文章编号:1004-0609(2010)01-0118-07

液相沉淀?热还原纳米Fe包覆Mo粉末微结构特征

银锐明1, 2,范景莲1,刘 勋1,张曙光1

(1. 中南大学 粉末冶金国家重点实验室,长沙410083;

2. 湖南工业大学 包装与材料工程学院,株洲412008)

摘 要:采用液相沉淀?热还原法制备纳米Fe包覆Mo合金粉末,研究还原过程中的晶粒组织及微结构并进行分析。结果表明:还原过程中,粉末晶粒平均晶粒尺寸随还原温度的升高而变小,微观应变在还原温度为600 ℃时最高,Mo晶粒先于Fe晶粒还原并长大至1 μm左右,Fe晶粒粒径最终保持为1.8 nm,并形成20 nm左右的薄层,沉积在Mo颗粒表面。

关键词:液相沉淀?热还原;Fe-Mo;晶粒组织;微结构

中图分类号:O648.4 文献标识码:A

Microstructure characteristics of nanometer Fe coated Mo powders prepared by liquid precipitation-thermal reduction method

YIN Rui-ming1, 2, FAN Jing-lian1, LIU Xun1, ZHANG Shu-guang1

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. College of Packaging and Material Engineering, Hunan University of Technology, Zhuzhou 412008, China)

Abstract: Nanometer Fe coated Mo powders were prepared by liquid precipitation and thermal reduction. The grain structure and microstructure of materials during the reduction process were discussed. The results show that the average grain size of Fe coated Mo powders decrease with increasing reduction temperature, and the microstrain reaches the maximum at the reduction temperature of 600 ℃. The reduction of Mo grains precedes over Fe grains and the Mo grains grow significantly. The microstructure of the Fe coated Mo alloy powders is the Mo particles with the size about 1 μm coated layer-by-layer by metastable Fe grains and normal state Fe grains whose lattice constant closes to Mo grains, and the total thickness is around 20 nm.

Key words: liquid precipitation-thermal reduction; Fe-Mo; grain structure; microstructure

Mo具有多种特殊优异的性能,如能增加钢铁硬度、韧性和抗腐蚀性能与在超高温度下保持稳定的性能。在钢中加Mo,可使钢具有均匀的细晶组织,并提高钢的淬透性,有利于削除回火脆性;在高速钢中,Mo可代替一部分W。Mo同其它合金元素配合一起广泛地应用于生产不锈钢、耐热钢、耐酸钢和工具钢,以及具有特殊物理性能的合金;Mo加于铸铁里可增大其强度和耐磨性[1]。故制备Fe-Mo合金粉加入钢中,可大幅提升钢铁性能。此外,Fe-Mo合金粉也广泛应用于其它特殊领域,如半导体[2?3]、磁记录和磁光存 储[4?5]及特种陶瓷[6?8]的制备。

材料性能与颗粒尺寸、微观结构紧密相关,当颗粒尺寸进入纳米数量级时,其具有不同常规的独特的物理、化学性质[9]。因此,纳米Fe-Mo合金粉的制备与研究引起了人们的广泛注意与研究。但是,目前制备纳米Fe-Mo合金粉方法是采用机械合金化[10?11],此方法缺陷是不能大批量生产,且机械合金化不可避免地引入较多杂质,对材料性能造成不利影响。近年来,MORALES等[12?13]研究了一种新的制备方法,即首先制备Fe-Mo三元氧化物,然后再氢气热还原裂解细化,最终制得纳米Fe-Mo合金粉,克服了不能大批量生产的缺点,并能获得成分均匀的Fe-Mo合金粉。但是,由于是将Fe2O3与MoO3连续24 h高温焙烧制得Fe-Mo三元氧化物,工艺仍十分复杂,并且对制得的Fe-Mo合金粉微结构没有进行深入研究。而液相沉淀法生产工艺简单且成本低廉[14],并能制备纳米Fe-Mo三元氧化物粒子,故在氢气热还原后获得的纳米Fe-Mo合金粉末的晶粒组织应更为细小、均匀。

本文作者采用液相沉淀法制备Fe-Mo三元氧化物,然后氢气高温还原制备Fe-Mo合金粉,并对其微结构特征进行研究。

1 实验

1.1 试剂

Fe(NO)3?9H2O,分析纯;(NH4)6Mo7O24?4H2O,分析纯;蒸馏水。

1.2 样品制备

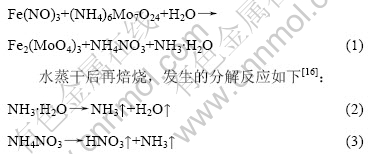

按元素摩尔比n(Fe)?n(Mo)=2?3的比例称取试剂Fe(NO)3?9H2O和(NH4)6Mo7O24?4H2O,分别加蒸馏水配制成质量浓度为378.5和248.5 g/L的溶液;将上述溶液缓慢混合并机械搅拌,混合完毕后将其置于设定温度为180 ℃的电热板上进行加热,将水分完全蒸干后再焙烧30 min,最后将残余物研磨过筛,得到前驱体粉末。溶液混合时可能发生的化学反应如下[15]:

将前驱体粉末(样品1),置入Al2O3坩埚中,推入氢气还原炉中还原,升温速度为5 ℃/min,分别在600、700、900下保温2 h,冷却至室温后手工研磨,得到待测实验粉末,分别为样品2、3、4。

1.3 样品表征

采用日本理学电机株式会社的D/max 2550型XRD衍射仪测试材料物理,测试条件:Cu Kα辐射,连续扫描方式采样,电压/电流40 kV/300mA,扫描速度4(?)/min。采用Jade5.0软件计算粉末的平均晶粒尺寸、微观应变及晶胞参数[17],Jade5.0软件参数设置:扣除Kα2,采用NBS Silicon?2作为衍射仪半峰宽曲线。采用JEOL公司的JSM?6360LV型电子扫描显微镜和Tecnai G2 20型电子透射显微镜观察材料微观结构。

2 结果与讨论

2.1 还原过程的晶粒组织分析

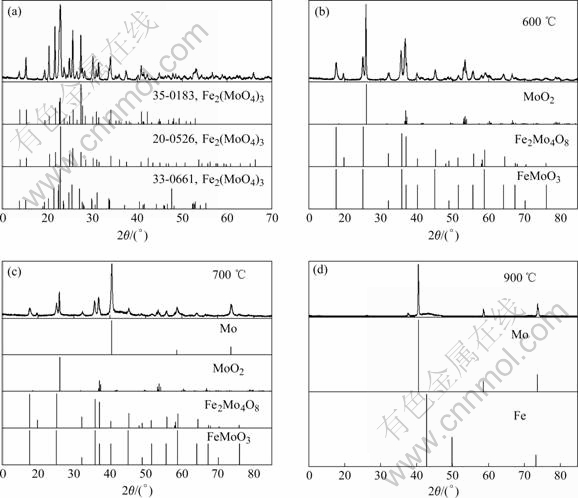

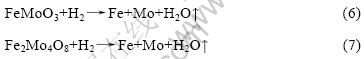

图1为样品1、2、3、4的XRD谱。由图1(a)可见,样品1的衍射峰与XRD谱数据库中编号为35-0183、20-0526、33-0661的Fe2(MoO4)3的X衍射峰位置对应吻合,可见样品1的物相由多晶型Fe2(MoO4)3组成。图1(b)中样品2主要存在MoO2、Fe2Mo4O8、FeMoO3等衍射峰。图1(c)中样品3主要存在Mo、MoO2、Fe2Mo4O8、FeMoO3等衍射峰,样品3中MoO2衍射峰强度与样品2比较明显变弱。图1(d)中样品4主要存在Mo衍射峰与Fe衍射峰较接近的非晶峰。文光远[18]表明,在1 100 ℃时Fe在Mo中的溶解度为2.7%(质量分数),对样品4中Mo的晶格常数为0.314 546 nm,而Mo衍射峰的晶格常数为0.3147 nm,相对变化极其微小,这也表明了Fe固溶到Mo中的数量有限,能谱分析表明,样品4主要存在Fe与Mo元素,故判断此非晶峰应为Fe的衍射峰所致。

图1 Fe-Mo合金前驱体粉末在不同温度下还原的XRD谱

Fig.1 XRD pattern of Fe-Mo precursor powder at different reducing temperatures: (a) Sample 1; (b) Sample 2; (c) Sample 3; (d) Sample 4

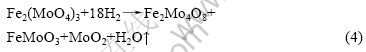

由上可知,当还原温度为600 ℃时,先驱体主要成分Fe2(MoO4)3被分解,反应方程式如下:

当还原温度为700 ℃时,分解产物中的MoO2被部分还原,方程式如下:

当还原温度为900 ℃时,MoO2被较为彻底地还原,原分解产物中的FeMoO3、Fe2Mo4O8被直接或间接还原为Mo与Fe金属颗粒,反应方程如下:

对样品1~4及粉末中Mo和Fe晶粒的平均晶粒尺寸及微观应变进行计算,结果如表1所列。由表1可以看出,样品的平均晶粒尺寸按样品1、2、3、4依次减小;粉末颗粒的微观应变按样品2、1、3、4依次减小;样品中Mo的平均晶粒尺寸按样品4、3依次减小,而微观应变反之;样品4中的Fe晶粒的平均晶粒尺寸只有1.8 nm,其晶粒尺寸太小微观应变可忽略不计。

表1 粉末晶粒平均尺寸与微观应变

Table 1 Average grain size and microstrain of powders

粉末平均晶粒尺寸变化的原因是随着还原过程的进行,气体还原剂分子H2必须扩散穿过固相产物层,在氧化物内部形成网状还原,使还原的晶粒破碎,从而细化晶粒[17]。因此,随着还原温度的上升,分解产物增多,细化晶粒得以进一步增强,粉末的平均晶粒尺寸逐渐变小。粉末中Mo的平均晶粒尺寸变化原因认为是:样品4在更高温度下还原,Mo晶粒被分解还原后晶粒长大更为快速。Fe晶粒的平均晶粒尺寸极

为细小,只有1.8 nm左右,结合前面的X衍射分析,认为其应是在还原程中最后阶段被还原出来,晶粒刚被分解出来而还没来得及发生高温晶粒长大或者有可能被Mo晶粒抑制长大。

样品2的微观应变最大,认为样品2在600 ℃还原分解反应最不充分,晶格畸变严重,结晶没有其它粉末完整,故微观应变最高。而随着温度的上升,反应逐步充分,结晶相对完整,则微观应变相对降低。同理,样品4中的Mo的微观应变小于样品3中的Mo晶粒,表明样品4中的Mo晶粒结晶相对完好。

2.2 微结构分析

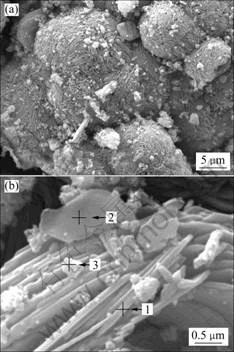

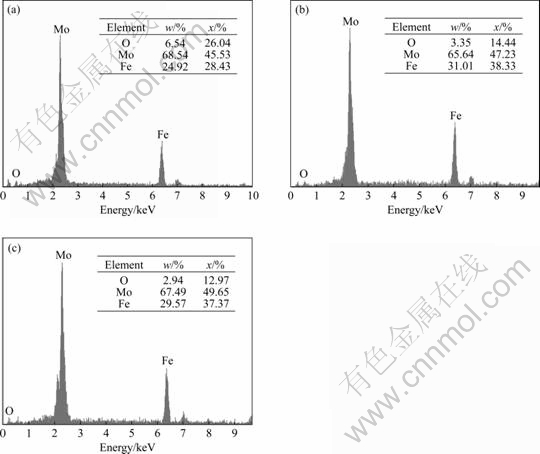

图2为样品1的SEM像。由图2(a)可以看出,粉末颗粒由片状、块状物组成,片状团聚成球,块状物分散在其中。由图2(b)可以看出,片状物晶粒厚度很薄,只有100~200 nm,但平侧面直径有2 μm左右,块状物则可能由粒径为数十纳米的晶粒团聚而成。分别对片状物与块状物进行能谱分析,结果如图3所示。由图3可见,片状物和块状物的x(Fe)?x(Mo)均接近2?3,可知物相为Fe2(MoO4)3。这与X射线衍射的结果是一致的。因此,粉末颗粒形貌不同,是由不同晶型Fe2(MoO4)3组成所致。

图2 样品1的SEM形貌

Fig.2 SEM images of sample 1

图3 图1(b)中各点的EDS分析

Fig.3 EDS analysis of three points in Fig.2(b): (a) Point 1 in Fig.2(b); (b) Point 2 in Fig.2(b); (c) Point 3 in Fig.2(b)

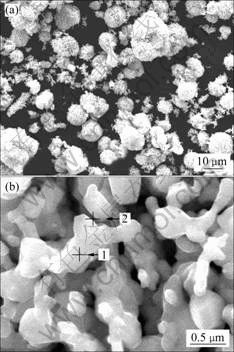

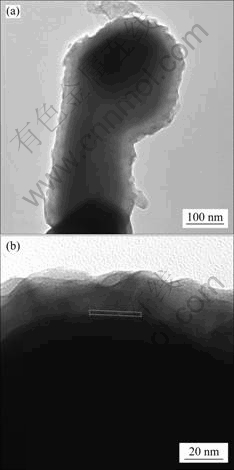

图4所示为样品4的SEM像。图4(a)表明粉末团聚成球,图4(b)表明粉末颗粒大小在1 μm左右,与表1中对样品4中的Mo颗粒平均晶粒尺寸计算结果较为接近。对图4(a)进行全图能谱面扫描,结果如图5(a)所示。由图5(a)可看出主要存在Fe、Mo元素,其摩尔比约为2?3。选择图4(b)中颗粒的中部与边缘进行EDS能谱分析,结果如图5(b)、(c)所示,表明颗粒中间Fe含量远低于颗粒边缘的Fe含量,从而认为颗粒边缘富集较多的Fe元素。对样品4进行TEM分析,结果如图6所示。由图6可以看出,颗粒结构为一层浅色物质包裹粘附在深色物质表层,浅色与深色物质的界面分明(见图6(b)标注),应为不同物质。

图4 样品4的SEM像

Fig.4 SEM images of sample 4

图5 图4中各点的EDS分析

Fig.5 EDS analysis of different points in Fig.4: (a) Surface scan of Fig.4(a); (b) Point 1 in Fig.4(b); (c) Point 2 in Fig.4(b)

图6 样品4的TEM像

Fig.6 TEM images of sample 4

根据透射电镜显微图像衬度原理[19],入射电子透过试样某区域的原子数目越多(试样厚),原子序数及密度越大,则被散射到物镜光阑外的电子就越多。而通过物镜光阑孔参与成像的电子数越少,所以该区域形成的像较暗。图1(d)表明,样品4中主要存在Fe与Mo相,其中Mo的密度远高于Fe,则Mo的成像相对要暗。此外,在表1中计算样品4中的Fe平均晶粒尺寸仅为1.8 nm,而图6中浅色物质仅有数十纳米厚。图5的EDS能谱表明,样品4只存在Fe与Mo元素,Fe元素富集于颗粒边缘,由此认为浅色物质为纳米Fe晶粒堆积而成,黑色物质为Mo颗粒。

李丹等[20]采用聚焦电子束加热的方法交替地蒸镀高纯度Fe与Mo薄层,发现当纳米铁层很薄时,即处于4.5 nm以下,Fe会改变自己的晶格常数,并沿Mo的bcc结构生长,形成新的铁亚稳定结构,电镜透

射衍射花样呈现的基本上是Mo的结构。但随着Fe薄层厚度的增加,Mo颗粒再没有足够的自由能束缚Fe原子,则Fe生长成自身的结构,显示出Fe自身的bbc结构。

由于Mo的氧化物能被Fe还原[21],则在后期还原粉末始终以Mo与Fe氧化物形式存在,Mo在后续高温

发生晶粒长大,当Mo颗粒长大到足够大时,Fe晶粒才被分解还原。由于Mo颗粒较大,故有足够的自由能束缚Fe原子,使Fe原子沉积在Mo颗粒表面并生长,形成与Mo结构相似的亚稳定结构层。但是,随着Fe原子生长沉积在Mo颗粒表层的Fe薄层厚度增加,Mo颗粒再没有足够的自由能束缚Fe原子,则Fe原子开始过渡生长成自身的晶体结构。

由此可以认为,本文制备的Fe包覆Mo粉末的微结构是1 μm左右的Mo颗粒被20 nm厚的Fe薄层包覆,Mo接触的Fe薄层内层Fe原子晶格常数与Mo的晶格常数接近,外层Fe原子为自身的晶体结构。

3 结论

1) 液相沉淀法?热还原制备纳米Fe包覆Mo粉末随着还原温度的上升,粉末的平均晶粒尺寸逐渐变小;还原粉末中Mo晶粒长大明显;Fe晶粒在最后阶段被还原,平均晶粒尺寸只有1.8 nm左右。

2) 液相沉淀法?热还原制备的纳米Fe包覆Mo粉末颗粒的微结构是20 nm厚的Fe薄层包覆,与Mo接触的Fe薄层内层Fe原子晶格常数与Mo的晶格常数接近,外层Fe原子为自身的晶体结构。

REFERENCES

[1] 雷斯 M A. 铁合金冶炼[M]. 周进华, 于 忠. 北京: 冶金工业出版社, 1981: 277.

LEISISI M A. Ferroalloy smelting[M]. ZHOU Jing-hua, YU Zhong. Beijing: Metallurgical Industry Press, 1981: 277.

[2] LEE Hung-sheng, YEN Hsien-cheng, WU Ming-cho, OU Szutsun-simon. Packaging base for semiconductor elements. US20060284305[P]. 2006?12?21.

[3] BREEDIS J F, CHAO C Y. Interdiffusion resistant Fe-Ni alloys having improved glass sealing. US4816216[P]. 1989?03?28.

[4] GEORGE S J, IGARASHI R Y, XIAO Y, HETNANDEZ J A, DEMUEZ M, ZHAO D, YODA Y, LUDDEN P, RUBIO L, CRAMER S. Extended X-ray absorption fine structure and nuclear resonance vibrational spectroscopy reveal that NifB-co, a FeMo-co precursor, comprises a Fe core with an interstitial light atom[J]. Journal of the American Chemical Society, 2008, 130(17): 5673?5680.

[5] MIGLIERINI M, KANUCH T, PAVUK M, JIRASKOVA Y, ZBORI R, MASLAN M, SVEC P.Evolution of structural changes in nanocrystalline alloys with temperature[J]. The Physics of Metals and Metallography, 2007, 104(4): 335?345.

[6] 韩杰胜, 王静波, 张树伟, 孟军虎, 吕晋军. Fe-Mo-CaF2高温自润滑材料的摩擦学特性研究[J]. 摩擦学学报, 2003, 23(4): 306?310.

HAN Jie-sheng, WANG Jing-bo, ZHANG Shu-wei, MENG Jun-hu, LU Jin-jun. Study on the tribological properties of Fe-Mo-CaF2 high temperature self-lubricating material[J]. Tribology, 2003, 23(4): 306?310.

[7] 苗明清, 傅正义, 张金咏, 龚伦军. TiB2/FeMo陶瓷的显微结构与力学性能[J]. 无机材料学报, 2005, 20(2): 499?502.

MIAO Ming-qing, FU Zheng-yi, ZHANG Jin-yong, GONG Lun-jun. Microstructure and mechanical properties of TiB2/FeMo cermet[J]. Journal of Inorganic Materials, 2005, 20(2): 499?502.

[8] CABIBBO M, PATERNOSTER C, CECCHINI A, FABRIZI A, MOLINARI A, LIBARDI S, ZADRAM M. A microstructure study of nanostructured Fe–Mo+1.5wt.%SiO2 and +1.5wt.%TiO2 powders compacted by spark plasma sintering[J]. Mater Sci Eng A, 2008, 496(1/2): 121?132.

[9] 张立德, 牟季美. 纳米材料和纳米结构[M]. 北京: 科学出版社, 2001.

ZHANG Li-de, MOU Ji-mei. Nanometer material and nanostructures[M]. Beijing: Science Press, 2001.

[10] KUYAMA J, ISHIHARA K N, SINGU P H. Mechanical alloying in iron-molybdenum system[J]. J Jpn Soc Powder Metall, 1991, 38(7): 910?913.

[11] INCAU M D, LEONI M, SCARDI P. High-energy grinding of FeMo powders[J]. Materials Research Society, 2007, 22(6): 1744?1753.

[12] MORALES R, SICHEN D, SEETHARAMAN S. Reduction kinetics of Fe2MoO4 fine powder by hydrogen in a fluidized bed[J]. Metallurgical and Materials Transactions B, 2003, 34: 661?667.

[13] MORALES R, ARVANITIDIS I, SICHEN D. Reduction of Fe2MoO4 by Hydrogen Gas[J]. Metallurgical and Materials Transactions B, 2002, 33: 589?594.

[14] YANG Hui-fang, XIAO Feng-juan, GU Ye-qiang, PENG Zheng, MI Zhen-tao. Preparation of CuSCN nano-particles by liquid-phase precipitation method[J]. Journal of Synthetic Crystals, 2004, 33(6): 965?968.

[15] 向铁根. 钼冶金[M]. 长沙: 中南大学出版社, 2002.

XIANG Tie-gen. Molybdenum metallurgy[M]. Changsha: Central South University Press, 2002.

[16] 杜博维次基А М, 基尔曼Я И. 硝酸铵工艺学[M]. 王令仪, 译. 北京: 化学工业出版社, 1983: 319.

Дубовицкий А М, Кильман Я И. Ammonium Nitrate technology[M]. WANG Ling-yi, transl. Beijing: Chemical Industry Press, 1983: 319.

[17] 晋 勇, 孙小松, 薛 岂. X射线衍射分析技术[M]. 北京: 国防工业出版社, 2008.

JIN Yong, SUN Xiao-song, XUE Qi, X-ray different analysis[M]. Beijing: National defense industry Press, 2008

[18] 文光远. 铁冶金学[M]. 重庆: 重庆大学出版社, 1993.

WEN Guang-yuan. Iron metallurgy[M]. Chongqing: Chongqing University Press, 1993.

[19] 张有纲. 电子材料现代分析概论(第二分册)[M]. 北京: 国防工业出版社, 1993.

ZHANG You-gang. Generality of electronic materials(the second fascicule)[M]. Beijing: National defense industry Press, 1993.

[20] 李 丹, 贺 汀, 潘 峰. Fe/Mo多层膜的微观结构与应力研究[J]. 真空科学与技术学报, 2004, 24(z2): 76?77.

LI Dan, HE Ding, PAN Feng. Microstructurs and stress of Fe/Mo multilayer films[J]. Journal of Vacuum Science and Technology,2004, 24(z2): 76?77.

[21] 李正邦, 张和生, 郭培民. 利用白钨矿, 氧化钼的直接还原合金化冶炼钼合金钢[J]. 钢铁研究, 1999(3): 52?56.

LI Zheng-bang, ZHANG He-sheng, GUO Pei-min. Smelting of W and Mo containing alloy steel with direct reducing and alloying of scheelite and molybenum oxide[J]. Research on Iron Steel, 1999(3): 52?56.

基金项目:国家自然科学青年基金资助项目(50804016);国家自然科学基金创新研究群体科学基金资助项目(50721003)

收稿日期:2009-03-03;修订日期:2009-09-14

通信作者:范景莲,教授,博士;电话:0731-88836652;E-mail: fjl@mail.csu.edu.cn

(编辑 李向群)