DOI: 10.11817/j.ysxb.1004.0609.2021-39014

压力-速度因素对Cf/PF-Cu复合材料载流摩擦磨损性能的影响

邓朝勇1,张红波1,尹 健1,熊 翔1,王 培1,孙 淼1,吴晓光1,李万千2

(1. 中南大学 粉末冶金国家重点实验室,长沙 410083

2. 中南林业科技大学 材料科学与工程学院,长沙 410004)

摘 要:采用模压法制备了一种新型的炭纤维混杂铜网增强树脂基复合材料(Cf/PF-Cu复合材料),并在销盘式载流摩擦磨损试验机上进行了试验。在电流分别为0 A和50 A条件下,研究压力(p)-速度(v)因素(简称pv因素,数值分别为5、10、15、20、25、30和35 MPa·m/s)对Cf/PF-Cu复合材料载流摩擦磨损性能的影响。结果表明:在非载流条件下,摩擦因数随pv值的增加呈逐渐下降趋势,质量磨损率则呈缓慢增加趋势,变化均非常小。在载流条件下,摩擦因数随pv值的增加变化不大,而质量磨损率则变化剧烈;当pv值在15~35 MPa·m/s范围时,质量磨损率随pv值的增加而急剧增加。在载流摩擦磨损过程中,随着pv值的增加,摩擦磨损机制逐渐由磨粒磨损转变为黏着磨损,在pv值达到35 MPa·m/s时则表现为显著的氧化磨损和熔融喷溅。

关键词:Cf/PF-Cu 复合材料;摩擦;磨损;磨损机制

文章编号:1004-0609(2021)-03-0682-09 中图分类号:U214.9 文献标志码:A

引文格式:邓朝勇, 张红波. 尹 健, 等. 压力-速度因素对Cf/PF-Cu复合材料载流摩擦磨损性能的影响[J]. 中国有色金属学报, 2021, 31(3): 682-690. DOI: 10.11817/j.ysxb.1004.0609.2021-39014

DENG Chao-yong, ZHANG Hong-bo, YIN Jian, et al. Effect of pressure-velocity factor on sliding friction and wear of Cf/PF-Cu composites[J]. The Chinese Journal of Nonferrous Metals, 2021, 31(3): 682-690. DOI: 10.11817/j.ysxb.1004.0609.2021-39014

在电力机车弓网系统里,受电弓滑板的作用是用于向导线取流,其性能对电力机车的正常运行有着重要影响[1-3]。在过去数十年中,科研人员先后开发了粉末冶金滑板、浸金属滑板和纯炭滑板等多种高性能受电弓滑板材料,并对各滑板材料的磨损机理进行了深入研究[4-17]。然而,影响摩擦过程的因素很多,磨损机理非常复杂。已有大量的研究表明[18-29],摩擦磨损过程中的电流、压力、速度、电弧、气氛、湿度等因素均对受电弓滑板的摩擦磨损性能产生显著的影响。

虽然已经对受电弓滑板材料摩擦磨损过程进行了大量的研究,但由于之前的研究多数集中在单因素方面,对多因素的综合考虑非常少,使得摩擦磨损机制仍然存在争议[30-32]。因此,为了更好地理解受电弓滑板的摩擦磨损机制,就需要同时考虑多个因素对摩擦磨损过程的影响。因为这些因素之间可能会产生协同效应,而这个问题一直被研究者所忽视。压力(p)-速度(v)因素(简称pv因素)在机械摩擦领域具有相互协同作用,这早已被大家所熟知,但在弓网系统的电气磨损领域却鲜有报道。EL-REFAIE等[33]、HU等[34]和WANG等[35]对pv因素在电刷领域的应用进行了报道,结果表明pv因素可以用于表征电刷的的磨损率和使用寿命,并有助于进一步研究其摩擦磨损机制。但上述研究结果仅适用于试验电流、速度和压力均极低的电刷材料,对于电流、速度和压力均极高的受电弓滑板材料并不适用。因此,本文采用本课题组最新制备的一种炭纤维混杂铜网增强树脂基复合材料(Cf/PF-Cu composites)在模拟受电弓滑板实际工况的条件下,考察了pv因素的协同作用对摩擦磨损机制的影响,为Cf/PF-Cu复合材料在滑动导电材料方面的应用提供试验基础。

1 实验

1.1 材料制备

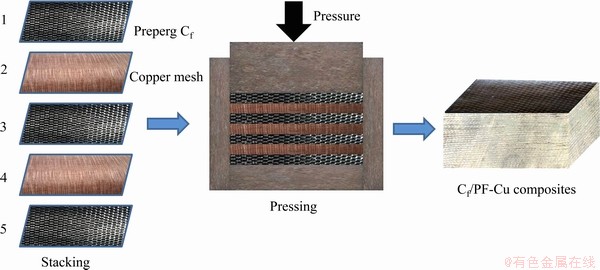

采用酚醛树脂(PF)(质量分数为55%)的预浸炭布,按一层预浸炭布一层铜网的方式进行叠层制备预制体。先将预制体置于烘箱内预固化,然后用平板硫化机在150 ℃和15 MPa下对其进行压制成型。取出压制样品置于180 ℃烘箱内释放应力2 h,而后随烘箱自然冷却至室温,制得树脂模压型Cf/PF-Cu复合材料。该复合材料的制备工艺如图1所示,其基本性能如表1所示。

表1 Cf/PF-Cu复合材料的基本性能

Table 1 Basic physical properties of Cf/PF-Cu and pure carbon composites

1.2 载流摩擦磨损性能测试

采用HST-100型高速载流摩擦实验机测试Cf/PF-Cu复合材料的载流摩擦磨损性能,设定速度范围为10~40 m/s,压力范围为0.3~0.9 MPa,pv值分别取5、10、15、20、25、30和35 MPa·m/s,电流分别取0 A和50 A。样品尺寸为20 mm×10 mm×8 mm,其中10 mm×8 mm为摩擦面。采用光敏二极管测量伴生电弧光强,K型热电偶测量试样表面温度;采用Quanta FEG 250型扫描电子显微镜观察试样摩擦表面形貌,以及采用EDAX2000型能谱仪对特定区域进行元素分析。图2所示为载流摩擦磨损试验机结构示意图。

2 结果与分析

2.1 pv因素对摩擦因数和磨损率的影响

图1 树脂模压型Cf/PF-Cu复合材料的制备工艺示意图

Fig. 1 Scheme showing preparation process of resin hot-pressing type Cf/PF-Cu composites

图2 HST-100型多功能载流摩擦磨损试验机结构示意图

Fig. 2 Schematic diagram of HST-100 multifunction friction and wear tester with electric current

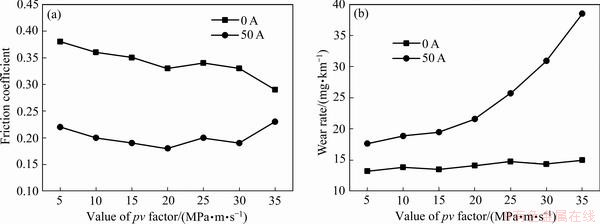

图3 pv因素对不同电流时摩擦因数和质量磨损率的影响

Fig. 3 Effects of pv factor on friction coefficient(a) and wear rate(b) with different electric currents

图3所示为pv因素对摩擦因数和质量磨损率的影响。由图3(a)可知,在非载流条件下,摩擦因数随pv值的增加呈逐渐下降趋势,而在载流(50 A)条件下,pv值在5~20 MPa·m/s范围内,摩擦因数随pv值的增加呈下降趋势,pv值在20~35 MPa·m/s范围内,摩擦因数随pv值的增加呈波浪式增加。在整个测试范围内,载流过程中的摩擦因数均显著低于非载流摩擦因数。由图3(b)可知,载流摩擦磨损过程中的质量磨损率均远高于非载流摩擦磨损过程中的。在非载流摩擦磨损过程中,质量磨损率随pv值的增加呈缓慢增加趋势,变化非常小。而在载流摩擦磨损过程中,pv值在5~15 MPa·m/s范围时,质量磨损率随pv值的增加缓慢增加;pv值在15~35 MPa·m/s范围时,质量磨损率随pv值的增加开始急剧增加。

有研究表明[36],机械磨损的质量磨损率与摩擦速度和加载压力之间存在线性相关,可表示为

(1)

(1)

式中:k为摩擦因数;p为加载压力;s为滑动距离。考虑到实际摩擦过程中接触压力跟加载压力并非完全一致,故对式(1)进行修正:

(2)

(2)

式中:p为实际接触压力;A为实际接触面积;v为滑动速度;t为滑动时间。那么,单位时间内的质量磨损率( )可表示为

)可表示为

(3)

(3)

由此可见,非载流摩擦磨损过程中,质量磨损率与pv值的变化关系与式(3)相吻合。而在载流摩擦磨损过程中,质量磨损率除了跟机械磨损有关外还跟电磨损和电弧烧蚀有关。有研究表明[37],载流摩擦磨损过程中的质量磨损率跟摩擦副表面产生的热量有关。根据电接触理论,摩擦副表面产生的热量主要来源于摩擦热、焦耳热和电弧热[38]。因此,单位时间内摩擦副表面产生的热量可以用下式表示:

(4)

(4)

由式(4)可知,摩擦副接触面的电阻对摩擦副表面产生的热量具有极其重要的影响。而真实的摩擦表面是由大量凸出的斑点组成,在摩擦过程中这些凸出斑点被电流产生的焦耳热、电弧热以及摩擦热不断加热,并随着温度的不断升高,这些凸出斑点逐渐发生软化、甚至熔融,导致大量的凸出斑点被破坏并脱离摩擦表面,从而改变摩擦表面电阻,进而影响电磨损过程。同时,由于摩擦表面大量凸出斑点的脱落以及电弧对摩擦表面的烧蚀作用,导致载流摩擦磨损条件下的质量磨损率要远高于非载流摩擦磨损过程。

2.2 pv因素对燃弧光强和燃弧率的影响

图4所示为pv因素对燃弧光强和燃弧率的影响。由图4可知,当pv值为5 MPa·m/s时,光敏二极管检测到的电弧数量极少,且强度微弱(燃弧率仅为0.08%,相对光强不足,100 a.u)。当pv值为20 MPa·m/s时,光敏二极管检测到的电弧数量显著增加,燃弧率达到1.16%,是pv值为5 MPa·m/s时燃弧率的14.5倍。同时,相对光强也明显增强。当pv值达到35 MPa·m/s时,光敏二极管所能检测到的电弧急剧增多,燃弧率达到3.57%。综上所述,随着pv值的增加,离线电弧变得越来越频繁,产生的电弧光强也越来越剧烈,从而导致摩擦试样表面温度快速增加。

图4 pv因素对燃弧光强和燃弧率的影响

Fig. 4 Variation of arc discharge rates and discharge light intensities under different values of pv factor

2.3 pv因素对表面温度的影响

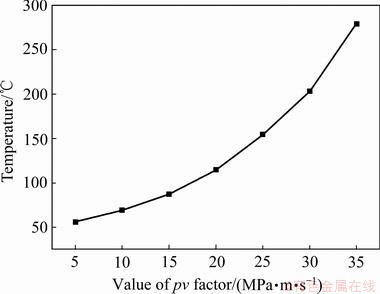

图5所示为不同pv值下试样表面的温度。由图5可知,随着pv值的增加,试样表面温度急剧增加。同时,曲线斜率不断增加,这表明试样表面温度增加的速率也在不断增加。根据电摩擦理论和前述分析可知,在电摩擦过程中,机械磨损是相对独立的。因此,增加的温度主要来源于焦耳热和电弧热。由图5中急剧增加的燃弧率可知,在pv值大于20 MPa·m/s时,电弧热对试样表面温度的作用远高于焦耳热的作用。

图5 50 A电流时不同pv值下试样表面的温度

Fig. 5 Steady state temperature of sample surface under different values of pv factor at 50 A electrical current

2.4 pv因素对表面形貌的影响

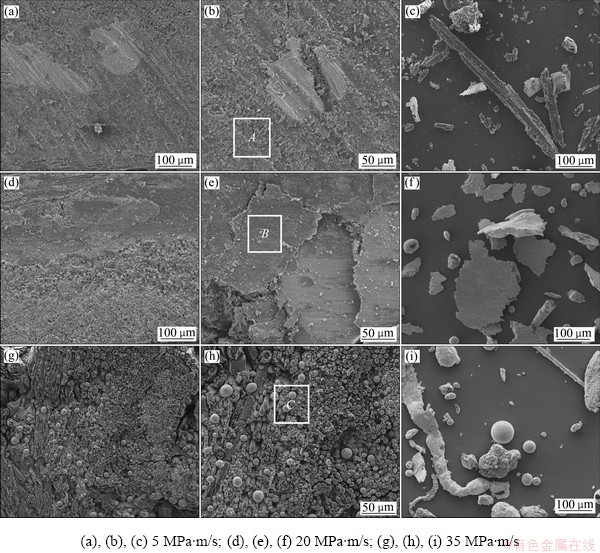

图6 不同pv值下试样表面形貌和磨屑形貌

Fig. 6 Worn surface morphologies and wear debris morphologies under different values of pv factor

图7 图6中A、B、C区域的EDS能谱

Fig. 7 EDS patterns of region A(a), region B(b) and region C(c) shown in Fig. 6

图6所示为不同pv值下试样表面形貌和磨屑形貌。由图6可知,当pv值为5 MPa·m/s时,摩擦表面存在明显的硬质相以及由硬质相导致的犁沟(见图6(a)和(b)),磨屑呈不规则的颗粒状(见图6(c)),同时夹杂一些断裂的炭纤维,这些现象均表明pv值在5 MPa·m/s时,摩擦磨损机制为典型的磨粒磨损。这是因为pv值在5 MPa·m/s时,燃弧率极低,电弧强度微弱,由此产生的电弧热非常少,未能使摩擦表面达到一个合适的温度,使摩擦副表面发生软化,表现出润滑效果。当pv值为20 MPa·m/s时,由于电弧放电加剧,摩擦表面温度升高,使得摩擦表面形成了一层较为均匀的润滑膜(见图6(d)),表现为黏着磨损。摩擦表面的润滑膜有效降低了摩擦因数,并在摩擦磨损初期对试样表面起到较好的保护作用。然而,随着表面载荷重复着加载-卸载过程,以及对偶件铜盘对试样表面不间断的剪切作用,使得一些脆性的摩擦膜与基体发生脱黏,呈大块的片状剥落,并在摩擦表面留下巨大的剥落坑(见图6(e)),从而导致质量磨损率增加(见图3(b))。由图7(b)可知,这层润滑膜主要是由炭和铜的氧化物组成,其中铜生成的产物主要是氧化亚铜(Cu2O)。当pv值达到35 MPa·m/s时,电弧放电非常剧烈,燃弧率和电弧强度均较pv值为20 MPa·m/s时的有较大增幅。由于电弧温度高达3500~4000 K[38],导致摩擦表面温度急剧升高。同时,电弧使摩擦表面发生严重烧蚀,摩擦试样表面的铜以及对偶件铜盘均发生严重的熔融喷溅,导致质量磨损率急剧增加(见图3(b))。由图7可知,随着pv值的增加,摩擦试样表面的铜元素和氧元素不断增加,这表明摩擦试样表面氧化程度不断增加。

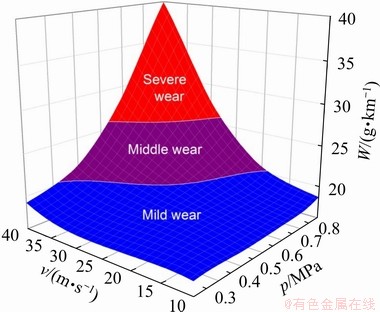

2.5 磨损图

根据载流摩擦磨损过程中不同pv值下的质量磨损率结果,经矩阵转变,拟合出随pv值变化的磨损率图(见图8)。由图8可知,质量磨损率受pv值的影响非常显著,其摩擦磨损行为难以用一种机制进行解释。根据磨损率的情况可大致分为3个区域,分别为轻微磨损区域(Mild wear)、中等磨损区域(Middle wear)和严重磨损区域(Severe wear)。结合上述摩擦表面的分析可知,轻微磨损区域pv值较小,燃弧率很低,表现为典型的磨粒磨损过程。中等磨损区域pv值较大,燃弧率显著增加,表现为黏着磨损和剥落磨损过程。严重磨损区域pv值最大,燃弧率最高,表现为明显的氧化磨损和熔融喷溅。

图8 不同pv值下的质量磨损图

Fig. 8 Worn map under different values of pv factor

3 结论

1) 在非载流条件下,摩擦因数随pv值的增加呈逐渐下降的趋势,而在载流(50 A)条件下,pv值在5~20 MPa·m/s范围内,摩擦因数随pv值的增加呈下降趋势,pv值在20~35 MPa·m/s范围内,摩擦因数随pv值的增加呈波浪式增加。在整个测试范围内,载流过程中的摩擦因数均显著低于非载流过程的摩擦因数。

2) 在非载流摩擦磨损过程中,质量磨损率随pv值的增加呈缓慢增加趋势,变化非常小。而在载流摩擦磨损过程中,pv值在5~15 MPa·m/s范围时,质量磨损率随pv值的增加缓慢增加;pv值在15~35 MPa·m/s范围时,质量磨损率随pv值的增加而急剧增加。载流摩擦磨损过程中的质量磨损率均远远高于非载流摩擦磨损过程的。

3) 在载流摩擦磨损过程中,随着pv值的增加,摩擦磨损机制逐渐由磨粒磨损转变为黏着磨损,在pv值达到35 MPa·m/s时则表现为显著的氧化磨损和熔融喷溅。

致谢

作者非常感谢国家自然科学基金(51302322)和湖南省自然科学基金(2017JJ3514)的资助!同时也十分感谢河南科技大学张永振教授、燕山大学战再吉教授以及西南交通大学陈光雄教授在实验过程给予的无私帮助!

REFERENCES

[1] DING T, CHEN G X, WANG X, et al. Friction and wear behavior of pure carbon strip sliding against copper contact wire under AC passage at high speeds[J]. Tribology International, 2011, 44(4): 437-444.

[2] AMBR P J, SIO J. Influence of pantograph suspension characteristics on the contact quality with the catenary for high speed trains[J]. Computers & Structures, 2012, 110/111(10): 32-42.

[3] NITUCA C. Thermal analysis of electrical contacts from pantograph-catenary system for power supply of electric vehicles[J]. Electric Power Systems Research, 2013, 96: 211-217.

[4] TANG Y, LIU H, ZHAO H, et al. Friction and wear properties of copper matrix composites reinforced with short carbon fibers[J]. Materials & Design, 2008, 29(1): 257-261.

[5] KUBOTA Y, et al. Sliding wear behavior of copper alloy impregnated C/C composites under an electrical current[J]. Wear, 2013, 302(1/2): 1492-1498.

[6] YIN J, ZHANG H, TAN C, et al. Effect of heat treatment temperature on sliding wear behaviour of C/C-Cu composites under electric current[J]. Wear, 2014, 312(1/2): 91-95.

[7] YANG L, RAN L, YI M. Carbon fiber knitted fabric reinforced copper composite for sliding contact material[J]. Materials & Design, 2011, 32(4): 2365-2369.

[8] WANG P, ZHANG H, YIN J, et al. Wear and friction behaviours of copper mesh and flaky graphite- modified carbon/carbon composite for sliding contact material under electric current[J]. Wear, 2017, 380/381: 59-65.

[9] DENG Chao-yong, ZHANG Hong-bo, YIN Jian, et al. Carbon fiber/copper mesh reinforced carbon composite for sliding contact material[J]. Materials Research Express, 2017, 4(2): 025602.

[10] ZHOU W, YI M, PENG K, et al. Preparation of a C/C-Cu composite with Mo2C coatings as a modification interlayer[J]. Materials Letters, 2015, 145: 264-268.

[11] YANG Q, LIU J, LI S, et al. Fabrication and mechanical properties of Cu-coated woven carbon fibers reinforced aluminum alloy composite[J]. Materials & Design, 2014, 57(5): 442-448.

[12] DING T, CHEN G X, LI Y M, et al. Arc erosive characteristics of a carbon strip sliding against a copper contact wire in a high-speed electrified railway[J]. Tribology International, 2014, 79(11): 8-15.

[13] 周文艳, 冉丽萍, 彭 可, 等. Mo2C改性涂层制备温度对C/C-Cu复合材料组织和性能的影响[J]. 中国有色金属学报, 2015, 25(4): 990-996.

ZHOU Wen-yan, RAN Li-ping, PENG Ke, et al. Influence of preparation temperature of Mo2C interlayer on microstructure and properties of C/C-Cu composites[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(4): 990-996.

[14] 万 成, 李继文, 王 展, 等. W-30Cu电接触材料直流电接触行为[J].中国有色金属学报, 2016, 26(1): 126-136.

WAN Cheng, LI Ji-wen, WANG Zhan, et al. Electrical contact behavior of W-30Cu contact material under direct current condition[J]. The Chinese Journal of Nonferrous Metals, 2016, 26(1): 126-136.

[15] 万 成, 李继文, 王 展, 等. 高致密细晶W-25Cu触头材料的电接触性能[J]. 中国有色金属学报, 2017, 27(3): 504-513.

WAN Cheng, LI Ji-wen, WANG Zhan, et al. Performances of high-density fine-grain W-25Cu electrical contact materials[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(3): 504-513.

[16] 陶麒鹦, 周晓龙, 周允红, 等. AgCuO电触头材料的接触电阻及电弧侵蚀形貌分析[J]. 稀有金属材料与工程, 2015, 44(5): 1219-1223.

TAO Qi-ying, ZHOU Xiao-long, ZHOU Yun-hong, et al. Contact resistance and arc erosion morphology of AgCuO electrical contact material[J]. Rare Metal Materials and Engineering, 2015, 44(5): 1219-1223.

[17] 周文艳, 冉丽萍, 彭 可, 等. Mo2C改性C/C-Cu复合材料的组织及载流摩擦磨损性能[J]. 复合材料学报, 2016, 33(9): 2074-2081.

ZHOU Wen-yan, RAN Li-ping, PENG Ke, et al. Structure and tribological property with electric current of Mo2C modified C/C-Cu composites[J]. Acta Materiae Compositae Sinica, 2016, 33(9): 2074-2081.

[18] WANG Y A, LI J X, YAN Y, et al. Effect of electrical current on tribological behavior of copper-impregnated metallized carbon against a Cu-Cr-Zr alloy[J]. Tribology International, 2012, 50: 26-34.

[19] SHANGGUAN Bao, ZHANG Yong-zhen, XING Jian-dong, et al. Comparative study on wear behaviors of metal-impregnated carbon material and C/C composite under electrical sliding[J]. Tribology Transactions, 2009, 53(6): 933-938.

[20] YANG Z, ZHANG Y, ZHAO F, et al. Dynamic variation of arc discharge during current-carrying sliding and its effect on directional erosion[J]. Tribology International, 2016, 94: 71-76.

[21] DEEVA V, SLOBODYAN S. Influence of gravity and thermodynamics on the sliding electrical contact[J]. Tribology International, 2017, 105: 299-303.

[22] BANSAL D G, STREATOR J L. Effect of operating conditions on tribological response of Al-Al sliding electrical interface[J]. Tribology Letters, 2011, 43(1): 43-54.

[23] LIN X Z, ZHU M H, JI-LIANG M O, ET AL. Tribological and electric-arc behaviors of carbon/copper pair during sliding friction process with electric current applied[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 292-299.

[24] GONG T, YAO P, XIAO Y, et al. Wear map for a copper-based friction clutch material under oil lubrication[J]. Wear, 2015, 328/329: 270-276.

[25] 邓联谱, 涂川俊, 陈 刚, 等. 抑弧油对滑板用C/C复合材料载流磨损性能的影响[J]. 粉末冶金材料科学与工程, 2014(6): 948-954.

DENG Lian-pu, TU Chuan-jun, CHEN Gang, et al. Effect of arc restraining oil on current-carrying wear characteristics of C/C composites[J]. Materials Science and Engineering of Powder Metallurgy, 2014(6): 948-954.

[26] 张会杰, 孙乐民, 张永振, 等. 环境气氛对C/C复合材料载流摩擦学性能的影响[J]. 摩擦学学报, 2015, 32(2): 236-241.

ZHANG Hui-jie, SUN Le-min, ZHANG Yong-zhen, et al. The influence of environmental atmosphere on the tribological performance of C/C composites under electrical current[J]. Tribology, 2015, 32(2): 236-241.

[27] 张会杰, 孙乐民, 上官宝, 等. 空气/氮气气氛下电流和摩擦速度对C/C复合材料载流摩擦磨损性能的影响[J]. 机械工程材料, 2015, 39(1): 94-97.

ZHANG Hui-jie, SUN Le-min, SHANGGUAN Bao, et al. Influences of current and friction speed on friction and wear performance with current of C/C composites under air/nitrogen atmospheres[J]. Materials for Mechanical Engineering, 2015, 39(1): 94-97.

[28] 周文艳, 彭 可, 冉丽萍, 等. 电流对Mo2C改性C/C-Cu复合材料载流摩擦磨损性能的影响[J]. 摩擦学学报, 2016, 36(4): 503-509.

ZHOU Wen-yan, PENG Ke, RAN Li-ping, et al. Effect of electrical current on tribological property of the Mo2C modified C/C-Cu composite[J]. Tribology, 2016, 36(4): 503-509.

[29] LARSEN T  , ANDERSEN T L, THORNING B, et al. Comparison of friction and wear for an epoxy resin reinforced by a glass or a carbon/aramid hybrid weave[J]. Wear, 2007, 262(7): 1013-1020.

, ANDERSEN T L, THORNING B, et al. Comparison of friction and wear for an epoxy resin reinforced by a glass or a carbon/aramid hybrid weave[J]. Wear, 2007, 262(7): 1013-1020.

[30] ZHANG X M, CHEN W P. Review on corrosion-wear resistance performance of materials in molten aluminum and its alloys[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(6): 1715-1731.

[31] SIMOES F, RODRIGUES D M. Material flow and thermo-mechanical conditions during friction stir welding of polymers: Literature review, experimental results and empirical analysis[J]. Materials & Design, 2014, 59(6): 344.

[32] EL-REFAIE A M F, AZIZ M M A, KHORSHID S A Y, et al. Effect of combined velocity and pressure on life time of carbon brushes[J]. IEEE Transactions on Energy Conversion, 2000, 15(2): 176-180.

[33] HU Z, CHEN Z, XIA J, et al. Effect of PV factor on the wear of carbon brushes for micromotors[J]. Wear, 2008, 265(3/4): 336-340.

[34] WANG Y A, LI J X, YAN Y, et al. Effect of PV factor on sliding friction and wear of copper-impregnated metallized carbon[J]. Wear, 2012, 289(25): 119-123.

[35] DREVNA M J, KASALES C J. Introduction to tribology[J]. Wiley, 2013: 431-436.

[36] BHUSHAN B. Principles of tribology[J]. Macmillan, 1975: 647-648.

[37] NAGASAWA H, KATO K. Wear mechanism of copper alloy wire sliding against iron-base strip under electric current[J]. Wear, 1998, 216(2): 179-183.

[38] KUBO S, KATO K. Effect of arc discharge on the wear rate and wear mode transition of a copper-impregnated metallized carbon contact strip sliding against a copper disk[J]. Tribology International, 1999, 32(7): 367-378.

Effect of pressure-velocity factor on sliding friction and wear of Cf/PF-Cu composites

DENG Chao-yong1, ZHANG Hong-bo1, YIN Jian1, XIONG Xiang1, WANG Pei1, SUN Miao1, WU Xiao-guang1, LI Wan-qian2

(1. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China;

2. School of Materials Science and Engineering, Central South University of Forestry and Technology, Changsha 410004, China)

Abstract:Carbon fibre (Cf) and copper fibre (Cu) fabric-reinforced phenol formaldehyde (PF) matrix composites (Cf/PF-Cu) were prepared by hot-pressing method, and then current-carrying friction and wear testing was carried on. The effect of pressure (p)-velocity (v) factor (pv factor for short) on the tribological behavior was investigated. Friction and wear tests were conducted on a pin-on-disc type wear tester. The tests were performed at two electrical currents (0 A and 50 A) and seven different combinations of contact pressure and sliding velocity (5, 10, 15, 20, 25, 30 and 35 MPa·m/s). The results indicate that the friction coefficient decreases with an increase in the pv value, and the wear rate slightly increases with an increase in the pv value when the current is 0 A. When the electrical current is 50 A, the friction coefficient increases little with the increase of the pv value, but the mass wear rate increases drastically. As the pv value increases, the wear behavior gradually changes from abrasive wear to adhesive wear. When the pv value reaches 35 MPa·m/s, the wear behavior performs as oxidative wear and melt ejection of copper alloy.

Key words: Cf/PF-Cu composites; wear; friction; wear mechanism

Foundation item: Project(51302322) supported by the National Natural Science Foundation of China; Project (2017JJ3514) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2019-05-20; Accepted date: 2020-06-10

Corresponding author: YIN Jian; Tel: +86-731-88836877; E-mail: melodycyd@163.com

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51302322);湖南省自然科学基金资助项目(2017JJ3514)

收稿日期:2019-05-20;修订日期:2020-06-10

通信作者:尹 健,副教授,博士;电话:0731-88836877;E-mail:melodycyd@163.com