J. Cent. South Univ. (2017) 24: 9-16

DOI: 10.1007/s11771-017-3403-2

An optimized hardness model for carburizing-quenching of low carbon alloy steel

ZHANG Xing(张星)1, TANG Jin-yuan(唐进元)1, ZHANG Xue-rui(张学瑞)2

1. State Key Laboratory of High Performance Complex Manufacturing, Central South University,

Changsha 410083, China;

2. School of Software, Central South University, Changsha 410083, China

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Central South University Press and Springer-Verlag Berlin Heidelberg 2017

Abstract: Research has been conducted about the hardness prediction for the carburizing and quenching process based on an optimized hardness simulation model, in accordance with the calculation rule of mixed phases. The coupling field model incorporates carburizing field analysis, temperature field analysis, phase transformation kinetics analysis and a modified hardness calculation model. In determination of the calculation model for hardness, calculation equations are given to be applied to low carbon content (x(C)≤0.5%) for the child phases and the martensite hardness is calculated for high carbon content (x(C)>0.5%) in alloy. Then, the complete carburizing-quenching hardness calculation model is built, and the hardness simulation data are corrected considering the influence of residual austenite (RA) on hardness. Hardness simulations of the carburizing and quenching process of 17CrNiMo6 samples have been performed using DEFORM-HT_V10.2 and MATLAB R2013a. Finally, a series of comparisons of simulation results and measured values show a good agreement between them, which validates the accuracy of the proposed mathematical model.

Key words: carburizing-quenching simulation; hardness model; DEFORM-HT; residual austenite; high carbon content

1 Introduction

In modern manufacturing process, carburizing- quenching has become a major hardening process for gears and other metal parts. As hardness distribution has a great impact on the service life of parts after heat treatment [1], it is meaningful to investigate the hardness distribution after carburizing-quenching.

For the hardness simulation of heat treatment, traditional hardness models are mainly divided into two categories [2]. The first category can be called calculation rule of mixed phases, in which the hardness of parts is calculated due to the child phases (such as ferrite, pearlite, bainite and martensite). However, this method is only applicable to low carbon content (x(C)≤0.5%) since it cannot consider the influence of residual austenite on hardness [3]. WOOD et al made a prediction for the quenching hardness of a steel cylinder using this method, and they estimated the hardness values of residual austenite as equals to those of martensite [4]. Later, CARLONE et al also made the same assumption when they analysed the quenching process [5]. YUAN and KANG predicted hardness values due to the volume fraction of martensite and summed up the formulas [6]. The second category is the method of Jominy Curves, which is the major method for hardness prediction of quenching [7]. There are some formulas about this method, but the use range for carbon content was limited (x(C)≤0.56%) [8]. The measured curves can avoid the limitation of carbon content, but the situation will become very complex when the carburizing process is involved, since measured data are mainly applied to the quenching process [9]. SUGIANTO et al made hardness predictions for carburizing-quenching of a SCr420 steel helical gear with Jominy curves. However, the Jominy distance of 0.8% C was taken by the carbon function of 0.2%-0.6% C, and the carbon function was taken from DEFORM data [10]. In a word, the traditional hardness models have some problems, in one aspect or another, for hardness simulation of the carburizing- quenching process.

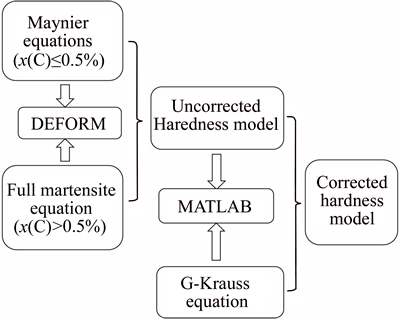

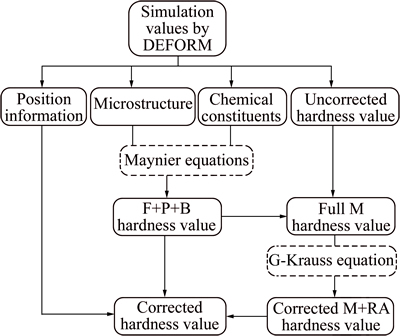

In the present work, a complete model has built for hardness simulation of carburizing-quenching process. The model incorporates carburizing field analysis, temperature field analysis, phase transformation kinetics analysis and a modified hardness calculation model. For the hardness calculation model shown in Fig.1, the focus is placed on the establishment of a suitable hardness calculation model for the carburizing and quenching process by taking into account the effect of high carbon content and residual austenite content on hardness. Then, simulations for the carburizing and quenching process of some 17CrNiMo6 samples have been carried out using DEFORM-HT_V10.2 and MATLAB R2013a, and some experiments have been conducted to verify the results of simulations. Finally, the temperature, carburizing depth, microstructures and hardness distribution have been discussed.

Fig. 1 Modified hardness calculation model

2 Model for carburizing-quenching process

The simulation of the carburizing-quenching process can be considered as metallic-thermal- mechanical coupling calculation, and the whole model covers four parts. 1) Carburizing field analysis, utilized used to analyze the diffusion of carbon during carburizing process; 2) Temperature field analysis, mainly used to analyze heat conduction during the whole process; 3) Phase transformation kinetics analysis, which describes different transformations during the whole process; 4) Hardness calculation model, which contains all the hardness calculation equations for hardness prediction.

2.1 Carburizing field analysis

Assuming nonsteady-state practical carburizing, the basic governing equation of the carbon diffusion into the iron matrix is known as Ficks second law [11-13]:

(1)

(1)

where C, t and xi denote the carbon content, the carburizing time and the position direction, respectively.

D is the diffusion coefficient, which is taken as a function of temperature and carbon content [14]:

(2)

(2)

where D0.4 is the diffusion constant (C=0.4%) and it is set to be 25.5 mm2·s-1; Q is carbon diffusion activation energy and it is set to be 141 kJ/mol; B is the constant which reflects the relationship between the carbon content and the diffusion coefficient and it is set to be 0.8; T and R denote temperature and gas constant, respectively.

The boundary condition is specified by the reaction across the surface layer and it is expressed as

(3)

(3)

where Ce and Cs are the employed carbon content from external environment during gas carburizing and the carbon content in the surface, respectively.

b is the carbon transfer coefficient and it can be expressed as

(4)

(4)

where β0 and E are constant and activation energy which are set, respectively, to be 0.00347 mm/s and 34 kJ/mol.

2.2 Temperature field analysis

The temperature field is governed by a heat conduction equation coupled with latent heat due to phase transformation [15]:

(5)

(5)

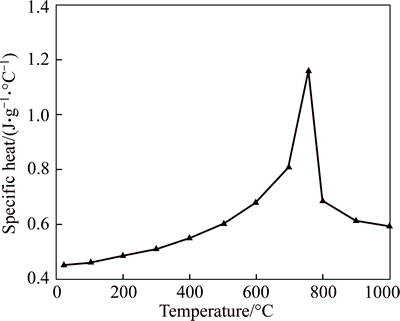

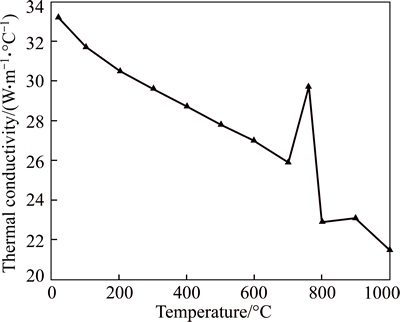

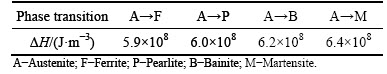

where ρ, c and k denote the density, the specific heat and the conductivity constant, respectively, with the thermal parameters shown in Figs. 2 and 3. lI denotes the latent heat produced by the progressive I constituent. For the latent heat, DARKEN and GURY proposed a diffusion calculation model while ERICSSON proposed a diffusionless model [16]. On this basis, the latent heat value of each child phase transformation can be determined, as shown in Table 1.

Fig. 2 Heat capacity of 17CrNiMo6 alloy

Fig. 3 Thermal conductivity of 17CrNiMo6 alloy

Table 1 Enthalpy of decomposition of austenite

The boundary condition of heat transfer on the surface is assumed to be

(6)

(6)

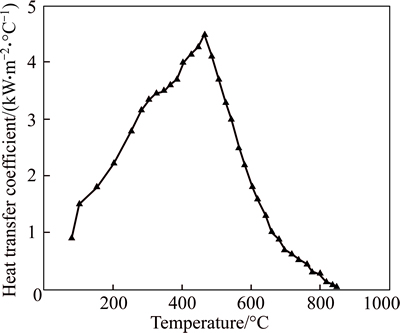

where h denotes the heat transfer coefficient which is a function depending on surface temperature. With a reference to the oil quenching experiments on a 17CrNiMo6 steel cylinder, the heat transfer coefficient between 17CrNiMo6 steel and KR128 is obtained, as shown in Fig. 4 [17]. TS and T∞ denote the surface temperature of the sample and the oil temperature, respectively.

Fig. 4 Heat transfer coefficient between 17CrNiMo6 steel and KR128

2.3 Phase transformation kinetics analysis

During heating before the gas carburizing and oil quenching process, the child phases transform to austenite that is assumed to be simplified diffusion as follows [18]:

(7)

(7)

where ξA is the austenite volume fraction; A and D are material constants taken as -4 and 2, respectively; T is the average element temperature; AC1 and AC3 are the lower and upper critical temperatures taken from CCT diagram, respectively.

The austenite transforms to child phases during the cooling and quenching processes. For the diffusion transformation, such as ferrite-pearlite transformation and bainite transformation, the volume fraction is expressed by Johnson-Mehl equation as follows:

(8)

(8)

where k and n are material constants which can be obtained by TTT diagram. All the CCT/TTT diagrams are calculated by JMatPro [19] and they are functions of carbon content.

For the martensite transformation which is diffusionless transformation, the following K-M equation is generally used:

(9)

(9)

where α is taken as 0.011.

Although there are numerous methods to calculate MS, most of them have restrictions imposed by carbon content. For carburized alloy steel, the application range of these equations cannot meet the requirements [20-21]. NUSHEH [22] has proposed an equation which can be applied to the calculation of MS in high carbon content when simulating the quenching of carburized steel:

(10)

(10)

This equation applies to the condition of 0.2%- 0.85% C.

2.4 Hardness calculation model

The mathematic model for hardness calculation incorporates hardness calculation of child phases in low carbon content, hardness calculation of martensite in high carbon content, and correction of hardness curve with the consideration of the effect exerted by residual austenite.

2.4.1 Determination of hardness of child phases

This sub-section mainly deals with hardness equations and critical cooling rate equations of child phases [23].

The hardness equation of ferrite-pearlite is

(11)

(11)

The hardness equation of bainite is

(12)

(12)

The hardness equation of martensite is

(13)

(13)

where HVI denotes the Vickers hardness of I phase; V is the critical cooling rate; x(C), x(Mn), x(Cr), x(Ni), x(Mo) etc are the element contents of steel.

CKЛЮEB analysed statistic data for austenite transformation kinetics curves of some common structure steels, and then summarized the respective equations for critical cooling rates of martensite, bainite and ferrite-pearlite.

The critical cooling rate of martensite VM (°C/h) is

(14)

(14)

The critical cooling rate of bainite VB (°C/h) is

(15)

(15)

The critical cooling rate of ferrite-pearlite VF-P (°C/h) is

(16)

(16)

where PA is an austenitizing parameter (heating time×heating temperature, and heating time is 1 h)

The applicable conditions of all the equations Eqs. (11)-(16) are as follows: x(C)≤0.50%, x(Mn)≤1.75%, x(Ni)≤3.0%, x(Cr)≤2.25%, x(Mo)≤1.0%, and x(Mn)+x(Ni)+ x(Cr)+ x(Mo)≤5.0%.

2.4.2 Equation for martensite hardness in high carbon content

It should be pointed out that only martensite transformation occurs in high carbon content. Since Eq. (13) is only applicable in low carbon content (x(C)≤0.50%), a new equation is needed for high carbon content. According to the calculation equation of full martensite proposed by YU [24], the martensite hardness value of alloy is generally higher than that of carbon steel by 1-2 HRC. On this basis, the equation for martensite hardness in high carbon content (x(C)>0.50%) can finally be determined as

(17)

(17)

2.4.3 Correction of hardness model

As DEFORM cannot consider the influence of residual austenite on hardness, the hardness of residual austenite should first be assumed to be equal to that of martensite. Then, the carbon distribution data, the volume fraction of every phase, and the hardness curve data are all put into Matlab, and the hardness curve is corrected by programming, as shown in Fig. 5.

Fig. 5 Programming by Matlab

G-Krauss summed up the reduced hardness of full martensite which was influenced by the volume fraction of residual austenite [22]:

(18)

(18)

Conversion to Rockwell metric yields:

(19)

(19)

Corrected martensite and residual austenite hardness is:

(20)

(20)

where HRCM is the initial hardness of martensite (residual austenite).

According to the calculation rule of mixed phases, the corrected hardness curve can be expressed as

(21)

(21)

where HRCI and ξI are hardness and volume fraction of each child phase respectively.

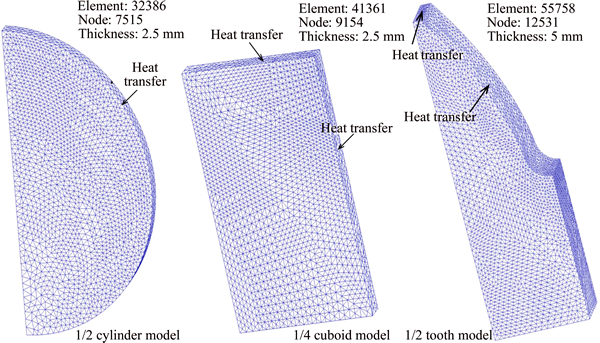

3 Finite element models and experimental procedure

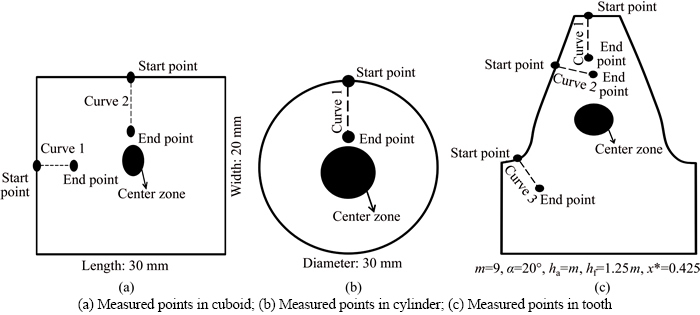

In order to verify the hardness simulation model, three different types of samples produced for hardness prediction are shown in Fig. 6. Figure 7 shows the measured points for different samples in cross-section.Considering the symmetry of samples, the simplified models are employed in simulations, and the finite element parameters and heat transfer boundaries are shown in Fig. 8.

Fig. 6 Three types of samples

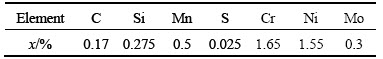

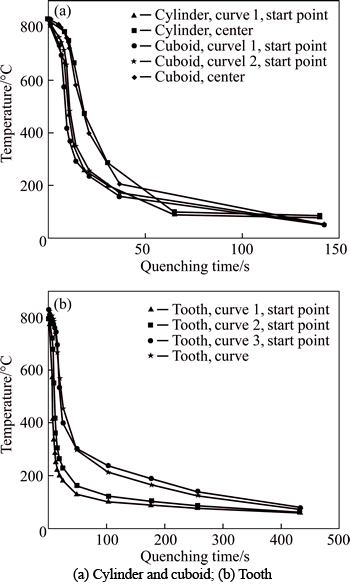

The material of samples is 17CrNiMo6 steel and the contents of its chemical elements are presented in Table 2. Then, Table 3 gives the carburizing-quenching process of samples.

4 Results and discussion

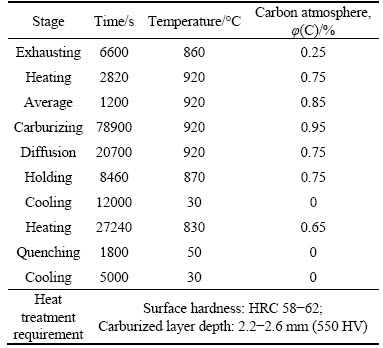

Figures 9(a) and (b) show the temperature change in the surface and center of three samples during the quenching process. From Fig. 9(a), it can be seen that the surface temperatures of the cylinder and the cuboid decrease rapidly and their cooling rates are similar. The cooling rate in the surface is seen to become slow when the temperature reaches about 250 °C. This may occur because of the latent heat generated from martensite transformation. The temperature in the center decreases relativity slowly until it reaches about 100 °C. It can be observed in Fig. 9(b) that the surface temperatures in the addendum and pitch circle decrease rapidly when the quenching process is started, which is especially the case for the addendum. The main reason for this phenomenon is that these parts are convex and the zones for heat transfer are relativity larger. The cooling rate in dedendum is slow, similar to the case for the cooling rate in center, the reason for which is that the dedendum is concave and the heat transfer is bad here.

Fig. 7 Measured points:

Fig. 8 Finite element models

Table 2 Element content of 17CrNiMo6

Table 3 Carburizing-quenching parameters of cylinder

Fig. 9 Temperature change of samples during quenching:

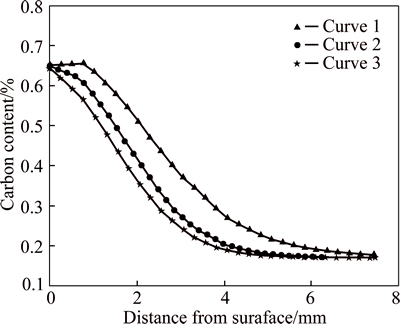

Figure 10 shows the distribution of carbon content in the tooth as a function of depth from the surface after the quenching process. It can be seen that the carbon content is about 0.65% in the surface of the tooth. The carbon content curves of addendum and pitch circle are higher than that of the dedendum, due to the fact that carbon diffusion can be easier at the convex part of the tooth.

Fig. 10 Distribution of carbon content in tooth

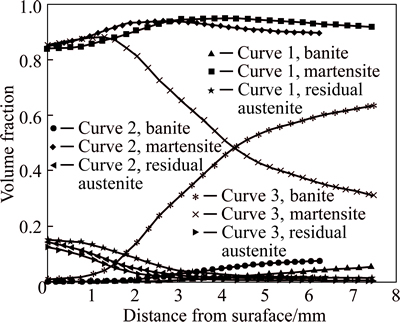

The main microstructures of the tooth are martensite, residual austenite and bainite after the carburizing- quenching process as shown in Fig. 11. There is mainly martensite transformation occurring in the addendum and pitch circle. The martensite contents in the surface and the interior are both more than 85% while the volume fraction of residual austenite is about 15% near the surface. The highest martensite content appears in the sub-surface, as the martensite start temperature here is higher than that in the surface and the cooling rate is faster than that in the center. Because the cooling rate is slow in the dedendum, the complete martensite transformation is only generated near the surface and there is much bainite produced in the center.

Fig. 11 Distribution of volume fraction of microstructure in tooth

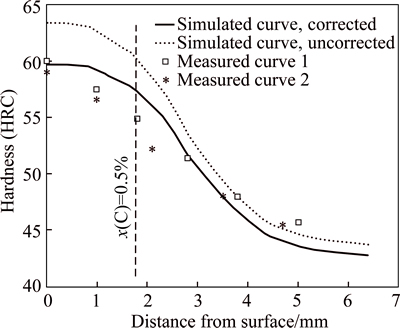

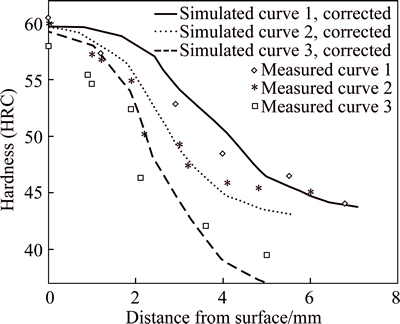

Figure 12 shows the hardness distribution in the cylinder. Two groups of hardness values have been measured (all data are averaged). The simulated hardness value near the surface is mainly affected by the martensite hardness equation for high carbon content and the corrected hardness model of residual austenite (x(C)>0.50%), while the simulated value near the center is mainly affected by the hardness model of mixed phases in low carbon content and the corrected hardness model of residual austenite (x(C)≤0.5%). It can be seen that the simulated values without correction are higher slightly than the measured values, especially for the part of high carbon content. The reason for this is that the hardness of this phase, which cannot be considered due to presence of residual austenite, is assumed to be equal to the hardness of martensite. A comparison of corrected simulated values and measured values shows that there is no significant difference between them. The maximum error with a value of about 6.5% occurs in the position about 1-2 mm away from the surface and the carbon content is in the range of 0.4%-0.6% here.

Fig. 12 Distribution of hardness in cylinder

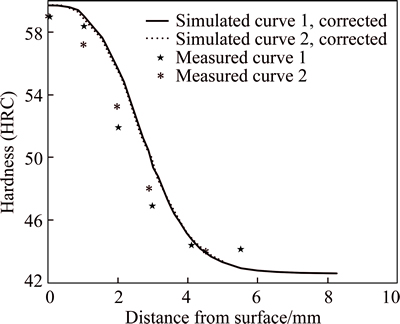

Figure 13 shows the hardness distribution in the cuboid, and two simulated curves are provided for different sides considering the difference in length and width. As shown in the figure, the two simulated hardness curves are highly consistent. The main reason for this is that the sample is small and the length difference of two sides is not large enough, so that the cooling rates are substantially the same in both directions. The two groups of the measured hardness values are slightly smaller than the corrected simulated values, but their trends are consistent. The maximum error, whose value is about 6.8%, is also found in the range of 1-2 mm away from the surface.

Figure 14 shows the hardness distribution in the tooth. It can be seen that the hardness curves for the addendum and the pitch circle are higher than the curve for the dedendum and the values of the former twocurves decrease slowly, as the major microstructure is martensite in these parts. The hardness values in the dedendum decrease rapidly because much banite is generated in the interior. The maximum error for the addendum hardness curve is about 3.3%. The pitch circle hardness curve has good agreement with the measured values in general and the maximum error is 7.5%. It can be easily seen that the simulated hardness values in the dedendum have a larger difference from the measured values and the maximum error is about 10%. What should be mentioned is that the appearance location for the maximum error is still in the range of 1-2 mm away from surface.

Fig. 13 Distribution of hardness in cuboid

Fig. 14 Distribution of hardness in tooth

5 Conclusions

1) After the carburizing process, the carbon content will become higher near the surface than in the initial state, which can reduce the martensite transformation start temperature. Then, a large amount of residual austenite is generated near the surface because of low martensite transformation start temperature.

2) As DEFORM cannot consider the influence of residual austenite on hardness, the hardness of residual austenite should first be assumed to be equal to that of martensite. Therefore, the simulated values without correction are in agreement with the measured values in low carbon content, but the difference between simulated and measured values in high carbon content is significant.

3) Within programming in Matlab, the comparisons of corrected simulated values and measured values show that they are well consistent which proves that the proposed hardness simulated model for carburizing- quenching process of low carbon alloy steel is accurate enough. The maximum error is always kept in the range of 1-2 mm away from the surface and the error is less than 7% in general.

4) Further studies are going to be performed to improve the computational model and verify the simulation results.

References

[1] CHEN Guo-min. Review on carburizing and hardening technology of gears in China [J]. Heat Treatment of Metals, 2008, 33(1): 25-33. (in Chinese)

[2] NIU Shan-ting. Research on 3D finite element simulation and parameter optimization for quenching process [D]. Ji’nan: Shandong University. School of Materials Science & Engineering, 2007. (in Chinese)

[3] MAYNIER P, DOLLET J. Hardenability concepts with applications to steels [M]. DOANE D V, KIRKALDY J S, eds. New York, USA: AIME, 1978: 518-544.

[4] WOODARD P R, CHANDRASEKER S, YANG H T. Analysis of temperature and microstructure in the quenching of steel cylinders [J]. Metallurgical and Materials Transactions B, 1999, 30B: 815-822.

[5] CARLONE P, PALAZZO G S, PASQUINO R. Finite element analysis of the steel quenching process: Temperature field and solid-solid phase change [J]. International Computers and Mathematics with Applications, 2010, 59: 585-594.

[6] YUAN J, KANG J, RONG Y, SISSON R. FEM modeling of induction hardening processes in steel [J]. Journal of Materials Engineering and Performance, 2003, 12(5): 589-596.

[7] KO D H, KO D C. Application of QFA coupled with CFD analysis to predict the hardness of T6 heat treated A16061 cylinder [J]. Journal of Mechanical Science and Technology, 2013, 27(9): 2839-2844.

[8] WANG Ai-xiang, GAO Jin-zhu, Heat treatment of new type high alloy carburizing gear steel 17CrNiMo6 [J]. Heat Treatment of Metals, 2010, 35(10): 82-86. (in Chinese)

[9] SMOLJAN B. Numerical simulation of steel quenching [J]. Journal of Materials Engineering and Performance, 2002, 11: 75-79.

[10] SUGIANTO A, NARAZAKI M, KOGAWARA M. Numerical simulation and experimental verification of carburizing-quenching process of SCr420H steel helical gear [J]. Journal of Materials Processing Technology, 2009, 209: 3597-3609.

[11] KIM N K, BAE K Y. Analysis of deformation in the carburizing-quenching heat treatment of helical gears made of SCM415H steel [J]. International Journal of Precision Engineering and Manufacturing, 2015, 16(1): 73-79.

[12] SONG Gang-sheng, LIU Xiang-hua, WANG Guo-dong. Numerical simulation on carburizing and quenching of gear ring [J]. Journal of Iron and Steel Research, International, 2007, 14: 47-52.

[13] CHEN Wei, LIU Yong, WANG Shun-xing. A calculating method for carbon diffusivity and transfer coefficient [J]. Journal of Henan University of Science and Technology: Nature Science, 2003, 24(1): 11-13. (in Chinese)

[14] ZHANG Xing, TANG Jin-yuan. Key technology in carburizing process simulation for 17CrNiMo6 steel annular gear [J]. Heat Treatment of Metals, 2015, 40(3): 185-189. (in Chinese)

[15] SUGIANTO A, NARAZAKI M, KOGAWARA M. Distortion analysis of axial contraction of carburized-quenched helical gear [J]. Journal of Materials Engineering and Performance, 2010, 19: 194-206.

[16] KANG S H, IM Y T. Thermo-elastic-plastic finite element analysis of quenching process of carbon steel [J]. Journal of Materials Processing Technology, 2007, 192-193: 381-390.

[17] LIU Zhi-xin. Numerical simulation of heat treatment process in 18CrNiMo7-6 and determination of heat transfer coefficient [D]. Dalian: Dalian Jiaotong University, 2013. (in Chinese)

[18] LI Zhi-chao, FREBORG A M. Modeling the effect of carburization and quenching on the development of residual stresses and bending fatigue resistance of steel gears [J]. Journal of Materials Engineering and Performance, 2013, 22: 664-672.

[19] SCHILL J P, GUO Z L. Modeling phase transformations and material properties critical to processing simulation of steels [J]. Materials and Manufacturing Processes, 2011, 26: 137-143.

J P, GUO Z L. Modeling phase transformations and material properties critical to processing simulation of steels [J]. Materials and Manufacturing Processes, 2011, 26: 137-143.

[20] LEE S J, LEE Y K. Finite element simulation of quench distortion in a low-alloy steel incorporating transformation kinetics [J]. Acta Materialia, 2008, 56: 1482-1490.

[21]  C H. 3D FEM simulation of steel quenching and investigation of the effect of asymmetric geometry on residual stress distribution [J]. Journal of Materials Processing Technology, 2008, 207: 211-221.

C H. 3D FEM simulation of steel quenching and investigation of the effect of asymmetric geometry on residual stress distribution [J]. Journal of Materials Processing Technology, 2008, 207: 211-221.

[22] NUSHEH M. Recent researches in metallurgical engineering-From extraction to forming [EB/OL]. Physics Web, www.intechopen.com, 2012.

[23] HUANG Chun-feng. Empirical formulas for process planning for steel heat treatment [J]. Aeronautical Manufacturing, 2000(4): 53-55. (in Chinese)

[24] YU Bai-hai. Computer design of steel [M]. Beijing: Metallurgical Industry Press, 1996: 10-36. (in Chinese)

(Edited by YANG Bing)

Cite this article as: ZHANG Xing, TANG Jin-yuan, ZHANG Xue-rui. An optimized hardness model for carburizing-quenching of low carbon alloy steel [J]. Journal of Central South University, 2017, 24(1): 9-16. DOI: 10.1007/s11771-017-3403-2.

Foundation item: Projects(51535012, U1604255) supported by the National Natural Science Foundation of China; Project(2016JC2001) supported by the Key Research and Development Program of Hunan Province, China

Received date: 2015-09-02; Accepted date: 2016-05-11

Corresponding author: TANG Jin-yuan, Professor; Tel: +86-731-88877746; E-mail: jytangcsu@163.com