DOI: 10.11817/j.issn.1672-7207.2017.03.015

单对水平支撑TBM支撑推进协调控制研究

饶云意,龚国芳,杨华勇

(浙江大学 流体动力与机电系统国家重点实验室,浙江 杭州,310027)

摘要:为使单对水平支撑硬岩隧道掘进机(TBM)撑靴支撑系统和推进系统协调从而具有更高的复杂地质适应性,提出TBM支撑推进协调控制系统。建立TBM支撑推进机构力学模型,根据模型推导推进缸压力与撑靴支撑缸压力的理论最优关系;设计一种TBM支撑推进协调控制液压系统,利用AMESim仿真软件对液压系统进行动态仿真分析,并以某工程地段实际推进压力谱为标准对该系统进行有效性分析。研究结果表明:相同推进位移下,撑靴支撑缸压力理论最优值与推进缸压力近似呈线性正相关;系统的撑靴支撑缸压力曲线能较好地跟踪其理论设定曲线而与推进压力及位移相协调,且其最大相对误差与均方误差分别为1.45%和0.05 MPa,小于实际工程中的最大相对误差1.72%与均方误差0.12 MPa,可见所建立的支撑推进协调控制系统有效。

关键词:单对水平支撑硬岩隧道掘进机;支撑推进协调控制;力学模型;液压系统

中图分类号:TH137.8 文献标志码:A 文章编号:1672-7207(2017)03-0666-09

Coordinated control of gripper and thrust system for single gripping TBM

RAO Yunyi, GONG Guofang, YANG Huayong

(State Key Laboratory of Fluid Power Transmission and Control, Zhejiang University, Hangzhou 310027, China)

Abstract: In order to coordinate the gripper and thrust system of single gripping hard rock tunnel boring machine (TBM) and get higher complex geology adaptability, a gripper and thrust coordinated control system was designed. The mechanical model of TBM gripper and thrust was proposed, the theoretical optimal interrelation between gripper cylinder and thrust cylinder pressure was derived from it. A TBM hydraulic system coordinating gripper and thrust cylinder was designed, dynamic simulation analyses were performed with AMESim and the validity analysis was based on the thrust pressure spectrum of practical engineering. The results indicate that there is an approximate positive correlation between the theoretical optimal gripper cylinder pressure and thrust cylinder pressure. The gripper cylinder pressure curve determined by thrust cylinder pressure and displacement tracks the theoretical setting curve accurately, and its maximum relative error and mean square error are 1.45% and 0.05 MPa, which are superior to 1.72% and 0.12 MPa in the practical engineering. Therefore, the TBM gripper and thrust system are coordinated, and the new hydraulic system is effective.

Key words: single gripping TBM; coordinated control of gripper and thrust system; mechanical model; hydraulic system

全断面硬岩隧道掘进机(hard rock tunnel boring machine,TBM)是机、电、液、光一体化的高技术大型工厂化隧道施工作业系统,具有掘进速度快、安全性高、利于环保、综合效益高等优点[1-2]。TBM按不同的结构和工作原理可以分为敞开式、护盾式、扩孔式和摇臂式等[3]。敞开式TBM适用于岩石完整性较好的隧洞,具有维护方便,价格较低的优点;其中单对水平支撑敞开式TBM又具备结构简单,操作灵活方便,换步时间短,并能够在推进中实现主机的连续姿态调整等优点,因此在我国运用广泛。在实际施工中,一般将TBM的撑靴支撑缸压力设定为常值,其推进力和撑靴支撑力也多采用人工调整的方法,而较少考虑TBM推进系统和撑靴支撑系统间的耦合特性,导致现有的TBM所控制的支撑力与推进力不协调,对复杂地质的适应性较差,进而造成工程事故;在相对较软的岩层掘进时,撑靴接地比压过大会破坏围岩的完整性,甚至造成隧洞侧壁坍塌[4-5];在较硬地层中掘进时,撑靴接地比压不足将导致撑靴无法承受推进反力和反扭矩而导致打滑。目前,对TBM的研究主要集中在刀盘刀具的设计及分布的优化和施工的掘进速率预测等方面[6-9],而对TBM支撑推进电液控制系统的研究相对较少。本文作者建立TBM支撑推进力学模型,分析计算出撑靴支撑缸压力与推进缸压力间的理论最优关系;同时设计出一种TBM支撑推进协调控制液压系统,能控制TBM的支撑力与推进力达到最优匹配,并结合工程实际数据对该系统进行仿真分析研究,验证其有效性。

1 TBM支撑推进力学模型

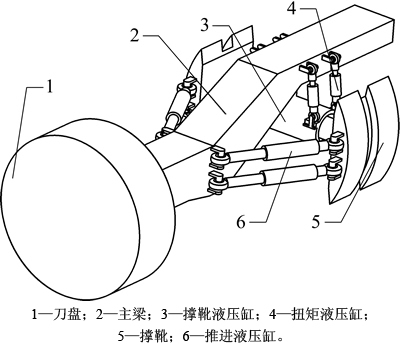

单对水平支撑TBM的一个支撑推进行程通过其撑靴支撑机构和推进机构来实现。撑靴支撑机构中的撑靴液压缸推动撑靴高压撑紧围压侧壁,支撑起整个机构;推进机构的推进液压缸高压推动刀盘掘进,完成一个支撑推进行程。为了研究单个支撑推进行程中TBM撑靴支撑力与推进力的协调控制,首先要探究在一定系统外载作用下,TBM撑靴支撑机构与推进机构二者驱动力的关系。对图1所示的TBM支撑推进机构进行力学分析与建模。由于系统外载荷与系统约束力、驱动力可构成平衡力系[10],通过系统的力及力矩平衡方程即可求解出支撑力与推进力间的关系式。

1.1 支撑推进机构力学模型

TBM推进前,已通过撑靴支撑液压缸驱动撑靴撑紧围岩,由推进液压缸推动主梁和刀盘等固接部件向前运动,由扭矩液压缸支撑主梁。推进时支撑推进机构受到的外载包括机构自身重力、刀盘处的推进反力与转动反力矩、护盾受到的围岩压力及摩擦力等。为便于对支撑推进机构进行力学分析,可对该机构的受力模型进行以下简化:撑靴撑紧围岩后,将撑靴靴体与围岩看作一体,即为固定端;TBM为直行掘进工况,不考虑偏载作用;仅考虑支撑换步机构重力,即刀盘、主梁和鞍架的重力,忽略支撑及推进液压缸及其球铰副重力,故液压缸可视为二力杆;围岩对刀盘护盾的作用分2部分:一是在重力作用下,围岩对刀盘护盾的支持力和摩擦力作用在护盾底部中心;二是不考虑重力时,围岩围压对护盾整体的正压力及摩擦力均匀分布在护盾四周,可等效为一个作用在刀盘中心点的摩擦阻力。

图1 TBM支撑推进机构示意图

Fig. 1 Diagram of TBM gripper and thrust mechanisms

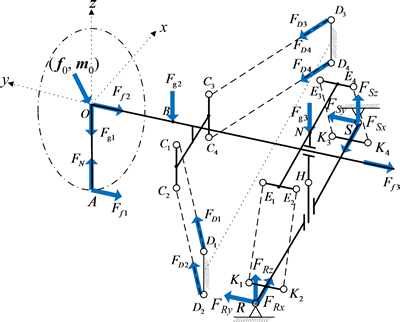

简化后的TBM支撑推进机构的受力情况如图2所示。以刀盘中心点O为原点建立空间坐标系O-xyz,(f0, m0)为围岩对刀盘的推进反力和反力矩;不考虑重力时围岩对刀盘护盾的等效摩擦力的作用点为O,单位方向矢量为-y,大小为Ff2;重力作用下围岩对刀盘护盾的支撑力和摩擦力的作用点为A点,单位方向矢量分别为z和-y,大小分别为为FN和Ff1;刀盘、主梁和鞍架部分的重力的作用点分别为O,B和N,单位方向矢量均为-z,大小分别为Fg1,Fg2,Fg3;撑靴提供给各推进液压缸的推进力的作用点为Di,各推进力的方向单位矢量为di,相对O点的位置矢量为ldi,各推进力为FDi;撑靴支撑液压缸与撑靴球铰间作用力的作用点为R和S,它们相对O点的位置矢量为lr和ls,设它们在xyz三向分力分别为FRx,FRy,FRz和FSx,FSy,FSz;后配套系统对支撑推进机构的作用力单位方向矢量为y,大小为Ff3。

图2 支撑推进机构受力示意图

Fig. 2 Diagram of TBM gripper and thrust mechanical analysis

由支撑推进机构在xyz三向的力平衡,可得:

(1)

(1)

由支撑推进机构在O点的力矩平衡,可得:

(2)

(2)

由式(1)和式(2)可计算出撑靴支撑缸与撑靴球铰间的作用力FRy,FRz和FSy,FSz与推进力FDi间的关系式:

(3)

(3)

(4)

(4)

其中:

(5)

(5)

(6)

(6)

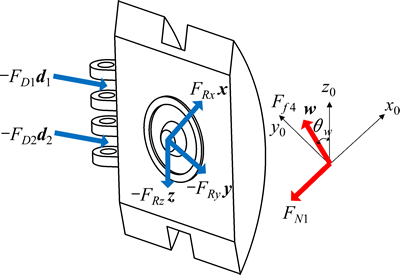

1.2 撑靴靴体力学模型

以左撑靴靴体为脱体受力分析对象,如图3所示,它受到推进缸的推力-FD1d1和-FD2d2;左撑靴液压缸球铰副作用力大小为FRx,FRy和FRz,单位方向矢量分别为x,-y和-z;侧壁围岩给撑靴的正向支撑力为FN1;围岩给撑靴的摩擦力为Ff4,单位方向向量为w,w与x垂直且w和z的夹角为θw;假设侧壁围岩与撑靴间的等效最大静摩擦因数为μ。

图3 撑靴靴体受力示意图

Fig. 3 Diagram of TBM gripper mechanical analysis

由左侧撑靴靴体在xyz三向力平衡,可得:

(7)

(7)

又侧壁围岩给撑靴的正向支撑力FN1与给撑靴的摩擦力Ff4间需满足:

(8)

(8)

由式(7)和式(8)可求出左侧撑靴液压缸撑紧力FRx与推进液压缸推进力FDi间的关系式:

(9)

(9)

(10)

(10)

假设TBM左撑靴撑紧的围岩单位面积可承受的压力为pmax,实际单位面积承受的压力为pr,左侧撑靴靴体竖向投影面积为S,则FRx应满足:

(11)

(11)

(12)

(12)

以式(9)和式(11)为在一定推进工况下撑靴撑紧力的约束条件,考虑TBM撑靴侧壁围岩受压应尽可能小,以式(12)中pr取最小值作为最优目标[11],可推导出当式(9)取等号时达到最优目标,此时式(9)中的撑靴撑紧力FRx与推进液压缸推进力FDi视作理论最优匹配且撑靴液压缸压力为理论最优。

2 TBM支撑推进协调控制液压系统

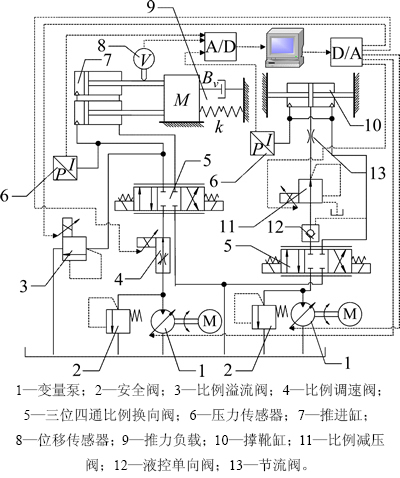

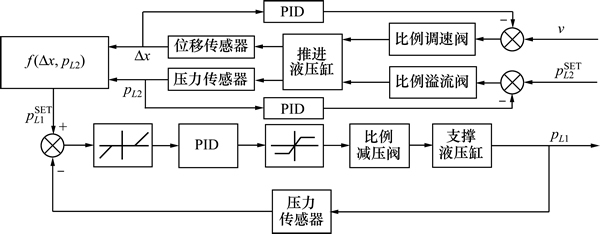

在TBM一个支撑推进工作行程中,撑靴液压缸的高压撑紧围岩侧壁和推进液压缸的高压推进刀盘是关键的动作。考虑支撑与推进液压系统间的耦合性,并针对该关键动作,设计出一种新型的支撑推进协调控制液压系统,其支撑推进控制原理如图4所示。

由于TBM推进液压缸分左右两组对称分布且其液压系统相同,现仅考虑TBM左侧推进液压缸组。在该支撑推进协调控制液压系统中,推进液压系统的控制方式为比例调速阀与比例溢流阀协同模式[12],撑靴撑紧液压系统的控制方式为比例减压阀单一模式;整体系统由变量泵、安全阀、比例调速阀、比例溢流阀、三位四通比例换向阀、比例减压阀、液控单向阀、节流阀和液压缸等组成。位移传感器实时监测各推进液压缸的位移,推进液压缸及撑靴支撑液压缸处的压力传感器实时监测所对应的油路压力;将采集的位移信号和2个压力信号经过A/D转换器、工控机及D/A转换器等组成的协调控制器处理并转化为3个电信号,进而控制系统中的比例调速阀、比例溢流阀和比例减压阀的阀芯开口量。

结合实际TBM的掘进过程,其推进缸压力由推进负载决定,推进缸溢流压力主要根据主输入压力指令调定,故而系统中撑靴支撑缸压力对推进缸压力协调控制可视为辅助限定推进缸压力的最大值,同时本文的支撑推进协调控制主要针对根据TBM的推进系统的推进缸的压力及位移协调控制撑靴支撑缸压力。

图4 TBM支撑推进协调控制液压原理简图

Fig. 4 TBM gripper and thrust coordinated control hydraulic system

当TBM撑靴缸高压撑紧侧壁围岩时,撑靴缸可视为静止状态,因此可将其负载模型简化为力模型。TBM撑靴支撑缸及负载模型的力平衡方程如下:

(13)

(13)

式中:A1为推进液压缸无杆腔面积;△pL1为推进液压缸无杆腔内压力改变量;△F1为作用在推进液压缸活塞杆上的外加负载力。

结合岩体力学中岩石的凯尔文组合本构模型[13],将TBM推进载荷模型简化为力与弹簧阻尼模型。对于TBM推进缸及负载模型,其力平衡方程如下:

(14)

(14)

式中:A2为推进液压缸无杆腔面积;△pL1为推进液压缸无杆腔内压力改变量;M为活塞及活塞杆等全部移动部件的折算总质量;△x为推进液压缸相对初始位置的位移;Bv为活塞及负载的黏性阻尼系数;k为负载模型弹簧刚度;△F2为作用在推进液压缸活塞杆上的外加负载力。

3 工程TBM样机支撑推进协调控制模型计算

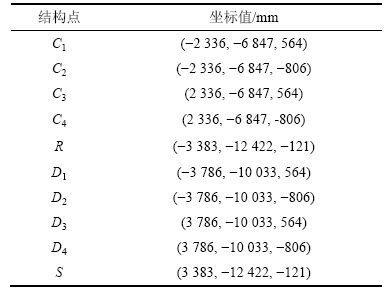

以西秦岭隧道出口长19.8 km的区段中采用的刀盘直径10.2 m 的TBM为例[14],由其结构参数测量并圆整得到单个推进行程初始位置的Ci,Di,R和S点坐标,如表1所示。

表1 TBM支撑推进机构关键结构点坐标

Table 1 Coordinates of key TBM gripper and thrust mechanisms points

在实际施工中,直行工况下的TBM 2组推进液压缸的推进力设定为相等,均为FD;代入式(9)计算可得:

(15)

(15)

其中,FRz可视为常数,

(16)

(16)

由于上述TBM采用的是单边撑靴双缸撑紧的形式,所以对于左撑靴,FRx=2A1pL1;对于推进液压缸,FD=A2pL2;并取支撑力与推进力最优匹配,即FN1=μFf4的情况,将它们代入式(15)可得支撑液压缸理论最优压力表达式:

(17)

(17)

由于m0>>F0,故FRz≈(-m0)/6.77;再对式(17)进行替换化简,可得:

(18)

(18)

其中,

(19)

(19)

(20)

(20)

(21)

(21)

(22)

(22)

上述TBM的撑靴液压缸的直径d1 = 810 mm,推进液压缸的直径d2=500 mm,即 A2/(2A1)=(d2/d1)2= 0.19。结合西秦岭隧道TBM施工地段的岩石特性[15-17],设定撑靴与围岩侧壁的等效最大静摩擦因数为μ=0.3~0.4。结合实际施工[15],假设单个推进行程内推进液压缸的初始设定压力为20 MPa,最大设定压力为34.5 MPa。刀盘高速旋转时的输出扭矩为4 710 kN·m,所以岩石给刀盘的反扭矩m0≈4 710 kN·m。则通过式(18)可以得到一定位移△x下的撑靴支撑缸压力pL1和推进缸压力pL2的理论最优数值关系。

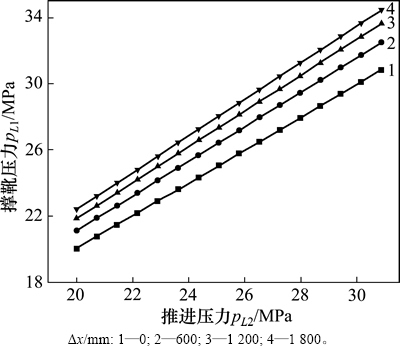

图5所示为μ取0.3时,推进缸推进位移△x分别为0,600,1 200,1 800 mm时的推进缸与支撑缸压力理论最优曲线。由图5可知:当△x一定时,推进缸压力与所对应的理论最优撑靴支撑缸压力近似呈线性正相关。相同的推进压力下,若△x的增大,则撑紧压力增大,且相同的△x增量下,撑紧压力增大量有减小的趋势。

图6所示为TBM推进缸压力pL2及其位移△x控制支撑缸压力pL1的协调控制结构,图中在PID控制前加入死区环节,避免当推进压力在误差允许范围内的小幅振荡时,撑靴系统仍调整支撑压力而产生无益波动。根据式(17)计算出控制量pL1和输入量pL2及△x的具体关系式。

图5 推进缸-支撑缸压力理论最优曲线

Fig. 5 Theoretical optimal curve of thrust and gripper cylinder pressure

(23)

(23)

式中: 为撑靴支撑缸压力的理论设定值;

为撑靴支撑缸压力的理论设定值; 为推进缸压力的理论设定值。

为推进缸压力的理论设定值。

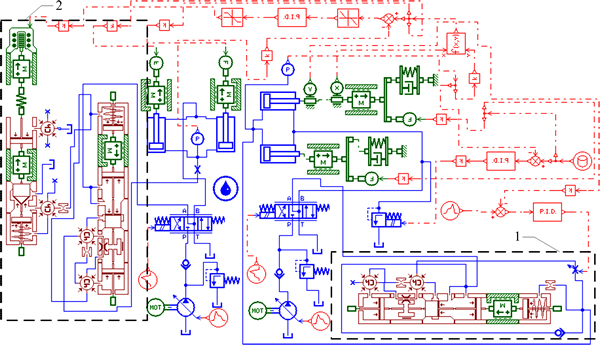

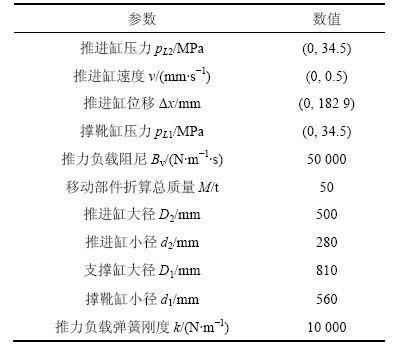

4 系统有效性仿真分析

结合图4搭建TBM支撑推进液压系统AMESim液压仿真模型,如图7所示,图中区域1为结合HCD库与液压元件库搭建比例调速阀机械模型,区域2为比例减压阀的机械模型。结合上述TBM机型参数及西秦岭隧道施工数据,设定系统的部分仿真参数,见表2。

图6 推进支撑协调控制结构图

Fig. 6 Control block diagram of gripper and thrust coordinated system

图7 支撑推进液压系统AMESim仿真模型图

Fig. 7 Gripper and thrust coordinated hydraulic system simulated model in AMESim

表2 系统仿真主要设定参数

Table 2 Main setting parameters of simulated system

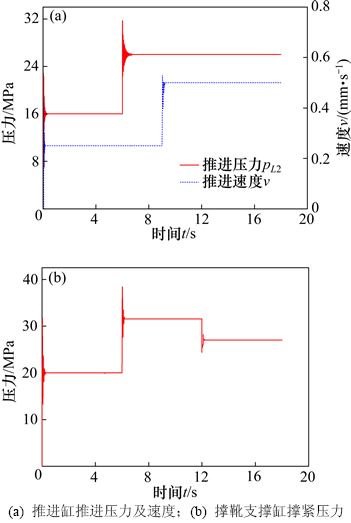

对所建立的推进液压系统单体和支撑液压系统单体分别进行仿真。设定推进缸初始推进速度为0.25 mm/s,9 s后调为0.5 mm/s;推进缸初始推进压力为16 MPa,外负载力为3 140 kN;6 s后调为26 MPa,外负载力为5 102 kN。设定TBM撑靴支撑缸的初始撑紧压力为20 MPa,6 s 上调为31.5 MPa,12 s下调为27 MPa。图8(a)所示为推进缸推进压力及速度仿真曲线。由图8(a)可知:调节推进压力和推进速度时,它们均可在短暂的振荡后保持为设定值。图8(b)所示为撑靴支撑缸撑紧压力的仿真曲线。由图8(b)可知:调节撑紧压力时,撑紧压力可在短暂的振荡后保持为设定值;综上可知,所建立的推进液压系统模型的推进压力及速度均可调控,支撑液压系统模型的撑紧压力可调控。

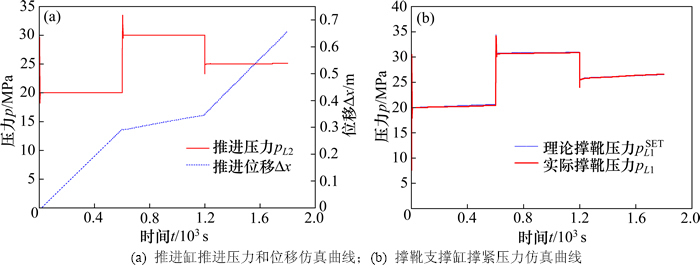

对所建立的支撑推进液压系统整体进行协调控制仿真。设定推进缸初始推进压力为20 MPa,外负载力为3 927 kN;600 s后调为30 MPa,外负载力为5 890 kN;1 200 s后调为25 MPa,外负载力为4 909 kN;初始推进速度设定为0.5 mm/s,600 s后下调约为0.1 mm/s,1 200 s后恢复为0.5 mm/s。图9(a)所示为推进缸推进压力位移仿真曲线,在600 s时,推进位移曲线斜率减小是对应着推进压力突然增大为30 MPa后,推进速度随之骤减;图9(b)所示为理论计算所设定的撑靴支撑缸撑紧压力曲线与协调控制仿真曲线,撑紧压力理论设定曲线是由图9(a)中的推进压力pL2和位移△x代入f(△x, pL2)计算所得,该曲线呈斜向上变化的趋势是由于推进缸位移△x在不断增大;图9(b)中撑紧压力协调控制仿真曲线可以较好地追踪理论设定曲线的变化,撑紧压力协调控制仿真值与理论设定值的最大相对误差仅为0.4%,均方误差率仅为0.14 MPa。

图8 推进支撑单体液压系统仿真曲线

Fig. 8 Simulation of gripper and thrust individual hydraulic system

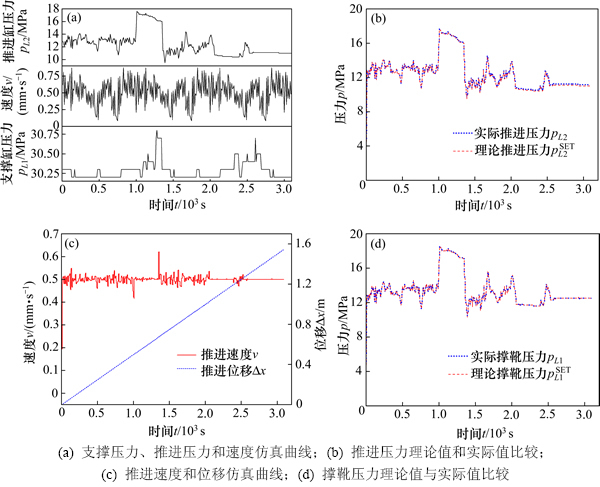

从TBM实际施工采集的数据中选取一段作为样本数据,其中的推进压力谱及同地段对应的推进速度及撑靴支撑缸撑紧压力如图10(a)所示;结合上诉样本数据对所搭建的仿真模型进行支撑推进协调控制仿真,仿真结果曲线如图10(b)~(d)所示。可知:该地段的推进压力最大波动率为41.4 %,标准差为18.58 MPa;其推进速度的平均值约为0.5 mm/s (1.8 m/h),最大波动率为83.2 %,标准差为1.9×10-4 m/s;其撑紧压力设定为常值,约为30 MPa,且最大波动率为1.72 %,标准差为0.12 MPa。图10(b)中,推进缸的推进压力仿真曲线可较好地跟随所设定的推进压力谱,计算可得它们的最大相对误差为1.4%,均方误差为0.10 MPa,远小于实际工程中推进压力的波动值。图10(c)中,推进缸的推进速度在所设定的速度0.5 mm/s附近振荡,推进压力调变量越大时推进速度的振荡幅度越大;计算可得仿真推进速度均值约为0.5 mm/s,最大相对误差为24%,仅为实际工程推进速度的1/4;仿真推进速度的均方误差为2.2×10-5 m/s,远小于实际工程推进速度的均方误差。图10(d)中, 协调控制支撑缸压力仿真曲线与理论设定曲线吻合度较高,其最大相对误差与均方误差分别为1.45%和0.05 MPa,小于实际工程中设定为常值的支撑缸压力的最大相对误差1.72%与均方误差0.12 MPa。综上,所建立的支撑推进协调控制液压系统是有效的。

图9 推进支撑整体液压系统协调控制仿真曲线

Fig. 9 Simulation of gripper and thrust coordinated control hydraulic system

图10 基于工程数据的推进支撑协调控制仿真曲线

Fig. 10 Simulation of gripper and thrust coordinated control hydraulic system based on engineering data

5 结论

1) 理论最优的TBM撑靴支撑缸压力可近似由推进缸压力和位移确定;在相同推进缸位移下,撑靴支撑缸压力理论最优值与推进缸压力近似呈线性正相关;推进缸压力不变时,撑靴支撑缸压力理论最优值与推进缸位移正相关,且等推进位移增量下的撑靴支撑缸压力增量有减小的趋势。

2) 所建立的TBM支撑推进协调控制液压系统有效;其推进压力可跟踪所设定的压力谱,推进速度可在压力突变时小幅度波动后稳定在所设定的速度值附近;通过推进缸压力及速度所控制的撑靴支撑缸压力与其理论设定值的最大相对误差和均方误差分别为1.45%和0.05 MPa,小于实际工程中支撑缸压力的最大相对误差1.72%和均方误差0.12 MPa。

3) 下一步将研究TBM刀盘转矩及转速和推进缸压力及速度等多因素共同协调控制撑靴与侧壁围岩间的接地比压而自动适应地层地质环境,使得本文的支撑推进协调控制模型更完善且更具有实际工程意义。

参考文献:

[1] ZHANG Kaizhi, YU Haidong, LIU Zhongpo, et al. Dynamic characteristic analysis of TBM tunneling in mixed-face conditions[J]. Simulation Modelling Practice and Theory, 2010, (18): 1019-1031.

[2] 杜彦良, 杜立杰. 全断面岩石隧道掘进机: 系统原理与集成技术[M]. 武汉: 华中科技大学出版社, 2010: 2-3.

DU Yanliang, DU Lijie. Full face hard rock tunnel boring machine: system principles and integrated design[M]. Wuhan: Huazhong University of Science and Technology Press, 2010: 2-3.

[3] FARROKH E, ROSTAMI J. Effect of adverse geological condition on TBM operation in Ghomroud tunnel conveyance project[J]. Tunneling and Underground Space Technology, 2009, 24(4): 436-446.

[4] 黄兴, 刘泉声, 刘滨, 等. 深部软弱地层TBM围岩力学行为试验研究[J]. 煤炭学报, 2014, 39(10): 1977-1986.

HUANG Xing, LIU Quansheng, LIU Bin, et al. Experimental research on the mechanical behavior of deep soft surrounding rock tunneling by TBM[J]. Journal of China Coal Society, 2014, 39(10): 1977-1986.

[5] 尹俊涛, 尚彦军, 傅冰骏, 等. TBM掘进技术发展及有关工程地质问题分析和对策[J]. 工程地质学报, 2005, 13(3): 389-397.

YIN Juntao, SHANG Yanjun, FU Bingjun, et al. Development of TBM-excavation technology and analyses & countermeasures of related engineering geological problems[J]. Journal of Engineering Geology, 2005, 13(3): 389-397.

[6] 耿麒, 魏正英, 杜军. 全断面岩石掘进机滚刀布置的优化方法[J]. 西安交通大学学报, 2013, 47(9): 100-105.

GENG Qi, WEI Zhengying, DU Jun. Cutter layout optimization method of full-face rock tunnel boring machine[J]. Journal of Xi’an Jiaotong University, 2013, 47(9): 100-105.

[7] LIU Jie, CAO Ping, JIANG Zhe, et al. Numerical simulation on effects of embedded crack on rock fragmentation by a tunnel boring machine cutter[J]. Journal of Central South University, 2014, 21(8): 3302-3308.

[8] 谭青, 徐孜军, 夏毅敏, 等. 2种切削顺序下TBM刀具破岩机理的数值研究[J]. 中南大学学报(自然科学版), 2012, 43(3): 940-946.

TAN Qing, XU Zijun, XIA Yimin, et al. Numerical study on mode of breaking rock by TBM cutter in two cutting orders[J]. Journal of Central South University (Science and Technology), 2012, 43(3): 940-946.

[9] GAO Li, LI Xibing. Utilizing partial least square and support vector machine for TBM penetration rate prediction in hard rock conditions[J]. Journal of Central South University, 2015, 22(1): 290-295.

[10] 王林涛. 盾构掘进姿态控制关键技术研究[D]. 浙江: 浙江大学机械工程学院, 2014: 64-69.

WANG Lintao. The key technology research on attitude control of thrust system for shield tunneling machine[D]. Zhejiang: Zhejiang University. School of Mechanical Engineering, 2014: 64-69.

[11] 曹中一, 王鹤, 吴万荣, 等. 喷浆机械手时间最优与脉动最优轨迹规划[J]. 中南大学学报(自然科学版), 2013, 44(1): 114-121.

CAO Zhongyi, WANG He, WU Wanrong, et al. Time-jerk optimal trajectory planning of shotcrete manipulators[J]. Journal of Central South University (Science and Technology), 2013, 44(1): 114-121.

[12] 胡国良, 龚国芳, 杨华勇, 等. 盾构掘进机模拟试验台液压系统集成及试验分析[J]. 农业机械学报, 2005, 36(12): 102-105.

HU Gongliang, GONG Guofang, YANG Huayong, et al. Hydraulic system integration and experimental analysis of shield tunneling machine for simulator test rig[J]. Transactions of the Chinese Society of Agricultural Machinery, 2005, 36(12): 102-105.

[13] 王文星. 岩体力学[M]. 长沙: 中南大学出版社, 2004: 85-86.

WANG Wenxing. Rock mechanics[M]. Changsha: Central South University Press, 2004: 85-86.

[14] 左庆林, 马怀祥, 徐明新. 状态检测技术在隧道掘进机上的应用[J]. 中国设备工程, 2013(11): 56-57.

ZUO Qinglin, MA Huaixiang, XU Mingxin. The application of state inspection technology in the tunnel boring machine[J]. China Plant Engineering, 2013(11): 56-57.

[15] 赵战欣. 西秦岭长大隧道TBM盘形滚刀磨损分析[J]. 建筑机械化, 2014(1): 79-81.

ZHAO Zhanxin. Wear analysis of TBM disc cutter in West Qinling super long tunnel[J]. Construction Mechanization, 2014(1): 79-81.

[16] 韩文梅, 康天合. 微凸体对抛光岩石表面静摩擦系数影响试验研究[J]. 岩土力学, 2013, 34(3): 674-678.

HAN Wenmei, KANG Tianhe. Experimental study of influence of asperity on static friction coefficient for polished rock surface[J]. Rock and Soil Mechanics, 2013, 34(3): 674-678.

[17] 霍军周, 杨静, 孙伟, 等. 不同TBM 支撑结构形式下的围岩稳定性分析[J]. 东北大学学报(自然科学版), 2014, 35(11): 1602-1606.

HUO Junzhou, YANG Jing, SUN Wei, et al. Stability analysis of surrounding rock under different TBM supporting forms[J]. Journal of Northeastern University (Natural Science), 2014, 35(11): 1602-1606.

(编辑 赵俊)

收稿日期:2016-03-13;修回日期:2016-05-17

基金项目(Foundation item):国家高技术研究发展计划(863计划)项目(2012AA041803);国家重点基础研究发展计划(973计划)项目(2013CB035404) ((Project(2012AA041803) supported by the National High Research Development Program (863 Program) of China; Project(2013CB035404) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:龚国芳,教授,从事掘进装备电液控制技术研究;E-mail: gfgong@zju.edu.cn