文章编号:1004-0609(2008)04-0703-07

半固态AZ91D镁合金触变注射成形过程

数值模拟及参数优化

张友法,刘勇兵,曹占义,张 亮,张倩倩

(吉林大学 材料科学与工程学院,汽车材料教育部重点实验室,长春 130022)

摘 要:为研究半固态浆料触变注射成形过程中,料筒温度、注射速度、模具温度以及螺杆转速对半固态合金产品的质量和性能的影响,利用拟合的初始粘度和极限剪切粘度关系式,基于Carreau粘度模型,模拟了不同工艺条件下的半固态AZ91D镁合金触变注射成形过程。结果表明,料筒温度和螺杆转速可以影响浆料的粘度并对后续成形过程中的其它参数产生影响。而注射速度主要对喷嘴和浇口的剪切作用有影响,模具温度对实验结果影响不大。通过对模拟实验结果的分析,优化的工艺参数条件下,浆料的充型过程平稳、顺利、完全充型,结果参数变化较大部位均集中在浇口部位,壳体部位各结果参数变化较小,且分布均匀。

关键词:半固态;AZ91D;触变注射;数值模拟;参数优化

中图分类号:TG 146.2 文献标识码:A

Numerical simulation and parameters optimization of thixomolded process for semisolid AZ91D magnesium alloy

ZHANG You-fa, LIU Yong-bing, CAO Zhan-yi, ZHANG Liang, ZHANG Qian-qian

(Key Laboratory of Automobile Materials of Ministry of Education, Department of Materials Science & Engineering,

Jilin University, Changchun 130022, China)

Abstract: To study the influence of barrel temperature, injection velocity, mold temperature and screw rotation speed on the quality and properties of products during molding process of thixomolded semisolid slurry, based on the initial and ultimate viscosities and the Carreau viscosity model, a series of thixomolded processes for semisolid AZ91D products were simulated under different processing conditions. The results show that the key parameters of simulated results are influenced by the viscosity that is controlled by barrel temperature and screw rotation speed during the preparation of semisolid slurry before the injection. However, the results for different injection velocities demand on the role of shear process of injection nozzle and gate, while the mold temperature has a weak effect on the results. Through the analysis of simulated results, using the optimized parameters, the results of the numerical simulation of the filling process demonstrate that the cavity is filled smoothly and completely. The differences of the results are mainly located at the cold plug catcher of runner system, and the results are almost constants and the distributions are uniform at the shell.

Key words: semisolid; AZ91D; thixomolded; numerical simulation; parameter optimization

镁合金被誉为21世纪的绿色工程材料,而半固态加工被称为21世纪最有前途的材料成形加工方法[1],用于镁合金工业生产的半固态触变注射成形技术(Thixomolding?)发展更是令人瞩目,其产品具有质量轻、比强度高、制造成本低、近终形成形、降噪减震和可回收等优异性能,应用越来越广泛[2-3]。触变注射成形过程主要包括:首先对料筒中原材料AZ91D镁合金颗粒进行加热,直至其需求的温度;同时加以螺杆的剪切搅拌,从而制备出半固态浆料;再在螺杆作用下输送浆料、蓄料;最后通过注射、保压、凝固、出模等过程生产出所需产品。其间主要工艺参数有料筒温度、螺杆转速、注射速度和模具温度[4-6]。料筒温度是最重要的一个工艺参数,决定着半固态浆料的固相分数,并影响半固态浆料中固相的形貌,最终影响产品的质量和性能[4-5, 7];螺杆转速与料筒中半固态浆料所承受的剪切率、摩擦热以及浆料的输送率、滞留时间有关,最终影响浆料的微结构[4-5];浆料的注射速度对组织影响较小[4-5, 8],主要对半固态浆料充型过程中的流动模式以及剪切率有较大影响,从而影响产品的质量和性能;模具温度对产品的组织和性能影响较小[4-5]。采用数值分析的方法模拟并预测半固态金属成形过程对观察半固态浆料复杂的充型过程,了解半固态成形特性,改善产品和模具设计以及提高工艺设计能力等提供了很好的帮助,并取得了很大的进展[9-11]。BARKHUDAROV等[12-13]基于简单粘度理论模型,对半固态Sn-15%Pb合金触变挤压过程进行了模拟,所得滞后曲线与实验结果较为相符。KAPRANOS等[14]分别对半固态A357合金的快速压缩变形压力变化进行了对比分析,认为半固态金属成形时的表观粘度与剪切速率和剪切时间密切相关。杨浩强等[15]对镁合金在阻尼冷管中的制备过程进行了三维数值模拟,获得了制备过程中半固态浆料的流动规律,为阻尼冷管法模具设计及工艺参数的优化提供了有效的理论指导。

本文作者根据现有的文献数据,利用平行板简单压缩法和Couette流变仪[16-18],分别研究低剪切速率和高剪切速率状态下半固态AZ91D的流变及触变特性,从而拟合出螺杆转速和料筒温度对半固态AZ91D合金的初始粘度以及极限剪切粘度的影响;采用数值模拟技术对其触变注射过程进行研究,观察半固态合金浆料充型过程中温度和速度等的分布情况,预测缺陷出现的部位,由此优化相应的工艺参数。

1 模拟实验

1.1 基本控制方程

从流体力学角度出发,对半固态AZ91D浆料充型过程进行模拟,其基本控制方程与其它液态或气态流体一样,包括质量守恒方程、动量守恒方程、能量守恒方程和自由表面控制方程。

1) 连续性方程

2) 动量方程

3) 能量方程

4) 体积方程

1.2 材料选择及模拟参数的设定

本研究选用AZ91D镁合金为模拟过程的半固态浆料,模具材料选用SKD61,其物性参数如表1所列。

表1 模具SKD61物性参数

Table 1 Physical parameters of die of SKD61

通过对影响触变注射件质量较大的料筒温度、螺杆剪切速率、注射速度和模具温度4个参数进行探讨,研究主要工艺参数对触变注射的影响,模拟过程基本流程如图1。模拟参数设置如表2所列。

图1 模拟过程流程图

Fig.1 Flow chart of thixomolding simulation

表2 主要工艺参数设置

Table 2 Setting of main processing parameters

1.3 半固态AZ91D合金的流变模型

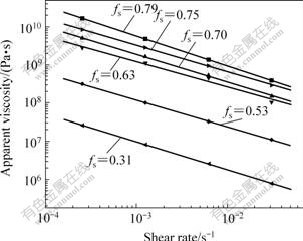

半固态AZ91D浆料属于非牛顿流体,其典型表观粘度随剪切速率变化如图2所示。可以看出,实际半固态浆料的流动曲线可以分为3个区域:第一牛顿区,该区粘度为通常作为初始粘度粘度η0,即 →0的粘度;假塑区,该区粘度为表观粘度ηa,随着

→0的粘度;假塑区,该区粘度为表观粘度ηa,随着 的增大,ηa减小;第二牛顿区,此时的粘度为极限剪切粘度η∞,随着

的增大,ηa减小;第二牛顿区,此时的粘度为极限剪切粘度η∞,随着 的增大,ηa变化很小。

的增大,ηa变化很小。

图2 半固态浆料Shear thinning特性示意图

Fig.2 Schematic diagram of shear thinning of semisolid slurry

为研究半固态AZ91D浆料在料筒中受螺杆转动的剪切搅拌过程,本研究将料筒螺杆的搅拌等效成如图3所示的同轴光筒搅拌过程,等效直径de为

图3 螺杆等效成同轴双筒示意图

Fig.3 Schematic diagram of relation for screw and barrel

忽略端面效应等因素影响,剪切速率可根据下式近似计算:

因此,本论文中设定的螺杆转速105、143和168 r/min,经计算,其对应的剪切速率分别为361.72、491.94和578.76/s。

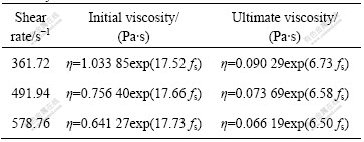

应用平行板简单压缩法,GEBELIN等[16]研究了低剪切速率下半固态AZ91D初始粘度的变化,如图4所示;应用Couette流变仪,甄子胜等[17]对高剪切速率下半固态AZ91D极限剪切粘度的变化进行了研究,如图5所示。根据上述实验数据,本研究拟合出半固态AZ91D合金的初始粘度和极限剪切粘度公式(表3)。

图4 低剪切速率下半固态AZ91D粘度变化[16]

Fig.4 Viscosities of semisolid AZ91D under low shear rate[16]

图5 高剪切速率下半固态AZ91D粘度变化[17]

Fig.5 Viscosities of semisolid AZ91D under high shear rate[17]

表3 初始粘度和极限剪切粘度拟合关系式

Table 3 Modeled equation of initial viscosity and ultimate viscosity

本研究采用Carreau模型来表征表观粘度的变化,以配合从低到高的整个剪切区域,同时根据毛卫民 等[18]的实验结果分析了剪切时间等参数对半固态AZ91D触变性的影响。由于触变注射成形过程充型时间极短,浆料温度变化也较小,因此浆料充型时不考虑温度变化对表观粘度的影响。

2 数值模拟结果及讨论

按照表2所示的工艺参数表,对触变注射成形过程进行模拟,结果如表4所列,包括充型过程温度变化、固相率、表面缺陷率、粘度变化、充型压力和充型时间。

表4 数值模拟实验结果

Table 4 Results of numerical simulation

表4中实验1到实验4为料筒温度不断升高的过程,根据半固态AZ91D镁合金的特殊性质的理论分析,半固态浆料的固相率将会降低,继而引起粘度的降低;同时,由于喷嘴及浇口等部位在浆料充型过程中的剪切作用,也会导致浆料粘度的降低。因此,料筒温度升高引起浆料粘度降低,充型压力减小,最终导致充型时间的增加。从实验1~4的结果可以看 出:随着料筒温度的增加,固相率、表面缺陷率、粘度、充型压力均降低,充型时间有所增加,完全与理论分析相吻合。根据以上分析,本研究中较佳的料筒温度可选择为600 ℃,以避免过低温度造成缺陷率增加,或过高料筒温度对模具的热冲击以及生产成本的增加。图6所示为应用实验3的工艺参数进行模拟得到的部分实验结果。由图可知,其温度分布、固相率分布、缺陷分布以及粘度分布不均匀的位置,均主要集中在冷料阱部位,说明此产品的模具设计十分合 理,当然这也与壳体部分体积较小,厚度较薄,所需的注射充型时间短有一定关系,本文作者曾就此进行过相关的研究[11]。

图6 实验3充型完毕时模拟结果

Fig.6 Results of simulation at end of filling process: (a) Temperature distribution; (b) Distribution of solid fraction; (c) Defects distribution; (d) Viscosity distribution

实验5到实验10为注射速度不断增加的过程。随着注射速度的增加,充型过程的温度变化越来越小,最大固相率相应减小,表面缺陷率及充型时间都有所降低;同时充型压力不断增加,而粘度变化减小,但变化都不是很大,这说明注射充型过程中,喷嘴及模具对浆料的剪切作用并不是很强烈。由于充型速度较低时,充型压力较小,可能会造成产品表面有熔接痕、产品轮廓不清晰,甚至模具型腔充不满、产品缺料不能成形等缺陷;而充型速度过高时,浆料对模具的冲击增大,同时容易造成充型过程中出现紊流现象,从而影响产品的表面质量和性能。因此,考虑到上述因素,同时结合本研究实验结果,较理想的注射速度为实验8的2.09 m/s或实验9的2.28 m/s。

由表4可知,实验3、8和15为螺杆剪切速率不断降低的过程。螺杆剪切速率的影响主要取决于注射前对浆料粘度的作用。从前面的分析可知,随着剪切速率的减小,浆料的粘度增大,从而对注射充型过程中的温度等参数产生影响,使得温度变化增大,并由此导致固相率增大、表面缺陷增多、充型压力增加及由其引起的充型时间的减小,这些特征均在数值模拟结果中体现出来了。因此,较佳的螺杆剪切速率选择实验3的578.76/s,对应的螺杆转速为168 r/min。

由表4可知,为观察模具温度对充型过程的影响,实验11~14及实验8为模具温度不断升高的过程。实验结果显示,模具温度对实验结果的影响并不是很大,缺陷和粘度都未发生变化。但模具温度较低时,浆料的冷却速度较大,且冷却速度不均匀性增加,产品各部位温差较大,现实生产中则表现为部分产品会产生翘曲、裂纹等缺陷。因此,较佳的模具温度为230 ℃。

综合以上实验结果分析,实验3对应的工艺参数较为理想。温度场显示浆料充型过程温度变化为565~600 ℃,且温差较大部位主要集中于冷料阱和浇道部位,壳体部位温度变化较小且分布均匀(图6(a))。固相率分布图(图6(b))与温度场(图6(a))的分布情况较为相似。缺陷及粘度变化主要位于冷料阱部分(图6(c)和(d)),壳体部位缺陷较少,接近于零,而粘度则处于一个较为稳定的值。浆料在整个充型过程中都以层流方式充型,充型过程平稳、顺利、完全。应用实验3进行的半固态AZ91D触变注射成形实验,已在本文作者其他相关论文中予以阐述[5, 19],结果表明:在此工艺参数条件下成形的产品,组织和力学性能都较为理想,组织中固相颗粒的平均等效尺寸为28.71 μm,拉伸强度达到239.24 MPa。

3 结论

1) 基于文献中AZ91D镁合金平行板压缩法和Couette流变仪的相关数据,拟合出本研究实验条件的剪切速率、固相率对半固态AZ91D合金的初始粘度和极限剪切粘度影响的关系式。

2) 料筒温度和剪切速率在浆料制备过程中对粘度有很大影响,继而影响成形过程中的其他参数;注射过程中,注射速度使喷嘴和浇口对浆料的剪切作用以及充型压力发生变化,从而影响其他参数;模具温度对实验结果参数的影响不大,但实际生产中也不可忽视。

3) 对比分析不同工艺参数条件下模拟的实验结果,在本研究实验条件下,较佳的料筒温度、注射速度、模具温度、螺杆转速的工艺参数分别为600 ℃、2.09 m/s或2.28 m/s、230 ℃和143 r/min。

4) 产品模具设计合理,较佳工艺参数模拟的结果显示充型过程平稳、顺利、完全,层流充型,温度及固相率变化大,缺陷多以及粘度变化大的部位均集中在冷料阱,壳体部位各结果参数几乎不变,且分布均匀。

REFERENCES

[1] FAN Z. Semisolid metal process[J]. International Materials Reviews, 2002, 47(2): 49-85.

[2] Czerwinski F. Injection molding magnesium alloys[J]. Advanced Materials & Processes, 2002, 160(11): 31-33.

[3] 胡红军, 杨明波, 彭 东, 王春欢. 镁合金触变注射成形技术综述[J]. 铸造, 2006, 55(8): 763-766.

HU Hong-jun, YANG Ming-bo, PENG Dong, WANG Chun-huan. Summary of magnesium alloy thixo-molding technology[J]. Foundry, 2006, 55(8): 763-766.

[4] CUI X P, LIU Y B, CAO Z Y, YANG X H, LIANG W. Influence of process conditions of thixomolding on the microstructure of magnesium mobile phone housing[J]. Materials Science Forum, 2005, 488/489: 377-380.

[5] ZHANG Y F, LIU Y B, ZHANG Q Q, CAO Z Y, CUI X P, WANG Y. Microstructural evolution of thixomolded AZ91D magnesium alloy with process parameters variation[J]. Mater Sci Eng A, 2007, 444: 251-256.

[6] KIM L K, KANG T H, KIM Y S, JEONG Y D , KWAK J S. Analytic and experimental method for making magnesium alloy products based on an injection moulding process[J]. International Journal of Advanced Manufacturing Technology, 2004, 23: 566-571.

[7] CZERWINSKI F, ZIELINSKA L, PINET P J, OVERBEEK J. Correlating the microstructure and tensile properties of a Thixomolded AZ91D Magnesium alloy[J]. Acta Materialia, 2001, 49: 1225-1235.

[8] GHOSH D, KANG K, BACH C, ROEMER J G. Development of ductile thixomolded magnesium alloys[C]//Proceedings of the 34th Anniversary Congregation of Metallurgists ‘Recent Metallurgical Advances in Light Metals Industries’. Canada, 1995: 473-479.

[9] 白越龙, 毛卫民, 李 强. 半固态金属充型过程数值模拟技术的研究进展[J]. 铸造技术, 2004, 25(12): 962-965.

BAI Yue-long, MAO Wei-min, LI Qiang. Research and development of the numerical simulation technology about filling process with semi-solid metallic materials[J]. Foundry Technology, 2004, 25(12): 962-965.

[10] ATKINSON H V. Modeling the semisolid process of metallic alloys[J]. Progress in Materials Science, 2005, 50: 341-412.

[11] ZHANG Y F, LIU Y B, CUI X P, CAO Z Y. Filling analysis for thixomolded process of AZ91D magnesium alloy[J]. Transaction Nonferrous Metals Society of China, 2006, 16: s117-s121.

[12] BARKHUDAROV M R, BRONISZ C L, HIRT C W. Three-dimensional thixotropic flow model[C]//KIRKWOOD D H, KAPRANOS P. Proceedings of the 4th International Conference on Semi-Solid Process of Alloys and Composites. Sheffield: University of Sheffield, 1996: 110-114.

[13] BARKHUDAROV M R. High pressure die casting simulation using FLOW-3D[J]. Die Cast Engineering, 1997, 5/6: 36-40.

[14] KAPRANOS P, KIRKWOOD K H. Modeling of structural breakdown during rapid compression of semisolid alloy slugs[C]//BHASIN A K. Proceedings of the 5th International Conference on Semi-Solid Process of Alloys and Composites. Golden: Colorado School of Mines, 1998: 11-19.

[15] 杨浩强, 谢水生, 李 雷, 黄国杰. 阻尼冷管法制备半固态浆料过程的数值模拟与参数优化[J]. 中国有色金属学报, 2006, 16(3): 488-494.

YANG Hao-qiang, XIE Shui-sheng, LI Lei, HUANG Guo-jie. Numerical simulation and parameters optimization of preparation of AZ91D magnesium alloy semi-solid slurry by damper cooling tube method[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 488-494.

[16] GEBELIN J C, SUERY M, FAVIER D. Characterisation of the rheological behaviour in the semi-solid state of grain-refined AZ91 magnesium alloys[J]. Mater Sci Eng A, 1999, 272: 134-144.

[17] 甄子胜, 毛卫民, 闫时建, 崔成林, 赵爱民, 钟雪友. 连续冷却条件下半固态AZ91D镁合金组织及流变特性[J]. 金属学报, 2003, 39(1): 71-74.

ZHEN Zi-sheng, MAO Wei-min, YAN Shi-jian, GUI Cheng-lin, ZHAO Ai-min, ZHONG Xue-you. Microstructure and rheological behavior of semi-solid state AZ91D alloy in continuously cooling process[J]. Acta Metallurgica Sinica, 2003, 39(1): 71-74.

[18] 毛卫民, 闫时建, 甄子胜, 钟雪友. 半固态AZ91D镁合金的触变性[J]. 金属学报, 2005, 41(2): 191-195.

MAO Wei-min, YAN Shi-jian, ZHEN Zi-sheng, ZHONG Xue-you. Thixotropic properties of semi-solid AZ91D magnesium alloy[J], Acta Metallurgica Sinica, 2005, 41(2): 191-195.

[19] 张友法, 刘勇兵, 张倩倩, 曹占义. 镁合金触变注射成形工艺优化及其数值模拟[J]. 北京科技大学学报, 2006, 28(s1): 94-96.

ZHANG You-fa, LIU Yong-bing, ZHANG Qian-qian, CAO Zhan-yi. Process optimization and numerical simulation for thixomolded magnesium alloy[J]. Journal of University of Science and Technology Beijing, 2006, 28(s1): 94-96.

基金项目:吉林大学‘985工程’资助项目

收稿日期:2007-07-10;修订日期:2007-11-29

通讯作者:曹占义,教授;电话:0431-85095874;传真:0431-85095876;E-mail: caozy@jlu.edu.cn

(编辑 何学锋)