改性活性炭水解COS催化剂的再生方法

于丽丽,易红宏,宁平,唐晓龙,李华,王红妍,杨丽娜

(昆明理工大学 环境科学与工程学院,云南 昆明,650093)

摘要:采用BET,SEM和XPS等技术,研究用于COS水解反应的活性炭(AC)负载Fe-Cu催化剂在固定床反应器中的失活与再生行为,重点考察水洗再生、N2热再生以及热再生温度对Fe-Cu/AC催化水解COS活性的影响。研究结果表明:水洗再生虽能洗去反应过程中沉积在催化剂表面的部分可溶性含硫物质,但同时可将表面的碱性基团洗去,使催化剂的水解活性降低;经99.99% N2热再生,催化剂的脱硫活性较强,活性恢复较理想;当再生温度为250~300 ℃时,催化剂表面的硫酸盐基本被除去,只有少量的单质硫存在;此外,采用N2热再生法可实现Fe-Cu/AC催化剂的多次再生,大大降低了工艺成本。

关键词:羰基硫;活性炭;水解

中图分类号:TE992.1 文献标志码:A 文章编号:1672-7207(2011)03-0841-07

Regeneration of modified activated carbons used as COS hydrolysis catalysts

YU Li-li, YI Hong-hong, NING Ping, TANG Xiao-long, LI Hua, WANG Hong-yan, YANG Li-na

(Faculty of Environmental Science & Engineering, Kunming University of Science & Technology,

Kunming 650093, China)

Abstract: The activated carbon supported Fe-Cu catalyst used for COS hydrolysis was prepared by gel precipitation method and characterized by BET, SEM and XPS techniques. The activity evaluation of COS hydrolysis over the catalyst was conducted in a fixed-bed reactor. The regeneration performance of the used Fe-Cu/AC catalyst was investigated using different methods. The results show that water-washing can flush away part of the dissolved sulfur-containing compounds on the surface of the catalysts, but it simultaneously causes the loss of a considerable amount of basic groups, consequently resulting in the decrease of the activity of the catalyst. Thermal regeneration by 99.99% N2 can remove the most sulfates, only leaving a very small amount of element sulfur in the catalyst surface. The Fe-Cu/AC catalyst can be regenerated by thermal N2 several times, which shows good regeneration performance and great decrease of the industrial production cost.

Key words: carbonyl sulfide; activated carbons; hydrolysis

近年来,经济持续增长使能源供需矛盾日益突出,如何科学利用高含硫能源逐步为人们所关注。羰基硫(COS)是化工原料气中典型的有机硫化物。COS不仅污染环境,而且影响化工产品的质量、腐蚀管道,引起催化剂中毒;因此,脱除化工原料气中的COS已成为减轻大气硫酸盐气溶胶的形成和提高化工产品质量的重要问题[1-3]。目前,COS水解催化剂大多采用γ-Al2O3作为载体,在水解有机硫的反应过程中形成的中间产物和单质硫可引起A12O3表面中毒,使—OH数量大量减少,减弱了A12O3对有机硫的催化氧化能力,并且该催化剂不易再生,大大增加了工艺成本[3-4]。活性炭是应用较广泛的催化剂/吸附剂载体,近年来,随着人们环保意识的增强和环境法规的日益严格,活性炭在废气治理方面的作用也越来越大。活性炭的吸附性能和催化性能取决于其孔隙结构和表面化学特性,后者主要取决于与碳表面呈化学结合的氧集团,即表面氧化物。表面氧化物赋予活性炭弱极性,增大或扩大了活性炭的催化性能,改变了炭对有机物、无机物的吸附选择性[5-7]。活性炭经改性处理可提高对H2S等酸性气体的脱除效果。活性炭表面的碱性环境有利于提高H2S的吸附性能,并且一定量水蒸气的存在更有利于H2S的吸附,因此,采用水解法在脱除COS的同时将产生的H2S脱除是可行的[6-10]。在微氧条件下,改性活性炭脱除COS和吸附H2S的过程会导致硫酸盐或/和硫沉积在催化剂上,引起催化剂活性下降,并且高温可加速催化剂中毒过程,因此,需要对催化剂进行再生[6]。再生方法主要包括水洗再生和热再生等。水洗再生可将催化剂表面溶解性和沉积的物质洗去;热再生可将催化剂表面吸附的硫转化成SO2[11-12]。在此,本文作者主要研究水洗再生和N2热再生对改性椰壳活性炭催化水解COS活性的影响。

1 实验

1.1 催化剂的制备

催化剂的载体选用椰壳活性炭,将其磨碎筛分成粒径为250~380 μm。用自来水和蒸馏水分别洗活性炭3~4次,然后,加入1 mol/L的KOH溶液煮沸1.5 h,再用蒸馏水洗至pH=6.0左右;用超声波水洗30 min,过滤后放在120 ℃烘箱中干燥3~4 h。配置金属硝酸盐溶液(Fe(NO3)3与Cu(NO3)2物质的量比为10:1),加入适量的Na2CO3制成胶体溶液,将活性炭浸入水溶胶中,用超声波浸渍30 min后于120 ℃烘箱中干燥,然后,在N2保护下于500 ℃焙烧3 h。将焙烧后的活性炭浸渍于质量分数为8%的KOH溶液中,超声波浸渍30 min后,在120 ℃下干燥3 h即可制成实验所需的催化剂(Fe-Cu/AC)。

1.2 催化剂再生

当Fe-Cu/AC催化剂转化COS的效率下降至90 %左右时停止反应,对催化剂进行再生,考察水洗再生和N2保护高温再生对催化剂活性的影响。水洗再生过程为: 将失活催化剂冷却至室温,加20 mL水洗涤,然后过滤,放在温度为120 ℃烘箱中干燥3 h。氮气保护高温再生过程为:先用流速为150 mL/min的N2吹扫炉膛30 min后,将催化剂样品放在管式炉中,以 5 ℃/ min的速率升温至一定温度,恒温吹扫3 h,然后,在N2气氛中降至30 ℃,再重复水洗再生过程。

1.3 催化剂活性的测定

COS催化水解反应在4 mm×100 mm(直径×高)的固定床石英反应器中进行,通过99.99% N2和1% COS进行配气。实验所用COS的质量浓度为1.55~1.60 g/m3。水蒸汽由水饱和器夹带进入反应器,催化剂用量为0.4 g,空速为1 000~2 000 h-1,反应温度为70 ℃,通过带循环水的水浴锅加热,控温精度为±1 ℃,反应前后,COS浓度通过HC-6微量硫分析仪(湖北省化学研究院制造,FPD检测器)在线测定,色谱柱为GDX104填充柱。

1.4 催化剂表征

催化剂的BET 面积和孔结构用美国康塔公司制造的NOVA2000e多点氮气吸附仪测定,分析吸附温度为77 K。催化剂表面形态通过波兰的XL30ESEM- TMP型扫面电镜研究催化剂样品反应前后形貌变化,采用Be 探针,样品预先经过真空处理。XPS实验在PerkinElmer PHI 5500型X线能谱仪上进行;采用 Al Kα射线,功率为200 W,分析精度为1 eV。Ar+发射源用于清洁样品表面,光电子能谱通过结合能为284.8 eV的不定型C 1s 进行校正,数据通过Gaussian- Lorentzian拟合。

2 结果与讨论

2.1 热再生温度的影响

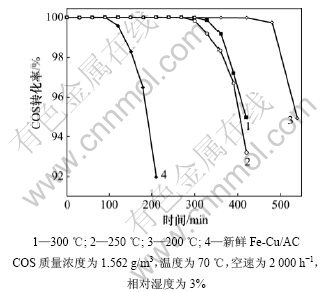

N2热再生温度对失活催化剂的再生影响很大,因此,本文考察不同温度对失活催化剂活性的影响,实验结果见图1。从图1可以看出:再生温度越高,对失活催化剂的活性恢复越有利。在200 ℃时,N2热再生对催化剂活性的恢复较差,催化活性下降较快;当温度升高到250~300 ℃时,再生后的催化剂活性恢复较好,虽然在250 ℃时N2热再生处理的效果比300 ℃时处理的效果略差,但考虑到能源的消耗问题,工业上可选250 ℃对Fe-Cu/AC催化剂进行再生。

2.2 不同再生方法的对比

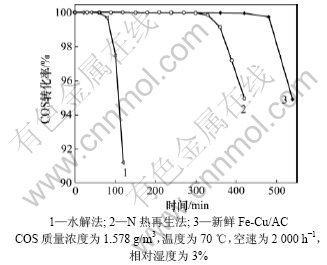

对脱硫反应后的Fe-Cu/AC催化剂进行水洗和N2热再生。不同再生方法对Fe-Cu/AC催化剂水解COS活性的影响见图2。由图2可以看出:于300 ℃时N2

热再生处理后的催化剂活性明显高于水洗法处理效

图1 N2热再生温度对催化剂活性的影响

Fig.1 Effect of N2 thermal regeneration on activity for hydrolysis COS

果,催化剂经过水洗再生后COS转化率大幅度下降。其原因可能是水洗法不仅能将催化剂表面附着的硫和一些硫酸盐除去,同时,也将表面的碱性基团洗去,减少了COS水解反应活性中心,因此,再生后的催化剂活性较弱。而N2热再生可将催化剂表面的硫溶解,经过水洗后催化剂表面的S和可溶性盐基本除去,同时,表面的一些硫酸盐在高温下转变成SO2气体而被除去。由于水洗过程使表面负载的碱基团大量减少,因此,需重新负载碱性物质使催化剂表面碱性基团的数量得到再生,再生后催化剂的活性与新鲜催化剂的活性相当。采用水洗法不能将催化剂的活性恢复,这也说明COS催化水解反应的活性中心是碱中心,表面碱基团的消耗是催化剂失活的主要原因之一。

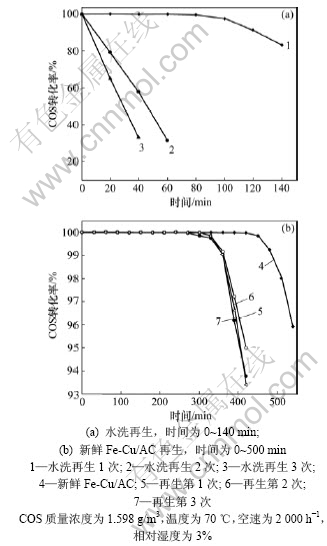

2.3 椰壳活性炭再生次数实验研究

不同再生方法对催化剂活性的影响见图2。从图2可以看出:N2热再生对活性炭基COS水解催化剂的再生处理效果优于水解法,因此,需考察催化剂再生次数对催化剂活性的影响。再生次数对催化剂活性的影响见图3。从图3可以看出:随着再生次数的增加,催化剂的活性下降,水洗法再生的催化剂在再生第2次以后几乎没有催化作用,而经N2热再生法处理的催化剂活性较高,再生次数对其影响较小,基本不随再生次数的增加而下降。此外,N2热再生对活性炭基COS水解失活催化剂的处理是可行的,并且再生次数对催化剂活性的影响较小。

图2 不同再生方法对催化剂活性的影响

Fig.2 Effect of different regeneration methods on catalyst performance for hydrolysis COS

图3 再生次数对催化剂活性的影响

Fig.3 Effect of regeneration frequency on catalyst performance for hydrolysis COS

为了进一步确定COS水解反应活性中心是碱中心,实验根据文献[6, 13]报道的联碱中和法,通过滴定测定了碱改性空白样AC、新鲜Fe-Cu/AC和N2热再生1次后的Fe-Cu/AC催化剂表面酸性基团和总碱性基团的质量摩尔浓度,其测定结果见表1。从表1可以看出:3种样品的表面酸碱基团均发生了一定程度的变化;Fe-Cu/AC催化剂碱性基团明显增加,与空白样相比,质量摩尔浓度增加了0.962 mmol/g,内酯基用滴定法已经检测不出,酚羟基的含量有所增加;再生1次后的催化剂表面碱性基团比新鲜催化剂质量摩尔浓度减少了0.149 mmol/g,内酯基含量仍检测不出,酚羟基质量摩尔浓度增加了0.025 mmol/g。实验结果表明,再生催化剂活性下降是表面碱性基团数量下降和一部分酸性基团数量增加引起的。其原因可能是N2热再生未能将催化剂表面生成的单质硫和硫酸盐完全除去(见XPS分析结果),阻塞了一部分表面活性位,再生后的催化剂碱性基团减少,酸性基团数量增加;因此,可以确定碱性基团是COS水解反应的活性中心。

表1 活性炭表面酸性基团和碱性基团质量摩尔浓度

Table 1 Mass molar concentration of acidity and basicity active carbon mmol/g

2.4 催化剂物性表征

2.4.1 比表面与孔径分布

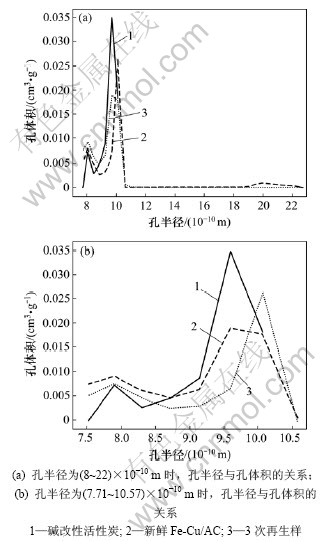

用N2吸附仪分析新鲜催化剂和3次再生后催化剂样的物性参数,结果见表2。从表2可知,3次再生后的催化剂与新鲜Fe-Cu/AC相比,其比表面积、总孔容积均明显增大,比表面积增大323.51 m2/g,总孔容积增大0.17 cm3/g,而平均孔半径则减小0.09 nm。比表面积明显增大并未使催化剂的活性提高,推测Fe-Cu/AC催化剂活性与孔半径有关。图4所示为3种样品的孔半径分布图,从图4(a)可以看出:3种样品的孔径分布主要集中分布在(7.71~10.57)×10-10 m,大于10.57×10-10 m以后碱改性催化剂和新鲜催化剂的孔体积已经为0。而经过3次再生后的催化剂在 (19~22)×10-10 m分布范围内出现扩孔现象,由此可知再生后催化剂比表面积和孔体积的增大主要是这一范围孔径增大所致。但对于催化反应来说,孔径越大,气体分子与催化剂的接触效果越差,而较多的微孔使

表2 不同样品的物性参数

Table 2 Physical parameters of different samples

图4 不同样品的孔径分布

Fig.4 Pore size distribution of activated carbons of various origins

得气体分子与催化剂有充分的反应时间,有利于提高催化剂的活性。图4(b)所示为(7.71~10.57)×10-10 m微孔的局部放大图。从图4(b)可以看出:新鲜Fe-Cu/AC催化剂增大了(7.71~8.83)×10-10 m范围的孔径,负载金属氧化物有利于这一范围孔径的增大。对比新鲜Fe-Cu/AC催化剂和3次再生催化剂可以看出:孔径分布在(7.71~9.66)×10-10 m范围内时,新鲜催化剂的孔体积均大于3次再生后催化剂的孔体积,而孔径为(9.66~10.57)×10-10 m时情况恰好相反。通过图3和图4结果分析推测,Fe-Cu/AC催化剂的活性主要受(7.71~9.66)×10-10 m范围孔径影响,微孔增多有利于COS水解反应活性的提高,而经过3次再生后的催化剂在该范围的孔道内仍有少量含硫化合物堵塞,使微孔体积减少,因此,催化剂的失活主要发生在活性炭的微孔处。

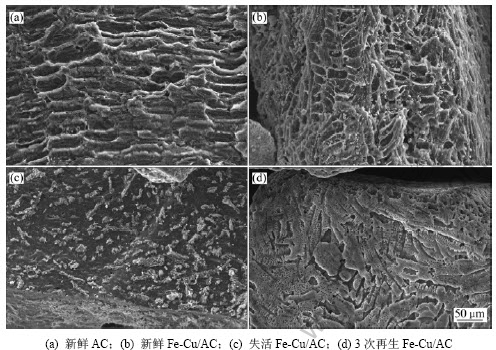

2.4.2 电镜扫描SEM分析

碱改性、新鲜Fe-Cu/AC、反应后和经过3次再生催化剂的SEM 谱图见图5。由图5(a)可知:新鲜的椰壳活性炭经过KOH改性后呈孔径相近、分布较均匀的网状结构;负载金属Fe-Cu后催化剂表面有晶体覆盖,仍呈分布较均匀的网状结构(见图5(b));失活后的催化剂颗粒形状相似,表面失去金属光泽,变得暗淡,颗粒间有一定的团聚,网状结构消失(见图5(c));而3次再生后的催化剂表面出现许多块状物质、催化剂的结晶度增大、表面的团聚程度增大、成分布较均匀的块状结构。由此可知:催化剂的失活主要是由于催化剂表面生成了许多块状晶体,阻塞了催化剂的活性孔道。

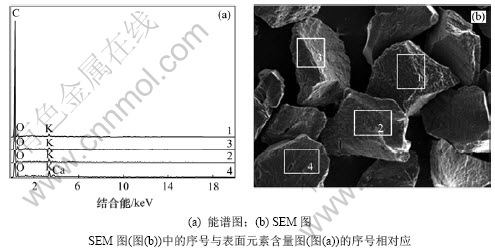

图6所示为KOH改性后椰壳活性炭表面元素的能谱图和SEM图。从图6(b)中标出的4个点可以看出:

图5 新鲜和失活后椰壳活性炭催化剂的SEM图

Fig.5 SEM photos of AC fresh and deactivated catalysts

图6 KOH改性椰壳活性炭表面元素的能谱图和SEM图

Fig.6 Spectrum and SEM images of element in modified active carbon by KOH

椰壳活性炭表面除了C,O,K和极少量的Ca元素以外,不含其他元素,催化剂失活后在表面测得的S含量均为反应生成的含硫化合物中的S含量。

2.4.3 XPS 表征分析

图7所示为新鲜Fe-Cu/AC催化剂和经过3次再生后催化剂反应失活后XPS谱图。从图7(a)可以看出:新鲜催化剂反应失活后的S 2p XPS谱图在168.31,169.63和171.24 eV处出现3个谱峰,对应XPS物质的标准谱图,Fe2(SO4)3和K2SO4的标准结合能均为169.1 eV,CuSO4的标准结合能为169.3 eV,这3种物质的结合能与XPS分析得到的结合能最接近,根据文献[14],结合能在169.0 eV以上为无机硫,因此,可以确定反应后有硫酸根生成,而在171.24 eV出现的峰值,标准图谱没有给出标准物质。Liu等[15]通过FTIR光谱和量子化学计算研究得出:以γ-Al2O3为载体时,COS水解产生了中间产物硫代碳酸氢盐(HSCO2-),中间产物通过氧化可生成最终氧化产物SO42-,因此,在171.24 eV处出现的峰值有可能是一种中间产物。表3所示为新鲜催化剂失活后3种物质的含量,硫酸盐的含量接近73.3%,其余26.7%可能是中间产物。从图7(b)可以看出:3次再生催化剂失活后的谱图仍然出现了3个谱峰,分别是在164.60,166.61和169.18 eV处。对比图7(a)可以看出:结合能的位置发生了变化,对应XPS的标准图谱,单质硫的结合能为164.10 eV,与实验测得的164.60 eV基本吻合,再生后的催化剂表面有未彻底氧化的单质硫存在;而Na2SO3的标准结合能为166.60 eV,与实验测得的166.61 eV吻合,在169.18 eV出现的结合能峰值与K2SO4,FeSO4,Fe2(SO4)3和CuSO4的标准结合能相近。由于催化剂同时含有这3种金属离子,因此,同样不能确定反应后的硫酸盐,但可确定反应后仍有硫酸根生成。3次再生催化剂失活后XPS元素含量见表4。从表4可以看出:3次再生后的催化剂表面生成了30.22%的单质硫和11.93% Na2SO3,硫酸盐只有57.85%。通过对比可知:再生后的催化剂表面不完全氧化产物增多,硫酸盐含量减少,说明多次再生的催化剂表面积累的物质阻塞了催化剂的活性位,占据了水解反应活性中心,使COS与碱性中心反应不彻底,亚硫酸盐的生成可能是在高温再生条件下单质硫将硫酸盐还原,生成了少量的亚硫酸根,所以,多次再生后的催化剂表面存在Na2SO3。根据XPS和SEM的研究可以看出:多次再生的催化剂表面含硫物种发生了变化,表面活性中心数量减少是催化剂活性下降的主要原因。

图7 不同催化剂失活后的XPS谱

Fig.7 XPS profiles of two used catalysts

表3 新鲜催化剂失活后XPS元素含量

Table 3 Elemental analysis of exhausted catalysts using XPS

表4 3次再生催化剂失活后XPS元素含量

Table 4 Elemental analysis of regeneration catalysts by there times using XPS

3 结论

(1) 水洗再生法只能洗去催化剂表面附着的很少量的含硫物质,再生后催化剂的活性与新鲜催化剂的活性相比相差较远。

(2) 采用N2热再生法时,催化剂的活性能恢复到新鲜催化剂的75%左右,并且再生次数对催化剂活性的影响不大,基本维持在较稳定的水平。

(3) COS水解反应主要发生在孔径为(7.71~9.66)×10-10 m的微孔处,催化剂失活主要是微孔被堵塞 所致。

(4) 负载金属Fe-Cu后催化剂表面有晶体覆盖,呈分布较均匀的网状结构,失活及再生后的催化剂表面有明显的晶体物质。

(5) 催化剂失活主要是因为表面有单质硫、硫酸盐、亚硫酸盐生成,占据了表面水解活性中心,导致催化剂表面碱基团数量减少,因此,活性有所降低。

参考文献:

[1] 李新学, 刘迎新, 魏雄辉. 羰基硫脱除技术[J]. 现代工, 2004, 24(8): 19-22.

LI Xin-xue, LIU Ying-xin, WEI Xiong-hui. Technology for carbonyl sulfide removal[J]. Modern Chemical Industry, 2004, 24(8): 19-22.

[2] WANG Li, Wang Shu-dong, YUAN Quan, et al. COS hydrolysis in the presence of oxygen: Experiment and modeling[J]. Journal of Natural Gas Chemistry, 2008, 17(1): 93-97.

[3] Williams B P, Young N C, West J, et al. Carbonyl sulphide hydrolysis using alumina catalysts[J]. Catalysis Today, 1999, 49(1/3): 99-104.

[4] Rhodesa C, Riddel S A, West J, et al. The low-temperature hydrolysis of carbonyl sulfide and carbon disulfide: A review[J]. Catalysis Today, 2000, 59(3/4): 443-464.

[5] Bagreev A, Rahman H, Bandosz J T. Study of regeneration of activated carbon used as H2S adsorbents in water treatment plant[J]. Advance in Environmental Research, 2002, 6(3): 303-311.

[6] Bagreev A, Adib F, Bandosz J T. pH of activated carbon surface as an indication of its suitability for H2S removal from moist air streams[J]. Carbon, 2001, 39(12): 1897-1905.

[7] Bouzaza A, Laplanche A, Marsteau S. Adsorption-Oxidation of hydrogen sulfide on activated carbon fibers: Effect of the composition and the relative humidity of the gas phase[J]. Chemosphere, 2004, 54(4): 481-488.

[8] Sparks D E, Morgan T, Patterson P M, et al. New sulfur adsorbents derived from layered double hydroxides (Ⅰ): Synthesis and COS adsorption[J]. Applied Catalysis B: Environmental, 2008, 82(3/4): 190-198.

[9] Toops T J, Crocker M. New sulfur adsorbents derived from layered double hydroxides (Ⅱ): DRIFTS study of COS and H2S adsorption[J]. Applied Catalysis B: Environmental, 2008, 82(3/4): 199-207.

[10] Sakanishi K, WU Zhi-heng, Matsumura A, et al. Stmultaneous removal of H2S and COS using activated carbons and their supported catalysts[J]. Catalysis Today, 2005, 104(1): 94-100.

[11] 林建英, 郭汉贤, 谢克昌. 羰基硫水解催化剂的失活行为研究[J]. 宁夏大学学报, 2001, 22(2): 192-194.

LIN Jian-ying, GUO Han-xian, XIE Ke-chang. Studies on deactivation of carbonyl sulfide hydrolysis catalyst[J]. Journal of Ningxia University: Natural Science Edition, 2001, 22(2): 192-194.

[12] 马建蓉, 黄张根, 刘振宇, 等. 再生方法对V2O5/AC催化剂同时脱硫脱硝活性的影响[J]. 催化学报, 2005, 26(6): 463-469.

MA Jian-rong, HUANG Zhang-gen, LIU Zhen-yu, et al. Effect of regeneration method on activity for simultaneous removal of SO2 and NO over V2O5/AC catalyst-sorbent[J]. Chinese Journal of Catalysis, 2005, 26(6): 463-469.

[13] 邱介山, 王艳斌, 邓贻钊. 几种活性炭表面酸性基团的测定及其对吸附性能的影响[J]. 炭素技术, 1996, 15(4): 11-17.

QIU Jie-shan, WANG Yan-bin, DENG Yi-zhao. Measurement of the acidic groups in activated carbon surface and their effect on adsorption behaviors[J]. Carbon Techniques, 1996, 15(4): 11-17.

[14] 代世峰, 任德贻, 宋建芳, 等. 应用XPS研究镜煤中有机硫的存在形态[J]. 中国矿业大学学报, 2002, 31(3): 225-228.

DAI Shi-feng, REN De-yi, SONG Jian-fang, et al. Application of XPS in research on occurrence of organic sulfur in vitrain[J]. Journal of China University of Mining & Technology, 2002, 31(3): 225-228.

[15] LIU Jun-feng, LIU Yong-chun, XUE Li, et al. Oxygen poisoning mechanism of catalytic hydrolysis of COS over Al2O3 at room temperature[J]. Acta Physico-Chimica Sinica, 2007, 23(7): 997-1002.

(编辑 陈灿华)

收稿日期:2010-01-11;修回日期:2010-04-25

基金项目:国家高技术研究发展计划(“863”计划)重点项目(2008AA062602);云南省教育厅科学研究基金资助项目(07C11400);国家自然科学基金资助项目(50908110);中国博士后科学基金资助项目(20090451431)

通信作者:易红宏(1976-),女,新疆博乐人,教授,博士,硕士生导师,从事大气污染治理研究;电话:0871-5170905;E-mail: yhhtxl@126.com