Trans. Nonferrous Met. Soc. China 22(2012) 2891-2897

Liquation cracking in laser beam welded joint of ZK60 magnesium alloy

YU Zhao-hui1, YAN Hong-ge2, YIN Xu-yu1, LI Ying1, YAN Guo-hua1

1. State Nuclear Power Plant Service Company, Shanghai 200233, China;

2. College of Materials Science and Engineering, Hunan University, Changsha 410082, China

Received 14 October 2011; accepted 16 January 2012

Abstract: The ZK60 magnesium alloy plates were welded by laser beam welding (LBW) and the microstructures in the partially melted zone (PMZ) of welded joints were investigated. For the as-cast alloy, the eutectoid mixtures along grain boundaries (GBs) in the PMZ are liquefied during welding, and their re-solidified materials present hypoeutectic characters, which lead to more severe segregation of the Zn element along GBs, and thus enhance the cracking tendency of the PMZ. The main reasons for liquation cracking of PMZ are described as that the absence of liquid at the terminal stage of solidification leads to the occurrence of shrinkage cavities in PMZ, from which liquation cracking initiates, and propagates along the weakened GBs under the tensile stress originating from solidification shrinkage and thermal contraction. Lower heat input can reduce the cracking tendency, and the plastic processing such as rolling also contributes to the mitigation of PMZ liquation cracking by reducing the size of eutectoid phases and changing their distribution in the base metal.

Key words: magnesium alloy; ZK60 alloy; laser beam welding; partially melted zone; liquation cracking

1 Introduction

Magnesium alloys have been considered as one of the most promising lightweight materials due to low density, high specific strength, and superior properties for absorbing vibration or shock energy, insulating electromagnetic interference and etc [1-3]. Their mass saving potential when used as structural materials in aircraft and automobile industries is beneficial to fuel economy and reducing CO2 emissions [4]. Compared with the AZ (Mg-Al-Zn) and AM (Mg-Al-Mn) series magnesium alloys, ZK (Mg-Zn-Zr) series alloys are of higher strength, better stress corrosion resistance and heat-treatability, especially ZK60 alloy [5]. However, it has been reported [6] that magnesium alloys with Zn as the major alloying element are more difficult to be welded due to a rather wide melting range which makes them sensitive to hot cracking including solidification cracking in the fusion zone (FZ) and liquation cracking in the partially melted zone (PMZ). Thus, the structural applications of ZK60 alloy are severely limited for its poor weldability. Compared with the solidification cracking, the liquation cracking is more complex and unpredictable [7,8], so it is significant to investigate the morphology and the metallurgical origin of the liquation cracking.

Up to date, a few investigations have been conducted on the phenomena of PMZ liquation and cracking of some magnesium welds, except for ZK series alloys [9-12]. MARYA and EDWARDS [9] found that die castings of Al-containing magnesium alloys often contained low melting point intermetallic compounds such as γ-Al12Mg17 (melting point of 450 °C) along the grain boundaries (GBs), which promoted the liquation in the PMZ. ZHU et al [11] investigated re-solidification behaviors in welded joints of AZ91 Mg cast alloy by using Gleeble thermal simulator and found that the original partially divorced eutectic structure has become a more regular eutectic phase in most of the PMZ. BAESLACK et al [12] studied the CO2 laser beam welded joint of as-cast WE54 alloy and indicated that this alloy is susceptible to the PMZ liquation cracking. The neodymium and yttrium-rich liquid solidifies to a lamellar eutectic structure along GBs, and the fine intergranular crack was observed in the PMZ along some of these GBs. For ZK series magnesium alloys, they may exhibit a more severe PMZ liquation and cracking due to the intermetallic compounds such as Mg51Zn20 with a relatively low melting temperature (only about 341 °C) [5].

However, the mechanism and remediation methods of the liquation and cracking in the PMZ are seldom studied in details. Therefore, the morphology of liquation crack and the structure of re-solidified material along GBs in the PMZ of as-cast ZK60 welds are studied in the work. Moreover, the liquation cracking mechanism is discussed and the mitigation methods are also proposed. The results are expected to be a guidance to develop a weldable magnesium alloy with high strength.

2 Experimental

The as-cast ZK60 magnesium alloy samples with the nominal composition of Mg-6%Zn- 0.45%Zr (mass fraction) and with the dimensions of 120 mm×100 mm×10 mm were cut from the central section of the ingot. Some samples were rolled to sheets with 2 mm in thickness, and then the sheets were cut to the samples with the dimensions of 100 mm×80 mm×2 mm. Both the as-cast and as-rolled samples were polished with abrasive paper to remove the oxides, and then cleaned by acetone before welding.

Welding was conducted without filler metal using a 3.0 kW continuous wave CO2 laser with the following properties: mode, TEM01; divergence, <2 mrad; beam diameter on focusing optic 38 mm; focused diameter 0.25 mm. The focal length of the parabolic mirror used for focusing the laser beam was 127 mm. During welding, samples were neither clamped down to any fixtures nor subjected to any augmented strains such as bending in order to avoid the interfering from the interaction between the weld metal and the PMZ. They were simply rested on the top of two copper carriages, as shown in Fig. 1. Variables used were laser power (1.3, 1.5, 1.7 and 1.9 kW), and welding speed (2.0, 2.5, 3.0 and 3.5 m/min). The focal point of laser beam was fixed on the top surface of the sample. High-purity argon (99.99%) was used to protect the molten pool with the constant flow rate of 12 L/min. The obtained welded joint was cut, polished and etched with a solution of 5 g tartaric acid+100 mL water for microstructural examination by optical microscopy (OM Leitz MM-6) and scanning electron microscopy using secondary electrons (SEM, FEI QUANTA-200). The precipitates in the PMZ and base metal were analyzed by X-ray diffraction (XRD, SIEMENS D-5000), and SEM with energy dispersive spectrometer (EDS).

Fig. 1 Configuration of welding process with sample unrestrained

3 Results and discussion

3.1 Microstructure of base metal

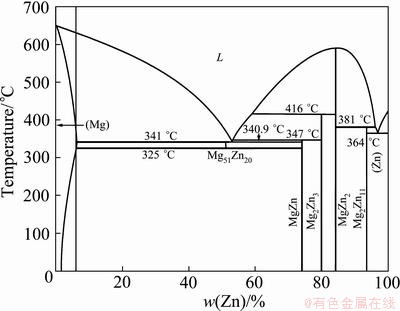

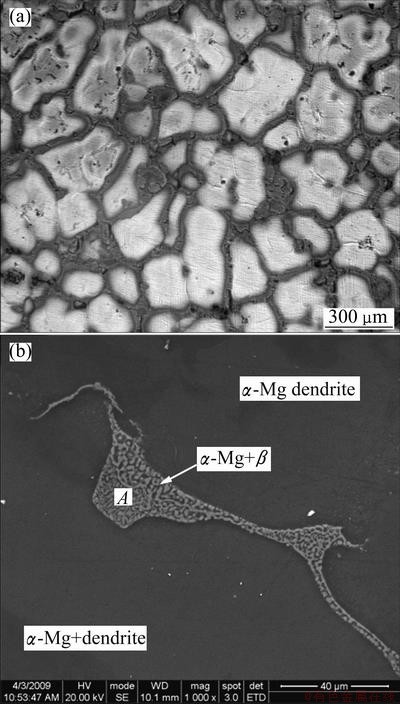

The Mg-Zn binary phase diagram is shown in Fig. 2 [5]. The large interval between the solidus and liquidus indicates that ZK60 alloy has a rather wide solidification temperature range. Since 6% Zn is about 13 times higher than that of Zr (0.45%), ZK60 alloy can be treated as a binary alloy of Mg-6%Zn as an approximation. The optical and SEM photographs of the base metal are shown in Fig. 3. As seen from Fig. 3(a), the as-cast base metal consists of a large primary α-Mg dendrite surrounded by metallic mixture. From Fig. 3(b), the metallic mixture is composed of α-Mg (dark) and β phase (light). According to the Mg-Zn phase diagram (Fig. 2) and the XRD pattern of the base metal (Fig. 4), the β phase is MgZn which may be a decomposition product of Mg51Zn20 through eutectoid reaction at 325 °C after casting [5].

Fig. 2 Mg-Zn phase diagram

Fig. 3 OM (a) and SEM (b) images of base metal

Fig. 4 XRD pattern of base metal

3.2 Microstructural evolution in partially melted zone

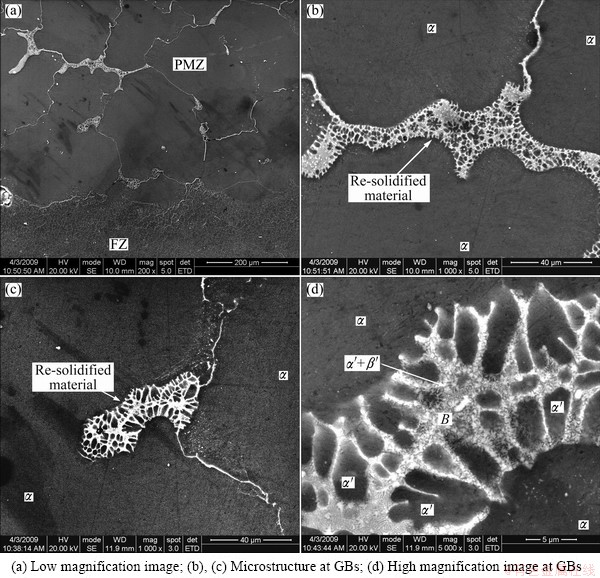

The eutectic temperature of ZK60 is only about 341 °C, but the melting temperature is higher than 640 °C as seen from Fig. 2. Thus, the PMZ will be severely liquated in spite of the low heat input during LBW. The microstructure of the PMZ is presented in Fig. 5. From Fig. 5(a), liquation occurs along GBs in PMZ. From Figs. 5(b) and (c), the re-solidified material along GBs in the PMZ consists of a great number of new-formed fine α′-Mg dendrites (dark) surrounded by a metallic mixture (light), which is in contradistinction from that in the base metal (Fig. 3(b)). From Fig. 5(d), the metallic mixture consists of α′-Mg (dark) and β′ phase (light). According to the XRD pattern (Fig. 6), the β′ phase along GBs in the PMZ is determined as Mg51Zn20, so the metallic mixture in the PMZ is a eutectic mixture. As mentioned above, Mg51Zn20 is a metastable phase, which can be usually decomposed into α-Mg and MgZn through eutectoid reaction after solidification [5]. However, due to the very rapid cooling rate in LBW [13], the Mg51Zn20 has been preserved in the PMZ. Therefore, the re-solidified material along GBs in the PMZ consists of primary α′-Mg dendrites surrounded by the eutectic mixtures (α′-Mg+Mg51Zn20), which has a hypoeutectic character. According to the theory of welding metallurgy [14], the rapid cooling rate shifts eutectic point toward the Zn-rich side, which leads to the liquid with eutectic composition solidifying to a hypoeutectic structure. During the solidification, the primary α′-Mg phase can be firstly solidified from the liquid along GBs in the PMZ, and then the remaining liquid changes its composition along the liquidus to a new eutectic point at the eutectic temperature with solidification proceeding. When the residual liquid phase reaches the composition of the new eutectic point, the eutectic reaction occurs. Thereby, the re-solidified material along GBs in the PMZ has a typical hypoeutectic structure.

Fig. 5 SEM images of PMZ

Fig. 6 XRD pattern of PMZ

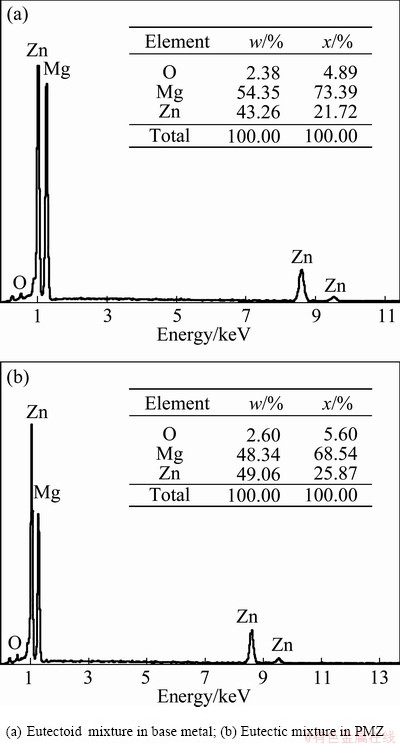

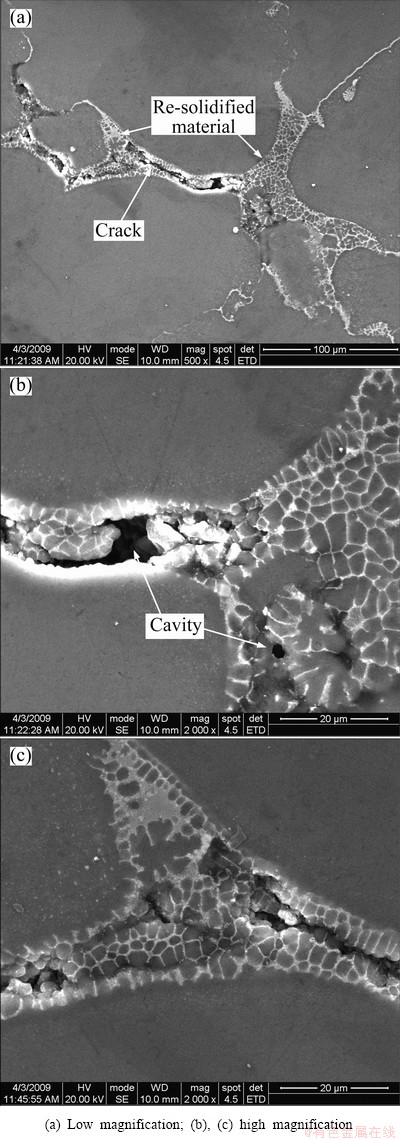

Figure 7 shows the EDS analysis results of eutectoid mixture in the base metal and the eutectic mixture in the PMZ. According to the EDS analysis, the Zn content of the eutectic mixture in the PMZ is about 49%, which is higher than the eutectoid mixture in the base metal (43%), indicating that Zn is segregated more severely in the PMZ compared with that in the base metal. Generally, severe segregation of solute occurs along GBs in the PMZ, making it highly susceptible to the liquation cracking [14]. Cracks can be observed clearly in the PMZ of as-cast ZK60 welded joints, as shown in Fig. 8. From Fig. 8(a), cracking in the PMZ is intergranular induced by the GBs liquation during welding, so it is a liquation cracking for the PMZ [14]. However, numerous new-formed fine α′-Mg dendrites are presented in the re-solidified material where the liquation cracking also occurs along the GBs of them, as shown in Figs. 8(b) and (c). For the small molten pools along GBs, the cracking is also characteristic of solidification cracking. So, the cracking in the PMZ of as-cast ZK60 alloy is featured with both liquation cracking and solidification cracking. The cracking mechanism is discussed in details in section 3.3.

Fig. 7 EDS analysis results of eutectic mixtures

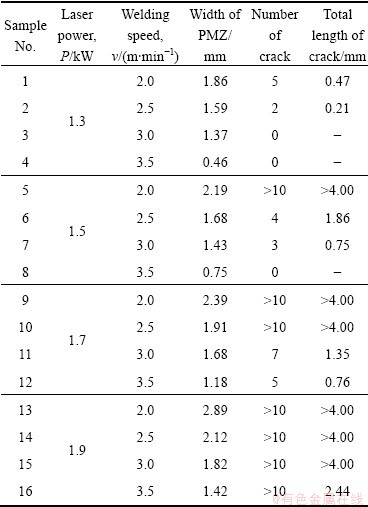

The width of the PMZ and the crack length under different welding parameters are listed in Table 1. It is obvious that both the laser power and the welding speed have a significant effect on the width of PMZ. Due to the fact that a higher laser power leads to the widening of the PMZ and more severe liquation, welded joints with the laser power of 1.9 kW contain more liquation cracks. A lower laser power in combination with a higher welding speed results in a narrower width of the PMZ and thus contributes to reducing the number and the length of the liquation cracks. For example, the amount and the length of the liquation cracks in the PMZ both decrease with the increase of the welding speed at a constant laser powder of 1.3 kW and no cracks can be observed in the PMZ with the welding speed of 3 and 3.5 m/min. Unfortunately, there are only three welded joints free from liquation crack in this work, suggesting that the as-cast ZK60 magnesium alloy is susceptible to liquation cracking during LBW.

Fig. 8 Cracks in PMZ

3.3 Mechanism of liquation cracking

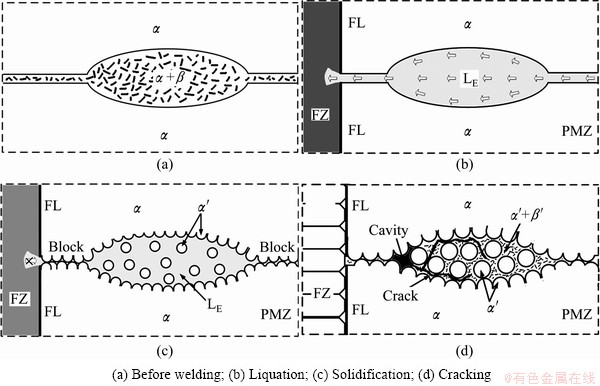

The mechanism of liquation cracking in the PMZ for the as-cast ZK60 welded joint is illustrated in Fig. 9. As mentioned above, eutectoid mixture consisting of α-Mg and β (MgZn) along GBs in the base metal is illustrated in Fig. 9(a). During welding, the eutectoid mixture in the PMZ liquefies by two steps. Firstly, as the heat source of welding approaching, the eutectoid mixture is heated up to the eutectoid temperature and the α-Mg and β(MgZn) are synthesized into β′ (Mg51Zn20) by the eutectoid reaction: MgZn+Mg→Mg51Zn20. Secondly, when the temperature of the PMZ reaches the eutectic temperature TE, liquation is initiated by the eutectic reaction: Mg51Zn20+Mg→LE, where LE is the liquid of the eutectic composition, and the LE is associated with rather a great increment in volume by converting from the solid state into the liquid state and temperature rising further [5]. Since the large α-Mg dendrites in the PMZ can hardly be melted, the LE cannot be contained by the space between them. Therefore, the overfilled LE will flow towards the FZ with the space between dendrites as channels and some will flow into the FZ, as shown in Fig. 9(b). With the heat source leaving, solidification occurs. At the beginning of solidification, the primary α′ phases precipitate from the liquid and epitaxially grow from the surface of the α-Mg dendrites, thus the liquid in narrow part of the pool solidifies immediately and blocks the channel for its filling back from the FZ, as shown in Fig. 9(c). Due to the absence of liquid, the cavities and porosities present in the re-solidified materials at the terminal stage of solidification, as shown in Fig. 8(b). Moreover, segregation of Zn in the re-solidified material is more severe, which can weaken the bond strength between the new formed grains [14]. In summary, the cavities and porosities located at the re-solidified material act as the origination of cracking. Under the tension stress caused by the solidification shrinkage and the thermal contraction, cracks will propagate along the GBs in the re-solidified material, as illustrated in Fig. 9(d). Obviously, the PMZ liquation cracking is one of the reasons for the as-cast ZK60 alloy exhibiting poor weldability.

Table 1 Width of PMZs and cracks length under different welding parameters

Fig. 9 Schematic illustration of liquation cracking

3.4 Remediation of liquation cracking

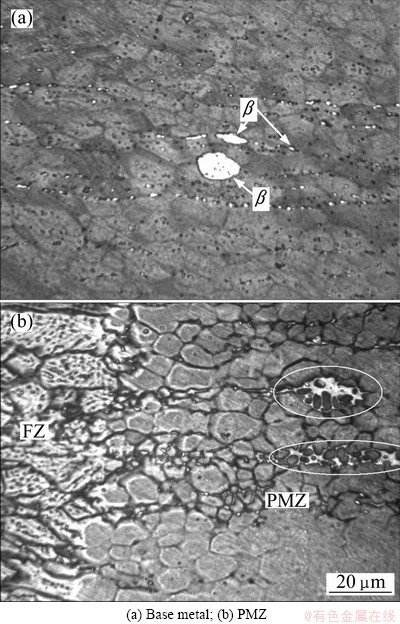

As mentioned above, the eutectoid mixture in the as-cast ZK60 alloy is net-like and large in size, which leads to liquation cracking in the PMZ. Therefore, the method for reducing liquation cracking can possibly be achieved by changing the distribution of the eutectoid phases and reducing their size. Plastic processing such as rolling can change the microstructure of the alloy greatly [15,16], so the effects of rolling on the weldability of ZK60 are also studied. Compared with the as-cast alloy, the β (MgZn) precipitates are much finer and distribute more uniformly in the as-rolled base metal, as shown in Fig. 10(a). From Fig. 10(b), the small liquid pools in the PMZ can also be formed from the liquation of large precipitates during LBW. Interestingly, the small pools in the PMZ are isolated and the liquid cannot flow out. Hence, no obvious crack is observed in the PMZ of the as-rolled ZK60 welded joint.

4 Conclusions

1) Extensive liquation occurs in the PMZ of the laser welded joints of as-cast ZK60 alloy, and the re-solidified materials along the GBs have a hypoeutectic structure, which leads to more severe segregation of the Zn element along GBs, and thus enhances the cracking tendency of the PMZ.

2) The absence of liquid at liquid pool in the PMZ during the solidification leads to the occurrence of shrinkage cavities. Liquation cracking initiates from the cavities and propagates along GBs in the re-solidified materials.

3) Lower heat input can reduce the cracking tendency, and plastic processing such as rolling also contributes to mitigation of the PMZ liquation cracking by reducing the size of eutectoid phases and changing their distribution in the base metal.

Fig. 10 OM photographs of as-rolled ZK60 alloy welded joint

References

[1] COMMIN L, DUMONT M, MASSE J E, BARRALLIER L. Friction stir welding of AZ31 magnesium alloy rolled sheet: Influence of processing parameters [J]. Acta Materialia, 2009, 57(8): 326-334.

[2] HEN Xian-hua, MAO Jian-jun, PAN Fu-sheng, PENG Jian, WANG Jing-feng. Influence of impurities on damping properties of ZK60 magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 20(7): 1305-1310.

[3] LIU Li-ming, SONG Gang, WANG Ji-feng. Microstructure and mechanical properties of wrought magnesium alloy AZ31B welded by laser-TIG hybrid [J]. Transactions of Nonferrous Metals Society of China, 2004, 14(3): 550-555.

[4] YU Zhao-hui, YAN Hong-ge, CHEN Qiong, SU Bin. Microstructures and mechanical properties of laser welded ZK40 high strength magnesium alloy [J]. Transactions of Nonferrous Metals Society of China, 2010, 21(4): 701-707. (in Chinese)

[5] AVEDESIAN M M, BAKER H. ASM specialty handbook: Magnesium and magnesium alloys [M]. Materials Park: ASM International, 1999: 16-19.

[6] KEARNS W H. Welding handbook [M]. Miami: American Welding Society, 1982: 396.

[7] HUANG C, KOU S. Liquation cracking in full-penetration Al-Cu welds [J]. Welding Journal, 2004, 83(2): 50-58.

[8] KOU S. Solidification and liquation cracking issues in welding [J]. JOM Journal of the Minerals Metals and Materials Society, 2003, 55(6): 37-42.

[9] MARYA M, EDWARDS G R. The laser welding of magnesium alloy AZ91 [J]. Welding World, 2000, 44(2): 31-37.

[10] ZHU T P, CHEN Z W, GAO W. Incipient melting in partially melted zone during arc welding of AZ91D magnesium alloy [J]. Materials Science and Engineering A, 2006, 416(1-2): 246-252.

[11] ZHU T P, CHEN Z W, GAO W. Microstructure formation in partially melted zone during gas tungsten arc welding of AZ91 Mg cast alloy [J]. Materials Characterization, 2008, 59(11): 1550-1558.

[12] BAESLACK W A, SAVAGE S J, FROES F H. Laser-weld heated-affected zone liquation and cracking in a high-strength Mg-alloy [J]. Journal of Materials Science Letters, 1986, 5(9): 935-939.

[13] YU Z H, YAN H G, CHEN J H, WU Y Z. Effect of Zn content on the microstructures and mechanical properties of laser welding ZK series magnesium alloys [J]. Journal of Materials Science, 2010, 45(14): 3797-3803.

[14] KOU S. Welding metallurgy [M]. Hoboken: Wliley-Interscience, 2002: 196-197.

[15] KAINER K U. Magnesium alloys and technology [M]. Weinheim: WILEY-VCH Verlag GmbH & Co. KG aH, 2003: 84-90.

[16] QUAN Ya-jie, CHEN Zhen-hua, LI Mei, YU Zhao-hui, GONG Xiao-san. Microstructure and properties of joints of wrought magnesium alloy AM60 plates welded by laser beam welding [J]. The Chinese Journal of Nonferrous Metals, 2007, 17(4): 525-529. (in Chinese).

ZK60镁合金激光焊接接头的液化开裂

俞照辉1,严红革2,尹绪雨1,李 颖1,闫国华1

1. 国核电站运行服务技术公司,上海 200233;

2. 湖南大学 材料科学与工程学院,长沙 410082

摘 要:采用激光对ZK60镁合金板材进行焊接,研究焊接接头半熔化区的显微组织。结果表明:铸态合金半熔化区中沿晶分布的共析混合物在焊接过程中出现液化,其凝固组织呈现亚共晶结构,这种结构导致晶界处的Zn元素偏析更为严重,从而加剧了该区域的开裂倾向;半熔化区液化开裂的主要原因是凝固最终阶段液相不足使得半熔化区液化部位产生缩孔,并成为裂纹源,在凝固收缩及热收缩所产生的拉应力作用下,裂纹沿弱化的晶界扩展;降低焊接热输入和对母材进行轧制等塑性加工均有利于提高该合金焊接时的抗液化裂纹性能,后者的作用主要在于细化共晶相的尺寸并改变其分布。

关键词:镁合金;ZK60合金;激光焊接;半熔化区;液化裂纹

(Edited by LI Xiang-qun)

Foundation item: Project (2011ZX06001-003) supported by the National Science and Technology Major Project, China; Project (51274092) supported by the National Natural Science Foundation of China

Corresponding author: YU Zhao-hui; Tel: +86-21-33326734; Fax: +86-21-33326888; E-mail: fishyzh@gmail.com

DOI: 10.1016/S1003-6326(11)61547-1