设计变量X1,X2,X3和X4的响应,并能得到很好的精度,可以用于后续工艺优化。

越大,回归模型的拟合程度越好。从表8可知:3个模型R2分别为87.66%,89.44%和88.43%,说明该模型的预测精度较好。综上所述,3个预测模型可较好地描述所提出的Y关于设计变量X1,X2,X3和X4的响应,并能得到很好的精度,可以用于后续工艺优化。

表5 弯曲载荷方差分析结果

Table 5 Variance analysis results of bending load

表6 最大损伤值方差分析结果

Table 6 Variance analysis results of maximum damage

表7 平板最小厚度方差分析结果

Table 7 Variance analysis results of minimum plate thickness

表8 3个目标量确定系数分析结果

Table 8 Determine coefficient analysis of three target quantity results

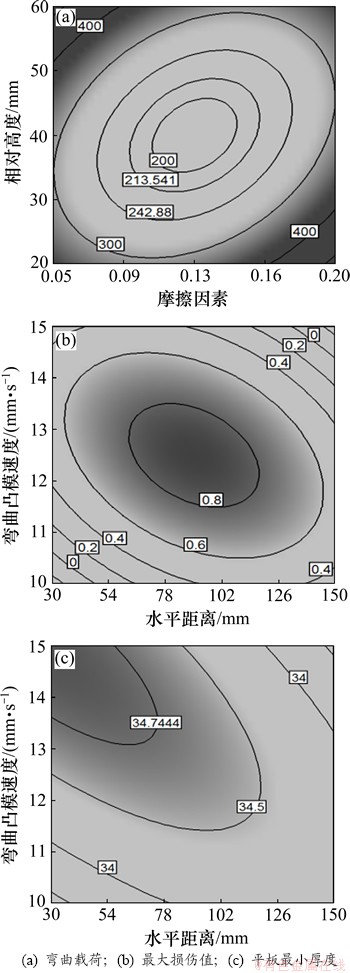

从各个模型方差分析可知,对于4个因素交互作用下,对弯曲载荷最显著的交叉因素为:X2*X3;对于最大损伤值影响最显著的交叉因素为:X1*X4;对于平板最小厚度的最显著交叉因素为:X1*X4。为了进一步分析各个工艺参数对3个响应优化量的影响,现选取影响各个响应优化量最显著的交叉因素来分析。图3(a)~(c)分别表示在水平距离为90 mm和弯曲速度12.5 mm/s时弯曲载荷与“X2*X3”的等高线图,摩擦因素为0.13和相对高度40 mm时最大损伤值“X1*X4”的等高线图,摩擦因素为0.13和相对高度40 mm时平板最小厚度与“X1*X4”的等高线图。

从图3(a)可以看出:当水平距离为90 mm,弯曲速度为12.5 mm/s时,响应值弯曲载荷随着相对高度的增加弯曲载荷逐渐降低。但当相对高度达到40 mm时,弯曲载荷随相对高度的增加而增加,同时,随着摩擦因素的增加弯曲载荷降低。当摩擦因素达到0.13时,随着摩擦因素增加弯曲载荷增加。此外,由等高线图可知:在整个工艺参数范围内,弯曲载荷主要分布在200~300 t内。对比原始模型可知,该新型渐进模具在降低弯曲载荷上有明显优势。

图3(b)可以看出:当摩擦因素为0.13、相对高度为40 mm时,响应值最大损伤值随着弯曲速度的增加其最大损失值也增加;当达到13 mm/s时,随着弯曲速度增加其最大损失值降低。对于水平距离变化量,响应值最大损失值随着水平距离的增加而增加;当水平距离达到90 mm时开始降低。从等高线图可知:当弯曲速度小于13 mm/s、水平距离为小于90 mm时,最大损失值小于0.6。

由图3(c)可知:当摩擦因素为0.13、相对高度为40 mm时,随着弯曲速度的增加平板最小厚度增加;随着水平距离增加平板最小厚度也增加;当水平距离达到102 mm时,随着水边距离的增加平板最小厚度降低。平板最小厚度大于34.5 mm占整个响应面图大部分区域且最大值为34.85 mm,没有超过工艺允许最大值,即可以知道该新型渐进弯曲模具生产的锻件能达到工艺要求。

图3 弯曲载荷、最大损伤值、平板最小厚度等高线图

Fig. 3 Contour images of bending load, maximum damage value and minimum plate thickness

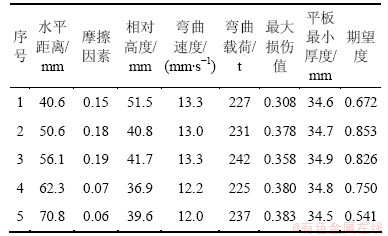

3 试验方案优化与验证

在实验结果分析及模型拟合的基础上,可利用Design-Expert8.0对试验参数进一步进行优化[15],即在弯曲载荷、最大损伤值、平板最小厚度三者之间取得一个最佳目标情况下,各个工艺参数取值的最优方案。表9所示为保证弯曲载荷小于250 t、最大损伤值小于0.4以及平板最小厚度大于34.5 mm的基础上获得的优化方案。

表9 优化工艺方案

Table 9 Program of process optimization

为了进一步验证该优化方案的正确性,为后续生产提供实际数据,表9中5组优化方案被运用于有限元模拟之中,其结果如表10所示。

表9中预测值为通过响应面优化得到的各响应因子的值,模拟值为把对应优化的工艺参数运用于数值模拟得到的各响应值。相对误差的计算式为

(6)

(6)

由表10可见:5组优化方案中各个响应值的相对误差均在±8%内,说明通过响应面优化得到优化工艺方案可信度高,此外方案4各个响应值的相对误差在±5%内,稳定性比较好,因此把方案4作为新型渐进弯曲模具结构的最优工艺参数并用于生产实践之中。为了更好地与生产实际结合,根据设备与现场实际情况对优化得到的工艺参数进行圆整,调整后的工艺参数为:水平距离为62.5 mm、摩擦因数为0.07、相对高度为37 mm、弯曲速度为12.5 mm/s。

表10 验证试验参数与结果分析

Table 10 Test parameters validation and result analysis

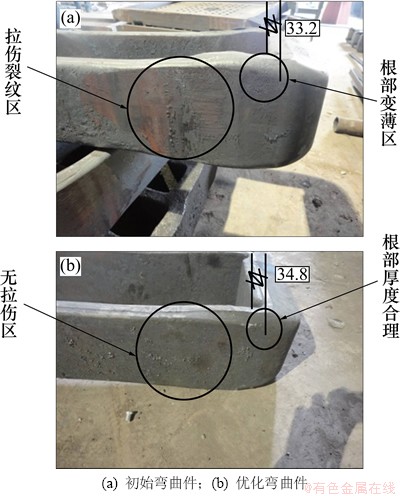

图4(a)和(b)所示分别表示原始模具与新型渐进弯曲模具生产所得的件。由图4可知:新型渐进弯曲模具生产的件在弯曲根部没有出现被拉伤的情况,其根部厚度为34.8 mm大于原始模型的33.8 mm,并大于工艺最低要求34.5 mm,以此证明其很好地满足工艺合理需求。此外生产实际过程中测得该新型渐进弯曲工艺所需的设备弯曲力为250 t,比初始模型的低了130 t左右,极大降低了折弯机的所需成形力,提高其使用寿命。综上所述,该新型渐进弯曲结构模对于钩尾框类厚板热弯曲工艺有降低弯曲载荷、降低根部出现裂纹以及有效地保证弯曲根部厚度的优势。

图4 初始弯曲件与优化弯曲件对比

Fig. 4 Comparison of initial bending parts with optimized bending parts

4 结论

1) 针对某工厂钩尾框弯曲工艺出现的问题,提出了一种新型渐进弯曲工艺,并对该新型渐进弯曲工艺进行了多目标优化分析。

2) 采用Design-Expert8.0软件对新型渐进弯曲工艺进行试验设计、结果分析和优化,并得到了多目标优化数学模型。

3) 通过误差优化分析和生产实践验证了,该新型渐进弯曲模结构能有效地降低弯曲载荷以及降低钩尾框根部出现裂纹的趋势,并能有效地保证钩尾框工艺尺寸,这为类似钩尾框厚板热弯曲工艺的提供了一定生产实践的指导作用。

参考文献:

[1] 徐倩, 谢基龙, 缪龙秀, 等. 基于单轴损失的货车钩尾框多轴疲劳寿命分析[J]. 铁道学报, 2002, 24(1): 19-22.

XU Qian, XIE Jilong, MIAO Longxiu, et al. Analysis of multi-axial fatigue life based on single axial stress condition of the coupler yoke[J]. Journal of the China Rail Way Society, 2002, 24(1): 19-22.

[2] 于兆华. 17号车钩、钩尾框疲劳寿命及可靠性分析[D]. 北京: 北京交通大学机械与电子控制工程学院, 2009: 38-50.

YU Zhaohua. 17 coupler hook tail frame fatigue life and reliability analysis[D]. Beijing: Beijing Jiaotong University. School of Mechanical, Electronic and control Engineering, 2009: 38-50.

[3] Wang C M, Lim G T, Reddy J N, et al. Relationships between bending solutions of Reissner and Minding plate theories[J]. Engineering Structures, 2001, 23: 839-849.

[4] Frederic Y M. Wan. Stress boundary conditions for plate bending[J]. International Journal of Solids and Structures, 2003: 4107-4123.

[5] 张德智. 金属厚板弯曲的工艺理论研究[D]. 辽宁: 大连交通大学材料科学与工程学院, 2007: 39-47.

ZHANG Dezhi. Investigation on the technological theory of sick metal sheet bending[D]. Liaoning: Dalian Jiaotong University. Institute of Material Science and Engineering, 2007: 39-47.

[6] 肖寒, 宋广胜, 严操, 等. 温热弯曲成形过程中AZ31镁合金型材的微观织构演变[J]. 中国有色金属学报, 2011, 21(8): 1814-1819.

XIAO Han, SONG Guangsheng, YAN Cao, et al. Microtexture evolution of AZ31 magnesium alloy profile during warm bending process[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(8): 1814-1819.

[7] 罗正章. 钩尾框成形工艺及实验研究[D]. 重庆: 重庆大学材料科学与工程学院, 2005: 11-44.

LUO Zhengzhang. Frame of trail hook form technics and research of experiment[D]. Chongqing: Chongqing University. Department of Material Science and Engineering, 2005: 11-44.

[8] 付殿禹, 郑乐启, 蒋鹏, 等. 17型锻造钩尾框热弯曲成形过程数字模拟[J]. 锻压技术, 2009, 34(3): 22-25.

FU Dianeyu, ZHENG Leqi, JIANG Peng, et al. FEM analysis of hot bending process for 17 type of coupler yokes[J]. Forging & Stamping Technology, 2009, 34(3): 22-25.

[9] 周杰, 李璐, 胡振志, 等. 锻造钩尾框新型斜弯曲模结构的参数[J]. 机械工程学报, 2010, 46(8): 25-30.

ZHOU Jie, LI Lu, HU Zhenzhi, et al. Parameters of slanting newing bending die structure of frame of trail hook made by forging[J]. Chinese Journal of Mechanical Engineering, 2010, 46(8): 25-30.

[10] 刘士士, 谷正气, 伍文广, 等. 基于响应面方法的车辆多目标协同优化[J]. 中南大学学报(自然科学版), 2012, 43(7): 2586-2592.

LIU Shishi, GU Zhengqi, WU Wenguang, et al. Multi- objective collaborative optimization of vehicle based on response surface methodology[J]. Journal of Central South University (Science and Technology), 2012, 43(7): 2587-2592.

[11] Zhao W T, Qiu Z P. An efficient response surface method and its application to structural reliability and reliability-based optimization[J]. Fininte Elements in Analysis and Design, 2013, 67: 34-42.

[12] 秦泗吉, 胡福泰, 李硕本. U形件自由弯曲力的计算及影响因素分析[J]. 塑性工程学报, 1998, 5(1): 34-39.

QIN Siji, HU Futai, LI Shuoben. Calculation of free bending for u-type parts and analysis of influence factors[J]. Journal of Plasticity Engineering, 1998, 5(1): 34-39.

[13] Palanivel R, KoshyMathews P. Prediction and optimization of procrss parameter of friction stir welded AA5083-H111 aluminum alloy using response surface methodology[J]. Journal of Central South University of Technology (English Edition), 2012, 19: 1-8.

[14] Mohamed M N, Amgad A A, Hamdani S, et al. Optimization of reaction parameters of radiation induced grafting of 1-vinylimidazole onto poly(ethylene-co-tetraflouroethene) using response surface method[J]. Radiation Physics and Chemistry, 2011, 80: 1222-1227.

[15] 刘佳, 张宏, 石岩. 基于Design-Expert V7设计的不锈钢激光非熔透搭接焊工艺优化研究[J]. 机械工程学报, 2011, 47(16): 52-60.

LIU Jia, ZHANG Hong, SHI Yan. Technology optimizing research on laser nonpenetration lap welding of stainless steel based on design-expert V7[J]. Journal of Mechanical Engineering, 2011, 47(16): 52-60.

(编辑 陈爱华)

收稿日期:2013-11-12;修回日期:2014-03-05

基金项目:中央高校基本科研业务费科研专项资金资助项目(CDJZR12130045)

通信作者:夏玉峰(1972-),男,四川营山人,副教授,博士,从事金属塑性成形技术研究及仿真模拟研究;电话:13452877856;E-mail: xyfeng@cqu.edu.cn