Effects of annealing process on electrical conductivity and

mechanical property of Cu-Te alloys

ZHU Da-chuan(朱达川)1, TANG Ke(唐 科)2, SONG Ming-zhao(宋明昭)1, TU Ming-jing(涂铭旌)1

1. College of Materials Science and Engineering, Sichuan University, Chengdu 610065, China;

2. College of Information Engineering, Chengdu Univesity of Technology, Chengdu 610059, China

Received 13 June 2005; accepted 5 December 2005

Abstract: The effects of annealing process on the electrical conductivity and mechanical properties of Cu-Te alloys were studied via AG-10TA electronic universal machine, SB2230 digital electric bridge, SEM and EDS. The results show that recrystallization and precipitation occur simultaneously during the annealing process of Cu-Te alloys. Tellurium precipitates as Cu2Te second phase. The grain size increases with the increasing of annealing temperature and time. The electrical conductivity increases monotonously. The tensile strength of Cu-Te alloy is higher than that of pure copper.

Key words: Cu-Te alloys; Cu2Te; electrical conductivity; mechanical property; annealing; recrystallization; precipitation

1 Introduction

Pure copper and copper alloys are widely used due to the high electrical conductivity, high heat transfer, corrosion resistance and excellent formability[1-5]. But the strength of pure copper is low and the strength gained during cold working will decrease quickly after annealing. So developing copper alloys, which not only have high strength, but also keep high electrical conductivity simultaneously, is necessary[6-10]. However, high strength and high conductivity are a contradiction for copper alloys. So the principle to develop high conductivity and high strength copper alloys is adding low-solubility elements to pure copper, forming super-saturation solid solution, and then making added elements precipitate as the second phases after annealing. Consequently, the electrical conductivity improves quickly and the strength of alloys is still high[11, 12]. Presently most researches are concentrated on Cu-Cr, Cu-Fe and so on, while the studies on Cu-Te alloys are limited[13-15]. The prior research showed that the electrical conductivity of Cu-Te alloys can reach 94%-103% IACS and Cu-Te alloys have special properties, such as anti-electric corrosion, arc- extinguishing synchronously[16, 17]. In order to get high strength and high electrical conductivity, exploring the annealing process is necessary. So the influence of interaction between precipitation and recrystallization of Cu-Te alloys during annealing process on their electrical conductivity and mechanical property is investigated in this paper.

2 Experimental

Cu-Te alloys were melted in a ZG-25A vacuum induction furnace by adding different amounts of pure tellurium to industrial copper in an argon protective atmosphere. Tellurium content at different areas of Cu-Te alloy ingots was detected by ICAP9000(N+M) plasma spectrum. The nominal composition of Te is shown in Table 1. Then the ingots were forged and hot-rolled to copper stick with diameter of 8 mm and the copper sticks were cold drawn to wires with diameter of 2 mm. At last, the copper wires were annealed in the vacuum resistance furnace. The tensile strength was measured by AG-10TA electronic universal machine. The electrical conductivity was measured by SB2230 digital electric bridge and the microstructure was investigated by JSM-5900LV scanning electronic microscope.

Table 1 Nominal composition and measured composition of Te in Cu-Te alloys (mass fraction, %)

3 Results

3.1 Effect of annealing temperature on electrical conductivity and tensile strength of Cu-Te alloy wires

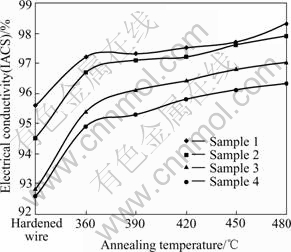

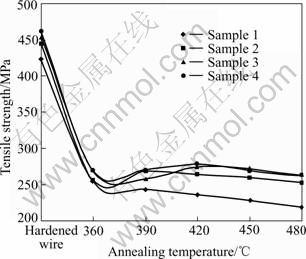

Figs.1 and 2 present the effects of annealing temperature on the electrical conductivity and tensile strength of Cu-Te alloy wires after annealing for 2 h.

Fig.1 Effect of annealing temperature on electrical conductivity of Cu-Te alloys

Fig.2 Effect of annealing temperature on tensile strength of Cu-Te alloys

It can be seen from Figs.1 and 2 that with the annealing temperature increasing, the electrical conductivity increases monotonously, while the tensile strength of Cu-Te alloys wire firstly decreases and finally fluctuates within small range.

3.2 Effect of annealing time on electrical conductivity and tensile strength of Cu-Te alloy wires

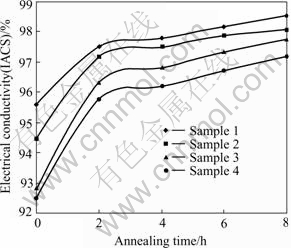

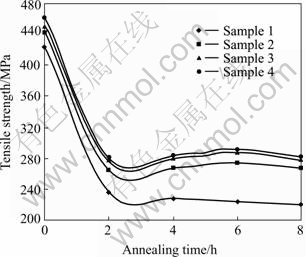

The variations in electrical conductivity and tensile strength of Cu-Te alloy wires after annealing at 420℃ for different times are shown in Figs.3 and 4, respectively.

Fig.3 Effect of annealing time on electrical conductivity of Cu-Te alloys at 420℃

Fig.4 Effect of annealing time on tensile strength of Cu-Te alloys at 420 ℃

As can be seen from Fig.3, with the extended time, the electrical conductivity of Cu-Te alloy wires exhibits consistent climb tendency. But a turning point appears in Fig.4.

3.3 Effect of annealing process on microstructure of Cu-Te alloys

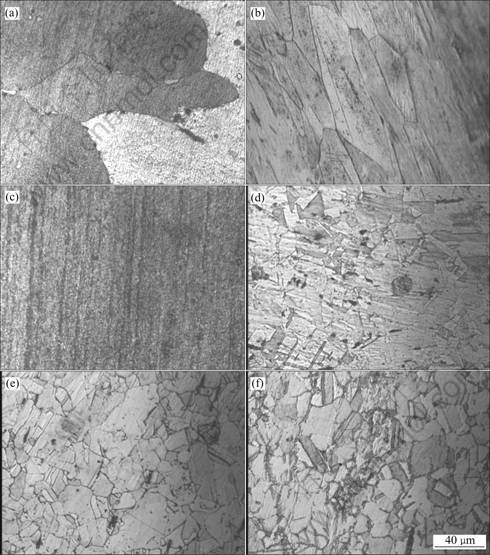

The microstructures of sample 3 in cast, hot- rolled, and cold-drawn state and annealed at different temperatures for 2 h were observed by XJP-6 metallograph, which are shown in Fig.5.

It can be confirmed that the recrystallization happens after annealing at 390 ℃ for 2 h, but recrystallization is incomplete. With the increasing temperature, the recrystallization process finishs and grains start to grow up.

Fig.5 Effect of annealing temperature on microstructure of sample 3: (a) Cast; (b) Hot-rolled; (c) Cold drawn; (d) Annealed at 390℃ for 2 h; (e) Annealed at 420 ℃ for 2 h; (f) Annealed at 450 ℃ for 2 h

Fig.6 shows the microstructures of sample 3 after annealing at 420 ℃ for 2 h and 6 h. It can be seen that prolonging annealing time makes grain grow up.

To ascertain the composition of precipitation, the engery dispersive spectrum (EDS) analysis were conducted on sample 3 after annealing at 420 ℃ for 6 h. Combining the EDS results with Cu-Te alloy phase diagram, the precipitation is determined to be Cu2Te.

4 Discussion

The main reason for the above changes lies on that recrystallization and precipitation happen in Cu-Te alloys simultaneously during annealing process. Firstly, trace tellurium dissolved in copper can improve the recrystallization temperature of copper because solute atoms can decrease the nucleation rate and growth rate of

Fig.6 SEM morphologies of sample 3 after annealing at 420 ℃ for different times: (a) 2 h; (b) 6 h

recrystallization. Meanwhile, these solute atoms congregate near dislocations, block the diffusion of vacancy, thus the recrystallzation grain of Cu-Te alloys is smaller than that of pure copper. With the annealing temperature increasing, recrystallization occurs, then the density of dislocation decreases and the deformation recovers. At the same time, some added elements precipitate as the second phase[18]. It is obvious that the precipitation phase will affect the crystallization process because the fine precipitations occur at dislocations and subgrain boundaries primarily[19]. This blocks the rearrangement of dislocations and movement of subgrain boundary, leading to the formation of high densities area of dislocation near the precipitation. These actions are in favor of recrystallization nucleation. On the condition that the annealing temperature is higher and time is longer, the recrystallization and precipitation of Cu-Te alloys continue, recrystallization grains grow up. Meanwhile the precipitation in front of recrystallization grain boundaries may resolve or grow up according to its original size, thus accelerating or retarding recry- stallization[20]. The reduction of dislocation density and bigger grains make the scatter to electrons decrease, thus the electrical conductivity increases. But the precipitated second phase strengthens the Cu-Te alloy during recrystallization process[21], so the tensile strength of the Cu-Te alloys is higher than that of the pure copper.

5 Conclusions

1) Recrystallization and precipitation happen simultaneously in Cu-Te alloys during annealing process.

2) With the annealing temperature increasing and time prolonging, grains grow up, leading to the electrical conductivity increase.

References

[1] Yamane T. Researches on copper and its alloys in Japan[J]. Research Bulletin——Hiroshima Institute of Technology, 2001, 35: 165-172.

[2] Tardent J P, Demestral B. New copper alloys for electrical, electronic and mechanical applications[J]. Wire Industry, 2001, 68: 173-176.

[3] MA J s, Huang F x, Huang L. Trends and development of copper alloys for lead frame[J]. Journal of Functional Materials, 2002, 33: 1-4.

[4] Murakami M, Horiguchi S, Yabuki A, Matsumura M. Copper alloys evaded by marine organisms—a copper alloy with both anti-fouling and anti-corrosion properties[J]. Corrosion Engineering–TOKYO, 2003, 51: 613-618.

[5] Belyakov V A, Fabritsiev S A. The prospects of copper alloys for VNS applications[J]. Fusion Engineering and Design, 1999, 45: 233-240.

[6] Oikawa K, Ido H, Mitsui H. Development of machinable high-strength copper-based alloys by sulfide dispersion[J]. Materials Transactions, 2003, 44: 2088-2093.

[7] ZHANG R f, SHEN N f. Review and prospect of researches on rapidly solidified high-strength high-conductivity copper alloys[J]. Materials Science and Energineering, 2001, 19: 143-147.

[8] ZHANG S L, Harper J M E, Heurle F M. High conductivity copper-boron alloys obtained by low temperature annealing[J]. Journal of Electronic Materials, 2001, 30: 11-13.

[9] LI M, Heuer J K, Stubbins J F, Edwards D J. Fracture behavior of high-strength, high-conductivity copper alloys[J]. Journal of Nuclear Materials, 2000, 283: 977-981.

[10] Kim K T, Jung W J, Choi C S. Influence of alloying elements on thermal conductivity and high temperature strength of copper based alloys[J]. Materials Science and Technology, 2001, 17: 455-458.

[11] Somani M C, Karjalainen L P. Improving the mechanical properties of copper alloys by thermo-mechanical processing[J]. Acta Metallurgica Sinica(English Letters), 2004, 17: 111-114.

[12] Lim C Y, Jung J H. Grain refinement of copper alloys by equal channel angular pressing[J]. Materials Science Forum, 2004, 449/452: 177-179.

[13] Tan L K, Li Y, Ng S C, Lu L. Effects of rare earth additions on structures and properties of rapidly solidified copper alloys[J]. Materials Science and Technology, 1999, 2: 169-179.

[14] Engler O. Recrystallisation textures in copper- manganese alloy[J], Acta Materialia, 2001, 49: 1237-1247.

[15] HUANG F X, MA J S, GENG Z T, NING H L, SUZUKI H G, GUO S M, YU X T, WANG T, LI H, LI X C. Effect of La, Fe(or Co)/Ti on aging characteristic of copper alloys[J]. Rare Metal Materials and Engineering, 2004, 33(3): 267-270.(in Chinese)

[16] Unnithan C H, Predeep P, Jayakumar S. Doping effect of copper in germanium tellurium semiconducting glass system[J]. Journal of Physics and Chemistry of Solids, 2003, 64: 707-709.

[17] Mostafa S N, Selim S R. Electrochemical investigations of a Cu-Te system and determination of the band gap for α-Cu2Te[J]. Electrochemical Acta, 1993, 38: 1699-1703.

[18] Menge R, Rettig S. In-line annealing of round and flat wires made of copper alloys and special materials[J]. Wire Journal International, 2003, 36: 95-99.

[19] Cotterill P, Mould P R. Recrystallization and Grain Growth in Metals[M]. London: Surry University Press, 1976. 158-163.

[20] Nestorovic S, Markovic D. Influence of alloying on the anneal hardening effect in sintered copper alloys[J]. Materials Transactions, 1999, 40: 222-224.

[21] Nomura Y, Suzuki R, Saito M. Strength of copper alloys in high temperature environment[J]. Journal of Nuclear Materials, 2002, 307: 681-685.

Foundation item: Project(50201010) supported by the National Natural Science Foundation of China; Project(20010610013) supported by Dectoral Subject Foundation of Ministry of Eduction

Corresponding author: ZHU Da-chuan; Tel: +86-28-85460830; Fax: +86-28-85460982; E-mail: zdc89@163.com

(Edited by YUAN Sai-qian)