文章编号:1004-0609(2013)11-3184-05

CeO2对渗Si层组织和高温氧化性能的影响

王红星,柳秉毅,杨少锋,张 炎

(南京工程学院 材料工程学院,南京 211167)

摘 要:采用浆料包渗法,以SiO2粉为渗Si源,纯Al粉为还原剂,NH4Cl作为活化剂,Al2O3为惰性添加剂,蛋白质(鸡蛋清)为粘结剂,在Cu表面预先镀Ni,随后表面浆料包渗Si制备渗层。研究CeO2氧化物对渗Si层组织和氧化性能影响。结果表明:渗剂中添加CeO2氧化物后,渗层组织由以Ni31Si12+Ni2Si金属间化合物为主转变为以Ni2Si 为主与NiSi混合的金属间化合物;渗Si层氧化增质由纯铜的1/4降低到纯铜的1/14,氧化产物为SiO2、Al2O3和少量的NiO,氧化层较致密而且颗粒细小,没有明显的裂纹和空洞出现,改善了抗高温氧化性能。

关键词:CeO2;渗Si层;氧化性能;Ni-Si金属间化合物

中图分类号:TG174.44 文献标志码:A

Effects of CeO2 addition on microstructure and high temperature oxidation resistance of siliconized coating

WANG Hong-xing, LIU Bing-yi, YANG Shao-feng, ZHANG Yan

(School of Materials Engineering, Nanjing Institute of Technology, Nanjing 211167, China)

Abstract: Using slurry pack cementation mixture with SiO2 as siliconizing source, pure Al powder as reducer, NH4Cl as activator, Al2O3 as inert additive and albumen (egg white) as cohesive agent, the electroplated specimens with a layer of electroplating nickel originally deposited on copper were siliconized to prepare coating. The effects of CeO2 oxides on the microstructures and high temperature oxidation resistance of coating were studied. The results show that the phases of the coating are transformed from Ni31Si12+Ni2Si to Ni2Si+NiSi intermetallics after adding CeO2 oxides. The oxidation mass gain of Si-Al coating is decreased from 1/4 to 1/14 of that of pure copper. The oxide is primarily composed of SiO2, Al2O3 and a small amount of NiO. The oxide layer with smaller grain size is dense without cracks and pores, which improves the high temperature oxidation resistance.

Key words: CeO2; siliconized coating; oxidation resistance; Ni-Si intermetallic compound

纯铜具有高导电性和导热性及优异的加工性能,在电子、通讯、电力传输、热交换等领域应用,尤其在高炉风口、连铸机结晶器零部件等都用铜材制造。但纯铜的高温氧化速率较快,铜制件高温下的使用寿命短,造成铜资源浪费很大[1]。

目前,提高纯铜表面性能的主要途径是采用整体合金化和表面改性,整体合金化是以损失其良好的传导性为代价,而采用表面改性技术在保持材料整体性能不变的前提下,赋予材料表面具有耐磨损、耐腐蚀、抗氧化等性能的涂层,满足材料的使用要求。目前强化纯铜表面提高性能方法很多,诸如气相沉积[2-3]、激光熔覆[4]、复合电沉积[5-6]、化学沉积[7]、等离子渗[8-9]等。在众多的表面改性技术中,固体粉末包渗技术具有操作过程简单、不需要专门的设备、加工成本低的优点,而且适用于处理形状复杂的零件,涂层和基体结合牢固,但存在漏渗现象。浆料包渗技术在具有固体粉末包渗技术优点的同时,克服了固体粉末包渗漏渗的不足,渗层厚度均匀、且涂层和基体呈冶金结合。

在渗剂中加入稀土元素可以加速渗镀,改善渗层组织,降低渗层的脆性,提高渗层的耐磨性和抗高温氧化性[10-12]。本文作者在前面研究[13-14]的基础上,通过在渗剂中添加稀土氧化物CeO2,试图改善渗Si层的抗氧化性能,研究CeO2氧化物对 Si渗层组织和高温氧化性的影响。

1 实验

将纯度为99.99%的紫铜块作为阴极,制成尺寸为15 mm×10 mm×2 mm的试样,用金相砂纸打磨、抛光。采用瓦特性镀镍溶液。电解镍板为阳极,在铜表面预镀镍。将电镀后的试样先用清水冲洗掉镀层表面的残留电镀液,然后用丙酮作清洗液,超声清洗、烘干备用。

根据前面研究结果[13-14],选用以下试剂:分析纯SiO2(45 μm)为渗Si源,35%(质量分数);Al粉(45 μm)为还原剂,25%;Al2O3作为惰性添加剂,30%;以蛋白质(鸡蛋清)作为粘结剂,NH4Cl和NaF作为复合活化剂,10%;添加适量的稀土氧化物CeO2。分别称取各组分放入研钵中,研磨5 min,混合均匀,然后,加入适量的鸡蛋清,用玻璃棒搅拌均匀,调制成浆料状涂覆于试样Ni镀层表面。将涂覆好的试样放入真空干燥箱,在80 ℃下真空干燥1 h。取出试样,放入自制的真空炉中,抽真空,用纯度为99.99%的氩气洗炉3次,然后通入氩气,升温至900 ℃,保温12 h,随炉冷却。

以丙酮为清洗液对包渗处理后的试样进行超声清洗,干燥后置于Al2O3坩埚中,连同坩埚一起用分析天平称量氧化前的质量。为了保证实验数据的准确,实验前瓷坩埚在1 000 ℃中烧至质量恒定,以除去其中的水分和杂质。将试样同预先烧制恒重的坩埚一起称量质量作为起始质量,称量后放入箱式炉内,同时也放入已经称量的装有纯铜块的坩埚,试样的尺寸基本一致,静止空气中分别氧化25、50、100、150和250 h。氧化结束后,随炉冷却到室温,将氧化后的试样连同坩埚一起称量。采用FEI SIRION场发射扫描电镜(SEM)配能谱分析仪(EDS)分析渗层氧化表面和截面元素变化趋势;渗层的相结构采用X射线衍射(XRD)仪分析;腐蚀剂为V(HNO3):V(HF):V(H2O)= 1:1:2的溶液。用精度为0.01 mg分析天平称量试样氧化前后质量。

2 结果与分析

2.1 稀土氧化物对渗Si层表面形貌的影响

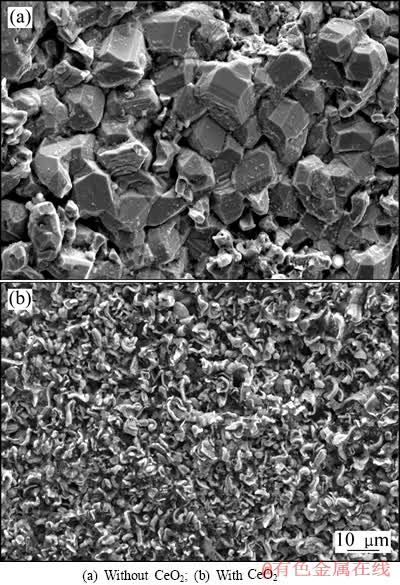

图1所示为铜表面镀镍后,经900 ℃料浆包渗12 h后渗层表面的SEM像。其中图1(a)所示为渗剂中无稀土氧化物的渗层表面形貌;图1(b)所示为渗剂中添加稀土氧化物的渗层表面形貌。从图1可以看出,渗剂中无稀土氧化物包渗时,渗层表面比较疏松,局部区域存在孔洞,晶粒粗大、呈多边形状。渗层表面的EDS元素分析表明,渗层表面含有Si和Al元素,其摩尔分数分别为33.03%和6.27%。添加稀土氧化物后,渗层中的晶粒明显得到细化,表面平整、致密。渗层表面的EDS元素分析结果表明, Si和Al元素的摩尔分数增加,分别为47.08%和8.26%。

图1 经900 ℃包渗12 h后渗层表面的SEM像

Fig. 1 SEM images of coating after slurry packing cementation at 900 ℃ for 12 h

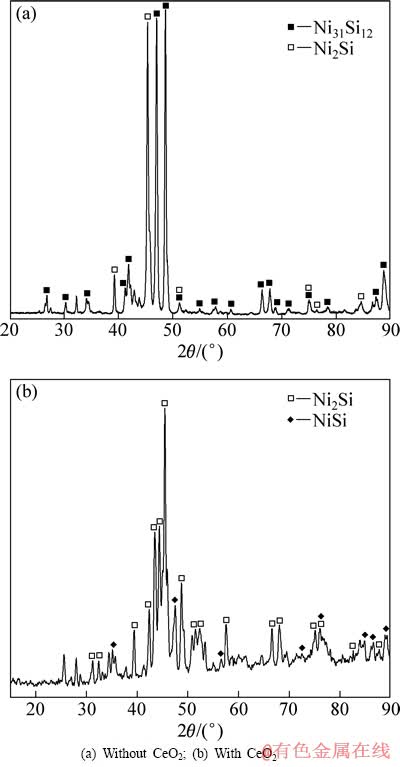

2.2 稀土氧化物对渗Si层表面结构的影响

图2(a)和2(b)所示分别为渗剂中无/有稀土氧化物、经900 ℃料浆包渗12 h后渗层表面的XRD谱。由图2可见,渗层组织由以Ni31Si12为主相和Ni2Si相两相混合组成,没有Al元素的化合物形成,Al原子固溶方式存在于Ni-Si化合物中。与未添加稀土氧化物的渗层组织相比,经稀土氧化物改性后,渗层组织中Ni-Si化合物的Si含量明显增加,由以Ni31Si12为主相转变为以Ni2Si为主相并出现了Si含量更高的NiSi相,同时,固溶在Ni-Si化合物中Al含量也增加。这与稀土的催化和催渗作用有关。稀土的催化作用表现在:一方面,加速了渗剂组分的分解;另一方面,对金属表面起到了净化和活化作用,有利于对Si、Al原子的吸附。有研究认为[15],稀土原子电负性低,易于形成正离子,在包渗过程中促使气态卤硅、铝化物断链,同时,夺取SiO2中的氧,使渗剂中的活性Si原子增加。稀土还可能与渗剂中的其他元素作用,形成某种形式的过度型化合物而发挥催化效果。此外,稀土元素本身更易于吸附于金属表面,并降低其表面能,为活性原子在金属表面的吸附创造了更为有利的条件。稀土的催渗作用在于其原子具有极强的渗透能力。由于稀土原子(如Ce原子)半径比Ni的大30%以上,很难占据Ni晶格与Ni形成置换固溶体,只能通过位错或晶界等缺陷处扩散进入金属表面,并在晶界偏聚;大尺寸稀土原子的渗入导致基体晶格严重畸变,增加空位的浓度。根据固体分子电子理论,稀土原子半径是可变的。稀土原子达到镍镀层表面产生吸附时,其价电子就被镍晶格吸引与镍原子形成电子键。稀土原子的第一电离能很小,即稀土原子失去电子所需能量很低,发生吸附后稀土原子的价电子容易发生偏移或部分地脱离原子核的束缚,引起稀土原子的极化或离子化,导致其原子半径减小;原子半径减小后的稀土原子通过空位或双空位扩散机制[16]进入渗层,稀土元素成为Si、Al原子的一种载体,为活性Si、Al原子的扩散开辟了更多的“通道”,创造了更为有利的条件,增加了扩散速度,从而减少了Ni、Si原子迁移后留下的空位,使得空洞减小甚至消失,改善渗层致密度和性能。

图2 经900 ℃包渗12 h后渗层表面的XRD谱

Fig. 2 XRD patterns of coating surface after slurry packing cementation at 900 ℃ for 12 h

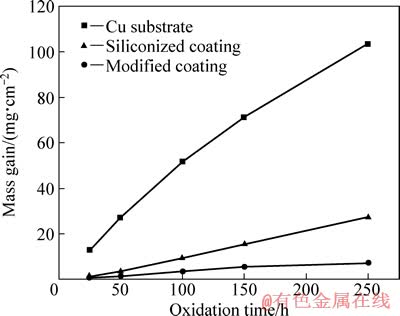

2.3 稀土氧化物对渗Si层抗氧化性能的影响

图3所示为渗Si层、稀土氧化改性渗Si层和铜基体在900 ℃静止空气中,等温氧化后,氧化时间与渗层表面单位面积氧化增质的关系。从图3可以看出,在氧化过程中,渗Si层和稀土改性渗Si层的氧化增质远远低于纯铜的氧化增质。这表明铜表面经过镀镍渗Si后,特别是CeO2的添加,改善了渗Si层的氧化性能。在氧化250 h后,渗Si层和改性渗Si层的氧化增质分别为27.248和7.358 mg/cm2,为纯铜的1/4和1/14,相应的氧化速率常数分别为3.0276×10-5和8.1756×10-6 g2/(cm4·s)。

图3 渗层和Cu在900 ℃空气中的氧化增质曲线

Fig. 3 Curves of mass gain of coatings and copper in air at 900 ℃

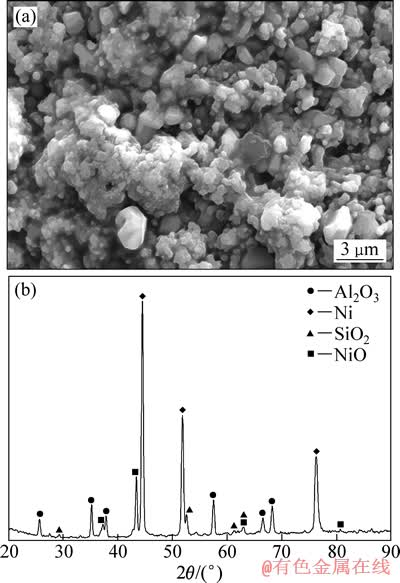

渗剂中有/无稀土氧化物的渗层经900 ℃氧化250 h后,氧化层的表面形貌及氧化产物的XRD谱分别如图4和5所示。比较图4(a)和图5(a)可看出,与未添加CeO2的渗层相比,稀土氧化物改性渗层氧化250 h后,氧化层表面较均匀分布着颗粒细小的氧化物,氧化层表面平整,没有明显的缺陷,如裂纹等,有利于抗氧化性能提高,同时,氧化后坩埚内的脱落物也较少。XRD谱表明(见图4(b)和图5(b)),渗层氧化产物由SiO2、Al2O3和NiO组成。

在渗层氧化初始阶段中,渗层表层中元素Al、Si发生选择性氧化,优先和O结合生成了Al2O3、SiO2,但是由于表层中的Ni含量高,表现出较高的活度,优先生成NiO的可能性较大;随着氧化时间的延长,渗层中元素Al、Si和O结合生成氧化物而消耗,O2-利用混合氧化物中产生的空隙和裂纹,向内扩散与镍镀层发生氧化,加速氧化过程。在渗剂加入稀土氧化物CeO2,氧化膜的晶粒细小。这表明稀土氧化物的添加,增加了氧化物的晶核数,改变了氧化膜的形成过程;同时,由于晶粒的细化,通过晶界的滑移,有效地释放渗层中应力的集中,降低了渗层在氧化过程中层内应力的积聚,增强了渗层与基体的粘结力和其形成氧化膜的抗剥落能力。这一现象与KOO等[17]报道的晶粒细化可显著提高渗层的塑性能力,从而增加氧化物的抗脱落能力的结果相一致。

图4 渗Si层在 900 ℃氧化250 h后的表面形貌及XRD谱

Fig. 4 Surface morphology (a) and XRD pattern (b) of siliconized coating after oxidation at 900 ℃ for 250 h

图5 改性渗Si层在900 ℃氧化250 h后的表面形貌及XRD谱

Fig. 5 Surface morphology (a) and XRD pattern (b) of modified siliconized coating after oxidation at 900 ℃ for 250 h

3 结论

1) 在纯铜表面预先镀镍,随后料浆包渗Si可制备出 Cu 基体/Ni 镀层/过渡层/Ni-Si金属间化合物多层结构。

2) 渗剂中添加 CeO2氧化物后,渗层组织由以Ni31Si12+Ni2Si金属间化合物为主转变为以Ni2Si为主与NiSi混合的金属间化合物。

3) 渗Si层氧化增质由改性前为纯铜的 1/4 降低到纯铜的 1/14,氧化产物为 SiO2、Al2O3和少量的 NiO,晶粒得到细化,改善了渗层的抗高温氧化性能,对铜基体表面起到了有效的保护作用。

REFERENCES

[1] 孙远敬, 岳立新, 张雅玲. 纯同多元共渗及热处理工艺研究[J]. 煤矿机械, 2006, 27(6): 1021-1022.

SUN Yuan-jin, YUE Li-xin, ZHANG Ya-ling. Multi-element penetration of copper and heat treatment technology[J]. Coal Mine Machinery, 2006, 27(6): 1021-1022.

[2] SHI Z Y, WANG D Q. Alumina particles in a copper matrix formed by aluminizing and internal oxidation[J]. Materials Science Letters, 1998, 17(6): 477-479.

[3] 张 毅, 田保红, 陈小红, 高颖颖, 刘 平, 李 炎. 纯铜稀土催渗渗铝及其内氧化[J]. 铸造技术, 2006, 27(3): 255-257.

ZHANG Yi, TIAN Bao-hong, CHEN Xiao-hong, GAO Ying-ying, LIU Ping, LI Yan. Study on aluminizing with RE and internal oxidation treatment of commercial pure copper[J]. Foundry Technology, 2006, 27(3): 255-257.

[4] LIU Fang, LIU Chang-sheng, TAO Xing-qi, CHEN Sui-yuan. Laser cladding of Ni-based alloy on copper substrate[J]. Journal of University of Science and Technology Beijing, 2006, 13(4): 329-332.

[5] 李雪松, 吴 化. 铜基表面电沉积Ni-SiC纳米复合镀层的制备及表征[J]. 铸造技术, 2008, 29(10): 1397-1401.

LI Xue-song, WU Hua. Preparation and characterization of Ni-SiC nano-composite coating by electrodepositing in copper substrate[J]. Foundry Technology, 2008, 29(10): 1397-1401.

[6] 李 鹏. 电沉积Cu-AlN复合镀层的制备和性能的研究[D]. 合肥: 合肥工业大学, 2010.

LI Peng. Study on preparation and properties of Cu-AlN with high performance coating by electrodeposition[D]. Hefei: Hefei University of Technology, 2010.

[7] CHENG Luo, XIANG Xiong, JIE Dong-shi. TiB2/Ni coatings on surface of copper alloy electrode prepared by electrospark deposition[J]. Transactions of Nonferrous Metals Society of China, 2011, 21: 317-321.

[8] 袁庆龙, 张跃飞, 苏永安, 池成忠, 唐 宾, 徐 重. 纯铜等离子渗钛层的高温氧化[J]. 中国腐蚀与防护学报, 2005, 25(2): 102-105.

YUAN Qing-long, ZHANG Yue-fei, SU Yong-an, CHI Cheng-zhong, TANG Bin, XU Zhong. Air oxidation at 400 ℃-700 ℃ of titanized pure copper prepared by a double glow discharge process[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(2): 102-105.

[9] BATENI M R, MIRDAMADI S, ASHRAFIZADEH F. Oxidation behavior of titanium coated substrate[J]. Surface and Coatings Technology, 2001, 139(2/3): 192-199.

[10] 文九巴, 杨柳松, 张金民, 朱利敏, 李安全. CeO2 改性渗铝层的动力学研究[J]. 材料热处理学报, 2007, 28(S1): 165-168.

WEN Jiu-ba, YANG Liu-song, ZHUANG Jin-min, ZHU Li-ming, LI Quan-an. Research on the growth kinetics of CeO2-modified aluminide coating[J]. Transactions of Materials and Heat Treatment, 2007, 28(S1): 165-168.

[11] 朱丽敏, 杨景洪, 王长生, 高习文. CeO2改性渗铝层及其氧化性能研究[J]. 材料热处理学报, 2007, 28(2): 110-112.

ZHU Li-min, YANG Jing-hong, WANG Chang-sheng, GAO Xi-wen. Microstructure and oxidation behavior of novel CeO2–modified aluminizing coating[J]. Transactions of Materials and Heat Treatment, 2007, 28(2): 110-112.

[12] 王红星, 李迎光, 储成林. CeO2对Ti-Al渗层组织和抗高温氧化性能的影响[J]. 稀有金属材料与工程, 2011, 40(2): 316-320.

WANG Hong-xing, LI Ying-guang, CHU Cheng-lin. Effects of CeO2 addition on microstructure and high temperature oxidation resistance of Ti-Al coating[J]. Rare Metal Materials and Engineering, 2011, 40(2): 316-320.

[13] WANG H X, CHU C L, SHENG X B, LING P H, DONG Y S. Study on siliconzing formation mechanism and its performance by slurry pack cementation on electro-deposited nickel layer on copper matrix[J]. Journal of Wuhan University of Technology: Materials Science, 2009, 24(6): 883-887.

[14] 王红星, 李迎光. Al含量对Cu基Ni镀层表面渗Si层组织和力学性能的影响[J]. 材料工程, 2010(2): 55-60.

WANG Hong-xing, LI Ying-guang. Effect of Al content on microstructure and mechanical properties of siliconized coating on surface of electro-deposited nickel layer on copper[J]. Materials for Engineering, 2010(2): 55-60.

[15] 张家春, 白书欣, 赵清海, 乔明俊, 王 蓉. 固体法稀土-硼共渗研究[J]. 国防科技大学学报, 1992, 14(4): 106-110.

ZHANG Jian-chun, BAI Shu-xin, ZHAO Qing-hai, QIAO Ming-jun, WANG Rong. Study on powder RE-boroning[J]. Journal of National University of Defense Technology, 1992, 14(4): 106-110.

[16] MEHRER H, GALLER R. Vacancy-mediated diffusion in quasicrystalline alloys[J]. Journal of Alloys and Compounds, 2002, 342(1/2): 296-301.

[17] KOO C H, BAI C Y, LUO Y J. The structure and high temperature corrosion behavior of IN-738LC[J]. Materials Chemistry and Physics, 2004, 86(2/3): 258-268.

(编辑 何学锋)

基金项目:南京工程学院博士启动基金资助项目(YKJ201203)

收稿日期:2012-03-30;修订日期:2013-09-06

通信作者:王红星,讲师,博士;电话:025-80118274;E-mail:wanghx@njit.edu.cn