碳纳米管和碳化硅对铜混合纳米复合材料显微组织和干滑动磨损行为的影响

来源期刊:中国有色金属学报(英文版)2016年第12期

论文作者:H. M. MALLIKARJUNA C. S. RAMESH P. G. KOPPAD R. KESHAVAMURTHY K. T. KASHYAP

文章页码:3170 - 3182

关键词:铜;碳纳米管;碳化硅;显微硬度;磨损机制;纳米复合材料

Key words:copper; carbon nanotubes (CNTs); SiC; microhardness; wear mechanisms; nanocomposite

摘 要:研究了多壁碳纳米管和碳化硅包覆铜增强铜基混合纳米复合材料的显微组织和摩擦性能。碳纳米管含量为1%~4%,碳化硅含量固定在4%。铜杂化纳米复合材料的合成过程包含球磨、冷压、烧结,随后热压。对混合纳米复合材料进行了密度、晶粒尺寸和硬度测试。在不同载荷条件下,在销-钢盘摩擦仪上采用干滑动磨损评估纳米复合材料的摩擦性能。结果表明,与纯铜相比,混合纳米复合材料的晶粒尺寸明显减小,4%碳纳米管增强杂化纳米复合材料的显微硬度提高了80%。混合纳米复合材料中碳纳米管含量的增加导致材料的摩擦因数和磨损率降低。

Abstract: Microstructure and tribological properties of copper-based hybrid nanocomposites reinforced with copper coated multiwalled carbon nanotubes (MWCNTs) and silicon carbide (SiC) were studied. Carbon nanotube was varied from 1% to 4% with silicon carbide content being fixed at 4%. The synthesis of copper hybrid nanocomposites involves ball milling, cold pressing and sintering followed by hot pressing. The developed hybrid nanocomposites were subjected to density, grain size, and hardness tests. The tribological performances of the nanocomposites were assessed by carrying out dry sliding wear tests using pin-on-steel disc tribometer at different loads. A significant decrease in grain size was observed for the developed hybrid composites when compared with pure copper. An improvement of 80% in the micro-hardness of the hybrid nanocomposite has been recorded for 4% carbon nanotubes reinforced hybrid composites when compared with pure copper. An increase in content of CNTs in the hybrid nanocomposites results in lowering of the friction coefficient and wear rates of hybrid nanocomposites.

Trans. Nonferrous Met. Soc. China 26(2016) 3170-3182

H. M. MALLIKARJUNA1,2, C. S. RAMESH3, P. G. KOPPAD4, R. KESHAVAMURTHY5, K. T. KASHYAP6

1. Advanced Composites Research Centre, P E S Institute of Technology, Bangalore 560085, India;

2. Department of Mechanical Engineering, Government Engineering College, K.R. Pet 571426, India;

3. Department of Mechanical Engineering, Alliance College of Engineering & Design, Alliance University, Anekal, Bangalore 562106, India;

4. Department of Mechanical Engineering, CMR Institute of Technology, Bangalore 560037, India;

5. Department of Mechanical Engineering, DayanandaSagar College of Engineering, Bangalore 56078, India;

6. Department of Mechanical Engineering, School of Engineering and Technology, Jain University, Bangalore, India

Received 2 November 2015; accepted 24 February 2016

Abstract: Microstructure and tribological properties of copper-based hybrid nanocomposites reinforced with copper coated multiwalled carbon nanotubes (MWCNTs) and silicon carbide (SiC) were studied. Carbon nanotube was varied from 1% to 4% with silicon carbide content being fixed at 4%. The synthesis of copper hybrid nanocomposites involves ball milling, cold pressing and sintering followed by hot pressing. The developed hybrid nanocomposites were subjected to density, grain size, and hardness tests. The tribological performances of the nanocomposites were assessed by carrying out dry sliding wear tests using pin-on-steel disc tribometer at different loads. A significant decrease in grain size was observed for the developed hybrid composites when compared with pure copper. An improvement of 80% in the micro-hardness of the hybrid nanocomposite has been recorded for 4% carbon nanotubes reinforced hybrid composites when compared with pure copper. An increase in content of CNTs in the hybrid nanocomposites results in lowering of the friction coefficient and wear rates of hybrid nanocomposites.

Key words: copper; carbon nanotubes (CNTs); SiC; microhardness; wear mechanisms; nanocomposite

1 Introduction

Carbon nanotubes (CNTs) possess superior mechanical, thermal and electrical properties, and have received considerable interest globally from the scientific community. The extremely high elastic modulus of 0.9-2 TPa, ultimate tensile strength close to 63 GPa and thermal conductivity of 3000 W/(m·K), high electrical conductivity of >106 S/m for single wall carbon nanotube (SWCNT) and >105 S/m for multiwalled carbon nanotube (MWCNT) have prompted material scientists and engineers to use them as emerging reinforcement for polymer, ceramic and metal matrix composites [1-3]. The last decade has seen a surge in research papers on CNT reinforced metal matrix composites in particular aluminium, copper, magnesium and nickel matrices based ones. Most of the papers have reported improved mechanical properties with addition of CNTs to the metal matrices [4-6].

In recent years, hybrid composites with multiple reinforcements have been developed which possess the combined properties of both the reinforcements. For applications like electrical sliding contact materials, the material should not only have good electrical properties but also possess excellent wear resistance. Copper is well known for its high electrical (5.8×107 S/m at 20 °C), and thermal conductivity (400 W/(m·K)), high coefficient of thermal expansion (17×10-6 K-1) with low strength (<220 MPa) and poor wear resistance. The hard ceramic particles like SiC [7], Al2O3 and TiC [8] which possess higher hardness, good abrasion resistance and high melting point can contribute to improvement in the strength as well as wear resistance of metal matrix composites. On the other hand, soft solid lubricating materials like graphite [9,10], carbon fibers [11] and MoS2 are used as secondary reinforcement. These solid lubricants enhance the tribological properties by formation of a thin solid lubricating film on the tribo-surface. This lubricating layer reduces the friction coefficient and decreases the wear rates. The inclusion of hard and soft reinforcement in copper matrix can enhance both strength and wear resistance which are much needed for sliding contact applications [12,13]. ZHAN and ZHANG [10] have reported the friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles developed by powder metallurgy technique. The dry sliding wear tests have been conducted using block on ring type tribometer at different loads. Copper-SiC-graphite composites do exhibit better tribological properties than that of Cu-SiC composites. Delamination wear was identified as a predominant wear mechanism in hybrid composites when tested under high loads. The worn surface analysis showed the presence of graphite-rich mechanically mixed layer contributing towards good anti-friction properties. RAMESH et al [7] have developed Cu-SiC- graphite hybrid composites by liquid metallurgy technique. It is reported that there is beneficial effect of graphite on the tribological properties of developed hybrid composites. The friction coefficient and wear rate of the developed hybrid composites were in between the values obtained for Cu-SiC and Cu-graphite composites. RAJKUMAR and ARAVINDAN [8] have reported the tribological properties of microwave sintered Cu-TiC- graphite hybrid composites. The friction coefficient and wear rates of hybrid composites were lower when compared with those of unreinforced copper. This has been attributed to the formation of mechanically mixed layer with high graphite content at the contact region of the tribo-surface. However, with the increase in sliding velocity from 1.25 to 2.51 m/s, an increase in friction coefficient as well as wear rate of hybrid composites has been reported.

In recent years, CNTs have been considered as a possible replacement for graphite in the conventional and hybrid composites owing their lubricating nature in addition to their high strength, thermal and electrical conductivity. In this regard, there are reports about development of self-lubricating composites for auto- motive applications using carbon nanotubes as reinforcement [13-15]. However, limited research has been done in synthesis and characterization of metal matrix hybrid nanocomposites involving CNT and SiC as reinforcements.

In the light of the above, this work focuses on development of copper hybrid nanocomposites with CNT and SiC as reinforcements using powder metallurgy technique. The effects of varying CNT mass fraction with fixed content of SiC on the microstructure, hardness, friction and wear properties of copper hybrid nanocomposites are discussed.

2 Experimental

2.1 Materials

Multiwalled carbon nanotubes with diameter in the range of 20-40 nm, length1-10 μm and density of 2.1 g/cm3, have been used as one of the reinforcement (As supplied by Chengdu Organic Chemicals Co., Ltd, China). The other reinforcement used is silicon carbide particles with size ranging in 20-30 μm and density of 3.21 g/cm3(Supplied by Grind well Norton, India). Lab grade electrolytic copper powder with 99.5% purity having particle size ranging from 2 to 8 μm and density of 8.94 g/cm3 was used as matrix material to develop copper-based hybrid nanocomposites.

2.2 Electroless copper coating on MWCNTs and SiC

It is well known that both MWCNT and SiC are non-wetting with copper owing to their high surface tension. In order to improve the interfacial bonding between MWCNT and SiC with that of copper, a conventional electroless coating method has been employed to coat both the reinforcements with copper. Precleaning of MWCNTs and SiC was carried out by HNO3 for about 5 h and oxidizing of its surfaces using nitric acid for 15 min at 60 °C to remove any unwanted impurities on MWCNTs and SiC. Further, sensitization of cleaned MWCNTs and SiC particles in stannous chloride solution was carried out followed by activation in palladium chloride solution. The activated MWCNTs and SiC particles were introduced into the electroless copper bath and copper coating obtained under optimal process conditions as reported by previous works [16-18].

2.3 Synthesis of hybrid nanocomposites

Different mass fractions of MWCNTs (1% to 4%) and SiC (4% fixed) with pure copper powder were mixed in a planetary ball mill (Supplied by Insmart Systems, Hyderabad, India). The vial of planetary ball mill was filled with matrix and reinforcement powders with stainless steel ball maintaining the ball to powder ratio to be 8:1. The speed of the vial was kept at 300 r/min with milling duration being 3 h. In order to avoid oxidation of starting powders during ball milling, ethanol was added as a process controlling agent. The milled composite powders were compacted by applying a pressure of 400 MPa using a 100 t hydraulic press for duration of 5 min. These green compacted samples were sintered in an electric furnace at 900 °C for about 8 h under argon-protected atmosphere. This was followed by hot pressing of the sintered powder compacts at a pressure of 400 MPa to improve the density of copper and hybrid nanocomposites.

2.4 Characterization

The theoretical densities of the copper and its hybrid nanocomposites were calculated by using rule of mixture while the actual density of copper and its nanocomposites samples were measured using Archimedes principle. The microhardness (HV) of copper and the developed nanocomposites were measured using Shimadzu Micro hardness tester. The hardness measurements were carried out on polished surface of hardened steel disc, pure copper and hybrid nanocomposite samples. A load of 500 g was applied on surface of the samples with dwell time of 10 s. An average hardness has been reported by making eight indentations at different locations on the specimen. The shape and size of milled hybrid nanocomposite powders and microstructure of hot-pressed hybrid nanocomposite samples were characterized by scanning electron microscope (JEOL 840A JSM) equipped with EDS and TEM.

2.5 Friction and wear test

The effects of addition of CNT and SiC on friction and wear properties of hybrid nanocomposites have been studied using a pin-on-disc tribometer (Make Ducom TR20-LE, Bangalore, India) in accordance with ASTM G99.

Cylindrical pins of 10 mm in diameter and 8 mm in length were served as test specimens while hardened steel disc with hardness HRC 62 (HV 790) was used as counter surface. The frictional force was measured by force transducer of accuracy of ±1 N. Tests were performed under ambient conditions (temperature 24 °C, humidity 50%) in air at a sliding velocity of 0.31 m/s for a total sliding distance of 558 m. Load was varied between 10 and 50 N in step of 10 N. The test duration for all the tests was maintained at 30 min.

The friction coefficients (μ) of copper and hybrid nanocomposites were evaluated by using the following formula:

μ=F/N (1)

where F is the frictional force and N is the normal force.

The wear rates of copper and composite samples were determined using mass loss method. In this method, the mass of copper and hybrid nanocomposite specimens were weighed before and after the wear test. A weighing balance with an accuracy of ±0.1 mg was used to calculate wear loss of composites.

Wear rate (Rw) was calculated by the following formula:

RW=Δm/(ρL) (2)

where Δm is the mass loss, ρ is the density, L is the sliding distance.

3 Results and discussion

3.1 Powder analysis

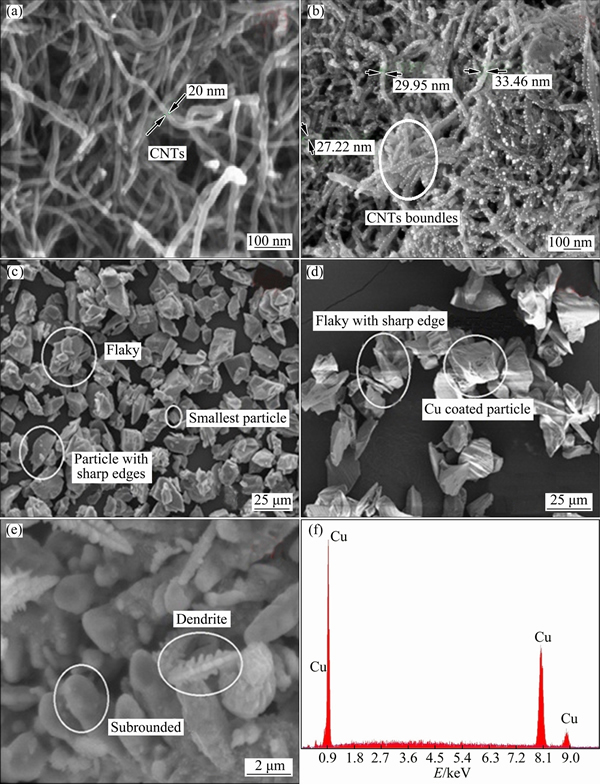

Figures 1(a) and (b) show the SEM images of uncoated and copper coated MWCNTs. The uncoated MWCNTs have the outer diameter in the range of 20-40 nm while its length ranges 1-10 μm. The outer diameter of copper coated MWCNTs lies in the range of 30-50 nm. Figures 1(c) and (d) show the SEM images of uncoated and copper coated silicon carbide. Uncoated silicon carbide exhibits angular shape with particle size ranging from 20 to 30 μm. Coated silicon carbide particles appear to be bright with their size ranging from 25 to 35 μm. Figures 1(e) and (f) show SEM image with EDS spectrum of pure copper powder of electrolytic grade. It is observed that the morphology of the copper powder is dendritic and the particle size is in the range of 2-8 μm. EDS spectrum of copper powder possesses three strong peaks of copper element indicating the highest degree of purity.

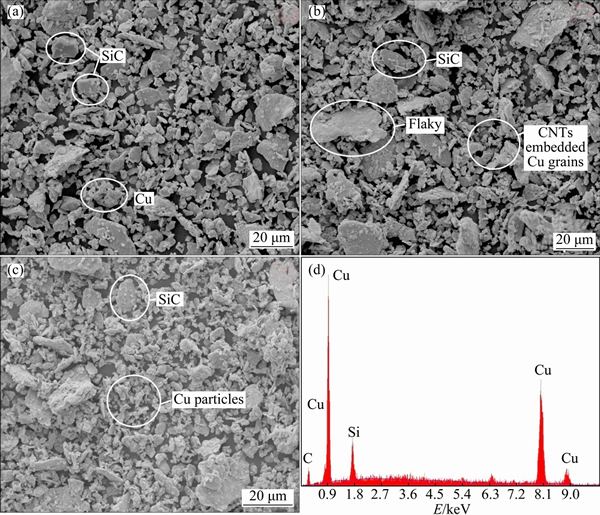

Figures 2(a)-(c) show the SEM images of the nanocomposite powder after ball milling at 300 r/min for 3 h. It is observed that after ball milling, the powder size of Cu, MWCNTs and SiC have increased when compared with procured powders. This can be attributed to fragmented, rewelding and flattening processes due to crushing by the steel balls during ball milling. The presence of MWCNTs and SiC in the Cu powder is confirmed by EDS spectrum as shown in Fig. 2(d).

3.2 Microstructural studies

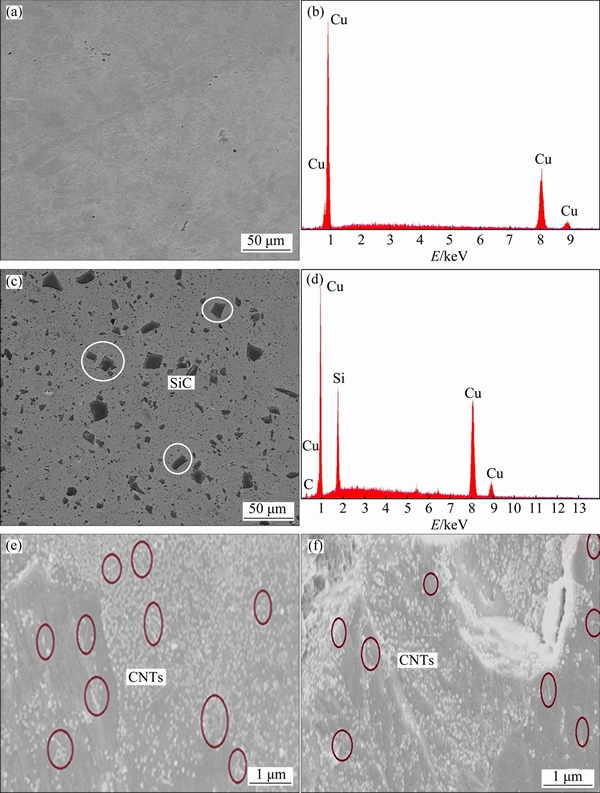

SEM images and EDS spectrum of copper and its hybrid nanocomposites are shown in Figs. 3(a)-(d). It is evident that a dense and pore-free hybrid nanocomposite is obtained which can be attributed to the hot pressing of the sintered billets. SiC particles are uniformly distributed in the copper matrix with a reaction-free interface resulting in good bonding between SiC and copper grains as evidenced in Fig. 3(c).

HRSEM photographs of hybrid nanocomposites are shown in Figs. 3(e) and (f). It is observed that carbon nanotubes are distributed uniformly in the copper matrix and no damage to carbon nanotubes has been observed after ball milling, sintering and hot pressing. No reaction product is observed at the interface resulting in good bond between copper matrix and the reinforcements as shown in Figs. 4(b)-(d). This can be attributed to copper coating provided on SiC and MWCNTs. The EDS spectrum taken at the interface of all the nanocomposites indicates the presence of Cu, Si and C elements only ruling out any possibilities of interfacial reaction as shown in Fig. 3(d).

Fig. 1 SEM images of uncoated MWCNTs (a), Cu coated MWCNTs (b), uncoated SiC (c), Cu coated SiC (d) and Cu (e), and EDS spectrum of Cu (f)

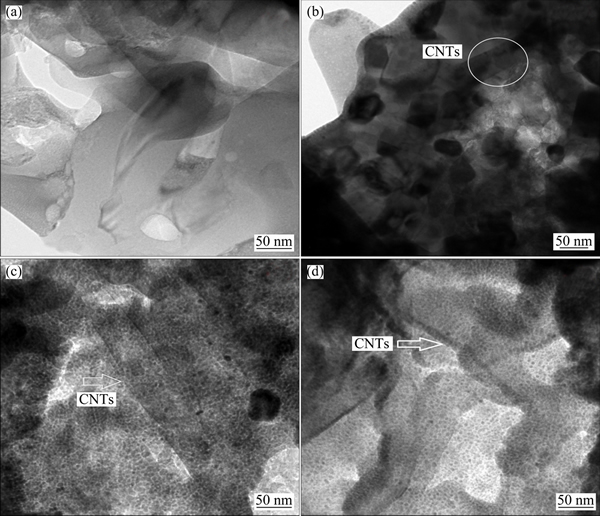

Figure 4 shows the HRTEM images of pure copper and its hybrid nanocomposites. It is observed that copper possesses minimum porosity as shown in Fig. 4(a). Uniform dispersion of carbon nanotubes in copper matrix is confirmed by HRTEM images of hybrid nano- composites (Figs. 4(b)-(d)) and show good interfacial bonding between carbon nanotubes and copper matrix. If any interfacial reaction occurs between matrix and reinforcements, it will lead to reduction in hardness and wear resistance of the nanocomposites. Further, it can be observed from all the micrographs that the level of porosity is very minimal in all hybrid nanocomposites as shown in Figs. 4(b)-(d).

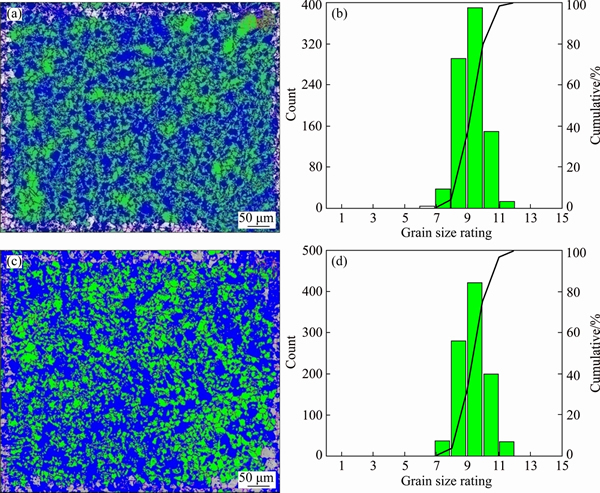

3.3 Grain size analysis

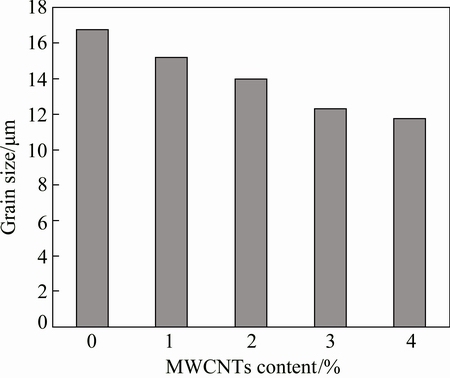

Figure 5 shows the optical images and histograms of grain size of hybrid nanocomposites. It is observed that the number of counts of grains corresponding to ASTM grain size rating 10 and 11 is significantly higher for 4% CNTs when compared with 1% CNT nanocomposite as shown in Figs. 5(b) and (d). Higher grain size rating indicates the smaller grain size of nanocomposite. The grain size of pure copper is 16.8 μm as shown in Fig. 6.

Fig. 2 SEM images of Cu/4SiC-1CNTs (a), Cu/4SiC-3CNTs (b), Cu/4SiC-4CNTs (c) nanocomposite powders and EDS spectrum (d) of Cu/4SiC-4CNTs nanocomposite powder (Ball milling time: 3 h, speed: 300 r/min)

It is observed that the average grain sizes of pure copper and Cu-4SiC-4CNTs hybrid composite are 16.8 μm and 11.8 μm respectively as shown in Fig. 6. The grain size of hybrid nanocomposites decreases with increasing content of MWCNTs. This could be due to inhibition in grain growth due to the presence of SiC and MWCNTs during the sintering process. The reduced grain sizes of the developed nanocomposites do significantly improve the hardness and wear resistance.

As per the Hall-Petch equation, the strength and hardness of material depend on its grain size. The smaller the grain size, the greater the obstruction to dislocation movement, resulting in higher hardness and wear resistance. Hence, as the grain size decreases with increase in CNT content in the developed nanocomposite, the hardness increases with increase in CNT content.

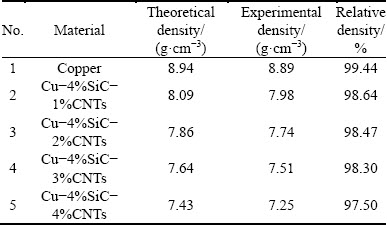

3.4 Density and hardness studies

Table 1 lists the theoretical and actual density of copper and copper hybrid nanocomposites. The theoretical density was calculated by using rule of mixture while experimentally densities were measured using the Archimedes principle. It is observed that the theoretical and experimental densities of hybrid nanocomposite reduce with increase in mass fraction of MWCNT for a given content of SiC. This can be attributed to the low densities of reinforcements namely MWCNT (2.1 g/cm3) and SiC (3.21 g/cm3). However, the relative density reduces marginally with increase in content of MWCNT.

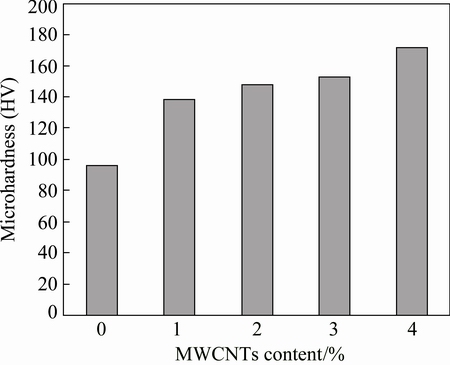

Figure 7 shows the variation of microhardness of copper hybrid nanocomposites with increased content of CNTs. It is observed that the hardness of hybrid nanocomposites increases with increase in content of MWCNTs for a given content of SiC. An improvement of 80% is observed in the hardness for 4% carbon nanotubes reinforced hybrid nanocomposite when compared with pure copper.

The improvement of hardness of hybrid nano- composites can be attributed to the following reasons.

1) Generation of dislocations due to thermal mismatch between MWCNTs, SiC and copper.

2) Reduction in average grain size of nano composites (11.8 μm) when compared with pure copper (16.8 μm). The smaller grain size will be obstacle for mobility of dislocations, which in turn leads to improvement in hardness [19].

3) Excellent interfacial bond between reinforcement and matrix material due to the beneficial effect of copper coating. Strong interfacial bond between reinforcements and the copper matrix ensures better load transfer from the matrix to reinforcements leading to higher hardness [19-21].

4) SiC being one of the hardest ceramics contributes significantly to improving the hardness of soft copper.

Fig. 3 SEM images with EDS spectra of copper (a, b) and Cu/4SiC-1CNTs developed nanocomposites (c, d), and high magnification SEM images of Cu/4SiC-1CNTs (e) and Cu/4SiC-2CNTs (f) nanocomposites (Sintering temperature: 900 °C)

3.5 Friction coefficient

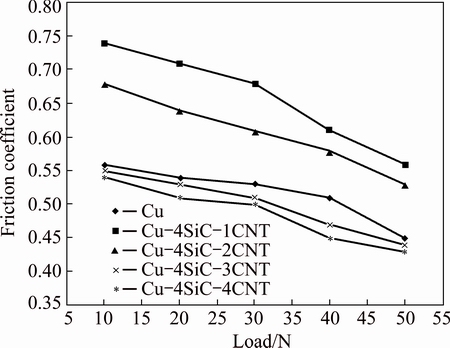

Figure 8 shows the variation of coefficient of friction with respect to applied load for copper and its hybrid nanocomposites. It is observed that the coefficient of friction decreases with increase in load for copper and the developed hybrid nanocomposites. This trend is in close agreement with copper alloy self-lubricating composites as reported in Refs. [7,10].

Fig. 4 HRTEM images of copper (a), Cu/4SiC-1CNTs (b), Cu/4SiC-2CNTs (c) and Cu/4SiC-3CNTs (d) hybrid nanocomposites

Fig. 5 Optical image and histogram of Cu/4SiC-1CNTs hybrid nanocomposite (a, b) and Cu/4SiC-4CNTs nanocomposite (c, d)

Fig. 6 Variation of grain size of hybrid nanocomposite with increased content of carbon nanotubes (SiC content is fixed at 4%)

Table 1 Theoretical and experimental density of copper and copper hybrid nanocomposites

Fig. 7 Variation of microhardness of copper and nano- composites with content of carbon nanotubes (SiC content is fixed at 4%)

Initially at low loads, higher adhesive force between sliding materials does exist, resulting in high coefficient of friction. However, with increase in load, the asperity of the junction of sliding surfaces gets sheared, resulting in lowering of coefficient of friction. Further, the extent of formation of metallic oxide film between the two mating surfaces is more at higher loads. Due to its low shearing strength, the oxide film formed provides improved lubricating effect. Further, the nanocomposites exhibit lower friction coefficient at all the loads studied for higher mass fraction of CNTs in comparison with pure copper. This can be attributed to the formation of a carbonaceous film on the contact surface in addition to metallic oxides. The squeezing out of CNTs onto sliding surface during wear test forms a carbonaceous film which acts as solid lubricant, resulting in low coefficient of friction especially for nanocomposites with higher content of CNTs. The decrease in friction coefficient with increase in CNT content may be attributed to increase in thickness of lubricating/tribolayer [22-24]. Tribolayer is a thin adherent interfacial film composed of oxides of copper, iron and carbonaceous film which induces lubricating effect at the interface. The thickness and characteristics of tribolayer are largely influenced by sliding conditions and quantity of reinforcements. The presence of oxides of copper, iron and carbon at the interface is confirmed by conducting EDS spectrum on the worn surface. The increased friction coefficient for lower content of CNTs in hybrid composites can be attributed to the presence of hard phase SiC particles [25].

Fig. 8 Variation of friction coefficient with load (Test duration: 30 min)

3.6 Effect of load and content of multiwalled carbon nanotube on wear rate

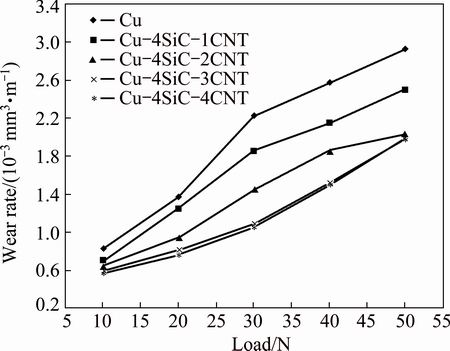

Figure 9 shows the variation of wear rate of pure copper and hybrid nanocomposites with load. It is observed that wear rate increases with increase in load in both pure copper and hybrid nanocomposites. However, at all the loads studied, developed nanocomposites exhibit lower wear rates when compared with unreinforced copper.

Further, the wear rate of hybrid nanocomposites increases with increase in content of CNTs at all the loads studied. The primary reason for improvement in the wear resistance of the nanocomposites is higher hardness of nanocomposites owing to the presence of silicon carbide and CNTs. Reinforced phase acts as load bearing elements and reduces the actual contact area of copper, leading to the improved wear resistance. In addition, the presence of hard and soft reinforcement contributes to formation of stable tribolayer which protects the actual surface of the specimen, resulting in lower wear rate.

Fig. 9 Variation of wear rate with applied load

Increased wear rate with increase in the applied load may be attributed to severe plastic deformation. Large extent of plastic deformation at higher loads leads to the increase of the size of the wear debris due to the increased subsurface cracking resulting in higher wear rates [25-28,31].

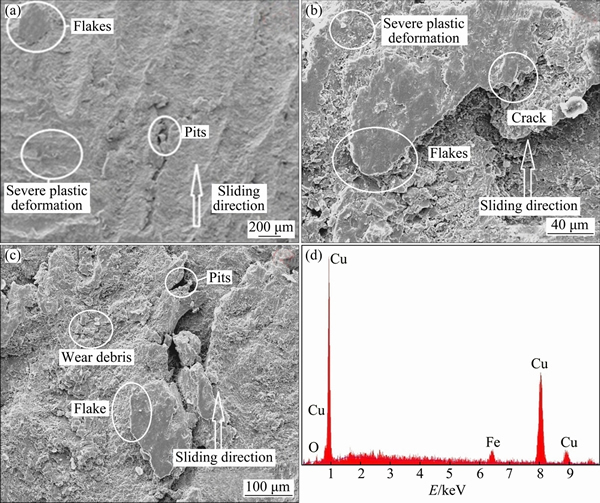

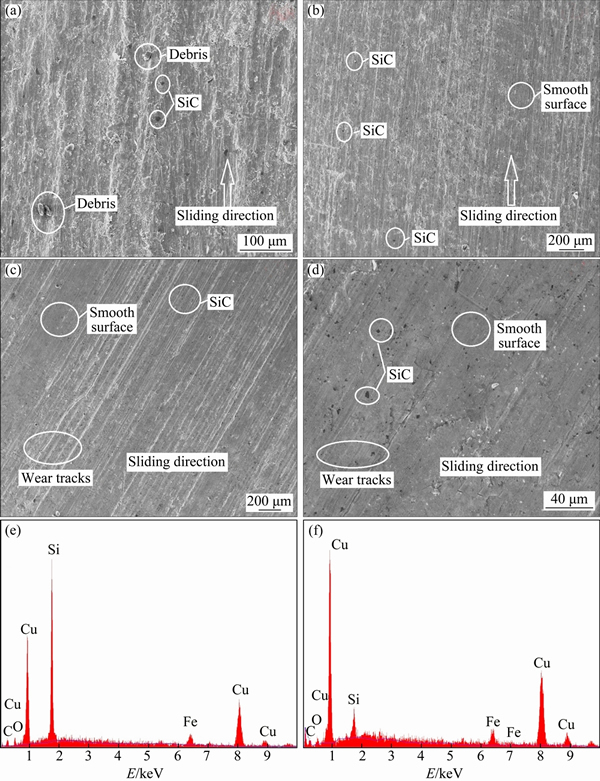

3.7 Wear surface analysis

Figures 10 and 11 show the SEM images with EDS spectra of the worn surfaces of copper and hybrid nanocomposites at different loads. It is observed that the worn surfaces of the hybrid composites exhibit a different morphology when compared with pure copper. This indicates a change in wear mechanism. The improved wear resistances of hybrid nanocomposites are supported by morphology of the worn out surfaces. For a given load and sliding velocity, the worn surface of pure copper exhibits deep and wide grooves at higher loads as observed in Figs. 10(a)-(c), while the hybrid composites exhibit fine grooves as shown in Figs. 11(a)-(d). This indicates extensive plastic deformation in copper at higher loads leading to higher wear rates when compared with the developed hybrid nanocomposites.

Fig. 10 SEM images of wear track of copper (load: 30 N) (a), copper (load: 40 N) (b), copper (load: 50 N) (c) and EDS spectrum (d) of wear track of copper

Fig. 11 SEM images of wear track of Cu/4SiC-1CNTs (a), Cu/4SiC-2CNTs (b), Cu/4SiC-3CNTs (c), Cu/4SiC-4CNTs nanocomposite (d) and EDS spectra of Cu/4SiC-1CNTs (e) and Cu/4SiC-4CNTs (f) nanocomposite (load: 40 N)

The presence of different elements on the worn surfaces of the nanocomposites is confirmed by EDS as shown in Figs. 11(e) and (f). EDS spectra shown in Figs. 10(d) and 11(e) and (f) confirm the formation of mechanically mixed layer (MML) of oxides of Fe, Cu and Si. It is also interesting to note that the presence of CNTs on the worn surface results in additional lubricating effect. The wornout surfaces do not show any evidence of debonding/pullout of reinforced phase which supports the existence of good bond between the matrix and reinforcement particles [32,33].

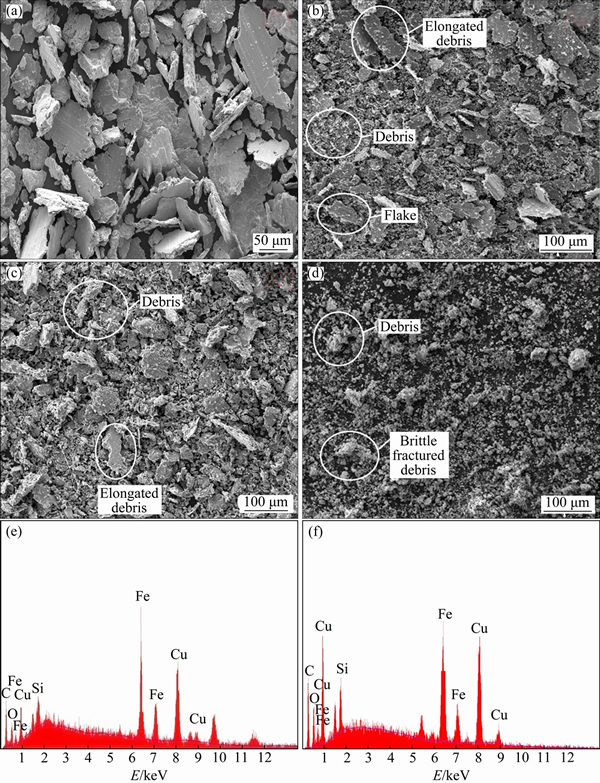

3.8 Analysis of wear debris

Figures 12(a)-(f) show the SEM images and EDS spectra of wear debris of copper and hybrid nanocomposites. It is observed that the wear debris of nanocomposites is finer when compared with pure copper.

Wear debris of pure copper exhibits elongated shapes indicating severe plastic deformation in the direction of sliding. The debris sizes of copper and hybrid nanocomposite are in the range of 50-100 μm and less than 50 μm, respectively. The significant change in the size and shape of the wear debris of nanocomposites may be attributed to its high hardness and less extent of plastic deformation. Further, the decrease in the size of the wear debris may also be attributed to the protective action of tribolayer as discussed earlier. The tribolayer formed during wear test minimizes the chance of direct contact between test specimen and sliding disc resulting in reduced size of wear debris. Figures 12(e) and (f) show the EDS spectra of wear debris of nanocomposites. It confirms the presence of oxides of copper, iron and carbon in the debris.

Fig. 12 SEM images of wear debris of copper (a), Cu/4SiC-1CNTs (b), Cu/4SiC-3CNTs (c), Cu/4SiC-1CNTs nanocomposite (d) and EDS spectra of Cu/4SiC-3CNTs (e), Cu/4SiC-4CNTs (load:40 N) nanocomposite (f)

4 Conclusions

Multiwalled carbon nanotube and silicon carbide reinforced copper composites have been fabricated by powder metallurgy. A significant decrease in grain size of the developed hybrid composites when compared with pure copper is observed. An improvement of 80% in the microhardness of the hybrid nanocomposite with 4% carbon nanotubes when compared with that of pure copper is observed. The friction coefficient of copper hybrid nanocomposites with carbon nanotube content between 3% and 4% is significantly lower than that of pure copper for all the loads studied. The wear rate of nanocomposites decreases with the increase in the carbon nanotube content for all the loads.

Acknowledgements

The authors wish to express their sincere gratitude to Prof. D. JAWAHAR, CEO, PES Group of Institutions, Dr. K. N. B. MURTHY, Vice chancellor, PES University, Dr. K. S. SRIDHAR, Principal and Dr. V. KRISHNA, HOD, Department of Mechanical Engineering, PESIT, Bangalore.

References

[1] IIJIMA S. Helical microtubules of graphitic carbon [J]. Nature, 1991, 354: 56-58.

[2] DEMCZYK B G, WANG Y M, CUMINGS J, HETMAN M, HAN W, ZETT A, RITCHIE R O. Direct mechanical measurement of the tensile strength and elastic modulus of multiwalled carbon nanotubes [J]. Materials Science and Engineering A, 2002, 334: 173-178.

[3] KIM P, SHI L, MAJUMDAR A, MCEUEN P L. Thermal transport measurements of individual multiwalled nanotubes [J]. Physical Review Letters, 2001,87: 215502-1-4.

[4] KOPPAD P G, SINGH V K, RAMESH C S, KOPPAD R G, KASHYAP K T. Metal matrix nanocomposites reinforced with carbon nanotubes [C]//TIWARI A, SHUKLA S K. Advanced Carbon Materials and Technology, Hoboken, USA: John Wiley & Sons Inc, 2014: 331-376.

[5] GUPTA M, NAI MUI LING SHARON. Magnesium, magnesium alloys, and magnesium composites [M]. Hoboken, USA: John Wiley & Sons Inc, 2011.

[6] BAKSHI S R, AGARWAL A. An analysis of the factors affecting strengthening in carbon nanotube reinforced aluminum composites [J]. Carbon, 2011, 49(2): 533-544.

[7] RAMESH C S, NOOR AHMED R, MUJEEBU M A, Abdullah M Z. Development and performance analysis of novel cast copper–SiC-Gr hybrid composites [J]. Materials & Design, 2009, 30(6): 1957-1965.

[8] RAJKUMAR K, ARAVINDAN S. Tribological performance of microwave sintered copper-TiC-graphite hybrid composites [J]. Tribology International, 2011, 44 (4): 347-358.

[9] PRABHU T R, VEDANTAMA S. Layer-graded Cu/B4C/graphite hybrid composites: Processing, characterization, and evaluation of their mechanical and wear behavior [J]. Tribology Transactions, 2015, 58(4): 718-728.

[10] ZHAN Y, ZHANG G. Friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles [J]. Tribology Letters, 2004, 17(1): 91-98.

[11] DONG S R, TU J P, ZHANG X B. An investigation of the sliding wear behavior of Cu-matrix composite reinforced by carbon nanotubes [J]. Materials Science and Engineering A, 2001, 313(1-2): 83-87.

[12] ZHAN Y Z, SHI X B, XIE H F. Microstructural investigation on antifriction characteristics of self-lubricating copper hybrid composite [J]. Materials Science and Technology, 2006, 22(3): 368-374.

[13] HE D H, MANORY R. A novel electrical contact material with improved self-lubrication for railway current collectors [J]. Wear, 2001, 249(7): 626-636.

[14] LI J, LIU Y, YANG X J. Mechanical properties and oil content of CNT reinforced porous Cu Sn oil bearings [J]. Composites Part B: Engineering, 2012, 43(4): 1681-1686.

[15] MOGHADAM A D, OMRANI E, MENEZES P L, ROHATGI P K. Mechanical and tribological properties of self-lubricating metal matrix nanocomposites reinforced by carbon nanotubes (CNTs) andgrapheme—A review [J]. Composites Part B: Engineering, 2015, 77: 402-420.

[16] WANG F, SUSUMU A, MORINOBU E. Metallization of multi-walled carbon nanotubes with copper by an electroless deposition process [J]. Electrochemistry Communications, 2004, 6(10): 1042-1044.

[17] ANG L M, HOR T S A, XU G Q, TUNG C H, ZHAO S P, WANG J L S. Decoration of activated carbon nanotubes with copper and nickel [J]. Carbon, 2000, 38(3): 363-372.

[18] LI Qun-qing, FANG Shou-shan, HAN Wei-qiang, SUN Chen-hang, LIANG Wen-jie. Coating of carbon nanotube with nickel by electroless plating method [J]. Japanese Journal of Applied Physics, 1997, 36: 501-503.

[19] UDDIN S M, TANVIR M, CHRISTOPH W, CARSTEN G, IVICA K, CHRISTOPH V, HELMUT H, ULRICH W, SIEGMAR R, HANS J F. Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites [J]. Composites Science and Technology, 2010, 70(16): 2253-2257.

[20] KOPPAD P G, RAM H R A, RAMESH C S, KASHYAP K T, KOPPAD R G. On thermal and electrical properties of multiwalled carbon nanotubes/copper matrix nanocomposites [J]. Journal of Alloys and Compounds, 2013, 580: 527-532.

[21] IMAI H, KONDOH K, SHUFENG L I, JUNKO U, BUNSHI F, MAKOTO T. Microstructural and electrical properties of copper titanium alloy dispersed with carbon nanotubes via powder metallurgy process [J]. Materials Transaction, 2014, 55(3): 522-527.

[22] RAJKUMAR K, ARAVINDAN S. Tribological studies on microwave sintered copper–carbon nanotube composites [J]. Wear, 2011, 270(9-10): 613-621.

[23] Chu Ke, Jia Cheng-chang, Jiang Li-kun, Li Wen-sheng. Improvement of interface and mechanical properties in carbon nanotube reinforced Cu-Cr matrix composites [J]. Materials & Design, 2013, 45: 407-411.

[24] XU W, HU HU, LI Jin-shan, ZHANG Yong-zhen, FU Heng-zhi. Tribological behavior of CNTs-Cu and graphite-Cu composites with electric current [J]. Transactions of Nonferrous Metals Society of China, 2012, 22(1): 78-84.

[25] JAROSLAV K, STEFAN E, JOZEF B, LUBOMIR K. Effect of composition on friction coefficient of Cu–graphite composites [J]. Wear, 2008, 265(3-4): 417-421.

[26] PRABHUDEV M S, AURADI V, VENKATESWARLU K, SIDDALINGSWAMY N H, KORI S A. Influence of Cu addition in dry sliding wear behaviour of A356 alloy [J]. Procedia Engineering, 2015, 97: 1361-1367.

[27] KOPPAD P G, RAM H R A, KASHYAP K T. On shear-lag and thermal mismatch model in multiwalled carbon nanotube/copper matrix nanocomposites [J]. Journal of Alloys and Compounds, 2013, 549: 82-87.

[28] SARMADI H, KOKABI A H, SEYED REIHANI S M. Friction and wear performance of copper–graphite surface composites fabricated by friction stir processing (FSP) [J]. Wear, 2013, 304(1-2): 1-12.

[29] MEN Zhen-qiang, LI Xi-bin, XIONG Yong-jun, ZHAN Jing. Preparation and tribological performances of Ni-P-multi-walled carbon nanotubes composite coatings [J].Transactions of Nonferrous Metals Society of China, 2012, 22(11): 2719-2725.

[30] LI Jing-fu, ZHANG Lei, XIAO Jin-kun, ZHOU Ke-chao. Sliding wear behavior of copper-based composites reinforced with graphene nanosheets and graphite [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3354-3362.

[31] GAO Yuan, JIE Jin-chuan, ZHANG Peng-chao, ZHANG Jian, WANG Tong-min, LI Ting-ju. Wear behavior of high strength and high conductivity Cu alloys under dry sliding [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 2293-2300.

[32] JAIN V, SARAVANAN M, ANANDANI R C, RAJIV S, GUPTA A K. Effect of sizing on friction and wear properties of copper-iron based sintered composites [J].Transactions of the Indian Institute of Metals, 2010, 63(1): 43-54.

[33] GANGATHARAN K, SELVAKUMAR N. Optimizing the dry sliding wear behavior of copper hybrid nano composites reinforced with MWCNTs and nano B4C using full factorial design [J]. Transactions of the Indian Institute of Metals, 2016, 69(3): 717-732.

H. M. MALLIKARJUNA1,2, C. S. RAMESH3, P. G. KOPPAD4, R. KESHAVAMURTHY5, K. T. KASHYAP6

1. Advanced Composites Research Centre, P E S Institute of Technology, Bangalore 560085, India;

2. Department of Mechanical Engineering, Government Engineering College, K.R. Pet 571426, India;

3. Department of Mechanical Engineering, Alliance College of Engineering & Design, Alliance University, Anekal, Bangalore 562106, India;

4. Department of Mechanical Engineering, CMR Institute of Technology, Bangalore 560037, India;

5. Department of Mechanical Engineering, DayanandaSagar College of Engineering, Bangalore 56078, India;

6. Department of Mechanical Engineering, School of Engineering and Technology, Jain University, Bangalore, India

摘 要:研究了多壁碳纳米管和碳化硅包覆铜增强铜基混合纳米复合材料的显微组织和摩擦性能。碳纳米管含量为1%~4%,碳化硅含量固定在4%。铜杂化纳米复合材料的合成过程包含球磨、冷压、烧结,随后热压。对混合纳米复合材料进行了密度、晶粒尺寸和硬度测试。在不同载荷条件下,在销-钢盘摩擦仪上采用干滑动磨损评估纳米复合材料的摩擦性能。结果表明,与纯铜相比,混合纳米复合材料的晶粒尺寸明显减小,4%碳纳米管增强杂化纳米复合材料的显微硬度提高了80%。混合纳米复合材料中碳纳米管含量的增加导致材料的摩擦因数和磨损率降低。

关键词:铜;碳纳米管;碳化硅;显微硬度;磨损机制;纳米复合材料

(Edited by Xiang-qun LI)

Corresponding author: H. M. MALLIKARJUNA; E-mail: mallikarjuna.hm@gmail.com

DOI: 10.1016/S1003-6326(16)64449-7