纳米SiC颗粒增强Ti-6Al-4V基复合材料的制备和力学性能

来源期刊:中国有色金属学报(英文版)2017年第1期

论文作者:G. SIVAKUMAR V. ANANTHI S. RAMANATHAN

文章页码:82 - 90

关键词:钛合金;纳米SiC颗粒;粉末冶金;硬度;抗压强度

Key words:titanium alloy; nano SiC particle; powder metallurgy; hardness; compressive strength

摘 要:采用粉末冶金技术制备含不同质量分数(0, 5%, 10%和15%)纳米SiC颗粒增强的Ti-6Al-4V(Ti64)金属基复合材料(MMCs),研究添加纳米SiC颗粒对复合材料力学性能如硬度和抗压强度的影响。结果表明,当压缩载荷为6.035 MPa时,复合材料具有最佳的相对密度(93.33%)。SEM显微组织观察结果表明,Ti64/5%SiCp复合材料的润湿性和结合力得到了提高。采用X射线衍射技术研究Ti64/SiCp复合材料中纳米SiC颗粒含量对其相组成的影响,并分析其力学性能与相组成的关系。含10%和15% SiCp的复合材料由于脆性界面反应产生了新相,此新相对复合材料的强度和硬度不利。Ti64/5%SiCp金属基复合材料的抗压强度和硬度较高,因此5% SiCp是此复合材料的最佳含量。

Abstract: Different mass fractions (0, 5%, 10%, and 15%) of the synthesized nano SiC particles reinforced Ti-6Al-4V (Ti64) alloy metal matrix composites (MMCs) were successfully fabricated by the powder metallurgy method. The effects of addition of SiC particle on the mechanical properties of the composites such as hardness and compressive strength were investigated. The optimum density (93.33%) was obtained at the compaction pressure of 6.035 MPa. Scanning electron microscopic (SEM) observations of the microstructures revealed that the wettability and the bonding force were improved in Ti64 alloy/5% nano SiCp composites. The effect of nano SiCp content in Ti64 alloy/SiCp matrix composite on phase formation was investigated by X-ray diffraction. The correlation between mechanical parameter and phase formation was analyzed. The new phase of brittle interfaced reaction formed in the 10% and 15% SiCp composite specimens and resulted in no beneficial effect on the strength and hardness. The compressive strength and hardness of Ti64 alloy/5% nano SiCp MMCs showed higher values. Hence, 5% SiCp can be considered to be the optimal replacement content for the composite.

Trans. Nonferrous Met. Soc. China 27(2017) 82-90

G. SIVAKUMAR1, V. ANANTHI2, S. RAMANATHAN3

1. CISL, Department of Physics, Annamalai University, Tamilnadu 608002, India;

2. Physics Section, FEAT, Annamalai University, Tamilnadu 608002, India;

3. Manufacturing Engineering Department, Annamalai University, Tamilnadu 608002, India

Received 22 November 2015; accepted 31 May 2016

Abstract: Different mass fractions (0, 5%, 10%, and 15%) of the synthesized nano SiC particles reinforced Ti-6Al-4V (Ti64) alloy metal matrix composites (MMCs) were successfully fabricated by the powder metallurgy method. The effects of addition of SiC particle on the mechanical properties of the composites such as hardness and compressive strength were investigated. The optimum density (93.33%) was obtained at the compaction pressure of 6.035 MPa. Scanning electron microscopic (SEM) observations of the microstructures revealed that the wettability and the bonding force were improved in Ti64 alloy/5% nano SiCp composites. The effect of nano SiCp content in Ti64 alloy/SiCp matrix composite on phase formation was investigated by X-ray diffraction. The correlation between mechanical parameter and phase formation was analyzed. The new phase of brittle interfaced reaction formed in the 10% and 15% SiCp composite specimens and resulted in no beneficial effect on the strength and hardness. The compressive strength and hardness of Ti64 alloy/5% nano SiCp MMCs showed higher values. Hence, 5% SiCp can be considered to be the optimal replacement content for the composite.

Key words: titanium alloy; nano SiC particle; powder metallurgy; hardness; compressive strength

1 Introduction

Metal matrix composites (MMCs) represent a new generation of engineering materials in which a strong ceramic reinforcement is incorporated into a metal matrix to improve its properties including specific strength, specific stiffness, wear resistance, excellent corrosion resistance and high elastic modulus [1,2]. MMCs combine metallic properties of matrix alloys (ductility and toughness) with ceramic properties of reinforcements (high strength and high modulus), leading to greater strength in shear and compression, and higher service-temperature capabilities, and control of physical properties such as density, coefficient of thermal expansion [3,4]. Thus, they have significant scientific, technological and commercial importance. During the last decade, because of their improved properties, MMCs have been used extensively for high performance applications such as in aircraft engines and more recently in the automotive industry [5,6]. Continuous fiber-reinforced titanium matrix composites (TMCs) are expensive due to high fiber costs and limited formality, and their properties are highly anisotropic. Thus, these materials have been restricted to very specialized applications. Discontinuous or particulate-reinforced TMCs are less expensive to fabricate and their properties are nearly isotropic. Thus, particulate-reinforced TMCs have been widely studied for structural applications [7,8]. Many studies have attempted to expend the range of applications and manufacturing techniques of these materials. TMCs, which have good wear resistance, high strength, and high strength stability through added reinforcement, exhibit advanced mechanical and chemical properties [9].

The poor tribological and thermo mechanical behaviors of titanium alloy were attributed to low hardness, relatively low tensile and compressive strengths. The addition of ceramic particle with TMCs matrix has been found to be an effective method for improving the tensile strength, shear strength, and hardness, and enhances wear resistance [10,11]. The particles investigated in previous works as reinforcements of titanium alloys are ceramics of TiC, TiO2, SiC, TiB, and TiB2 [11]. The mechanical properties of MMCs can be further enhanced by decreasing the size of ceramic particulate and/or matrix grains from micrometer to nanometer level [12-14]. The nano SiC particle is better choice for reinforcement of TMCs matrix. Among various fabrication processes, powder metallurgy (PM) is the most diverse manufactured approach. One attraction of PM is the ability to fabricate high quality complex parts to close tolerances in an economical manner. In essence, PM makes a net shape, high performance and less prone to porosity and defects [15].

The purpose of the present work is to produce nano SiCp by using high energy ball milling, fabricate SiCp-reinforced metal matrix composites by powder metallurgy method and investigate the effect of nano SiC particle content on the porosity and mechanical properties of nano SiCp-reinforced TMCs.

2 Experimental

2.1 Materials

Ti-6Al-4V alloy was used as the matrix material and SiC particles with average particle size of 20 μm were used as the reinforcement. The SiC powder was supplied by Alfa Aesar A13561, German. In this work, titanium powder of 99% purity (average particle size of 44 μm, supplied by Kemphasol, Mumbai), aluminium fine powder of 99.7% purity (average particle size of 44 μm, supplied by Lobachemi, Mumbai) and vanadium powder of 99.5% purity (average particle size of 44 μm, supplied by Aesar Alfa) were used as raw materials for this study. An industrial standard titanium alloy mixture, titanium powder 90% (mass fraction), aluminium powder 6% (mass fraction) (α-phase stabilizer) and vanadium 4% (mass fraction) (β-phase stabilizer) were mechanical alloyed to make Ti6Al4V alloy (Ti64 alloy). All the powders were milled in a high energy ball mill to obtain homogeneous alloy [16].

2.2 Production of nano SiCp

The size reduction of SiC from micron to nano level (<75 nm) was achieved by high energy planetary ball mill (Retsch, PM 100). The following parameters were the milling parameters such as ball to powder mass ratio (BP ratio 40:1), constant milling time (8 h) and constant rotational speed (300 r/min) [17,18]. The wet milling method was used to mill the powder. The organic compound toluene (C6H6—CH3) was filled in the ball mill chamber in adequate quantity [19] and its level was frequently checked. After the end of one complete cycle time, the milled powders with toluene were poured into a pyrex container, dried in an oven at 70 °C for 24 h, de-agglomerated in a mortar and sieved.

2.3 Production of composites

Different mass fractions (0, 5%, 10% and 15%) of nano SiC particle-reinforced Ti64 alloy metal matrix composites were produced by using powder metallurgy technique. The basic steps in powder metallurgy (PM) include mixing, compacting, and sintering of mixtures of powders constituting the matrix and reinforcements. After the mixing operation, mixtures of powders are pressed (compacted) in a die at the pressure that makes the particle adhere at contacting points. 100 t hydraulic pressing machine [20,21] was used for compaction. The blended powder mixtures were cold compacted by using the suitable punch and dies set assembly [22]. Several designated pressures of 4.365, 5.432, 5.82 and 6.305 MPa [23] were used to make cylindrical specimens. The maximum density was obtained to be about 93.33% in compaction pressure of 6.305 MPa with a diameter of 31 mm and a length of 22.85 mm.

The compacts were heated at 125 °C for 2 h for the vaporization of solvent and decomposition of stearic acid. They were then placed in the vacuum chamber and heated to 250 °C at vacuum of 5.33×104 Pa for 4 h to remove the residual gases.

The green compacts having the maximum density were subsequently sintered at 1200 °C in high temperature tubular furnace with argon atmosphere. Choking time of 2 h was maintained and followed by cooling to room temperature in the furnace itself [24,25]. Similar procedure was adopted for preparing Ti64 alloy/ nano SiCp composites. The hot extrusion was carried out in the 150 t hydraulic press with argon atmosphere. Alloy and composite billets were loaded into the container and the die assembly was heated to 850 °C using a split type resistance furnace for 30 min. The billet temperature was measured by using a chromel/alumel thermocouple located at 2 mm away from the inner wall of the container. When the desired temperature was reached, the billets were soaked for 30 min and extruded in the ratio of 2. Liquid paraffin with graphite mixture (mass ratio of 5:1) was used as a surface lubricant. The extrusion process was carried out not only for producing structural shapes but also to get more homogeneous particle distribution with the refinement of the particle size. Also, the extrusion process minimized the compaction defects in the composites.

From the hot-extruded billets (31 mm in diameter and 22.85 mm in length), the cylindrical specimens of required dimensions (9 mm in length and 6 mm in diameter) were machined (wire cut) using wire cutting machine and used for further study.

2.4 Density measurement and porosity

The experimental density (bulk density) of the composites was obtained by Archimdian method. The theoretical density was calculated using the rule of mixture. Bulk density was calculated by using Eq. (1) [26]:

(1)

(1)

where ρB is the bulk desity, msat is the saturated mass, md is the dry mass, and msus is the suspended immersion mass.

Porosity (P) was calculated by using Eq. (2) [27]:

(2)

(2)

2.5 Hardness and compressive strength tests

The microhardness of the polished face of composite specimens was found at room temperature using an HMV-2T Schimadzu. The hardnesses of Ti64 alloy and composites were measured after polishing to a 1 μm finish. To evaluate the Vicker microhardness, several indentations were made on the faces of the composite at various loads and a dwell time of 10 s. The hardness values of Ti64 alloy and Ti64 alloy/nano SiCp composite specimens were taken at different places on the surface. The average of these values was considered in this result.

Compressive tests were used to assess the mechanical behavior of the composites and matrix alloy. The surface of the samples was polished with 600-grit sand paper. The compressive strength was tested and recorded by using a universal testing machine (UTM).

2.6 Microstructures and particle size

Ti matrix alloy and composite billets were polished with 600-grit sand papers and subsequently polished on cloth using diamond paste of 6 and 1 μm. Microscopic examinations of the composites and matrix alloy were carried out using a JSM-5610LV scanning electron microscope (SEM).

The phase identifications were performed by X-ray diffraction (XRD model: X’Pert PRO PAN) analytical technique using Cu Kα radiation. AFM images were recorded for the nano SiC particles by using AGILENT– N9410A series 5500 AFM.

3 Result and discussion

3.1 Particle size

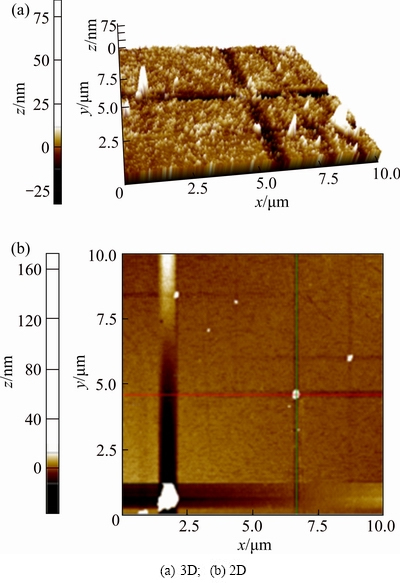

The atomic force microscope image (3D) of the ball-milled SiC nano particles is shown in Fig. 1(a) and 2D representation of height image and line profile of the synthesized SiC nano particles is shown in Fig. 1(b). The average particle size of SiCp observed is 75 nm. The surface of the SiCp is found as irregular and rough shape.

Fig. 1 AFM images of ball-milled SiC nano particles

The increased surface roughness supports the higher surface energy of nano SiCp. The results reveal that the size reduction of SiCp from micron to nano level was achieved by high energy planetary ball milling (Retsch, PM 100) [28].

3.2 Density and porosity

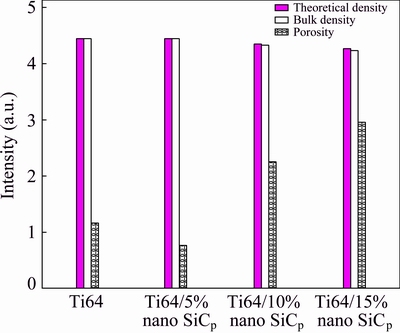

The graphs of theoretical, bulk density and porosity of the composites according to the mass fractions of nano SiCp are shown in Fig. 2. It can be seen that the theoretical density of 5% nano SiCp composites increases and that for 10% and 15% SiCp composites (as expected from the rule of mixtures). The same trend was also observed in bulk density (Archimedies principle). The experimental densities are observed to be lower than the theoretical densities. The density measurements showed that the composites contained some porosities. The amount of porosity in the composites increased with increasing mass fraction of the SiC particles. Similar results have observed in previous investigations [29-31]. 5% nano SiCp composite has a very low porosity among the other three composites with different contents of SiCp. The result suggests that 5% of nano SiCp is effective, due to the removal of pores and it enhances the mechanical properties of the composites. More pores are filled by nano SiCp and therefore, the number of open pore decreases, at 5% nano SiCp composite.

Fig. 2 Physical properties of experimental composites

The effects of low wettability and high agglomeration at high reinforcement content and pore nucleation at the matrix interface are the reasons for higher porosity for 10% SiCp and 15% SiCp. When the nano SiCp content increases more than 5%, the excess of unreacted SiC particles create pores, whose volume expands due to the increased pressure of the gas inside the closed pores. The reduction of porosity in the SiCp- reinforced alloy composite can be written in the following sequences, i.e., Ti alloy/5% nano SiCp> Ti alloy>Ti alloy/10% nano SiCp>Ti alloy/15% nano SiCp.

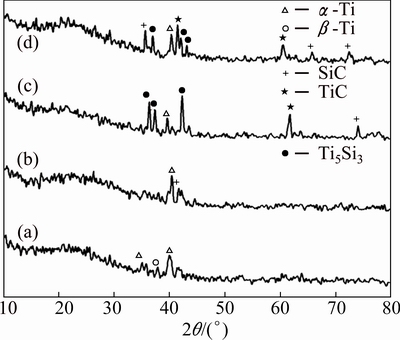

3.3 X-ray diffraction analysis

The XRD patterns of Ti64 alloy and Ti64 alloy/nano SiCp composites are shown in Fig. 3. ANDERSSON and WARREN [32] reported that, in reactive systems, SiC reacts with the metal to form silicides and carbides. Such reactions are thermodynamically possible between SiC and Ti. Ti reacts with SiC rapidly to produce TiC and Ti5Si3.

Fig. 3 XRD patterns of Ti64 alloy (a) and Ti64 alloy/5% nano SiCp (b), Ti64 alloy/10% nano SiCp (c) and Ti64 alloy/15% nano SiCp (d) composites

SiC+Ti→TixSiy+TiC (3)

The Ti64 alloy consists of an α-Ti phase as a major phase and it is observed for all the patterns nearly at 2θ=35°, 40.16°, and β-Ti phase as a minor phase observed at 2θ=38.45° which corresponds to reflection (100), (101) of HCP structure and (110) of BCC structure with d spacing values of 2.249 and 2.350  , respectively. The observed values well coincide with the standard JCPDS cards No. 89-2762 and 89-3726.

, respectively. The observed values well coincide with the standard JCPDS cards No. 89-2762 and 89-3726.

The α-Ti and β-Ti phases observed at 2θ=40.19° (101) and 2θ=38.37° (110) are coexistent with a new peak at 2θ=41.80° (104) formed in 5% SiCp specimen due to the hexagonal structure of silicon carbide (JCPDS card No. 29-1128).

The intensity of α-Ti phase (peak) significantly decreased in 10% and 15% SiCp specimens and subsequently some new peaks (Ti5Si3 and TiC) with high intensity grew up at 2θ=36.92° (210), 37.63° (102), 42.14° (300) which belong to reflections due to Ti5Si3 phase (JCPDS card No. 08-0041, 78-1429). TiC phase is observed at 2θ=62.19° (220) in 10% SiCp specimen. The high intensity of TiC is formed at 2θ=41.43° (200), and 60.30° (220) (JCPDS card No. 06-0614) in 15% SiCp specimen. The reinforcement material SiCp is formed at 2θ=73.39° (203) (JCPDS card No. 29-1128) in 10% SiCp specimen and higher intensity is observed at 2θ=35.62° (102) and 72.40° (202) in 15% SiCp specimen.

3.4 Microstructures

SEM images of the 0, 5%, 10% and 15% SiC particle-reinforced Ti64 alloys are shown in Fig. 4. The microstructure of Ti64 alloy is shown in Fig. 4(a). It can be seen that Ti64 alloy has distinctive Widmanstatten structure. It consists of two phases: the phase began to appear in the form of the plates as the specimen is slowly cooled near the β transus temperature [33]. Some β phases (thin dark region) are observed between α platelets in monolithic alloy, which is in good agreement with the report [34] where approximately 95% (volume fraction) α phase and only 5% (volume fraction) β phase are observed for furnace cooled Ti64 specimen. Figure 4(b) shows good bonding between matrix and reinforcement. Addition of ceramic nano particles into the titanium matrix sustains the crystallite size reduction and better particle size distribution. The surface of Ti64 alloy with 5% nano SiCp was the smoothest, and most uniform layer formation was achieved. The homogeneous distribution of composition is attributed to good wettability between Ti64 alloy and reinforcement.

It can be concluded that 5% nano SiCp (Fig. 4(b)) particles are bonded well with the Ti64 alloy matrix. The nano particle size in the present work is about 75 nm, the Orowan strengthening mechanism works more significantly than the micro-sized ceramic particles. It clearly showed that, there were no voids and discontinuities, when nano SiCp was dispersed in the titanium matrix. The inhibitory effect is more remarkable with the increase in the nano SiC [35].

Fig. 4 SEM images of experimental composites

Increasing the content of nano SiCp (10% to 15%) in the matrix will result in more Ti64 alloy/nano SiC interfaces, and consequently large numbers of void formation sites are observed and shown in Figs. 4(c) and (d). This indicates that the weak bonding is observed between the SiCp and Ti64 alloy particle. Addition of nano SiCp more than 5% can increase the porosity, resulting in the decline in strength of the corresponding specimen. This is because the pore can nucleate at SiCp sites and the contact surface area increases, which would result in higher porosity level [36]. Increasing the mass fraction of nano SiCp leads to the formation of TiC and Ti5Si3 phases. These porosities and formation of reaction zone will lower the bonding of interface between the reinforcement and matrix phase.

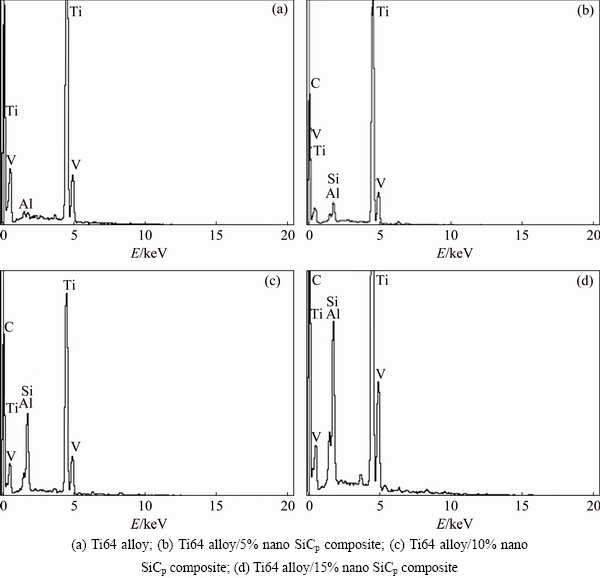

3.5 Energy dispersive spectroscopy (EDS) spectra

EDS spectra of Ti64 alloy and Ti64 alloy/ nano SiCp reinforced composite specimens are shown in Fig. 5. EDS analysis taken from sintered Ti64 alloy sample exhibited that only Al, V and Ti elements present in the mass fractions of 5.5%, 4.0% and 90.5%, respectively.

Ti64 alloy/5% nano SiCp composite sample exhibited Al, V, Ti, Si and C elements present in the mass fractions of 5.51%, 3.70%, 85.64%, 2.40% and 2.75%, respectively. Ti64 alloy/10% nano SiCp composite sample exhibited Al, V, Ti, Si and C elements present in the mass fractions of 5.35%, 3.55%, 80.50%, 5.15% and 5.45%, respectively. Ti64 alloy/15% nano SiCp composite sample exhibited aluminium, vanadium, titanium, silicon and carbon elements present in the mass fractions of 4.90%, 3.13%, 76.19%, 7.26% and 8.52%, respectively.

The peaks of Si and C indicate the presence of SiC and the peaks of Ti, Al, and V are attributed to the matrix of Ti64 alloy. The mass fractions of Si and C increased with increasing reinforcement content. EDS spectra confirm the presence of SiCp in the reinforced Ti64 alloy composite specimen.

It is evidently seen from all the EDS spectra and it is inferred that there is no oxygen present in the extruded sample since the hot extrusion was carried out in the argon atmosphere.

3.6 Hardness and compressive strength

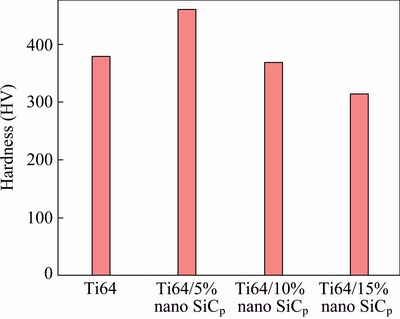

The Vickers hardness of the composites is shown in Fig. 6. Vickers hardness of Ti64 alloy specimen is HV 380 [37,38] and the hardness increased significantly (20%) for 5% nano SiCp reinforced Ti64 alloy specimen to HV 460, which could be attributed to the presence of harder ceramic particulate in the matrix. The presence of such hard surface area of the specimen offers more resistance to plastic deformation which leads to the increase in the hardness of the specimen, which is directly related to the forces that exist between atoms in the solid. The decrease of hardness for 10% (HV 369) and 15% (HV 315) SiCp specimens is due to greater agglomeration of particles and higher degree of defects and micro porosity present in the specimens during processing.

Fig. 5 EDS analysis of experimental composites

Fig. 6 Vickers hardness of Ti64 alloy and Ti64 alloy /nano SiCp composites

The higher hardness value of 5% nano SiCp can provide its inherent properties to the Ti64 alloy matrix and can act as a hindrance to the dislocation motion, which is attributed to the improvement of hardness value, and reduction of porosity was another reason behind the improvement of hardness [39]. The matrix deforms plastically to accommodate the volume expansion due to incorporation of hard reinforcement particles. Similar behavior was observed by SINGLA et al [40]. MURTY et al [41] reported that the stronger the reinforcement particles bond to alloy matrix, the higher the Vickers hardness becomes.

Further increase of 10% and 15% SiCp with Ti64 alloy resulted in decreasing the Vickers hardness. The results also revealed that a large scattering of hardness was observed for each individual composite, which may be due to the presence of residual internal stresses resulting from the thermal expansion mismatch between Ti64 alloy and nano SiCp. The Vickers hardness is known to be very sensitive to the residual internal stresses [42].

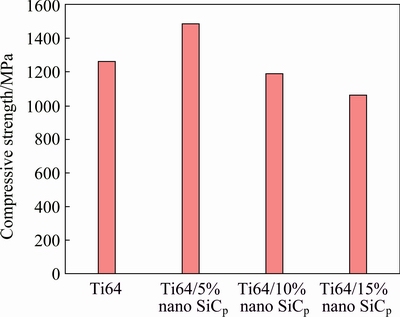

The compressive strength of the composite was investigated by determining their failing load. The compressive strength of the composites is shown in Fig. 7. The 5% nano SiCp reinforced Ti64 alloy composite (1483 MPa) has improved (17%) compressive strength than the Ti64 alloy (1263 MPa) [43,44]. The values of 10% and 15% nano SiCp reinforced Ti64 alloys are found to be 1189 and 1064 MPa, respectively. The tendency of 5% nano SiCp towards higher compressive strength with higher density and lower porosity is established. This finding for the 5% nano SiCp composites leads to the increase of vitrification level and a reduction of internal cracks and voids formation. Also, good bonding between 5% nano SiCp particle and matrix phase can be considered to be responsible for the increase in strength. The nano particulate improves the mechanical properties in the monolithic system because of Orrowen strength mechanism.

Fig. 7 Compressive strength of Ti64 alloy and Ti64 alloy/nano SiCp composites

When the increase of the nano SiCp reinforcement content is above the optimum value (5%), brittle interfacial reaction products TiC and Ti5Si3 are formed [11] and the debonding would be expected to occur as a result of processing condition and act as critical flaws, which lower the strength of the 10% and 15% SiCp specimens. It is observed that, nano SiCp grains embedded in the matrix phase which has a detritus effect on the compressive strength mainly because of the occurrence of porosity and agglomeration [45,46]. It may be one of the reasons for a low strength in 10% and 15% nano SiCp reinforced Ti64 alloys.

4 Conclusions

1) Nano SiC particle-reinforced Ti64 alloy composites were successfully fabricated by the powder metallurgy method. Density, porosity, hardness, compressive strength, phase formation and SEM microstructures of MMCs were investigated.

2) The optimum density (93.33%) was obtained at the compaction pressure of 6.305 MPa. SEM observation of the microstructures showed that the wettability and the bonding force were improved in Ti64 alloy/5% nano SiCp composites.

3) The new phase formation of brittle interfaced reaction formed at the 10% and 15% SiCp composite specimens and resulted in no beneficial effect on the strength and hardness. Hence, 5% composite specimens can be considered to be the optimal replacement content.

4) The compressive strength and hardness of Ti64 alloy/5% nano SiCp MMCs showed higher value. Porosity of the composites increased with increasing mass fraction of nano SiC particles.

Acknowledgement

The authors thank the professor and head, Manufacturing Engineering Department, Annamalai University for providing fabrication and mechanical testing facilities. The authors also thank CISL, Department of Physics, Annamalai University for the support in using AFM and SEM for experimentation. The authors are gratefully acknowledging Prof. and Dr. N. SELVAKUMAR, the director, Nano Centre of MepcoSchlenk Engineering College, Sivakasi, Tamil nadu, India.

References

[1] HANUMANTH G S, IRONS G A. Particle incorporation by melt stirring for the production of metal-matrix composites [J]. Materials Science, 1993, 28: 2459-2465.

[2] KUMAR B A, MURUGAN N. Metallurgical and mechanical characterization of stir cast AA6061-T6–AlNp [J]. Composite Material Design, 2012, 40: 52-58.

[3] HUANG L J, CUI X P, GENG L, FU Y. Effects of rolling deformation on microstructure and mechanical properties of network structured TiBw/Ti composites [J]. Transactions of Nonferrous Metals Society of China , 2012, 22: 79-83.

[4] PURAZRANG K, KAINER K U, MORDIKE B L. Fracture toughness behavior of a magnesium alloy metal-matrix composite produced by the infiltration technique [J]. Composites, 1991, 22: 456-462.

[5] TZAMTZIS S, BAREKAR N S, HARI BABU N, PATEL J, DHINDAW B K, FAN Z. Processing of advanced Al/SiC particulate metal matrix composites under intensive shearing—A novel rheo-process [J]. Composites: Part A, 2009, 40: 144-151.

[6] MIRACLE D B. Metal matrix composites—From science to technological significance [J]. Composites Science and Technology, 2005, 65: 2526-2540.

[7] RAGUNATH A S. Review on particulate-reinforced titanium matrix composites [J]. Materials Science, 1997,32:1-16.

[8] SAEID GHESMATI T, ABOLFAZL B, SEYED A S,  J. Microstructural aspects of in-situ TiB reinforced Ti-6Al-4V composite processed by spark plasma sintering [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1353-1714.

J. Microstructural aspects of in-situ TiB reinforced Ti-6Al-4V composite processed by spark plasma sintering [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 1353-1714.

[9] KIMI Y, CHOIM J, KIMY J, LEE Y Z. Friction and wear behavior of titanium matrix (TiB+TiC) composites [J]. Wear, 2011, 271: 1962-1965.

[10] OH J C, YUN E, GOLKOVSKI M G, LEE S. Improvement of hardness and wear resistance in SiC/Ti-6Al-4V surface composites fabricated by high-energy electron beam irradiation [J]. Materials Science and Engineering A, 2003, 351: 98-108.

[11] POLETTI C, BALOG M, SCHUBERT T, LIEDTKE V, EDTMAIER C. Production of titanium matrix composites reinforced with SiC particles [J]. Composites Science and Technology, 2008, 68: 2171-2177.

[12] MA Z Y, LI Y L, LIANG Y, ZHENG F, BI J, TJONG S C. Nanometric Si3N4 particulate-reinforced aluminum composite [J]. Materials Science and Engineering A, 1996, 219: 229-231.

[13] TJONG S C, MA Z Y. Microstructural and mechanical characteristics of in-situ metal matrix composites [J]. Materials Science and Engineering R, 2000, 29: 49-56.

[14] ABDERRAZAK H, ABDELLAOUI M. Synthesis and characterization of nanostructured silicon carbide [J]. Materials Letters, 2008, 62:3839-3841.

[15] ZHANG Y Z, HUANG L J, LIU B X, GENG L. Hot deformation behavior of in-situ TiBw/Ti6Al4V composite with novel network reinforcement distribution. [J]. Transactions of Nonferrous Metals Society of China, 2012, 22: 465-471.

[16] RAMANATHAN S, KRISHNAMOHAN S. Synthesis and characterisation of nano SiCp [J]. International Journal of Auto and Autonomous System, 2012, 4(7): 319-321.

[17] SUMRERNG R, PRINYA C. Utilization of bagasse ash in high-strength concrete [J]. Material & Design, 2012, 34: 45-50.

[18] OLADIJI A O, BORODE J O, ADEWUYI B O, OHIJEAGBON I O. Development of porcelain insulators from locally sourced materials [J]. Research Information in Civil Engineering, 2010, 7(1): 47-58.

[19] LEMINE O M, LOULY M A, AL-AHMARI A M. Planetary milling parameters optimization for the production of ZnO nano-particles [J]. International Journal of Physics Science, 2010, 5(17): 2721-2729.

[20] KRISHNAMOHAN S, RAMANATHAN S. Study on pulverized silicon carbide powders produced by high energy ball mill [J]. Journal of Manufacturing Engineering, 2014, 9(1): 1-9.

[21] SUMATHI M, SELVAKUMAR N. Investigation of Cu-SiC composite performs during cold upsetting [J]. Materials and Manufacturing Processes, 2001, 26: 826-831.

[22] TJONG S C, MENG Y Z. Morphology and performance of potassium titanate with potassium titanate whiskers [J]. Applied Polymer Science, 1999,72(4):501-508.

[23] PRASAD Y V R K, SESHACHARYALU T, MEDEIROS S C, FRAZIER W G. Effect of preform microstructure on the hot working mechanisms in ELI grade Ti-6Al-4V: Transformed β vs equiaxed (α+β) [J]. Materials Science and Technology, 2000, 16(5): 511-516.

[24] CHEN W, YAMAMOTO Y, PETER W H, GORTI S B, SABAU A S, CLARK M B. Cold compaction study of armstrong process for Ti-6Al-4Vpowders [J]. Powder Technology, 2011, 214: 194-199.

[25] NARAYANASAMY R, SELVAKUMAR N, PANDEY K S. Phenomenon of instantaneous strain hardening behavior of sintered Al-Fe composite preforms during cold axial forming [J]. Material & Design, 2007, 28: 1358-1363.

[26] YAMAMOTO Y, PETER W H, SABAU A S, SARMA G B, KIGGANS J O, NUNN S, AKHTAR K. Low cost titanium near-net-shape manufacturing using armstrong and/or hydride-dehydride CP-Ti and Ti-6Al-4V powders [C]//Proceedings of International Conference on Powder Metallurgy & Particulate Materials, Powder Materials. Princeton, NJ, USA, 2010: 27-30.

[27] LIU B, LIU Y, HE X Y, TANG H P, CHEN L F, HUANG B Y. Preparation and mechanical properties of particulate-reinforced powder metallurgy titanium matrix composites [J]. Metallurgical and Materials Transactions A, 2007, 38: 2825-2831.

[28] KRISHNAMOHAN S, RAMANATHAN S. Synthesis and characterization of Ti6Al4V alloy by powder metallurgy [J]. International Journal of Engineering Research & Technology, 2013, 2(11): 2725-2728.

[29] RECEP C, MUHARREM P,  O P. The effect of reinforcement volume ratio on porosity and thermal conductivity in Al-MgO composites [J]. Materials Research, 2012, 15: 1057-1063.

O P. The effect of reinforcement volume ratio on porosity and thermal conductivity in Al-MgO composites [J]. Materials Research, 2012, 15: 1057-1063.

[30] KOK M. Production of metal matrix (Al2O3-reinforced) composite materials and investigation of their machinability by ceramic tools [D].  : Firat University, 2000.

: Firat University, 2000.

[31] GHOST P K, RAY S. Influence of process parameters on the porosity content in Mg-alumina cast particulate composite produced by vortex method [J]. Transactions of the American Foundry Society, 1988, 214: 775-782.

[32] ANDERSSON C H, WARREN R. Silicon carbide fibres and their potential for use in composite materials: Part I [J]. Composites, 1984, 15: 16-24.

[33] DONACHIE J R M. Titanium: A technical guide [M]. OH: ASM International, 2000: 203-217.

[34] JOVANOVIC M T, TADIC S, ZEC S, MIS KOVIC Z, BOBIC I. The effect of annealing temperatures and cooling rates on microstructure and mechanical properties of investment cast Ti-6Al-4V alloy [J]. Material & Design, 2006, 27: 192-199.

[35] MONTEALEGRE M, NEUBAUERE A, TORRALBA J M. Influence of nano-reinforcements on the mechanical properties and microstructure of titanium matrix composites [J]. Composites Science and Technology, 2011, 71: 1154-1162.

[36] DINESH K K, GEETA A, RAJESH P. Properties and characterization of Al-Al2O3 composites processed by casting and powder metallurgy routes (Review) [J]. International Journal of Latest Trends in Engineering and Technology, 2013, 2(4): 486-496.

[37] OH J M, HEO K H, KIM W B, CHOI G S, LIM J W. Sintering properties of Ti6Al4V alloys prepared using Ti/TiH2 powders [J]. Materials Transactions, 2013, 54 (1): 119-121.

[38] SIVAKUMAR G, ANANTHI V, RAMANATHAN S. Fabrication and evaluation of synthesized nano SiC reinforced titanium alloy composites by powder metallurgy route [J]. International Journal of Engineering Research & Technology, 2015, 4(7): 1105-1108.

[39] RANA R S, RAJESH PUROHIT DAS S. Fabrication and testing of ultrasonically assisted stir cast AA5083-SiCp composites [J]. International Journal of Engineering Research and Applications, 2013, 3(5): 386-393.

[40] SINGLA M, DWIVEDI D D, SINGH L, CHAWLA V. Development of aluminium based silicon carbide particulate metal matrix composite [J]. Journal of Minerals & Materials Characterization & Engineering, 2009, 8(6): 455-467.

[41] MURTY B S, THAKU S K, DHINDAW B K.On the infiltration behavior of Al, Al-Li and Mg melts through SiCp bed [J]. Metallurgical and Materials Transactions A, 2000, 31: 319-325.

[42] DONG Y L, XU F M, SHI X L, ZHANG , ZHANG Z J, YANG J M, TAN Y. Fabrication and mechanical properties of nano-/micro- sized Al2O3/SiC composites [J]. Materials Science and Engineering A, 2009, 504: 49-54.

[43] MATTHEW J, DONACHIE Jr. Titanium: A technical guide [M]. 2nd ed. Ohio: ASM International, 2000.

[44] BOYER R R, WELSCH G E, COLLINGS E W. Material properties hand book of titanium alloy [M]. Ohio: ASM International, 1994.

[45] ABOU-EL-KHAIR M T, ABDEL ALI A. Erosion-corrosion and surface protection of A356Al/ZrO2 composite produced by vortex and squeeze casting [J]. Materials Science and Engineering A, 2007, 454: 156-163.

[46] BREVALA E, CHENGA J P, K.AGRAWALA D, GIGLAP, DENNISB M, ROYAR, PAPWORTH A J. Comparison between microwave and conventional sintering of WC/CO composites [J]. Materials Science and Engineering A, 2005, 391: 285-295.

G. SIVAKUMAR1, V. ANANTHI2, S. RAMANATHAN3

1. CISL, Department of Physics, Annamalai University, Tamilnadu 608002, India;

2. Physics Section, FEAT, Annamalai University, Tamilnadu 608002, India;

3. Manufacturing Engineering Department, Annamalai University, Tamilnadu 608002, India

摘 要:采用粉末冶金技术制备含不同质量分数(0, 5%, 10%和15%)纳米SiC颗粒增强的Ti-6Al-4V(Ti64)金属基复合材料(MMCs),研究添加纳米SiC颗粒对复合材料力学性能如硬度和抗压强度的影响。结果表明,当压缩载荷为6.035 MPa时,复合材料具有最佳的相对密度(93.33%)。SEM显微组织观察结果表明,Ti64/5%SiCp复合材料的润湿性和结合力得到了提高。采用X射线衍射技术研究Ti64/SiCp复合材料中纳米SiC颗粒含量对其相组成的影响,并分析其力学性能与相组成的关系。含10%和15% SiCp的复合材料由于脆性界面反应产生了新相,此新相对复合材料的强度和硬度不利。Ti64/5%SiCp金属基复合材料的抗压强度和硬度较高,因此5% SiCp是此复合材料的最佳含量。

关键词:钛合金;纳米SiC颗粒;粉末冶金;硬度;抗压强度

(Edited by Wei-ping CHEN)

Corresponding author: V. ANANTHI; Tel: +91-9952745076; E-mail: ananthi2312@yahoo.com

DOI: 10.1016/S1003-6326(17)60009-8