DOI: 10.11817/j.ysxb.1004.0609.2020-36420

铝-镁异种合金板材超声焊接工艺

曹秒艳1, 2,田少杰1, 2,胡 晗1, 2,房凯旋1, 2

(1. 燕山大学 机械工程学院,秦皇岛 066004;

2. 燕山大学 河北省轻质结构装备设计与制备工艺技术创新中心,秦皇岛 066004)

摘 要:以6061铝合金和AZ31B镁合金板材为研究对象,采用单一变量法展开铝-镁异种合金板材超声焊接试验(振动频率为20 kHz)。以焊接参数(焊接压力、振幅、时间、焊件厚度)为单独变量展开焊件力学性能测试和焊件界面微观形貌观测。结果表明:当焊接压力小于0.3 MPa时,金属接触面之间摩擦热难以迅速生成,难以形成有效焊点;在以焊接振幅和焊接时间为单独变量的焊接试验中,当焊接振幅为8 μm、焊接时间为0.75 s时,焊件力学性能最佳;但是随上述参数进一步增加,导致焊接能量过大反而造成焊接力学性能下降;焊件厚度对焊接接头力学性能影响规律与焊接压力、振幅、时间基本一致,在焊件厚度为0.3 mm时达到最佳焊接效果,参数过大或过小均不利于有效焊接的形成;在维氏硬度测试中发现焊接硬度呈现由中心区域发散式扩散的硬度分布规律;随着焊接压力逐渐增加,焊件界面微观形貌呈现不同阶段特征,当呈现波浪形特征时焊接效果达到最佳。

关键词:轻合金;超声金属焊接;力学性能;微观形貌

文章编号:1004-0609(2020)-12-2789-09 中图分类号:TG456 文献标志码:A

铝、镁、钛等轻合金的开发利用在汽车轻量化[1]的大环境下得到了极大的发展,相应的铝、镁、钛等轻合金成形领域的研究也得到了快速发展,其中轻合金焊接工艺就是众多学者关注的重要领域之一。目前,常见的焊接方法包括电弧焊、电阻焊、摩擦焊、钎焊、激光焊、高频焊等,但是由于铝、镁、钛等轻合金的焊接性能差、导热率高、受热后容易吸氢氧化等特点,使得轻合金的焊接工艺成为阻碍轻合金应用的难题[2]。超声焊接技术就是在这种大背景下出现的。经过众多学者试验研究[3-5],证实超声焊接工艺的可行性和焊接件性能的可靠性。

超声金属焊接技术是通过对合金表面施加垂直方向的压力以及水平方向的高频振动,从而使得焊接件间的温度迅速提升形成牢固的焊接接头,实现材料的固相连接[6]。超声焊接技术具有突出优势[7-8]:首先,焊接件材料种类繁多,范围广泛,可焊接性强,如铜、镍、铝材料的焊接;第二,超声焊接技术对材料表面的粗糙度以及材料的清洁程度要求并不严格,不需要对材料表面做清洁及氧化膜去除处理,焊接方便、快捷;第三,超声焊接过程温度变化不足材料熔点的50%,避免材料发生严重变形或熔融;第四,超声焊接周期短,焊接接头具有良好的力学性能,对焊接周围区域的损伤较小。随着功率超声技术的发展,以及轻量化技术的要求,超声焊接技术的优越性越来越明显。

由于各种材料性能优势不同,将其组合使用可获得更良好的材料性能优势,因此复合材料的研制得到了广泛关注[9]。采用高性能轻质材料,是提高零部件性能、实现装备轻量化的有效途径之一[10],如铝制合金板材及管材、镁制合金板材及管材和其他多种金属与非金属组成的复合材料[11]。高性能轻质材料以铝、镁复合材为代表,镁合金质量更轻,比强度更高,具备优越的阻尼吸震降噪和吸热性能,其中以变形镁合金AZ31B为代表;而铝合金抗腐蚀性更好、价格低廉、应用广泛,以经过热处理预拉伸工艺后的铝合金6061为代表。为了使铝镁合金的性能优势充分互补,平衡材料的性能,铝镁复合材料的构建得到广泛研究与开发,被誉为21世纪最有发展潜力的非铁金属材料之一。

超声焊接工艺中,抗拉剪切强度、抗剥离强度以及焊接区域硬度是检验焊件焊接效果的重要力学性能指标。本文作者以6061铝合金板与AZ31B镁合金板为研究对象,展开铝-镁异种合金间的超声焊接试验;并运用焊件的抗拉剪切强度、抗剥离强度测试试验以及硬度测试试验探究不同焊接参数对于焊件性能的影响;最后通过观测不同压力参数下焊件界面微观形貌,进一步探究超声焊接成形机理。

1 铝-镁异种合金间超声焊接试验及力学性能测试

1.1 超声焊接试验

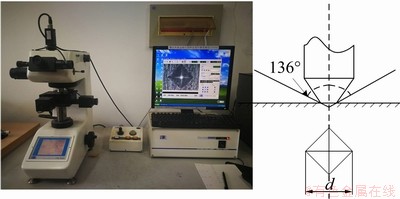

异种合金超声焊接试验在超声波金属点焊机上完成,其主要由试验参数控制箱、超声波振动系统以及铁砧组成。试验参数可通过焊接机控制面板进行设置,包括焊接压力、振幅、以及时间等重要焊接参数。试验装置如图1所示,在正式进行超声焊接试验之前,需要对焊接工具头进行最后的校核处理,方法是将一张复写纸夹于两张白纸中间,置于工作台上,通过气缸的作用使焊接工具头下压,观测白纸上是否留下颜色清晰均匀的压痕;若不均匀,对焊接工具头进行微调处理,直至白纸上的压痕清晰均匀为止。

图1 超声焊接试验装置

Fig. 1 Ultrasonic welding test equipment

焊接试验采用单一变量法,在固定其他焊接参数条件下,进行不同超声振幅、焊接压力、焊接时间、材料厚度的超声焊接试验。探究不同工艺参数对异种合金焊接效果的影响。

1.2 抗拉剪切强度力学性能测试试验

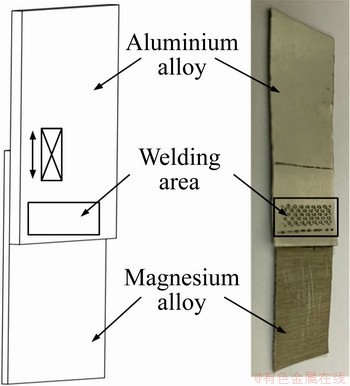

抗拉剪切强度测试试验用焊件搭接方式为上下反向搭接,其具体搭接方式如图2所示。

图2 抗拉剪切强度测试用焊件

Fig. 2 Testing tensile shear strength of welds

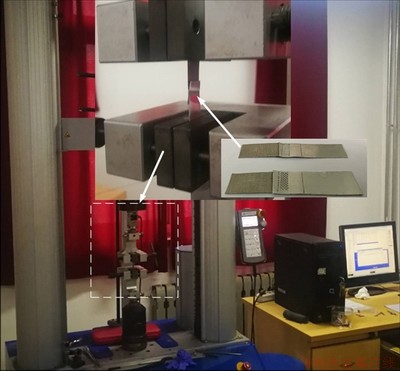

图3 焊件抗拉剪切强度测试

Fig. 3 Testing tensile shear strength of welds

抗拉剪切强度力学性能测试在电子万能试验机上进行,其焊件的抗拉剪切强度测试试验装置如图3所示。

为保证实验数据的准确性,取每种焊接参数下的3~4个试样进行拉伸测试,利用式(1)计算焊件抗拉剪切强度,并将获得的最接近的三组数据进行平均值计算。

(1)

(1)

式中:Q为焊接接头断裂最大载荷值(N);S为焊接接头的有效面积(mm2); 为剪切强度(MPa)。

为剪切强度(MPa)。

1.3 抗剥离强度力学性能测试试验

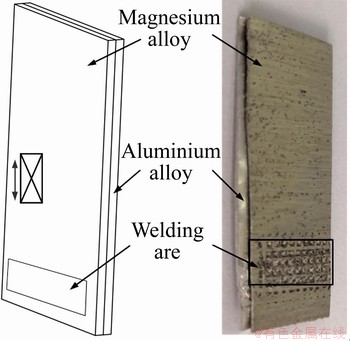

抗剥离强度测试试验用焊件搭接方式为上下同向平行搭接,其具体搭接方式如图4所示。

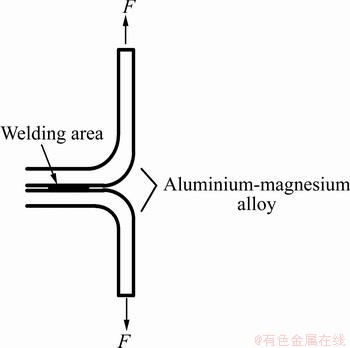

抗剥离强度测试试验同样在电子万能拉伸试验机上完成。在做剥离试验前,需要将超声焊件沿焊接接头区域垂直对折90°如图5所示。每个参数下取多个试件断裂时的最大载荷,并进行平均值计算,通过式(2)来计算焊接接头的抗剥离强度。

(2)

(2)

式中:F为焊接接头在断裂时的最大载荷值(N);B为有效受力线长度(mm); 为剥离强度(N/mm)。

为剥离强度(N/mm)。

图4 抗剥离强度测试用焊件

Fig. 4 Weld for peel strength test

图5 剥离强度测试示意图

Fig. 5 Schematic diagram of peel strength test

1.4 异种合金焊件硬度测试结果与分析

由于铝合金和镁合金均为物理特性较软的材料,焊件焊点的形成对镁合金或者铝合金硬度必然存在影响。为了探究不同参数对超声焊接接头硬度的影响规律,分别对不同参数下的焊件进行显微硬度测试。试验装置如图6所示,首先将待测样件平放在载物台上,通过位置的调整使施压装置对四棱锥形的金刚石压头(顶角为136°)加压,样件表面会形成一个压痕,保压一段时间后自动卸载。通过上位机显示锥压痕图形测量对角线的长度,将值代入式(3)来计算不同参数下材料不同位置的硬度值。

(3)

(3)

式中:HV为材料的维氏硬度值;F为试验力(N);d为两压痕对角线长度的平均值(mm)。

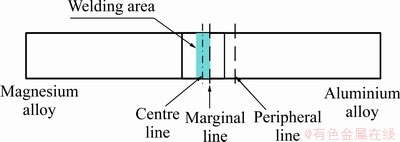

本文通过对同种合金不同压力参数下焊接件的不同位置进行了硬度测量,主要分为焊接区域的中心线位置、焊接区域的边缘线位置以及非焊接区域的外围线位置,如图7所示。为保证准确性,对每个位置区域进行多点取值,并对其进行平均值的计算。

图6 维氏硬度测试

Fig. 6 Vickers hardness test

图7 维氏硬度采点图

Fig. 7 Vickers hardness point chart

2 焊接参数对铝-镁异种合金超声焊件力学性能影响结果及分析

2.1 焊接振幅对抗拉剪切强度及抗剥离强度影响及分析

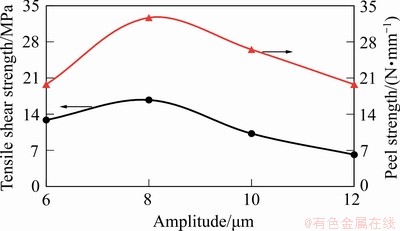

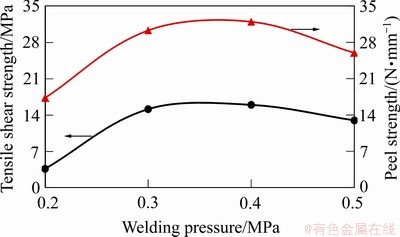

根据异种合金的焊接试验方案进行超声焊接试验,并进行力学性能测试试验。在焊件厚度均为0.3 mm、焊接时间为0.5 s、焊接压力为0.4 MPa的条件下,焊接振幅分别设定为6、8、10、12 μm获得不同振幅条件下焊件抗拉剪切强度和抗剥离强度变化规律如图8所示。

图8 焊接振幅对焊接接头力学性能影响曲线

Fig. 8 Influence curves of welding amplitude on mechanical properties of welded joint

由图8可知,在不同焊接振幅条件下,随焊接振幅的增大,不管是焊件抗拉剪切强度还是抗剥离强度均存在强度峰值点,在本试验条件下强度峰值点出现在振幅8 μm处。振幅未达到8 μm之前抗拉剪切强度和抗剥离强度随振幅增大而增大,振幅高于8 μm之后,抗拉剪切强度和抗剥离强度随振幅增大而减小。

焊接振幅对于力学性能的影响主要体现在改变振幅后,影响材料内部塑性流动的位错在低振幅条件下随振幅增加向着有利于塑性流动的趋势演变[12],导致材料塑性提高,材料犬牙交错的机械嵌合的焊点更容易形成。当振幅继续增大,一方面材料内部位错缠结严重,导致材料塑性降低,焊接效果减弱[13]不利于有效焊点的形成;另一方面,超声焊接过程中振幅与能量呈正比,大振幅的施加意味着高能量的输入,而较高的能量易在焊接接头处产生孔洞缺陷[14],导致焊接接头力学性能发生先增强后减弱的现象。

2.2 焊接压力对抗拉剪切强度及抗剥离强度影响及分析

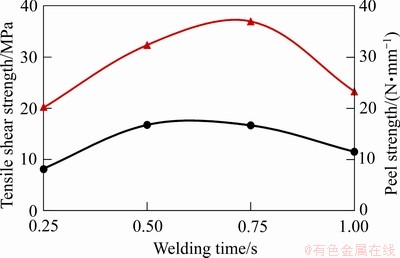

图9所示为在焊件厚度均为0.3 mm、焊接时间为0.5 s、焊接振幅为8 μm条件下,焊接压力分别为0.2、0.3、0.4、0.5 MPa时获得的抗拉剪切强度及抗剥离强度变化曲线。

图9 焊接压力对焊接接头力学性能影响曲线

Fig. 9 Influence curves of welding amplitude on pressure properties of welded joint

图9中所示在不同焊接压力条件下,随着焊接压力的增大,焊接接头的抗拉剪切强度曲线和抗剥离强度曲线一致的呈现先增大后减小的变化趋势,在焊接压力为0.35 MPa左右时焊接接头力学性能达到最大值。

焊接压力在小于0.35 MPa时,抗拉剪切强度和抗剥离强度随着焊接压力增大而增大。原因在于较低焊接压力时,超声振动在焊接面间的摩擦未生成足够使材料迅速温升的有效功,仅是焊接表面或焊接凸点间的摩擦,无论焊接振幅以及振动频率多大、焊接时间多长均不能对焊接效果产生明显影响;随着焊接压力的增大,摩擦产生的有效功得以体现,从而促进了有效焊点的形成。

在焊接压力大于0.4 MPa时,焊接接头的力学性能随着焊接压力的增大而减弱。过高焊接压力一方面会在焊接过程中将有效焊点压溃;另一方面压力过大导致摩擦过度。过多的能量输入焊接过程,同样会在焊接接头产生孔洞等缺陷,导致焊件力学性能降低。

2.3 焊接时间对抗拉剪切强度及抗剥离强度影响及分析

在焊接中,焊接时间被认为是影响焊缝强度和质量的最重要参数之一,其大小对焊接能量的输入起决定性作用,不仅影响材料的塑性变形,还对摩擦热的产生以及温升起到不可或缺的作用。图10所示为在焊件厚度均为0.3 mm、焊接压力为0.4 MPa、焊接振幅8 μm、焊接时间不同的情况下,焊接时间分别为0.25、0.5、0.75、1 s的条件下获得的抗拉剪切强度及抗剥离强度变化曲线。

图10 焊接时间对焊接接头力学性能影响曲线

Fig. 10 Influence curves of welding time on mechanical properties of welded joint

由图10可看出,随着焊接时间的增大,焊件的抗拉剪切强度在0.5 s到0.75 s之间达到最大值,抗剥离强度在0.75 s附近达到峰值;整体呈现先增强后减弱的趋势。

超声焊接时间导致焊件力学性能产生先增后减规律性变化的主要原因在于:焊接时间过短,导致金属接触面间大面积氧化物还未被清除,只能形成焊件凸点间的连接,无法形成大面积有效焊点,导致焊接接头力学性能较差;焊接时间过长,焊件间产生热量过多,材料产生严重变形,且材料因温升过高接近材料熔点使材料变软,焊点极易发生压损,导致有效焊点面积变小,从而影响焊件的力学性能。

2.4 焊件厚度对抗拉剪切强度及抗剥离强度影响及分析

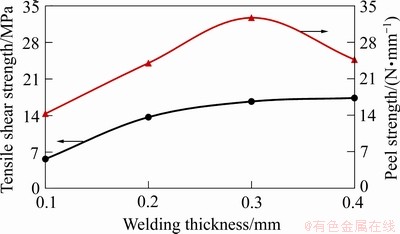

在焊接压力为0.4 MPa、焊接振幅8 μm、焊接时间为0.5 s、镁合金AZ31B板厚为0.3 mm条件下,铝合金板厚分别为0.1、0.2、0.3和0.4 mm时抗拉剪切强度及抗剥离强度变化曲线如图11所示。

图11 焊件厚度对焊接接头力学性能影响曲线

Fig. 11 Influence curves of welding thickness on mechanical properties of welded joint

在其他焊接参数相同的情况下,发现在镁合金AZ31B板材厚度不变的情况下,随着铝合金6061板材厚度的增大,焊接接头的力学性能在铝合金板材厚度0.3 mm附近达到最佳焊接效果,同样呈现先升后降的规律。

该结果说明当焊件厚度较薄时,同等条件下的焊接参数使得焊件温升更加迅速,材料软化效果也更加明显,有效焊点也更易被压溃,导致焊件力学性能降低。

超声焊接过程中,由于焊接温度场呈现由中心向四周逐渐衰减的规律[15],当焊件过厚时,过多的温度散失在传导的过程中,有效焊点形成所需的温度提供不足,导致焊接件接头的力学性能呈现减小趋势。

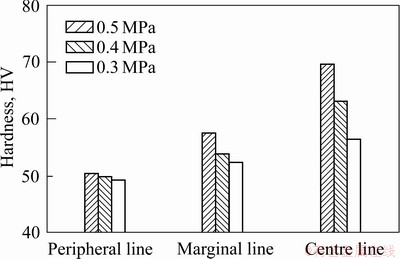

2.5 焊接压力对不同焊接位置硬度影响

通过采集在超声振幅8 μm、不同焊接压力焊件焊接区域下外围线、边缘线和中心线三个位置的维氏硬度,获得焊接压力对铝镁异种合金的微观硬度的影响曲线如图12所示。

图12 焊接压力对维氏硬度影响曲线

Fig. 12 Effect of welding pressure on vickers hardness curve

由图12可知,在不同压力条件下维氏硬度值出现了由焊接中心向外围梯度式降低的现象,这与文献 [15]中温度场的位置变化规律一致,且随着压力的增加,硬度值得到明显的提升。

这一现象主要是因为增大压力,焊接接触面间的接触得到进一步的贴合,更多的摩擦有用功得以生成,温度进一步升高,材料内部晶粒细化,晶体内亚晶界增多[16],从而改善了材料力学性能。

2.6 焊接参数对焊件力学性能影响及分析

通过改变超声焊接参数(焊接振幅、焊接压力、焊接时长、焊件厚度)获得的焊件焊接性能结果可以看出:焊接振幅、焊接压力、焊接时长、焊件厚度等在超声焊接中均存在最佳值,使焊接达到最佳效果。

超声焊接过程中焊接参数对于焊接效果的影响主要有两个方面:首先,超声振动对于材料内部微观组织的影响,超声振动的介入使材料发生“软化”,材料内部位错向着有利于塑性流动的方向发展。而长时间、大振幅的超声振动又会导致材料发生“硬化”,材料内部位错发生塞积、堆垛,使材料塑性变差,这也是超声振幅过大(大于8 μm)时,焊件力学性能变差的根本原因。其次,超声焊接过程主要是超声焊头与焊件、焊件之间、焊件与下砧板之间进行摩擦,焊件间瞬间产生大量热,致使材料局部融化使材料间发生固相连接,而在焊件间进行热输入的同时,材料相应的发生热致软化。参数过高导致材料热输入过量,材料软化程度加剧,导致焊接接头处容易发生焊件压溃、焊接接头区域变薄等现象,最终导致材料力学性能减弱。

3 超声焊接微观形貌观测分析与焊接机理

3.1 超声焊件微观形貌及组织观测

微观形貌的观察是检验焊接质量的有效方法,同时为不同参数下焊件的力学性能试验分析提供微观组织焊接机理依据,焊接接头的微观形貌充分地反映了焊接的形成过程以及焊接接头的质量状态。所以本节通过观测不同压力下的焊件界面微观形貌探讨不同参数对焊接成形机理的影响。

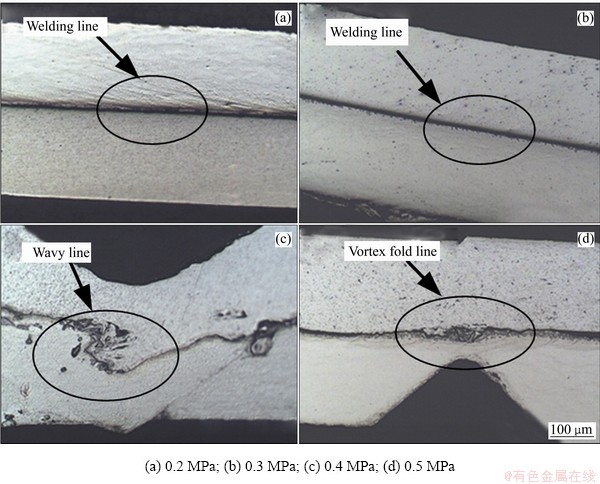

在超声焊接件时间为0.5 s焊接振幅为8 μm、焊件厚度均为0.3 mm、焊接压力分别为0.2、0.3、0.4、0.5 MPa情况下的制备试样,在显微镜的放大倍率200倍下获得微观组织形貌如图13所示。

在焊接压力为0.2 MPa时,焊接区域以焊接线的形式存在,且焊接线平整、粗大,说明在此焊接条件下,焊接结合较弱,大面积有效焊点并未生成,焊件之间只是较弱的搭接在一起,焊接面并未实现良好的接触。在焊接压力为0.3 MPa时,焊件界面间的焊接线明显变细,且焊接线更加平整,由于随着焊接压力的增大,摩擦功的加大促进了能量的持续输入,使得接触面间的材料软化,从而促进了焊接面的有效结合。在焊接压力为0.4 MPa时,整个结合面发生了良好的接触,焊接线进一步细化,且焊接线以波浪线的形态存在,说明随着焊接压力的继续加大,材料得到充分的软化,在超声振动的作用下,使得接触面形成了波浪线的形态,此时达到最佳焊接状态。在焊接压力为0.5 MPa时,焊接面虽然发生了良好的接触,接触线同样存在波浪线的形式,但是相比于焊接压力为0.4 MPa时焊接件的微观组织形貌,焊接线开始变宽,这是由于在材料的充分软化状态下,高能量的持续输入,使得金属界面间形成的焊接线发生折叠现象,焊接线从细小的波浪形转变为涡旋形,焊点的嵌入深度较深,不仅在较深焊点部位产生涡旋形焊接线,而且将焊件压溃导致焊接件的厚度变薄。

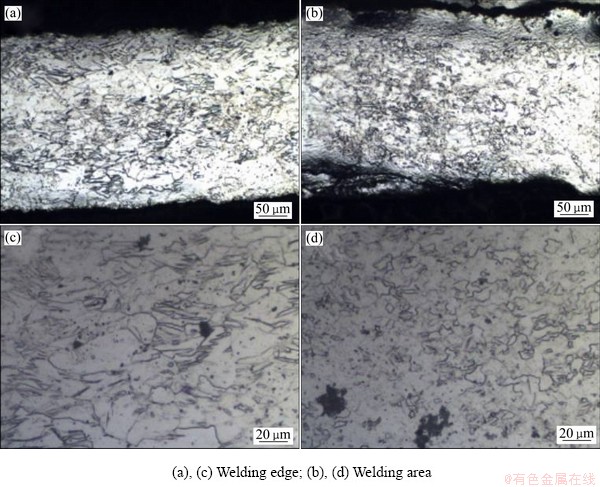

图14所示为超声焊接件时间为0.5 s焊接振幅为8 μm、焊件厚度均为0.3 mm、焊接压力分别为0.3 MPa下的AZ31B镁合金金相组织图。

由图14可看出,超声焊接结束后,在焊接边缘区域轧制态镁合金组织晶粒相对于焊接区域较大,其中细长条状晶粒较多,晶粒尺寸大约为18 μm;在焊接区域出现细小晶粒,晶粒尺寸在6 μm左右;这可能是由于在超声焊接过程中,超声振动一方面导致剧烈的塑性变形,另一方面摩擦热达到较高变形温度导致材料发生动态再结晶,且细化程度出现由中心向四周逐渐衰减的变化,与焊接接头硬度变化规律类似,导致焊接接头处力学性能出现由中心向四周逐渐衰减的规律性变化。

3.2 超声焊接机理探究

由不同焊接压力的微观组织形貌可得:在低焊接压力情况下,焊接区域虽产生了结合,但是并未发生明显的波浪线位移。随着焊接压力的增加,焊接界面发生超声软化现象,在超声振动的作用下使得界面产生明显的波浪形结合,且焊接线发生明显的细化现象。

图13 不同焊接压力下焊件微观形貌

Fig. 13 Microstructures of welds under different welding pressures

图14 不同焊接区域金相组织

Fig. 14 Microstructures of different welding areas

当焊接压力进一步增大发现波浪形位移逐渐消失,取而代之的是波浪折叠线结合,使得焊接界面的接触线逐渐变宽。由焊件的力学性能试验可知:压力为0.4 MPa时,焊接力学性能最好;而此时正好是焊接线呈现波浪形结合形态的时候。当焊接压力大于0.4 MPa时,焊件的力学性能出现下降趋势。整个超声焊接试验过程焊接面间的焊接线演变主要分为三个阶段:

第一阶段为弱连接阶段,此时焊接区域均生成明显的焊接线,说明焊接件已经发生明显的结合,但并未产生材料的软化现象。此状态下的焊件的力学性能较差。

第二阶段为波浪形阶段,此阶段为焊接性能最佳阶段。随着超声焊接参数的增大,有效能量的输入使得材料产生迅速的温升,接触面间的材料得以完全软化。从而使得焊接工具头滚花的嵌入深度逐渐变深,焊件在焊接工具头的作用下生成波浪线形状的焊接线。此时超声焊接件的结合最佳。

第三阶段为折叠形阶段。在超声焊接件形成波浪形焊接线时,若继续增大超声焊接工艺参数,超声能量的输入使得焊接线在波浪形状态下逐渐发生重叠,且焊接线变粗变宽,使得焊接效果曲线弱化。此时由于在材料完全软化的状态下高能量的持续输入导致焊接线重叠,焊件较软位置发生焊件压溃现象焊件变薄,从而导致焊件力学性能有弱化趋势。此时焊件较波浪形连接阶段焊件力学性能相对较弱。

超声焊接工艺的连接机理是学术界主要探讨问题之一。由不同焊接压力参数下的微观形貌图可知:材料焊接界面虽发生波浪形位移,但整体较为平整,是板材在焊头压力和焊头高频振动作用下发生相对运动,生成的摩擦热以及超声振动的声软化效应使板材的塑性流动能力增强,从而实现材料的固相连接。这与文献[17]发现的超声焊接界面间的温度并未达到材料的熔点而实现冶金连接的现象一致。

4 结论

1) 通过抗拉剪切强度和抗剥离强度测试试验得知铝/镁异种合金超声焊接工艺参数(焊接振幅、时间、焊接压力以及焊件厚度)对焊接接头力学性能的影响规律基本一致:随着超声焊接工艺参数的增大,焊接接头的力学性能基本呈现先增强后减弱的趋势;在以焊接振幅、焊接时间、焊接压力、焊件厚度为单独变量的焊接试验方案中,8 μm振幅、焊接时长0.75 s、焊接压力0.35 MPa、焊件厚度3 mm时焊接效果最为理想;工艺参数的大小对能量的传递起到重要作用,直接决定焊接界面能否形成有效的温升实现材料间的固相连接。

2) 不同焊接压力条件下焊件硬度呈现由中心区域向外围梯度式降低的分布规律,且中心区域硬度最高;这与超声焊接温度场变化规律一致,准确的验证了超声焊接试验中焊接参数对焊件力学性能影响规律的可靠性。

3) 通过对不同焊接压力下焊接接头的微观形貌进行观测发现:随着超声焊接压力的增加,焊接接头微观组织形貌具有不同焊接阶段的特征:弱连接阶段(0.2 MP、0.3 MPa)、波浪形阶段(0.4 MPa)、折叠形阶段(0.5 MPa)。波浪形阶段(0.4 MPa)的焊接效果最佳,力学性能也最可靠。

REFERENCES

[1] 范子杰, 桂良进, 苏瑞意. 汽车轻量化技术的研究与进 展[J]. 汽车安全与节能学报, 2014, 5(1): 1-16.

FAN Zi-jie, GUI Liang-jin, SU Rui-yi. Research and development of automotive lightweight technology[J]. Journal of Automotive Safety and Energy, 2014, 5(1): 1-16.

[2] 宋友宝, 李 龙, 吕金明, 严 安, 周德敬. 7xxx系铝合金焊接研究现状与展望[J]. 中国有色金属学报, 2018, 28(3): 492-501.

SONG You-bao, LI Long, Lü Jin-ming, YAN An, ZHOU De-jing. Research status and perspective of 7xxx series aluminum alloys welding[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(3): 492-501.

[3] TSNJINO J, UEOKA T, KIKUCHI Y. Configuration of large capacity ultrasonic complex vibration sources with complex transverse vibration rods and a disk with multiple transducers[J]. JSME International Journal, 2006, 49(3): 695-702.

[4] NAMBU S, SETO K, LIN J Y, KOSEKI T. Development of a bonding interface between steel/steel and steel/Ni by ultrasonic welding[J]. Science and Technology of Welding & Joining, 2018, 23(8): 687-692.

[5] REN Da-xin, ZHAN Kun-min, PAN Min, GANG Song, ZHAN De-wang. Ultrasonic spot welding of magnesium alloy to titanium alloy[J]. Scripta Materalia, 2017, 126: 58-62.

[6] 刘 鹏, 李亚江, 耿浩然, 王 娟, 颜礼文. Mg/Al异种金属的焊接研究现状[J]. 焊接技术, 2006, 35(2): 23-24.

LIU Pen, LI Ya-jiang, GENG Hao-ran, WANG Juan, YAN Li-wen. Research status of welding of Mg/Al dissimilar metals[J]. Welding Technology, 2006, 35(2): 23-24.

[7] WATANABE T, SAKUYAMA H, YANAGISAWA A. Ultrasonic welding between mild steel sheet and Al-Mg alloy sheet[J]. Journal of Materials Processing Technology, 2009, 209(15/16): 5475-5480.

[8] 阮世勋, 雷运青. 金属超声焊及应用[J]. 新技术新工艺, 2004(12): 38-40.

RUAN Shi-xun, LEI Yun-qing. Ultrasonic metal weld and its applications[J]. New Technology & New Process, 2004(12): 38-40.

[9] 柳绪静, 刘黎明, 王 恒, 宋 刚. 镁铝异种金属激光-TIG复合热源焊焊接性分析[J]. 焊接学报, 2005, 26(8): 40-43, 5.

LIU Xu-jing, LIU Li-ming, WANG Heng, SONG Gang. Analysis of weldability of laser-TIG composite heat source for magnesium-aluminum heterogeneous metals[J]. Transactions of the China Welding Institution, 2005, 26(8): 40-43, 5.

[10] 杨 龙, 黄 玲. 内高压热态成形设备设计研发[J]. 机械设计与制造, 2018, 326(4): 221-223, 227.

YANG Long, HUANG Ling. The design of a device for inner high pressure forming at elevated temperature[J]. Machinery Design & Manufacture, 2018, 326(4): 221-223, 227.

[11] 王建辉, 黄澜涛, 张 靖. 轻合金成形制造技术浅析[J]. 机电信息, 2017(24): 100-101.

WANG Jian-hui, HUANG Lan-tao, ZHANG Jing. Brief analysis on manufacturing technology of light alloy forming[J]. Mechanical and Electrical Information, 2017(24): 100-101.

[12] 姚喆赫, 陈子辰, 梅德庆. 超声能场在金属微/介观成形中的作用理论及实验研究[J]. 机械工程学报, 2018, 54(1): 98.

YAO Zhe-he, CHEN Zi-chen, MEI De-qing. Theorical and experimental studies on effects of ultrosonic energy field in micro/meso metal forming[J]. Journal of Mechanical Engineering, 2018, 54(1): 98.

[13] 蒋少松, 杨天豪, 孙宏宇, 何玉石, 卢 振, 王瑞卓. 超声波振动对钛箔拉伸性能及位错分布的影响[J]. 材料工程, 2019, 47(2): 84-89.

JIANG Shao-song, YANG Tian-hao, SUN Yu-hong, HE Yu-shi, LU Zhen, WANG Rui-zhou. Influence of ultrasonic vibration on tensile properties and dislocation distribution of titanium foil[J]. Journal of Materials Engineering, 2019, 47(2): 84-89.

[14] 赵玉津, 张慧敏, 罗 震, 冯梦楠, 郭 客. 焊接能量对铝/钛超声波焊接接头性能的影响[J]. 天津大学学报(自然科学与工程技术版), 2017, 50(1): 43-48.

ZHAO Yu-jing, ZHANG Hui-ming, LUO Zhen, FENG Meng-nan, GUO Ke. Effect of welding energy on the performance of the Al/Ti joints obtained by ultrasonic welding[J]. Journal of Tianjin University (Science and Technology), 2017, 50(1): 43-48.

[15] 李 欢, 曹 彪, 杨景卫, 崔晓宇. Cu-Al异种金属超声焊接过程模拟[J]. 焊接学报, 2017, 38(8): 5-9, 129.

LI Huan, CAO Biao, YANG Jing-long, CUI Xiao-yu. Ultrasonic welding process simulation of Cu-Al dissimilar metal[J]. Transactions of the China Welding Institution, 2017, 38(8): 5-9, 129.

[16] 叶雄林, 朱有利. 超声冲击细化22SiMn2TiB超高强钢焊接接头晶粒研究[J]. 热加工工艺, 2006(6): 12-14.

YE Xiong-ling, ZHU You-li. Investigation on fining grain of ultrahigh strength steel welding joint by ultrasonic impact treatment[J]. Hot Working Technology, 2006(6): 12-14.

[17] HUI Huang, CHEN Jian, YONG Chae-lim, HU Xiao-hua, CHENG Jia-hao, FENG Zhi-li, SUN Xin. Heat generation and deformation in ultrasonic welding of magnesium alloy AZ31[J]. Journal of Materials Processing Tech, 2019, 272: 125-136.

Ultrasonic welding technology of aluminum-magnesium alloy plates

CAO Miao-yan1, 2, TIAN Shao-jie1, 2, HU Han1, 2, FANG Kai-xuan1, 2

(1.College of Mechanical Engineering, Yanshan University, Qinhuangdao 066004, China;

2. Hebei Light Structural Equipment Design and Manufacturing Technology Innovation Center, Yanshan University, Qinhuangdao 066004, China)

Abstract: The ultrasonic with the vibration frequency of 20 kHz welding test of 6061 and AZ31B was conducted through single variable method. The samples with an independent variable welding parameters (welding pressure, amplitude, time, welding thickness) were tested for mechanical properties and interface micro-morphology. The results show that, when the welding pressure is less than 0.3 MPa, the heat of friction cannot be generated quickly between metal contact surfaces. Therefore, it is difficult to form the effective solder joints. In the welding test using welding amplitude and welding time as independent variables, the welding amplitude of 8 μm and welding time of 0.75 s will result in the best mechanical performance. However, with the further increase of the above parameters, the excessive welding energy will lead to mechanical degradation. The effect of welding thickness on mechanical properties of welding parts is consistent with welding pressure, amplitude and time, the welding effect is best when the welding part thickness is 0.3 mm, in appropriated parameter is not conducive to effective welding formation. In Vickers hardness test, the distribution of welding hardness appeared from the center to outward. With the increase of welding pressure, the interface micro-morphology of welded parts presents different stage characteristics. The welding effect is the best when the interface micro-morphology of the welded part presents the wave shape.

Key words: light alloy; ultrasonic metal welding; mechanical properties; micro-morphology

Foundation item: Projects(51775480, 51305385) supported by the National Natural Science Foundation of China; Project(E2018203143) supported by the Natural Science Foundation of Hebei Province, China

Received date: 2019-06-18; Accepted date: 2020-05-16

Corresponding author: CAO Miao-yan; Tel: +86-335-8057031; E-mail: jacmy@ysu.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51775480,51305385);河北省自然科学基金资助项目(E2018203143)

收稿日期:2019-06-18;修订日期:2020-05-16

通信作者:曹秒艳,教授,博士;电话:0335-8057031;E-mail:jacmy@ysu.edu.cn