改善颗粒增强金属基复合材料塑性和韧性的途径与机制

来源期刊:中国有色金属学报2000年第5期

论文作者:秦蜀懿 张国定

文章页码:621 - 629

关键词:颗粒增强金属基复合材料;塑性;韧性;有限单元法;宏观结构设计

Key words:particle reinforced metal matrix composite; ductility; toughness; finite element method; macrostructure-design

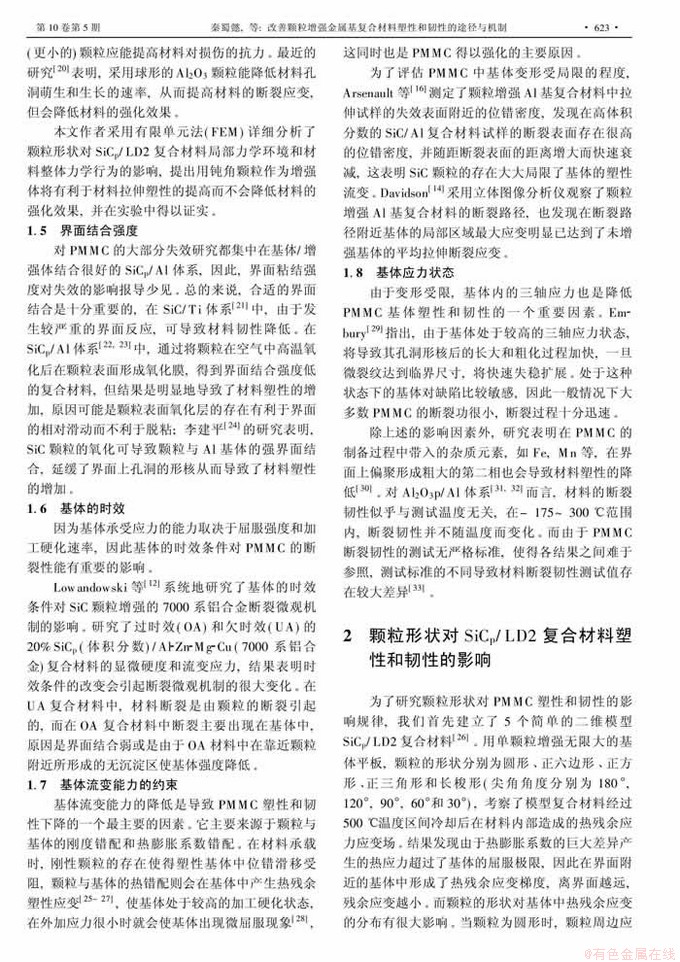

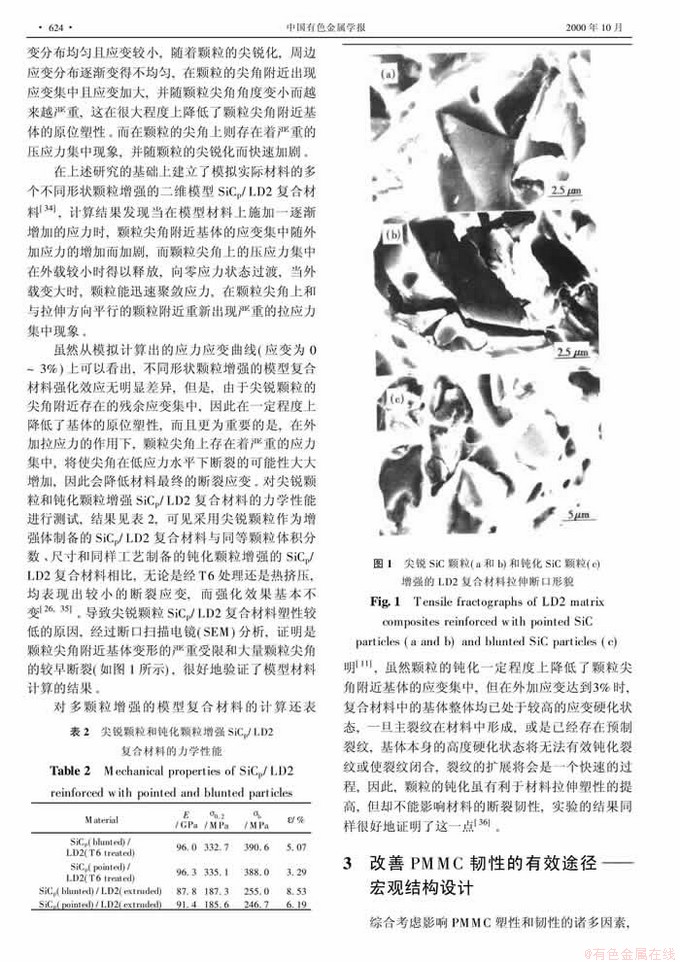

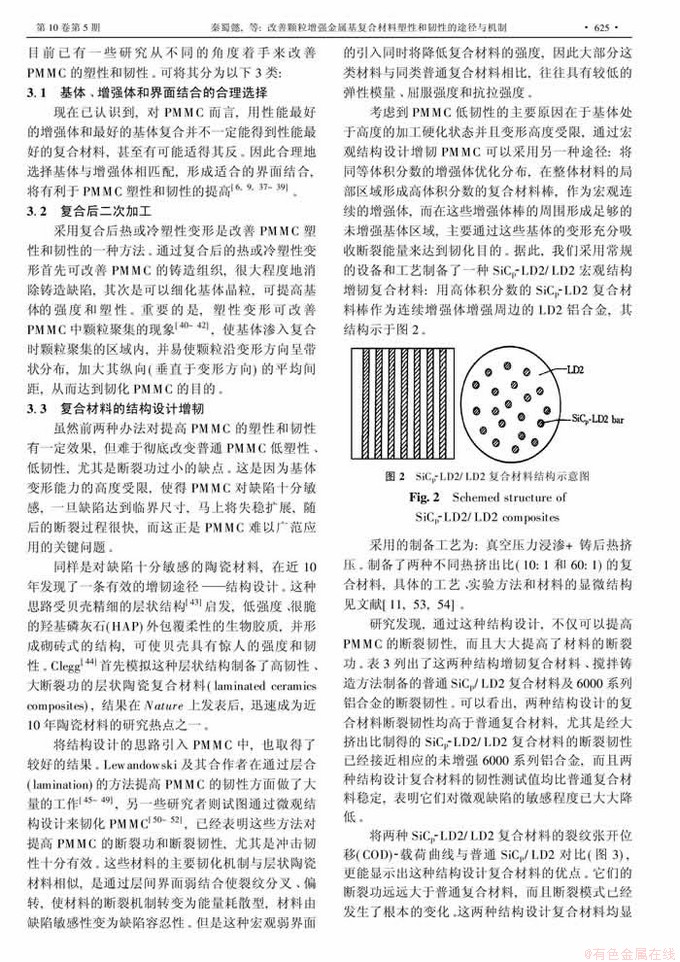

摘 要:评述了影响颗粒增强金属基复合材料塑性和韧性的各种因素,在此基础上深入研究了颗粒形状对SiCp/LD2复合材料塑性和断裂韧性的影响规律。 采用有限单元法分析不同形状的SiC颗粒增强的LD2复合材料的微区力学环境和整体力学行为, 结果表明颗粒的尖锐化导致基体内应变集中和颗粒尖端断裂的可能性加剧,因而降低材料的塑性; 而在外加载荷的作用下, 由于复合材料基体整体均处于较高的加工硬化状态, 因此颗粒形状对材料断裂韧性的影响并不明显。 钝化处理过的颗粒和普通颗粒增强的SiCp/LD2复合材料的力学性能对比和断口分析验证了有限元分析的结果。 对复合材料的宏观结构进行设计是提高复合材料韧性的一条有效途径。对以高体积分数连续SiCp/LD2复合材料棒作为增强体的LD2宏观结构韧化复合材料的研究表明, 与同类普通复合材料相比, 以大比率热挤出的结构设计复合材料断裂韧性可提高32%, 已接近基体合金的断裂韧性水平; 而且材料的断裂功大大提高, 断裂过程呈现阶段性, 完全改变了传统复合材料的断裂模式,避免了普通颗粒增强金属基复合材料突发灾难性失效的缺点。

Abstract: The factors influencing the ductility and toughness of particle reinforced metal matrix composites were commented. Taking these as a background, the effect of particle shape on the ductility and fracture toughnessof SiCp/LD2 composites was deeply studied. Finite element method was used to analyze the microzone mechanical environment and overall mechanical behavior of LD2 matrix composites reinforced with different shaped SiC particles. The resultsshow that particle pointing can increase the strain concentration in the matrix and the fracture possibility of the particles. Therefore, the tensile ductility of the composite reinforced with pointed particle will be decreased. When anexternal load is applied, the composite is under a condition of high workhardening, so the particle shape has little effect on fracture toughness of the composites. Comparison on the mechanical properties and fracture surface analyses of two SiCp/LD2 composites reinforced with blunted and conventionalparticles validates the results of finite element analyses. Designing the macrostructure of composite is an efficient way to improve toughness. LD2 matrix macrostructuretoughening composites reinforced with continuous high volume fraction SiCpLD2 composite bars were studied. Compared with similar conventional composite, the fracture toughness of the structuredesigned composite extruded by alarge ratio can be increased by 32% and is close to the fracture toughness levelof unreinforced matrix alloys. Furthermore, the fracture energy of this kind ofcomposites is greatly improved. Their fracture occurs by stages. This macrostructuredesigned method changes the fracture model of the conventional composites completely and can avoid the disadvantage of catastrophic failure of conventional particle reinforced metal matrix composites.