旋锻对Mo-Ti-Zr合金性能及显微组织的影响

罗明,范景莲,成会朝,田家敏,卢明园

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘 要:将Mo粉、Ti 粉和Zr粉按质量比99.35?0.55?0.10混合,采用冷等静压和1 920 ℃高温烧结制备直径为 28 mm的Mo-Ti-Zr合金棒材,然后,将合金棒材进行旋锻形变强化后续处理。研究旋锻工艺对Mo-Ti-Zr合金棒材密度、硬度等性能和组织结构变化的影响。研究结果表明:随着变形程度的增加,Mo-Ti-Zr合金棒材的相对密度和硬度逐步提高;在1 250 ℃旋锻,当断面收缩率为33%时,Mo-Ti-Zr合金棒材相对密度提高到98.5%,洛氏硬度(HRB)为92.8。当断面收缩率为19.2%时,Mo-Ti-Zr合金棒材致密化速率最低;烧结态Mo-Ti-Zr合金棒材断口呈现典型的沿晶脆性断裂特征,晶界强度低;在1 250 ℃旋锻,当断面收缩率达到33%时,Mo-Ti-Zr合金棒材转变为穿晶和沿晶的混合型断裂, 晶界强度增加;在1 380 ℃旋锻时,晶粒发生合并与长大。

关键词:Mo-Ti-Zr合金棒材;旋锻;相对密度;断口形貌

中图分类号:TF125.2 文献标志码:A 文章编号:1672-7207(2010)01-0097-06

Influence of rotary forging on mechanical properties and microstructure of Mo-Ti-Zr alloy

LUO Ming, FAN Jing-lian, CHENG Hui-chao, TIAN Jia-min, LU Ming-yuan

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: Mo-Ti-Zr alloy rods with diameter of 28 mm were prepared by mixing the elemental powders according to the mass ratio of m(Mo)?m(Ti)?m(Zr)=99.35?0.55?0.10, cold isostatic pressing and high temperature sintering at 1 920 ℃, then the alloy rods were rotary forged. The influences of the rotary forging process on the relative density, hardness and microstructure of Mo-Ti-Zr alloy rods were investigated. The results are as follows. The relative density and hardness of Mo-Ti-Zr alloy rods increase gradually with the increase of deformation amount. The relative density of Mo-Ti-Zr alloy rods reaches 98.5% and hardness is HRB 92.8 after rotary forging to deformation amount of 33% at 1 250 ℃. The increase of relative density of Mo-Ti-Zr alloy rods reaches the lowest after rotary forging to deformation amount of 19.2%. The fracture type of sintered Mo-Ti-Zr alloy rods is of intergranular fracture and the grain boundary strength is weak. The fracture type of Mo-Ti-Zr alloy rods changes to the mixing type of transgranular fracture and intergranular fracture and the grain boundary strength is strengthened after rotary forging to deformation amount of 33% at 1 250 ℃. The molybdenum grains mergence and growth occur after rotary forging at 1 380 ℃.

Key words: Mo-Ti-Zr alloy rods; rotary forging; relative density; fracture surface morphology

钼合金具有优良的导电、导热以及耐腐蚀性能,而且具有较低的热膨胀系数、较高的硬度和很高的高温强度,因而应用广泛[1]。钼合金的常用制备方法有电弧熔化-铸造法和粉末冶金法。相对于电弧熔化-铸造法,粉末冶金法可以节省真空自耗电弧炉、大型挤压机和锻锤以及相应的高温加热炉等大型设备,简化工序,降低消耗,提高生产能力及成品率。但粉末冶金法制备的钼合金由于具有一定的孔隙,使其强度和韧性大大降低[2]。无论采用何种方法制备Mo-Ti-Zr合金棒材,最后都要进行热挤压或锻造,以改善塑性和加工性能[3]。通常是采用热挤压和锻造相结合的方法,只采用热挤压变形是不够的,还必须进行充分的锻造变形使组织得到进一步均匀化[4]。由于Mo-Ti-Zr合金棒材热变形加工比较困难,烧结后的合金首先应进行热挤压开坯,然后锻造,而这样的加工工艺对提高合金的力学性能有不利影响[5]。粉末热锻是将烧结的预成形坯加热后在闭式模中锻造成零件的一种新工艺,它将传统的粉末冶金与精密模锻很好地结合起来,兼具粉末冶金和精密模锻两方面的优点:经热锻制备的零件相对密度高,具有较均匀的细晶粒组织,物理和力学性能大大提高[6-7];同时,它又保持普通粉末冶金少切削、无切削的工艺优点,具有成形精确、材料利用率高等特点。因而,粉末锻造已广泛应用于各种钼合金[8-11]的研究中。研究不经过热挤压而直接热锻的Mo-Ti-Zr合金棒材,对获得低成本、高性能的Mo-Ti-Zr合金棒材有着重要的实际意义。本文作者采用冷等静压、高温烧结和直接高温旋锻的方法制备Mo-Ti-Zr合金棒材,研究了旋锻温度,断面收缩率对合金棒材性能与显微组织的影响,探讨Mo-Ti-Zr合金棒材高温旋锻致密化过程和机理以及对断口形貌的影响规律。

1 实验

实验采用高纯Mo粉末中添加0.55% Ti和0.1% Zr合金元素粉末,将粉末混合球磨5 h,然后采用冷等静压成形,压力为200 MPa,保压1 min,在氢气气氛于1 000 ℃预烧2 h,再在钨棒炉中于1 920 ℃烧结2 h制备出直径28 mm的Mo-Ti-Zr合金棒材,然后,将烧结合金棒材分别在1 250 ℃和1 380 ℃ 2种温度下直接进行不同形变量的旋锻,并将烧结和旋锻后的合金棒材沿径向用线切割切成标准“工”字型拉伸试样,采用排水法测定烧结态和旋锻试样的密度,采用HRBVU-1875.8型布洛维光学硬度计测试洛氏硬度,在日产JSM-5600LV型扫描电镜上观察拉伸试样断口形貌特征。

2 结果与讨论

2.1 旋锻对Mo-Ti-Zr合金棒材断口形貌的影响

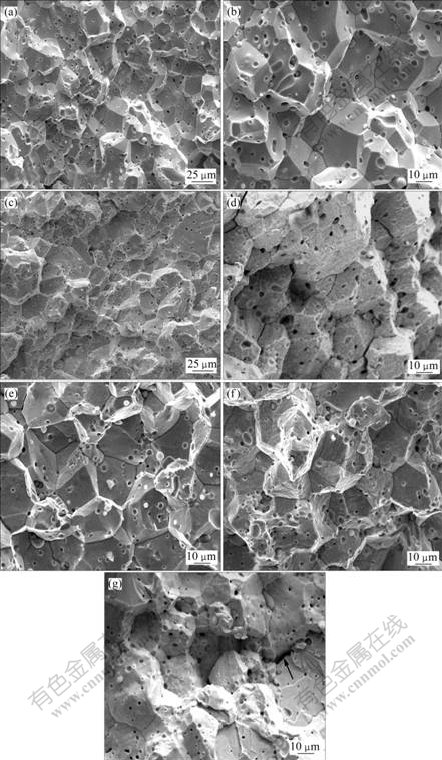

图1(a)和图1(b)所示为烧结态Mo-Ti-Zr合金棒材拉伸样断口形貌特征。由图1(a)和1(b)可见:合金中的Mo晶粒近似等轴状,其晶粒度为20~30 μm,晶界光滑平整,断口呈现典型的脆性沿晶断裂特征,晶界上分布有规则的圆形孔隙,孔隙大小为2~5 μm,局部存在连通的长条状孔隙。孔隙可能是高温烧结未消除的孔隙或拉伸断裂过程中第二相复合氧化物粒子 (Mo, Zr, Ti)xOy脱离Mo基体而产生的。前一种孔隙产生的原因可能是烧结过程中氢气还原氧化的Mo,Ti和Zr颗粒产生的水蒸汽残留导致的;后一种孔隙是晶界存在的第二相复合氧化物粒子(Mo, Zr, Ti)xOy[12]与Mo晶粒的界面结合力弱,在拉伸断裂过程中它与Mo晶粒变形协调性差脱离所形成。因此,常温下由于有烧结残留孔隙和氧化物第二相粒子(Mo, Zr, Ti)xOy 2种裂纹源,加上界面易于偏聚氧、碳等杂质元素,Mo-Ti-Zr合金棒材易于产生沿晶脆性断裂,界面结合强度低。图1(c)和图1(d)所示是温度为1 250 ℃、断面收缩率为33%的Mo-Ti-Zr合金棒材拉伸样断口形貌特征。从图1(c)可以看出:断口呈穿晶和沿晶混合型断裂,大部分直径为20~30 μm的晶粒发生沿晶断裂,少数大晶粒发生穿晶解理断裂。从图1(d)可以看出:断口平面与拉伸轴基本垂直,断面较平整,呈沿晶脆断特征,孔隙数目显著减少,孔径减为1~2 μm,三角晶界孔隙和长条状孔隙消失,表明于1 250 ℃、断面收缩率为33%的形变时,晶粒在旋锻压力作用下发生一定的塑性变形而填充孔隙,从而使晶粒接触增加,并且在晶粒接触面之间原子发生扩散作用,形成物理冶金结合,孔洞缩小和消失,从而导致钼晶粒之间的结合强度增加。这一推论与EI-Rakayby等[13]的观点一致。图1(e)和图1(f)所示为于1 380 ℃、断面收缩率为16%和28%的Mo-Ti-Zr合金棒材断口形貌特征。可见:当断面收缩率为16%时,由于晶粒塑性变形不太明显,Mo晶粒基本保持等轴状,其尺寸与烧结态晶粒相差不大,所不同的是晶界上孔隙数量和尺寸减小,晶界表面渐显凹凸不平,但拉伸断口呈现沿晶脆性断裂特征,此时,界面结合强度低;当断面收缩率为28%时,Mo晶粒发生明显塑性变形,此时,Mo晶粒由等轴状变成长轴不规则状,界面发生明显凹凸不平,并且可以看到撕裂痕迹,Mo晶粒断面出现明显滑移流动痕迹,说明此时Mo晶粒发生相对滑移而且晶粒界面强度增加。这是由于形变量增大,晶界孔隙数目减小与闭合,晶粒之间产生更多的界面结合以及高温作用下的物理冶金结合增强,在断裂过程中沿晶界发生一定的塑性变形,相邻两晶粒逐步脱离。图1(g)所示为于1 380 ℃、断面收缩率为36%的Mo-Ti-Zr合金棒材断口形貌。可以看出:Mo晶粒发生明显合并与长大,此时晶界变得模糊不清,晶界上微孔隙增多,界面结合强度低,易产生裂纹,如图1(g)中箭头所示,这证明在1 380 ℃旋锻变形时,由于旋锻温度提高而使变形量增加,但同时由于锻造温度太高而易于使Mo晶粒在大变形应力和温度的综合作用下发生晶粒合并与长大。

(a),(b) 烧结态;(c),(d) 温度为1 250 ℃,断面收缩率为33%;(e) 温度为1 380 ℃,断面收缩率为16%;

(f) 温度为1 380 ℃,断面收缩率为28%;(g) 温度为1 380 ℃,断面收缩率为36%

图1 不同变形条件下Mo-Ti-Zr合金棒材断口的SEM形貌

Fig.1 SEM morphologies of fracture section of Mo-Ti-Zr alloy rods under different deformation conditions

2.2 旋锻对Mo-Ti-Zr合金棒材致密化的影响

由于粉末冶金烧结态Mo-Ti-Zr合金棒材存在残留的孔隙,旋锻变形过程主要是塑性变形过程,可以看成是晶粒与晶粒之间相对运动的结果。烧结态合金棒在锻造过程中产生塑性变形而达到致密化,此时金属基体同时产生塑性变形和致密化。这与致密金属的锻造有所不同,致密金属塑性变形的微观机构主要是依靠金属晶体的位错运动和晶粒之间的相对运动。而多孔粉末冶金烧结体的塑性变形和致密化机构,不仅与金属基体产生的晶间和晶内变形有关,而且与孔隙的变形有很大关系。

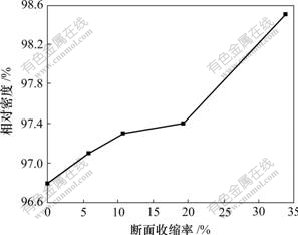

图2所示为Mo-Ti-Zr合金棒材在1 250 ℃锻造时旋锻过程中合金棒材相对密度与断面收缩率变化的关系。由图2可见:随着变形程度的增加,Mo-Ti-Zr合金棒材的相对密度逐步提高。当断面收缩率为10.7%时,相对密度提高到97.3%;当断面收缩率为33%时,相对密度提高到98.5%。

图2 1 250 ℃旋锻时Mo-Ti-Zr合金棒材相对密度和断面收缩率的关系

Fig.2 Relationship between relative density and reduction of cross section of Mo-Ti-Zr alloy rods at 1 250 ℃

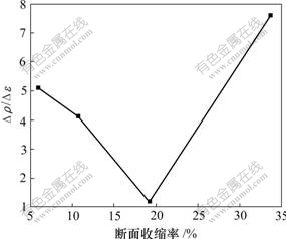

图3所示为Mo-Ti-Zr合金棒材在1 250 ℃锻造时旋锻过程中致密化速率与断面收缩率的关系。致密速率? ρ/? ε表示单位应变下相对密度的增量,其中:? ρ为相对密度的变化,? ε表示断面收缩率的增量,它主要反映了变形过程中相对密度变化的快慢。可见:当断面收缩率为19.2%时,致密速率达到最小;当断面收缩率小于19.2%时,致密速率随断面收缩率增加逐渐减小,此时主要是孔隙的运动;而当断面收缩率超过19.2%时,致密速率增大,发生塑性变形并进一步消除孔隙。这表明在旋锻的各个阶段,Mo-Ti-Zr合金棒材的致密化机理不同。在旋锻初期,其致密速率较高,随着变形与致密化的进行,产生加工硬化现象而影响了粉末材料的致密化。粉末材料的加工硬化包括Mo-Ti-Zr合金棒材的致密化引起几何硬化和位错密度增加产生的应变硬化。在后续旋锻过程中,每旋锻1次,锻件回炉在1 250 ℃保温15 min,由于Mo合金层错能较大,位错容易产生束集,在高温作用下有足够的时间发生滑移和攀移,从而产生回复软化作用。因此,随着断面收缩率增大,长时间高温产生的软化作用增强,应变硬化效应减弱,致密速率也相应提高。此后,由于粉末材料的密度越来越高,使得粉末材料以变形为主。即在变形初期,主要以致密化为主,在后期,以变形为主;在二者之间,变形与致密化是同时进行的。

图3 1 250 ℃旋锻时Mo-Ti-Zr合金棒材致密化速率和断面收缩率的关系

Fig.3 Relationship between densification rate and reduction of cross section of Mo-Ti-Zr alloy rods at 1 250 ℃

2.3 旋锻对Mo-Ti-Zr合金棒材硬度的影响

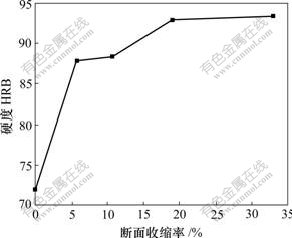

图4所示为旋锻Mo-Ti-Zr合金棒材断面收缩率对硬度的影响。由图4可以看出:随着形变的增加,旋锻钼棒的硬度也相应提高。对于烧结态Mo-Ti-Zr合金棒材,其硬度为HRB 72;当旋锻使断面收缩率小于6%时,主要发生孔隙的变形、压缩而使密度增加和硬度提高,此时硬度达到HRB 87.8;当断面收缩率增加到11%时,致密速率减小,同时,硬度增长较慢;当断面收缩率为11%~19%时,变形与致密化同时进行,Mo-Ti-Zr合金棒材的致密化引起几何硬化和位错密度增加而产生应变硬化,此时硬度增加明显;当断面收缩率达到19%时,硬度达到HRB 92.8;断面收缩率继续增加时,钼晶粒变形进一步增大,但高温产生的热软化效应增强,此时硬度保持平稳。

图4 1 250 ℃旋锻时Mo-Ti-Zr合金棒材硬度和断面收缩率的关系

Fig.4 Relationship between hardness and reduction of cross section of Mo-Ti-Zr alloy rods at 1 250 ℃

2.4 分析与讨论

孔隙易于造成应力集中而成为裂纹源,而孔隙对拉应力非常敏感,从而使多孔预成形坯在拉应力状态下具有低塑性的特点。由公式σ = σ0exp(-bθ)(其中:σ为强度;σ0为致密金属强度;b为比例系数;θ为孔隙度)可知:孔隙度减小导致强度和塑性显著提高。Mo- Ti-Zr合金棒材在旋锻过程中同时经历了晶粒间塑性变形与孔隙闭合。当温度升高时,晶界强度降低,塑性变形则先从晶界产生。对于粉末冶金多孔体来说,晶界特性比较复杂,在其内部存在2种晶界,即原始颗粒内晶界和颗粒间晶界。这2种晶界都含有较多的缺陷,尤其原始颗粒间晶界往往存在大量的缺陷和夹杂物,使得晶界强度降低,容易产生滑移和塑性流动。随着形变的增加,孔隙发生剪切变形和压缩闭合,从而通过高温镟锻可以显著消除孔隙而提高相对密度,而硬度表示合金局部抵抗塑性变形的能力,与相对密度、位错密度都有关系,相对密度的提高导致硬度显著 提高。

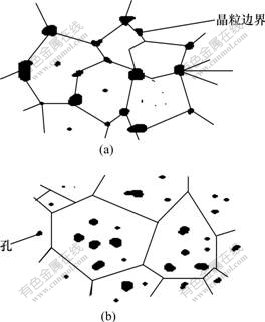

但采用高温镟锻工艺却达不到全致密,这与烧结体内孔隙有关。由于粉末烧结体中的孔隙是以可消除孔隙和不可消除孔隙2种方式存在的(如图5所示)[15],在高温下,晶界的强度减小,晶粒之间通过蠕变和相对滑移产生运动,使得晶界之间的孔隙在热锻应力的作用下发生剪切变形和闭合而消除,但晶粒内部的孔隙由于晶粒难以变形而得以保留。旋锻过程中孔隙变化有3种可能[14]:(1) 孔隙经变形后闭合,并通过高温状态下的再结晶过程和原子扩散过程而焊合;(2) 孔隙只发生变形,既没有形成冶金结合,也没有形成带尖端的裂纹;(3) 孔隙演变成裂纹。可见:在旋锻过程中,如果孔隙变化按第1种情况发生,合金棒坯的力学性能就会提高。由于合金中存在第2相氧化物粒子(Mo, Zr, Ti)xOy,可以产生弥散强化,但在旋锻过程中当直径较大的Mo晶粒和小的(Mo, Zr, Ti)xOy晶粒接触在一起时,(Mo, Zr, Ti)xOy晶粒优先变形。此时大晶粒与小晶粒由于接触表面应变不同,两者相对位移的大小与方向上也不同,这就可能导致由直径不同的晶粒所形成的接触界面弱化,最终产生断裂。

(a) 可消除孔隙;(b) 不可消除孔隙

图5 2种孔隙的存在方式示意图

Fig.5 Sketch map of two existence mode of pores

高温对孔隙闭合有显著的影响。一方面,提高加工温度会降低Mo合金的变形抗力,而且加工温度升高,原子扩散能力增强,有利于闭合之后的孔洞表面形成物理冶金结合;另一方面,在加工过程中,当颗粒发生迁移时,颗粒表面的氧化膜会由于颗粒之间移动而产生摩擦,以及颗粒表面发生磨损而破坏,此时,由于氧化膜破碎,清洁表面的面积会增大,从而有利于颗粒之间形成良好的结合。当旋锻温度过高时,可能加剧孔洞周围颗粒表面的氧化程度,使孔洞相互连接而长大。根据受力分析,在旋锻过程中孔隙处于三向压应力状态[16]。在压应力作用下,孔隙表面逐渐靠拢,直到距离小于原子间力的作用半径,结果产生微小的单个结合区段(结合桥),结合桥开始扩展,又产生新桥而使结合面不断增加,形成良好的物理冶金结合,三向压应力还能抵消或降低由于不均匀变形产生的附加拉应力,三向压应力能将Mo晶粒在塑性变形时受到破坏的部分晶内和晶间结合回复。因此,随着三向压应力增加,各种微裂纹被焊合,金属结构致密。在粉末冶金Mo-Ti-Zr合金棒材中不可避免存在孔隙和第2相氧化物粒子(Mo, Zr, Ti)xOy夹杂,在三向压缩的主变形状态下,面缺陷变成线缺陷,有利于孔隙的消除。因此,旋锻对合金相对密度的提高更加明显。

3 结论

(1) 随着变形程度的增加,Mo-Ti-Zr合金棒材的相对密度和硬度逐步提高。在1 250 ℃旋锻,当断面收缩率为33%时,相对密度提高到98.5%,硬度为HRB 92.8。当断面收缩率为19.2%时,致密化速率最低。Mo-Ti-Zr合金棒材在旋锻的各个阶段致密化机理是不同的。

(2) 烧结态Mo-Ti-Zr合金棒材断口呈现典型的沿晶脆性断裂特征,界面结合强度低。Mo-Ti-Zr合金棒材在1 250 ℃旋锻,当断面收缩率达到33%时,断口呈穿晶和沿晶混合型断裂,钼晶粒之间的结合强度增加。在1 380 ℃旋锻时,由于锻造温度太高而易于使Mo晶粒在大变形应力和温度的综合作用下发生晶粒合并与长大。

(3) 孔隙消除机理主要是高温使闭合之后的孔洞表面形成物理冶金结合,以及三向压应力使各种微裂纹被焊合。

参考文献:

[1] 李洪桂. 稀有金属冶金学[M]. 北京: 冶金工业出版社, 1990.

LI Hong-gui. Metallurgy of rare metals[M]. Beijing: Metallurgical Industry Press, 1990.

[2] 任学平, 康永林. 粉末塑性加工原理及其应用[M]. 北京: 冶金工业出版社, 1998.

REN Xue-ping, KANG Yong-lin. Theory and application of powder plastic working[M]. Beijing: Metallurgical Industry Press, 1998.

[3] 成会朝, 范景莲, 刘涛. TZM钼合金制备技术及研究进展[J]. 中国钼业, 2008, 32(6): 40-45.

CHEN Hui-cao, FAN Jing-lian, LIU Tao. Preparation and research development of TZM molybdenum alloys[J]. China Molybdenum Industry, 2008, 32(6): 40-45.

[4] 郑欣, 张清, 张军良. Mo-Ti-Zr棒材加工方法的分析[J]. 稀有金属快报, 2004, 23(7): 29-31.

ZHENG Xin, ZHANG Qing, ZHANG Jun-liang. Preparation methods analyse of Mo-Ti-Zr rods[J]. Rare Metals Letters, 2004, 23(7): 29-31.

[5] 蔡宗玉, 金建民, 陈桦. 高性能TZM钼合金棒研制[J]. 上海钢研, 1993, 3: 9-12.

CAI Zong-yu, JIN Jian-min, CHEN Hua. Manufacture of the TZM molybdenum alloy sticks with high property[J]. Shanghai Steel Study, 1993, 3: 9-12.

[6] Katsumi Y. Improvement of machinability of sintered composite-type alloyed steel powder[J]. American Society of Mechanical Engineers, Production Engineering Division, 1993, 67(6/7): 151-157.

[7] Lenel F V, Ansell G S, Morris R C. Modern developments in powder metallurgy[M]. New York: Plenum Press, 1971.

[8] 陈畅, 汪明朴, 谭望. Mo-C棒的横向弯曲性能[J]. 中南大学学报: 自然科学版, 2009, 40(1): 129-134.

CHEN Chang, WANG Ming-pu, TAN Wang. Transverse bending property of molybdenum-carbon bars[J]. Journal of Central South University: Science and Technology, 2009, 40(1): 129-134.

[9] 张建德, 曾舟山, 谢飞. 热变形致密细晶粒钼棒的组织和性能[J]. 粉末冶金材料科学与工程, 2008, 13(4): 235-239.

ZHANG Jian-de, ZENG Zhou-shan, XIE-Fei. Microstructures and properties of fine-grained molybdenum rod prepared by hot deformation[J]. Materials Science and Engineering of Powder Metallurgy, 2008, 13(4): 235-239.

[10] Cockeram B V. The mechanical properties and fracture mechanisms of wrought low carbon arc cast (LCAC), molybdenum-0.5pct titanium-0.1pct zirconium (TZM), and oxide dispersion strengthened(ODS) molybdenum flat products[J]. Materials Science and Engineering A, 2006, 418(1/2): 120-136.

[11] Mrotzek T, Hoffmann A, Martin U. Hardening mechanisms and recrystallization behaviour of several molybdenum alloys[J]. International Journal of Refractory Metals & Hard Materials, 2006, 24(4): 298-305.

[12] 范景莲, 卢明园, 成会朝. 微量合金元素Ti, Zr对Mo合金性能和显微组织的影响[J]. 稀有金属材料与工程, 2008, 37(8): 1471-1474.

FAN Jing-lian, LU Ming-yuan, CHEN Hui-cao. Effect of alloyed elements Ti, Zr on the property and microstructure of Mo alloy[J]. Rare Metal Materials and Engineering, 2008, 37(8): 1471-1474.

[13] EI-Rakayby A M, Mills B. The role of primary carbides in the wear of high speed steels[J]. Wear, 1986, 112(3/4): 327-340.

[14] 崔振山, 任广升, 徐秉业. 圆柱体内部空洞的热锻闭合条件[J]. 清华大学学报, 2003, 43(2): 227-229.

CUI Zhen-shan, REN Guang-sheng, XU Bing-ye. Void closing conditions for solid cylinders during hot forging[J]. Journal of Tsinghua University: Science and Technology, 2003, 43(2): 227-229.

[15] 王佳玲, 陈卓, 陈华. 铁基粉末烧结热锻材料的组织和性能[J]. 长春工业大学学报: 自然科学版, 2005, 26(1): 62-65.

WANG Jia-ling, CHEN Zhuo, CHEN Hua. Study on the microstructures and properties of forged iron-base sintered materials[J]. Journal of Changchun University of Technology: Natural Science Edition, 2005, 26(1): 62-65.

[16] 张启修, 赵秦生. 钨钼冶金[M]. 北京: 冶金工业出版社, 2005.

ZHANG Qi-xiu, ZHAO Qing-shen.Tungsten and molybdenum metallurgy[M]. Beijing: Metallurgical Industry Press, 2005.

收稿日期:2009-05-12;修回日期:2009-08-10

基金项目:国家自然科学基金委员会创新研究群体科学基金资助项目(50721003);国防军工新材料项目(JPPT-115-2-662)

通信作者:范景莲(1967-),女,湖南常德人,教授,从事难熔合金和纳米新材料的研究;电话:0731-88836652;E-mail: fjl@mail.csu.edu.cn

(编辑 陈爱华)