DOI:10.19476/j.ysxb.1004.0609.2017.06.07

高压扭转变形的Al-Zn-Mg-Cu-Zr合金显微组织及织构

丁永根,王薄笑天,李 萍,薛克敏

(合肥工业大学 材料科学与工程学院,合肥 230009)

摘 要:在380 ℃变形条件下对不同高径比的Al-Zn-Mg-Cu-Zr合金试样进行高压扭转实验,借助于EBSD和XRD技术分析变形Al-Zn-Mg-Cu-Zr合金的显微组织、第二相粒子和织构的演变规律。结果表明:在高压扭转过程中,大量第二相粒子从过饱和Al基体中脱溶析出,显微组织明显细化,在部分三叉晶界处出现了细小的动态再结晶组织;材料织构强度随着高径比的减小而减弱;当高径比为0.20时,晶粒的择优取向方向也发生了明显变化,晶粒在<102>、<111>方向上出现了择优取向。

关键词:Al-Zn-Mg-Cu-Zr合金;高压扭转;显微组织;织构;高径比

文章编号:1004-0609(2017)-06-1125-07 中图分类号:TG379 文献标志码:A

Al-Zn-Mg-Cu-Zr系超高强铝合金作为新一代的优质结构铝合金材料,具有密度小、比强度高、韧性好、扩散性能好、热加工性能以及焊接性能优异等特点,已经被广泛应用于武器系统、航空航天及核工业等尖端领域[1-3]。Al-Zn-Mg-Cu-Zr合金化程度高,微观组织中存在大量的多元合金相,其形态、尺寸和分布对材料的性能具有非常重要的影响[4-6]。传统的金属加工方法如轧制、锻造等改善组织性能的能力有限,难以获得组织均匀、性能优良的合金材料。

大量研究表明[7-9],高压扭转工艺(High pressure torsion,HPT)可应用于各种金属材料的制备过程,并使材料晶粒尺寸细化、组织性能均匀。其基本原理是在轴向施加强大压力的同时周向上做剪切变形[10]。这种强塑性变形工艺可以获得较大变形量,促使过饱和固溶体脱溶析出稳定相[11-12],而且可以诱导时效状态下Al-Zn-Mg-Cu-Zr合金中多元合金相(T相Al2Mg3Zn3和η相MgZn2)回溶,形成过饱和固溶体[13]。与传统工艺相比,高压扭转工艺在挖掘Al-Zn-Mg-Cu-Zr合金强度、硬度和超塑性等性能方面更有优势。

本文作者借助于电子背散射衍射技术(Electron backscattered diffraction,EBSD)和X射线衍射技术(X-ray diffraction,XRD),探讨Al-Zn-Mg-Cu- Zr合金在高压扭转变形过程中微观组织、第二相粒子和织构的演变规律,为获得组织均匀性能优良的铝合金材料提供理论依据。

1 实验

高压扭转实验采用天津理化工程研究院提供的Al-Zn-Mg-Cu-Zr合金,初始态为经T6处理的轧制板材,板厚为30 mm,其主要成分如表1所示。采用线切割沿板厚方向切取d 50 mm×10 mm,d 40 mm×10 mm,d 30 mm×15 mm 3组试样,在KSL-1100X箱式电阻炉中加热到380 ℃。在配备压扭旋转台的YH39-1000型模锻液压机上进行高压扭转实验,其中转台速度固定为0.4 r/s,扭转圈数为5圈。取1/4高压扭转变形后的试样在XRD-6100型衍射仪上进行X射线衍射实验,测试时管电压为40 kV,管电流为 40 mA,扫描衍射角为10°~90°,步宽为 0.01°。再取1/4高压扭转变形后试样经机械研磨后,采用高氯酸和无水乙醇(高氯酸与无水乙醇的体积比为1:9)的混合溶液进行电解抛光,电解抛光时间约为20~35 s。试样处理完成后,采用配备有SEM-EBSD系统的JSM-7001F型场发射扫描电镜进行EBSD实验,扫描测试区域的面积为100 μm×100 μm,扫描步长取0.1 μm。测试时组织观测区域为压缩方向(对应RD方向)和横向(对应TD方向)组成的平面,法向ND垂直于观测平面。

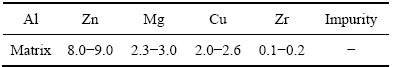

表1 Al-Zn-Mg-Cu-Zr合金主要化学成分

Table 1 Main chemical composition of Al-Zn-Mg-Cu-Zr aluminum alloy (mass fraction, %)

2 结果与讨论

2.1 显微组织分析

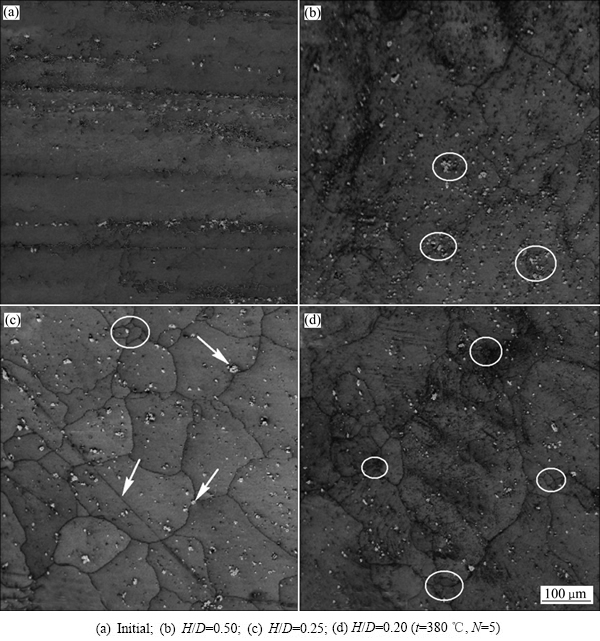

图1所示为380 ℃变形条件下经高压扭转5圈后Al-Zn-Mg-Cu-Zr合金的EBSD显微组织。由图1可以发现,经过T6处理的Al-Zn-Mg-Cu-Zr轧制板材,其显微组织沿轧制方向明显被拉长,晶粒粗大(见图1(a))。

Al-Zn-Mg-Cu-Zr合金中大量的第二相如T相Al2Mg3Zn3、η相MgZn2等经T6处理后固溶进Al基体,少量的第二相(图中白色亮点所示)沿晶界呈链状分布,晶粒内部含量相对较少。经高压扭转剪切变形后,初始拉长的组织被剪切细化,晶粒破碎出现一定的等轴化趋势(见图1(b))。此时,大量的第二相粒子主要分布于晶粒内部,局部区域还出现了少量的团聚现象(见图1(b)圆圈所示部位)。这表明在强大的静水压力(GPa级别)下,高压扭转剪切变形促使第二相粒子从过饱和Al基体中脱溶析出[10-11]。此外,第二相粒子的尺寸、形态也出现了一定变化,有球形、方形和棒状的第二相粒子出现。

图1 不同高径比条件下Al-Zn-Mg-Cu-Zr合金高压扭转变形后的EBSD显微组织

Fig. 1 EBSD microstructures of Al-Zn-Mg-Cu-Zr alloy under different aspect ratios

高压扭转过程中材料的等效应变与高径比密切相关,研究表明[14]可采用以下公式表示其等效应变程度:

(1)

(1)

式中: 表示剪切应变;N表示扭转圈数;D表示试样直径;H表示试样高度。当材料的高径比减小为0.25时,高压扭转的剪切作用增强,等效应变程度增大,变形后组织明显细化,晶粒的等轴化程度更高,在部分三叉晶界处出现了细小的等轴晶粒(见图1(c))。大量的第二相粒子主要分布于晶粒内部,少数分布于晶界处(见图1(c)箭头所示)。同时,在图1(c)左下方45°方向还出现了一条明显的剪切变形带,这表明金属在高压扭转过程中发生了明显的塑性流动和剪切变形。图1(d)所示为高径比为0.20时的显微组织,可以发现,在三叉晶界处细小的等轴晶组织明显增多(见图1(d)圆圈所示部位)。这是由于高压扭转过程中扭转圈数较大,等效应变程度更高,应变积累量较大,材料内部形变储存能较高,同时剪切变形过程中会产生温升效应,两者共同作用导致高压扭转过程中Al-Zn-Mg-Cu-Zr合金发生了动态再结晶现象,在晶界处形成了细小的等轴晶组织。除此以外,晶界处合金元素浓度较大,部分溶质原子在晶界处偏聚,这为再结晶形核提供了化学和物理条件。

表示剪切应变;N表示扭转圈数;D表示试样直径;H表示试样高度。当材料的高径比减小为0.25时,高压扭转的剪切作用增强,等效应变程度增大,变形后组织明显细化,晶粒的等轴化程度更高,在部分三叉晶界处出现了细小的等轴晶粒(见图1(c))。大量的第二相粒子主要分布于晶粒内部,少数分布于晶界处(见图1(c)箭头所示)。同时,在图1(c)左下方45°方向还出现了一条明显的剪切变形带,这表明金属在高压扭转过程中发生了明显的塑性流动和剪切变形。图1(d)所示为高径比为0.20时的显微组织,可以发现,在三叉晶界处细小的等轴晶组织明显增多(见图1(d)圆圈所示部位)。这是由于高压扭转过程中扭转圈数较大,等效应变程度更高,应变积累量较大,材料内部形变储存能较高,同时剪切变形过程中会产生温升效应,两者共同作用导致高压扭转过程中Al-Zn-Mg-Cu-Zr合金发生了动态再结晶现象,在晶界处形成了细小的等轴晶组织。除此以外,晶界处合金元素浓度较大,部分溶质原子在晶界处偏聚,这为再结晶形核提供了化学和物理条件。

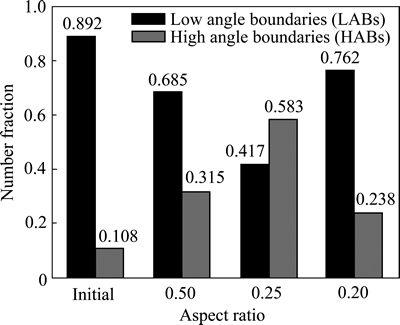

图2所示为EBSD分析Al-Zn-Mg-Cu-Zr合金高压扭转变形后大角度晶界和小角度晶界分布的统计结果。由图2可以发现,在380℃的变形条件下,Al-Zn-Mg- Cu-Zr合金高压扭转5圈后,大角度晶界(晶界取向角 >15°)的比例在高压扭转过程中总体上呈现增大的趋势,当高径比为0.25时,大角度晶界比例最高为0.583。这表明高压扭转变形过程中,随着等效应变程度的增大,剪切变形作用增强,在切应力作用下位错源增殖产生的位错向亚晶界、晶界处迁移,不同滑移面上的位错在晶界和粗大的第二相粒子前形成位错缠结,高密度的位错缠结会分割低位错密度的区域。同时,高压扭转过程中扭转圈数较大,材料内部形变储存能较高,Al-Zn-Mg-Cu-Zr合金发生了动态再结晶现象,显微组织中形成了一定量的具有大角度晶界的再结晶晶粒,因此,大角度晶界比例在高压扭转过程中会明显增加。此外,可以发现当高径比为0.20时大角度晶界的比例出现明显降低,而此时小角度晶界(晶界取向角2°≤

>15°)的比例在高压扭转过程中总体上呈现增大的趋势,当高径比为0.25时,大角度晶界比例最高为0.583。这表明高压扭转变形过程中,随着等效应变程度的增大,剪切变形作用增强,在切应力作用下位错源增殖产生的位错向亚晶界、晶界处迁移,不同滑移面上的位错在晶界和粗大的第二相粒子前形成位错缠结,高密度的位错缠结会分割低位错密度的区域。同时,高压扭转过程中扭转圈数较大,材料内部形变储存能较高,Al-Zn-Mg-Cu-Zr合金发生了动态再结晶现象,显微组织中形成了一定量的具有大角度晶界的再结晶晶粒,因此,大角度晶界比例在高压扭转过程中会明显增加。此外,可以发现当高径比为0.20时大角度晶界的比例出现明显降低,而此时小角度晶界(晶界取向角2°≤ ≤15°)的比例升高,为0.762。这表明在高压扭转5圈条件下,当高径比小于0.25时已不能单纯的通过减小高径比来进一步提高剪切变形程度。

≤15°)的比例升高,为0.762。这表明在高压扭转5圈条件下,当高径比小于0.25时已不能单纯的通过减小高径比来进一步提高剪切变形程度。

图2 不同高径比条件下Al-Zn-Mg-Cu-Zr合金高压扭转变形后大角度晶界和小角度晶界分布图

Fig. 2 LABs and HABs distributions of Al-Zn-Mg-Cu-Zr alloy after HPT under different aspect ratios

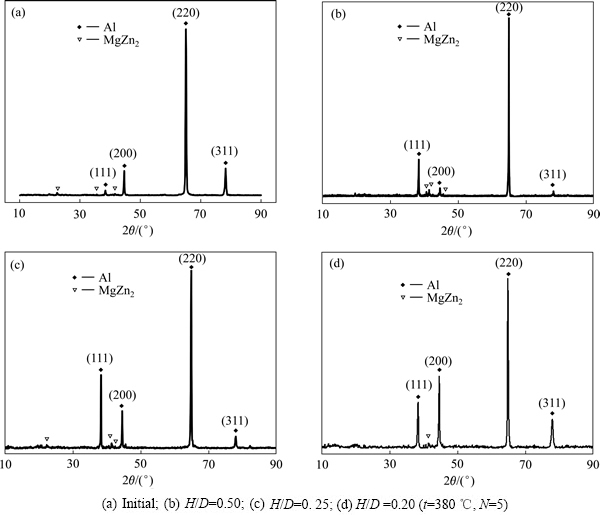

2.2 XRD分析

Al-Zn-Mg-Cu-Zr合金原始材料及高压扭转变形后试样的XRD谱如图3所示。从图3中可以发现,(220)晶面的衍射峰强度最高,这表明铝合金晶粒在(220)晶面方向生长有利且有序。在高压扭转变形过程中,率先达到临界分切应力的滑移系开始启动,随之,其他晶粒也参与运动,以保持变形协调、连续、稳定地进行,因此,(220)晶面特征峰强度开始减弱,其余晶面特征峰的强度开始此消彼长。(111)晶面特征峰的强度相对原始材料明显增强,这与高压扭转变形的过程有关。不同高径比的材料在高压扭转变形时会有一个镦粗过程,高径比越大镦粗作用越明显,变形沿(111)晶面程度较大,因此,图3(b)和(c)中(111)晶面特征峰强度变化较为明显。衍射峰的强度在一定程度上反映了晶粒度的变化,高压扭转变形前试样在(200)和(220) 晶面上衍射峰尖而高,变形后衍射峰强度明显降低,这表明高压扭转过程中发生了晶粒细化[15]。

此外,XRD谱中出现了MgZn2的特征衍射峰,但是受制于XRD对被检测物质含量的要求,在测量范围内只能够标注出MgZn2的存在。由此可以看出,MgZn2的特征峰主要出现在铝基体特征峰(111)晶面和(200)晶面之间。同时可以看到,初始试样的MgZn2相的特征峰强度很低,高压扭转变形后特征峰强度明显增强,这是由于初始试样经过T6处理,第二相粒子如MgZn2等已固溶进铝基体,而在高压扭转过程中过饱和的Al基体会脱溶析出稳定相MgZn2,对组织起到一定的弥散强化作用。

图3 Al-Zn-Mg-Cu-Zr合金高压扭转变形前后的XRD谱

Fig. 3 XRD patterns of Al-Zn-Mg-Cu-Zr alloy before and after HPT under different aspect ratios

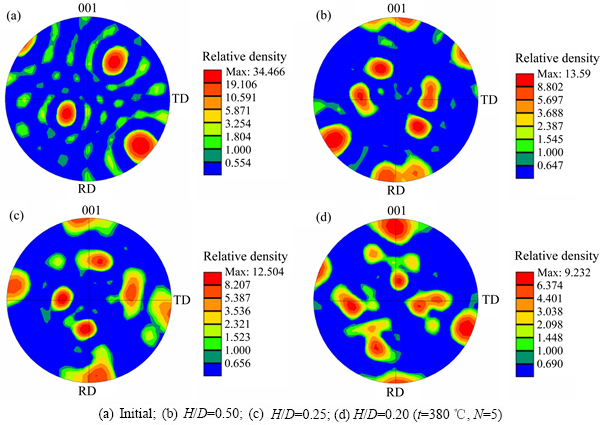

图4 不同高径比条件下Al-Zn-Mg-Cu-Zr合金高压扭转变形前后的极图

Fig. 4 Pole figures of Al-Zn-Mg-Cu-Zr alloy before and after HPT under different aspect ratios

2.3 极图与反极图分析

Al-Zn-Mg-Cu-Zr合金原始材料及高压扭转变形后的极图如图4所示。对比面心立方晶系铝的标准极图可知,Al-Zn-Mg-Cu-Zr原始材料在{100} <001>和{011}<001>方向上存在织构,其最大极密度值为34.466。这表明经过T6处理的Al-Zn-Mg- Cu-Zr轧制板材在高压扭转变形前已经存在强度非常高的板织构,材料内部各向异性较强,不同区域内材料性能不均匀。如图4(b)所示,在380℃变形条件下,经高压扭转变形5圈后,Al-Zn-Mg-Cu-Zr合金在{110}<001>、 <001>、{101}<001>和{010}<001>方向上都存在织构,但最大极密度值减小到13.598。这表明经高压扭转变形后晶粒的择优取向减弱,各向同性增强,变形区内材料的性能逐渐趋于均匀。当高径比减小为0.25时,如图4(c)所示,剪切变形后Al-Zn-Mg-Cu-Zr合金的织构强度进一步减弱,其最大极密度值为12.504,且只在

<001>、{101}<001>和{010}<001>方向上都存在织构,但最大极密度值减小到13.598。这表明经高压扭转变形后晶粒的择优取向减弱,各向同性增强,变形区内材料的性能逐渐趋于均匀。当高径比减小为0.25时,如图4(c)所示,剪切变形后Al-Zn-Mg-Cu-Zr合金的织构强度进一步减弱,其最大极密度值为12.504,且只在 <001>和{110}<001>方向存在织构。如图4(d)所示,当变形材料的高径比为0.2时,其等效应变程度最大,剪切变形后织构强度最弱,其最大极密度值为9.232。这表明随着高径比逐渐减小,高压扭转变形等效应变程度逐渐增大,剪切作用增强,材料内部的各向异性减弱,整个变形区域内材料性能趋于均匀[16]。

<001>和{110}<001>方向存在织构。如图4(d)所示,当变形材料的高径比为0.2时,其等效应变程度最大,剪切变形后织构强度最弱,其最大极密度值为9.232。这表明随着高径比逐渐减小,高压扭转变形等效应变程度逐渐增大,剪切作用增强,材料内部的各向异性减弱,整个变形区域内材料性能趋于均匀[16]。

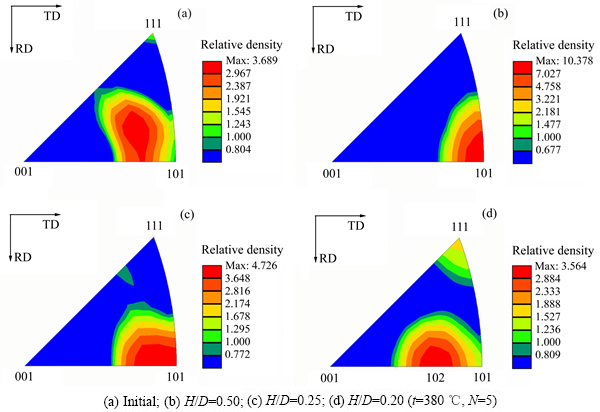

Al-Zn-Mg-Cu-Zr合金原始材料及高压扭转变形后的反极图如图5所示。分析原始材料的反极图可以发现,在<101>方向上晶粒出现了明显的择优取向,其最大极密度值为3.689。如图5(b)所示,在380 ℃变形条件下,经高压扭转变形5圈后,Al-Zn-Mg-Cu-Zr合金在<101>方向上晶粒的择优取向程度增强,其最大极密度值增大到10.378。当高径比减小到0.25时,在<101>

方向上晶粒的择优取向程度随之减弱,其最大极密度值减小到4.726。分析图5(d)所示的反极图可以发现,晶粒的择优取向方向发生了明显变化,即晶粒在<102>、<111>方向上出现择优取向,且织构强度进一步减弱,最大极密度值减小到3.564。这表明高压扭转变形过程中,不同晶粒之间发生了明显的旋转变形,使晶粒的择优取向方向发生变化。

3 结论

1) 经T6处理的Al-Zn-Mg-Cu-Zr合金原始材料,晶粒沿轧制方向明显被拉长,第二相粒子沿晶界呈链状分布;经高压扭转变形后,第二相粒子从过饱和Al基体中脱溶析出,形态也出现了一定变化,有球形、方形和棒状的第二相粒子出现,主要分布于晶粒内部,局部区域还出现了一定程度的第二相粒子团聚现象。

2) 经高压扭转变形后,Al-Zn-Mg-Cu-Zr合金晶粒尺寸随着高径比的减小而明显减小,在高径比为0.20时出现了细小的动态再结晶组织;大角度晶界的比例在高压扭转过程中总体上呈现增大的趋势,当高径比为0.25时大角度晶界比例最高为0.583。

图5 不同高径比条件下Al-Zn-Mg-Cu-Zr合金高压扭转变形前后的反极图

Fig. 5 Inverse pole figures of Al-Zn-Mg-Cu-Zr alloy before and after HPT under different aspect ratios

3) Al-Zn-Mg-Cu-Zr合金原始材料在{100}<001>和{011}<001>方向上存在强度非常高的板织构,高压扭转过程中随着高径比的减小,织构强度明显减弱,材料的各向异性减弱;当高径比为0.20时晶粒的择优取向方向发生了明显变化,晶粒在<102>、<111>方向上出现了择优取向。

REFERENCES

[1] 刘 斌, 汪明朴, 雷 前, 段雨露, 刘林贤, 虞洪春. 喷射沉积法制备Al-Zn-Mg-Cu-Zr合金的显微组织与性能[J]. 中国有色金属学报, 2015, 25(7): 1773-1780.

LIU Bin, WANG Ming-pu, LEI Qian, DUAN Yu-lu, LIU Lin-xian, YU Hong-chun. Microstructure and properties of Al-Zn-Mg-Cu-Zr alloy prepared by spray deposition method[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1773-1780.

[2] CHEN Qiang, XIA Xiang-sheng, YUAN Bao-guo, SHU Da-yu, ZHAO Zu-de. Microstructure evolution and mechanical properties of 7A09 high strength aluminium alloy processed by backward extrusion at room temperature[J]. Materials Science and Engineering A, 2013, 588: 395-402.

[3] 何振波, 李慧中, 梁霄鹏, 尹志明. Al-Zn-Mg-Sc-Zr合金的热变形行为及加工图[J]. 中国有色金属学报, 2011, 21(6): 1220-1228.

HE Zhen-bo, LI Hui-zhong, LI Xiao-peng, YIN Zhi-ming. Hot deformation behavior and processing map of Al-Zn-Mg-Sc-Zr alloy The Chinese Journal of Nonferrous Metals, 2011, 21(6): 1220-1228.

[4] 王一鑫. Al-Zn-Mg-Cu系高强铝合金快速凝固条件下微合金化及作用机理[D]. 哈尔滨: 哈尔滨工业大学, 2008.

WANG Yi-xin. Micro-alloying and mechanism of Al-Zn-Mg-Cu ultra high strength aluminum alloy prepared by rapid solidification[D]. Harbin: Harbin Institute of Technology, 2008.

[5] 宁爱林. 析出相及其分布对高强铝合金力学性能的影响[D]. 长沙: 中南大学, 2007.

NING Ai-ling. The effect of precipitates and distribution on the mechanical properties of high strength aluminum alloy[D]. Changsha: Central South University, 2007.

[6] 舒文祥, 郭明星, 侯陇刚, 崔 华, 庄林忠, 张济山. Al-Zn-Mg-(Cu)合金抗应力腐蚀性能影响因素分析[J]. 材料导报, 2013, 27(7): 1-10.

SHU Wen-xiang, GUO Ming-xing, HOU Long-gang, CUI Hua, ZHUANG Lin-zhong, ZHANG Ji-shan. Effect of different factors on the stress corrosion cracking of Al-Zn-Mg-(Cu)[J]. Materials Review, 2013, 27(7): 1-10.

[7] HORITA Z, LANGDON T G. Achieving exceptional super plasticity in a bulk aluminum alloy processed by high-pressure torsion[J]. Scripta Materialia, 2008, 58 (11):1029-1032.

[8] DOBATKIN S V, BASTARACHE E N, SAKAI G, FUJITA T. Grain refinement and superplastic flow in an aluminum alloy processed by high-pressure torsion[J]. Materials Science and Engineering A, 2005, 408(1/2): 141-146.

[9] IVANISENKO Y, LOJKOWSKI W, VALIEV R Z. The mechanism of formation of nanostructure and dissolution of cementite in a pearlitic steel during high pressure torsion[J]. Acta Materialia, 2003, 51(18): 5555-5570.

[10] 康志新, 彭勇辉, 赖晓明, 李元元, 赵海东, 张卫文. 剧塑性变形制备超细晶/纳米晶结构金属材料的研究现状和应用展望[J]. 中国有色金属学报, 2010, 20(4): 587-598.

KANG Zhi-xing, PENG Yong-hui, LAI Xiao-ming, LI Yuan-yuan, ZHAO Hai-dong, ZHANG Wei-wen. Research status and application prospect of ultrafine grained and/or nano-crystalline metallic materials processed by severe plastic deformation[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(4): 587-598.

[11] 许晓嫦, 刘志义, 党 朋, 于文斌, 宁爱林. 强塑性变形下Al-Cu合金不同析出相的回溶及性能变化[J]. 材料导报, 2006, 20(S2): 463-472.

XU Xiao-chang, LIU Zhi-yi, DANG Peng, YU Wen-bing, NING Ai-ling. Re-dissolution and evolution of properties of different precipitated phases in Al-Cu alloy under severe plastic deformation[J]. Materials Review, 2006, 20(S2): 463-472.

[12] 许晓嫦, 刘志义, 党 朋, 于文斌, 宁爱林. 压缩变形对6063铝合金的变形特性和析出相粒子回溶的影响[J]. 材料热处理学报, 2006, 27(4): 73-76.

XU Xiao-chang, LIU Zhi-yi, DANG Peng, YU Wen-bing, NING Ai-ling. Compression deformation behavior of 6063 aluminum alloy and phase particles back and insoluble influence[J]. Transactions of Materials and Heat Treatment, 2006, 27(4): 73-76.

[13] SHIMA S, TERENCE G. A critical evaluation of the processing of an aluminum 7075 alloy using a combination of ECAP and HPT[J]. Materials Science and Engineering A, 2013: 52-58.

[14] VALIEV R Z. Nanostructuring of metals by severe plastic deformation for advanced properties[J]. Nature Materials, 2004(3): 58-64.

[15] HUANG Run, HAN Yong. Structure evolution and thermal stability of SMAT-derived nanograined layer on Ti-25Nb-3Mo- 3Zr-2Sn alloy at elevated temperatures[J]. Journal of Alloys and Compounds, 2013, 554: 1-11.

[16] 李成铭, 李 萍, 赵 蒙, 甘国强, 薛克敏. TA15钛合金的热变形微观组织与织构分析[J]. 中国有色金属学报, 2014, 24(1): 91-96.

LI Cheng-ming, LI Ping, ZHAO Meng, GAN Guo-qiang, XUE Ke-min. Microstructures and textures of TA15 titanium alloy after hot deformation[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 91-96.

Microstructures and textures of Al-Zn-Mg-Cu-Zr alloy after high pressure torsion

DING Yong-gen, WANG Bo Xiao-tian, LI Ping, XUE Ke-min

(School of Materials Science and Engineering, Hefei University of Technology, Hefei 230009, China)

Abstract: Al-Zn-Mg-Cu-Zr alloys with different height-diameter ratios were deformed by high pressure torsion at 380 ℃. The evolution of microstructures, second-phase particles and textures were studied by electron backscattered diffractometry (EBSD) and X-ray diffractometry (XRD). The results show that a large number of second-phase particles precipitate from supersaturated Al matrix, the microstructures are significantly refined, fine dynamic recrystallization structure occurs at the trigeminal grain boundaries. The density of textures reduces with height-diameter ratios decreasing. When the height-diameter ratio decreases to 0.20, the preferred orientation direction of grains has also undergone a significant change, it occurs on the direction of <102> and <111>.

Key words: Al-Zn-Mg-Cu-Zr alloy; high pressure torsion; microstructure; texture; height-diameter ratio

Foundation item: Project(51575153) supported by the National Natural Science Foundation of China

Received date: 2016-05-03; Accepted date: 2016-08-30

Corresponding author: LI Ping; Tel: +86-551-62901368; E-mail: li_ping@hfut.edu.cn

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51575153)

收稿日期:2016-05-03;修订日期:2016-08-30

通信作者:李 萍,教授,博士;电话:0551-62901368;E-mail: li_ping@hfut.edu.cn