等离子转移弧堆焊碳化钨/Ni基复合材料堆焊层的参数优化

来源期刊:中国有色金属学报(英文版)2018年第12期

论文作者:魏莹 魏先顺 陈波 左建勇 马天才 沈军

文章页码:2511 - 2519

关键词:等离子转移弧堆焊;镍基复合材料;显微组织;堆焊参数优化

Key words:plasma transferred arc hardfacing; Ni-based composite; microstructure; welding parameter optimization

摘 要:采用等离子转移弧堆焊技术制备高碳化钨含量的镍基复合材料(Stelcar 65合金),并通过正交试验优化Stelcar 65合金的堆焊参数。堆焊电流、送粉率和堆焊速度等参数均对碳化钨的分解有显著影响。正交试验优化后的最佳堆焊电流、最佳送粉率和最佳堆焊速度分别为100 A、25 g/min 和 40 mm/min,堆焊层无裂纹、无分解。并对优化后的堆焊层显微组织和显微硬度进行分析。

Abstract: Ni-based composite coatings with a high content of tungsten carbides (Stelcar 65 composite coatings) were synthesized by plasma transferred arc (PTA) hardfacing. The welding parameters of Stelcar 65 composite coatings were optimized by orthogonal tests. The PTA welding parameters including welding current, powder feed rate and welding speed have significant influence on the tungsten carbide degradation. The values for the optimum welding current, powder feed rate and welding speed were determined to be 100 A, 25 g/min and 40 mm/min, respectively. The produced WC/Ni-based composite coatings were crack- and degradation-free. The microstructure of deposited layers, as well as the microstructure and microhardness of the optimal coating were further analyzed.

Trans. Nonferrous Met. Soc. China 28(2018) 2511-2519

Ying WEI1, Xian-shun WEI1, Bo CHEN1, Jian-yong ZUO2, Tian-cai MA3, Jun SHEN1

1. School of Materials Science and Engineering, Tongji University, Shanghai 201804, China;

2. Railway and Urban Rail Traffic Academy, Tongji University, Shanghai 201804, China;

3. College of Automotive, Tongji University, Shanghai 201804, China

Received 27 November 2017; accepted 13 July 2018

Abstract: Ni-based composite coatings with a high content of tungsten carbides (Stelcar 65 composite coatings) were synthesized by plasma transferred arc (PTA) hardfacing. The welding parameters of Stelcar 65 composite coatings were optimized by orthogonal tests. The PTA welding parameters including welding current, powder feed rate and welding speed have significant influence on the tungsten carbide degradation. The values for the optimum welding current, powder feed rate and welding speed were determined to be 100 A, 25 g/min and 40 mm/min, respectively. The produced WC/Ni-based composite coatings were crack- and degradation-free. The microstructure of deposited layers, as well as the microstructure and microhardness of the optimal coating were further analyzed.

Key words: plasma transferred arc hardfacing; Ni-based composite; microstructure; welding parameter optimization

1 Introduction

Hardfacing technologies are important methods to enhance the wear resistance of surface materials. These technologies include flame spraying [1,2], laser melt injection [3], laser cladding [4], plasma cladding [5], solution precursor plasma spray (SPPS) [6], plasma transferred arc (PTA) [7], chemical vapor deposition (CVD) [8] and physical vapor deposition (PVD) [9]. Among these technologies, PTA welding deposition is the most utilized method in industries due to its low production cost, low dilution rate and high productivity [10-13]. Moreover, the metallurgical bond between the substrate and the deposited material obtained from the PTA weld welding deposition process ensures a remarkable performance in tribology and wear environments [14]. With regards to materials for coating protection in severe corrosion, wear and tribology environments, Ni-based hardfacing alloys have attracted much attention in mineral, oil and power generation industry [15-17]. Wear and tribology properties of metallic hardfacing materials are usually reinforced by the hard particles of WC, Cr3C2, VC, Al2O3, Mo and TiC [18-21]. The tungsten carbide is an excellent candidate to enhance the performances of the deposited coatings used in severe wear environment. The size and type of tungsten carbides have a great influence on the wear resistance of the coatings [22,23]. The coating reinforced with an eutectic mixture of WC and W2C exhibited better performances in high stress and impact wear tests [23]. Besides, the deposited coatings with higher volume fraction of tungsten carbides would conduct better wear resistances [24]. Recently, Stellite Stelcar alloys have been developed to serve as a hardfacing coating material. In addition, the Stelcar alloys are metal matrix composites (MMCs) that are typically mixed with large amounts of tungsten carbides particles (WC/W2C) and Ni-based alloys.

However, large amounts of tungsten carbides in Stelcar alloys are vulnerable to carbide degradation during the PTA deposition process. The WC degradation can trigger the formation of brittle phase in the matrix and hard phase, which deteriorates the mechanical properties of MMCs [25,26]. In order to decrease carbide degradation, PTA parameters should be optimized. The coatings in the PTA welding process are influenced by many parameters, such as welding current, welding speed, powder feed rate, oscillation width, preheating temperature and working gas flux [16,27]. Given that PTA welding deposition is a process of melting and solidification, the carbide degradation process may be controlled by optimizing the melt superheating [28]. In addition, three welding parameters such as plasma current, powder feed rate and welding speed are related to the heat input. Plasma current plays an important role in the temperature of molten pool, in which the heat input influences the dilution rate and bonding strength between the MMCs coating and the substrate. In addition, an appropriate powder feed rate should be selected to maintain a sufficient energy input for melting the alloy powders. The welding speed is associated with the plasma arc energy per unit time, which implies that a high welding speed may cause particle splash, although heat efficiency decreases at low welding speed. High heat input increases grain size by dominating the elemental diffusion process [29].

In the current study, orthogonal experiment approach was employed to optimize PTA welding parameters to minimize the carbide degradation in Stelcar 65 alloy coatings. The effect of PTA parameters on microstructure was also investigated. Optimal welding parameters with regards to low tungsten carbide degradation were obtained and the mechanism of tungsten carbide degradation was discussed.

2 Experimental

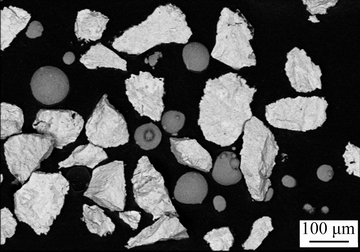

Stellite Stelcar 65 alloy is a blend of Ni-based alloys with 65% (mass fraction) tungsten carbides. The chemical compositions of Stelcar 65 alloy and the morphology of the alloy powders are listed and shown in Table 1 and Fig. 1, respectively. Sharp-edged fused and crushed tungsten carbide particles with size range of 37-193 μm were found in the alloy. Particle sizes of Ni-based alloy powders were distributed between 25 and 100 μm.

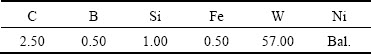

Table 1 Chemical compositions of Stelcar 65 alloy (mass fraction, %)

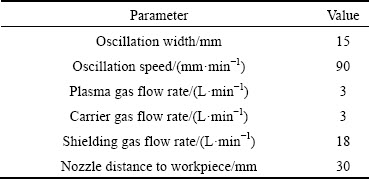

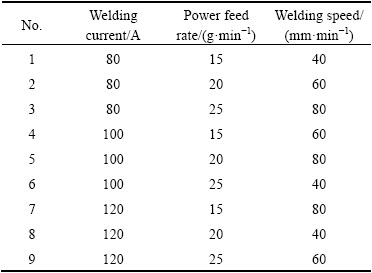

The Stellite Stelcar 65 alloys were deposited on a 10 mm-thick 45# carbon steel by PTA process. The carbon steel plate was preheated to 300 °C before deposition. High purity Ar gas was used as the plasma, carrier and shielding gas. As given in Table 2, PTA welding parameters, such as oscillation width, oscillation speed, nozzle distance to workpiece, and flow rates of plasma, carrier and shielding gases were constant during the PTA welding, whereas the other three welding parameters including welding current, powder feed rate and welding speed were optimized by orthogonal test (Table 3). A L9(34) orthogonal array was designed to investigate the influence of welding current, powder feed rate and welding speed parameters on the microstructure and carbide degradation of deposition coatings. A series of nine comprehensive experiments were conducted in sequence in this study.

Fig. 1 SEM image of Stelcar 65 powders

Table 2 Constant welding parameters during PTA process

Table 3 Factors considered during PTA process

After deposition, the PTA samples were cut into the size of 10 mm × 10 mm × 10 mm. The coatings were polished, and then etched using 5% nital (5 mL nitric acid and 95 mL alcohol). The phases of Stelcar 65 alloy powders were examined by an X-ray diffractometer (XRD, D/max2550VB3+/PC) with Cu Kα radiation at a scanning speed of 5 (°)/min. The microstructure of PTA deposition coatings was observed under scanning electron microscope with energy disperse X-ray analyzer (SEM, Quanta 200 FEG). The microhardness of the deposition was conducted under a Vickers tester (HVS-1000A) using a load of 1.96 N. Image Pro Plus analysis software was applied to measuring the content of tungsten carbides in the PTA deposition coatings.

3 Results and discussion

3.1 Microstructure of as-deposited coating

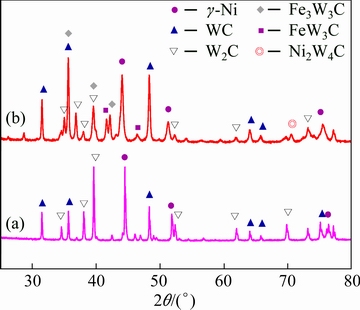

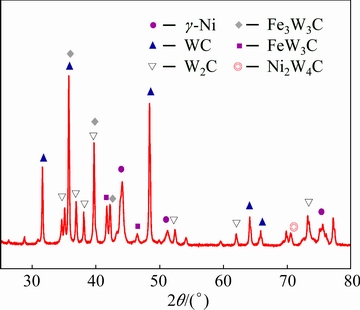

The XRD patterns of Stelcar 65 alloy powders are presented in Fig. 2(a). The crystalline peaks in the XRD pattern of alloy powders were identified to be γ-Ni (PDF card #70-1849), W2C (PDF card #79-0743) and WC (PDF card #73-0471) phases. The XRD results indicate that the tungsten carbide in Stelcar 65 alloy powders was a mixture of W2C and WC phases, which is a typical structure of fused tungsten carbide [25]. Figure 2(b) shows a typical XRD pattern of as-deposit Stelcar 65 alloy coating (welding current, 100 A; powder feed rate, 20 g/min; welding speed, 60 mm/min). Besides the γ-Ni, W2C and WC phases, Fe3W3C (PDF card #89-7205), FeW3C (PDF card #23-1128) and Ni2W4C (PDF card #20-0796) phases were present in the as-deposited coatings. As seen from the XRD pattern for the as-deposited coating, the intensity of W2C peaks reduces dramatically while the intensity of WC peaks increases.

Fig. 2 XRD patterns for powders (a) and typical as-deposited coating (b)

During the PTA welding process, the metal matrix composites (MMCs) powders were gradually dissolved and recrystallized under the thermal effect of high temperature plasma. Ni alloys dissolved initially due to their low melting point (900-1400 °C) compared with tungsten carbide ((2785±10) °C) [30]. At ultrahigh temperature, the tungsten carbides dissolved partially. In addition, Fe and Ni would gather around the tungsten carbides, causing Fe-W-C and Ni-W-C ternary systems to appear. If the diffusion rate of C is rather higher than that of W [31], the content of C would be lower than W in the ternary system. By combining the ternary diagram [32,33], the η phase formation occurred, which was identified to be Fe3W3C, FeW3C and Ni2W4C (Fig. 2(b)), resulting in the decomposition of tungsten carbides. Finally, the thermodynamic equilibrium state would be attained to restrain the η phase grains from growing up. As a result, the W and C were left in the eutectic liquids [34]. In accordance to the W-C phase diagram [35], the solidification transformation in the molten liquids is a series of complex reactions. Primary WC is the prior precipitated phase during the eutectic reaction, followed by W2C [36]. As a result, the content of W2C decreased, and recrystallized WC was the main phase of the interface between the Ni matrix and tungsten carbides [37].

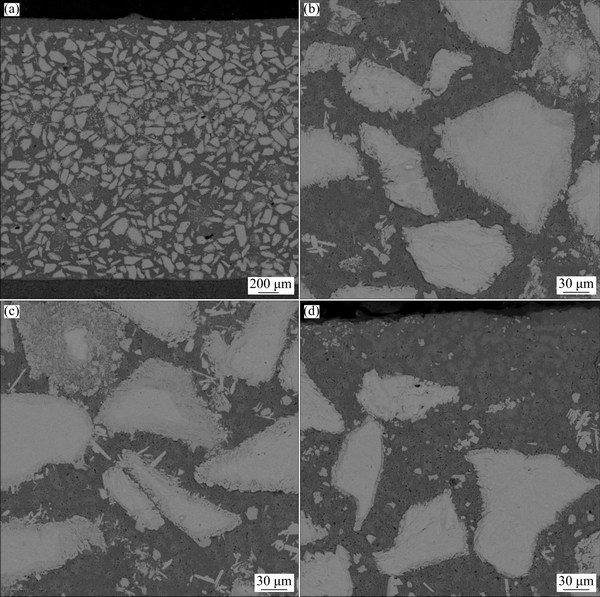

Figure 3(a) shows the microstructure of as-deposited coating in transverse cross section. The tungsten carbide particles with bright contrast were homogenously distributed in the Ni-based alloy matrix. Some pores near the surface were detected. However, the interfaces of tungsten carbide and the alloy matrix varied greatly in different layers in the transverse cross section. On the fusion line layer (Fig. 3(b)), the temperature gradient (G) and the growth rate of grain (R) were at maximum and minimum point, respectively, during the PTA process. As the holding time went to infinity, a state without chemical flux induced the existence of planar crystals [38]. Substantial amounts of Fe were detected by EDS (Spot A) in planar crystals. Moreover, Fe diffused from the steel substrate to the fusion layer due to dilution, which indicated a good metallurgical bonding between the MMCs and the substrate. On the middle layer of as-deposited coating (Fig. 3(c)), the ratio of G/R gradually decreased and the planar crystals transformed to cellular dendrites, rather than columnar dendrites [39]. Combined with the XRD and EDS results, the dendrites were determined to be γ-Ni phase, which was similar to the result referred in the previous work [40]. Moreover, interdendritic eutectics which dissolved C, W, Fe and other elements were also observed. As shown in Fig. 3(d), the fusion zone boundary on the surface layer was perpendicular to the welding orientation. Thus, the R was as large as the welding speed. Moreover, G was very low because of continuous heat power from the plasma arc. As a result, columnar dendrites formed due to the remarkably little ratio of G to R. The tungsten carbides in the surface layer were exposed to intensive thermal radiation by plasma arc, resulting in the existence of some needle-like phases in the alloy matrix. Given the considerably high heat input on the surface layer, tungsten carbides were easy to dissolve. The EDS results (Spots B and C, given in Table 4) illustrated that the content of W in needle-like phases was around 70%, and some Ni and Fe elements were also detected. The needle-like phase may be M6C (Fe3W3C or Ni2W4C) [34,41].

Fig. 3 SEM images of typical as-deposited Stelcar alloy coating in transverse cross section (a) and details at positions of fusion layer (b), middle layer (c) and top layer (d)

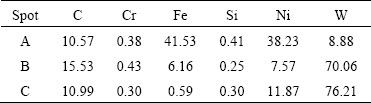

Table 4 Chemical composition of typical as-deposited Stelcar alloy coating in transverse cross section (mass fraction, %)

3.2 Welding parameter optimization

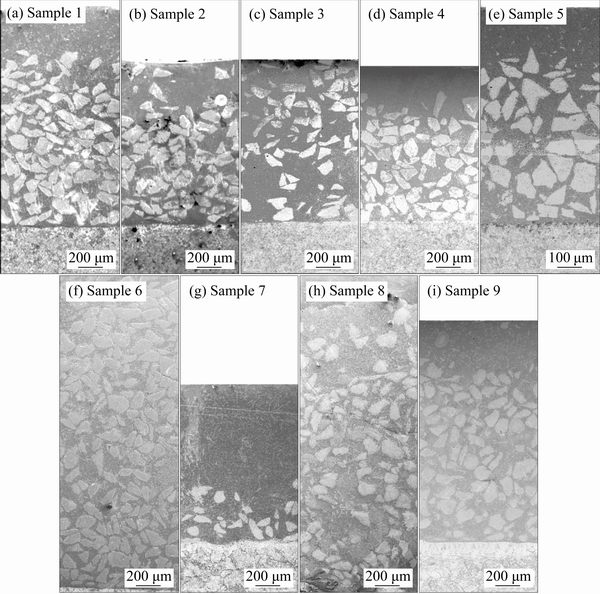

To minimize the degree of tungsten carbide degradation, three welding parameters including welding current, powder feed rate and welding speed were optimized by orthogonal test. Samples 1-9 were deposited by PTA with parameters listed in Table 3. Figure 4 shows the SEM images of PTA deposit coating samples 1-9 in the transverse cross section. As shown in Fig. 4, three welding parameters play an important role in the microstructure and tungsten carbide degradation.

Fig. 4 SEM images of Stelcar alloy coating samples with different processing parameters

Three welding current values (80, 100 and 120 A) were used in orthogonal test. When the welding current was at a low level (80 A) (Figs. 4(a-c)), the alloy powder particles may not be completely melted, resulting in the increase of surface roughness. As the current was increased to 100 A (Figs. 4(d-f)), the surface quality of the coatings was improved. When the coatings were processed with higher deposition current (120 A), the powder particles were overheated, and the degradation of tungsten carbides became very serious (Fig. 4(g)), which was corresponded with the previous work [42]. The welding current is a direct reflection of heat energy input, and the welding current has a great influence on dilution rate and element penetration degree [43]. On coatings processed with lower deposition current (80 A), the fusion lines were straight, which implied a lower dilution rate. Curved fusion lines (Figs. 4(d-f)) were observed at high deposition current (120 A), indicating the unexpected increase in dilution rate.

The powder feed rate also has a great influence on the microstructure of as-deposited coatings. Three powder feed rates (15, 20 and 25 g/min) were used. Settlement of tungsten carbide particles was observed at a powder feed rate of 15 g/min (Figs. 4(a, d, g)). The thickness of as-deposit coatings increased at a high powder feed rate (25 g/min) (Figs. 4(c, f, i)). Increasing the powder feed rate was also beneficial to the homogeneous distribution of the WC [44].

Finally, the thickness of the as-deposited coatings was mainly affected by the welding speed. A thick coating could be obtained at a low welding speed (Figs. 4(f, h)). When the welding speed was increased to 80 mm/min, the thickness of coating was reduced to 1000 μm (Figs. 4(c, e, g)). The thin coating can be illustrated in two aspects: the high welding speed reduced the heat energy input per unit length [45], and the volume of alloy powders deposited on per unit time was lower due to the high welding speed [46].

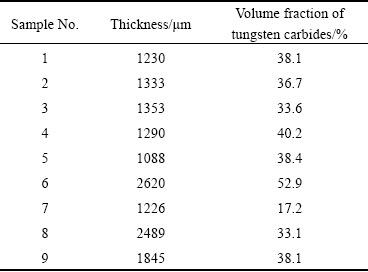

As for the contrast differences between tungsten carbide particles and Ni-based matrix alloy, tungsten carbides remaining in the coatings were evaluated by calculating the volume fraction of tungsten carbide using the transverse cross section of SEM images. The statistical results are given in Table 5. The volume fraction and distribution of tungsten carbide particles within the matrix varied considerably with the PTA welding parameters. The volume fraction of tungsten carbide particles was in the range of 17.2%-52.9%.

Proper welding parameters are the key to suppress the degradation of tungsten carbides. Further analysis of the factors and the mean variance revealed that the reliabilities on the influence of the welding current, powder feed rate and welding speed were 0.95, 0.9 and 0.9, respectively. Moreover, the best parameters of welding current, powder feed rate and welding speed were determined to be 100 A, 25 g/min and 40 mm/min, respectively.

Table 5 Thickness of as-deposited coatings and volume fractions of tungsten carbides

3.3 Microstructure of as-deposited coating with optimum parameters

The SEM images of coating deposited using the optimal parameters are shown in Fig. 5. A Stelcar alloy coating with high volume fraction of tungsten carbide (52.85%) was obtained. Most tungsten carbide particles retain their original irregular sharp-edged morphology (Fig. 5(a)). It should be noted that no needle-like phase was observed across the transverse cross section compared with previous samples, indicating a lower tungsten carbide degradation degree and outstanding mechanical properties [47]. The distribution of tungsten carbide particles was more homogenous in different layers than in other samples. In the fusion layer (Fig. 5(b)), straight fusion line was observed in the interface of Stelcar alloy coating and carbon steel substrate, which indicated a low dilution rate. In the middle layer (Fig. 5(c)), the tungsten carbide particles homogenously arranged. Abundant tungsten carbide particles were preserved in the top layer (Fig. 5(d)), which was favorable to the improvement of surface mechanical properties. The XRD pattern of high quality Stelcar alloy coating is presented in Fig. 6, where the intensity of tungsten carbide in this coating was very strong. The high strong intensity indicated the large amount of tungsten carbides and the diminutive distance between them, which was undoubtedly beneficial to the mechanical performances [26].

Fig. 5 SEM images of Stelcar alloy coating deposited using optimal parameters on transverse cross section (a) and details at different regions of fusion layer (b), middle layer (c) and top layer (d)

Fig. 6 XRD pattern of Stelcar alloy coating deposited using optimal parameters

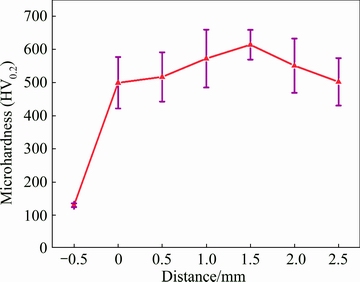

Figure 7 shows the microhardness of the transverse cross section in the Stelcar alloy coating. The substrate hardness was measured randomly and the mean microhardness was around HV0.2 130. To measure the hardness of the matrix, the transverse cross section was divided into several layers, beginning from the fusion line with an interval of 0.5 mm. The mean microhardness of the nickel matrix was about HV0.2 540. Thus, the mean microhardness of Ni-based matrix is much higher than that of carbon steel substrate due to the formation of brittle secondary carbides [48]. Because of the fine cellular grains of dendrites forming in the middle section, the microhardness of that section was clearly higher than in other regions, resulting in a peak value. On the surface layer, the grains grew into columnar dendrites, equiaxed dendrites and steering dendrites, decreasing the microhardness [46].

Fig. 7 Microhardness of Stelcar alloy coating deposited using optimal parameters

4 Conclusions

1) Stelcar 65 alloy coating was vulnerable to carbide degradation due to the inappropriate parameters. Fe3W3C, FeW3C and Ni2W4C phases were presented after the tungsten carbide degradation.

2) High current conditions (120 A) lead to overheat effects, and the degradation of tungsten carbides became serious.

3) Powder feed rate and welding speed have a great influence on the thickness of the as-deposited coating. The coating thickness increased at a high powder feed rate and a low welding speed.

4) The optimum welding current, powder feed rate and welding speed were determined to be 100 A, 25 g/min and 40 mm/min, respectively.

References

[1] BRADAI M A, BOUNAR N, BENABBAS A, ATI A. Study of microstructure, phases and microhardness of metallic coatings deposited by flame thermal spray [J]. Journal of Materials Processing Technology, 2008, 200: 410-415.

[2] BELAMRI A, ATI A, BRACCINI M, AZEM S. Hypereutectoid steel coatings obtained by thermal flame spraying-Effect of annealing on microstructure, tribological properties and adhesion energy [J]. Surface and Coatings Technology, 2015, 263: 86-99.

[3] VREELING J A, OCELIK V, HOSSON J T. Ti-6Al-4V strengthened by laser melt injection of WCp particles [J]. Acta Materialia, 2002, 50: 4913-4924.

[4] MORGADO J M, MATITO A, TORRELO A, SCHWARTZ L B, ORFAO A, ESCRIBANO L. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding [J]. Optics and Laser Technology, 2015, 68: 191-201.

[5] XU Guo-jian, KUTSUNA M, LIU Zhong-jie, ZHANG Hong. Characteristics of Ni-based coating layer formed by laser and plasma cladding processes [J]. Materials Science and Engineering A, 2012, 417: 63-72.

[6] SAREMI M, VALEFI Z. The effects of spray parameters on the microstructure and thermal stability of thermal barrier coatings formed by solution precursor flame spray [J]. Surface and Coatings Technology, 2013, 220: 44-51.

[7] KIM H J, YOON B H, LEE C H. Wear performance of the Fe-based alloy coatings produced by plasma transferred arc weld-surfacing process [J]. Wear, 2001, 249: 846-852.

[8] SAOUBI R, RUPPI S. Wear and thermal behaviour of CVD α-Al2O3 and MTCVD Ti(C,N) coatings during machining [J]. CIRP Annals, 2009, 58: 57-60.

[9] CHEN S, QU S J, HAN J C. Microstructure and mechanical properties of Ni-based superalloy foil with nanocrystalline surface layer produced by EB-PVD [J]. Journal of Alloys and Compounds, 2009, 484: 626-630.

[10] FERNANDES F, LOPES B, CAVALEIRO A, RAMALHO A, LOUREIRO A. Effect of arc current on microstructure and wear characteristics of a Ni-based coating deposited by PTA on gray cast iron [J]. Surface and Coatings Technology, 2011, 205: 4094-4106.

[11] DENG De-wei. Present status and development tendency of plasma transferred arc welding [J]. Journal of Mechanical Engineering, 2013, 49: 106-112.

[12] DULIAS U, FANG L, GAHR K H. Effect of surface roughness of self-mated alumina on friction and wear in isooctane-lubricated reciprocating sliding contact [J]. Wear, 2002, 252: 351-358.

[13] BALASUBRAMANIAN V, VARAHAMOORTHY R, RAMACHANDRAN C S, BABU S. Abrasive slurry wear behavior of stainless steel surface produced by plasma transferred arc hardfacing process [J]. Surface and Coatings Technology, 2008, 202: 3903-3912.

[14] LIU Yuan-fu, XIA Zhi-ying, HAN Jian-min, ZHANG Gu-ling, YANG Si-ze. Microstructure and wear behavior of (Cr,Fe)7C3 reinforced composite coating produced by plasma transferred arc weld-surfacing process [J]. Surface and Coatings Technology, 2006, 201: 863-867.

[15] SUDHA C, SHANKAR P, RAO R V, THIRUMURUGESAN R, VIJAYALAKSHMI M, RAJ B. Microchemical and microstructural studies in a PTA weld overlay of Ni-Cr-Si-B alloy on AISI 304L stainless steel [J]. Surface and Coatings Technology, 2008, 202: 2103-2112.

[16] GURUMOORTHY K, KAMARAJ M, RAO K P, RAO A S, VENUGOPAL S. Microstructural aspects of plasma transferred arc surfaced Ni-based hardfacing alloy [J]. Materials Science and Engineering A, 2007, 456: 11-19.

[17] GATTO A, BASSOLI E, FORNARI M. Plasma Transferred Arc deposition of powdered high performances alloys: Process parameters optimisation as a function of alloy and geometrical configuration [J]. Surface and Coatings Technology, 2004, 187: 265-271.

[18] HOU Q Y, HE Y Z, ZHANG Q A, GAO J S. Influence of molybdenum on the microstructure and wear resistance of nickel-based alloy coating obtained by plasma transferred arc process [J]. Materials and Design, 2007, 28: 1982-1987.

[19] ROKANOPOULOU A, SKARVELIS P, PAPADIMITRIOU G D. Microstructure and wear properties of the surface of 2205 duplex stainless steel reinforced with Al2O3 particles by the plasma transferred arc technique [J]. Surface and Coatings Technology, 2014, 254: 376-381.

[20] CELIK O N. Microstructure and wear properties of WC particle reinforced composite coating on Ti6Al4V alloy produced by the plasma transferred arc method [J]. Applied Surface Science, 2013, 274: 334-340.

[21] TAKATANI Y, TOMITA T, TANI K, HARADA Y. Corrosion behavior of aluminum weld overlay alloys with dispersed niobium carbide particles in sodium chloride solution [J]. Journal of Thermal Spray Technology, 1996, 5: 154-160.

[22] JANKAUSKAS V, ANTONOV M, VARNAUSKAS V, SKIRKUS R, GOLJANDIN D. Effect of WC grain size and content on low stress abrasive wear of manual arc welded hardfacings with low-carbon or stainless steel matrix [J]. Wear, 2015, 328-329: 378-390.

[23] SUNDARAMOORTHY R, TONG S X, PAREKH D, SUBRAMANIAN C. Effect of matrix chemistry and WC types on the performance of Ni-WC based MMC overlays deposited by plasma transferred arc (PTA) welding [J]. Wear, 2017, 376-377: 1720-1727.

[24] FISHER G, WOLFE T, YARMUCH M, GERLICH A, MENDEZ P. The use of protective weld overlays in oil sands mining [J]. Australian Welding Journal, 2012, 57: 12-14.

[25] KATSICH C, BADISCH E. Effect of carbide degradation in a Ni-based hardfacing under abrasive and combined impact/abrasive conditions [J]. Surface and Coatings Technology, 2011, 206: 1062-1068.

[26] NEVILLE A, REZA F, CHIOVELLI S, REVEGA T. Erosion– corrosion behaviour of WC-based MMCs in liquid–solid slurries [J]. Wear, 2005, 259: 181-195.

[27] LIU Yuan-fu, ZHOU Yong-lin, ZHANG Qian, PU Fei, LI Rong-hua, YANG Si-ze. Microstructure and dry sliding wear behavior of plasma transferred arc clad Ti5Si3 reinforced intermetallic composite coatings [J]. Journal of Alloys and Compounds, 2014, 591: 251-258.

[28] ILO S, JUST C, XHIKU F. Optimisation of multiple quality characteristics of hardfacing using grey-based Taguchi method [J]. Materials and Design, 2012, 33: 459-468.

[29] ASKARIANI S A, PISHBIN H, MAHDI M J. Effect of welding parameters on the microstructure and mechanical properties of the friction stir welded joints of a Mg-12Li-1Al alloy [J]. Journal of Alloys and Compounds, 2017, 724: 859-868.

[30] LU Shan-ping, KWON O Y, GUO Yi. Wear behavior of brazed WC/NiCrBSi(Co) composite coatings [J]. Wear, 2003, 254: 421-428.

[31] GUILEMANY J M, PACO J M, MIGUEL J R, NUTTING J. Characterization of the W2C phase formed during the high velocity oxygen fuel spraying of a WC + 12 pct Co powder [J]. Metallurgical and Materials Transactions A, 1999, 30: 1913-1921.

[32] XU Pei-quan, ZHAO Xiu-juan, YANG De-xin, YAO Shun. Study on filler metal (Ni-Fe-C) during GTAW of WC-30Co to 45″ carbon steel [J]. Journal of Materials Science, 2005, 40: 6559-6564.

[33] LIU De-jian, LI Li-qun, LI Fu-quan, CHEN Yan-bin. WCp/Fe metal matrix composites produced by laser melt injection [J]. Surface and Coatings Technology, 2008, 202: 1771-1777.

[34] CHEN Guo-qing, ZHANG Bing-gang, WU Zhen-zhong, SHU Xi, FENG Ji-cai. Microstructure transformation and crack sensitivity of WC-Co/steel joint welded by electron beam [J]. Vacuum, 2017, 139: 26-32.

[35] KURLOV A S, GUSEV A I. Tungsten carbides and W-C phase diagram [J]. Inorganic Materials, 2006, 42: 121-127.

[36] CHEN Wei-ting, MEREDITH C H, DICKEY E C. Growth and microstructure-dependent hardness of directionally solidified WC-W2C eutectoid ceramics [J]. Journal of the American Ceramic Society, 2015, 98: 2191-2196.

[37] JUST C, BADISCH E, WOSIK J. Influence of welding current on carbide/matrix interface properties in MMCs [J]. Journal of Materials Processing Technology, 2010, 210: 408-414.

[38] BOUSSINOT G, APEL M. Phase field and analytical study of mushy zone solidification in a static thermal gradient: From dendrites to planar front [J]. Acta Materialia, 2017, 122: 310-321.

[39] LI Kai-bin, LI Dong, LIU Dong-yu, PEI Guang-yu, SUN Lei. Microstructure evolution and mechanical properties of multiple-layer laser cladding coating of 308L stainless steel [J]. Applied Surface Science, 2015, 340: 143-150.

[40] LIYANAGE T, FISHER G, GERLICH A P. Influence of alloy chemistry on microstructure and properties in NiCrBSi overlay coatings deposited by plasma transferred arc welding (PTAW) [J]. Surface and Coatings Technology, 2010, 205: 759-765.

[41] ZHAO Min-hai, LIU Ai-guo, GUO Mian-huan, LIU De-jian, WANG Zhi-jian, WANG Chang-bai. WC reinforced surface metal matrix composite produced by plasma melt injection [J]. Surface and Coatings Technology, 2006, 201: 1655-1659.

[42] HE Jian-hong, ICE M, LAVERNIA E J, DALLEK S. Synthesis of nanostructured WC-12 pct Co coating using mechanical milling and high velocity oxygen fuel thermal spraying [J]. Metallurgical and Materials Transactions A, 2000, 31: 541-553.

[43] BHARATH R R, RAMANATHAN R, SUNDARARAJAN B, SRINIVASAN P B. Optimization of process parameters for deposition of Stellite on X45CrSi93 steel by plasma transferred arc technique [J]. Materials and Design, 2008, 29: 1725-1731.

[44] LI Fu-quan, GAO Zhen-zeng, LI Li-qun, CHEN Yan-bin. Microstructural study of MMC layers produced by combining wire and coaxial WC powder feeding in laser direct metal deposition [J]. Optics and Laser Technology, 2016, 77: 134-143.

[45] BHARGAVA P, PAUL C P, PREMSINGH C H, MISHRA S K, KUMAR A, NAGPURE D C, SINGH G, KUKREJA L M. Tandem rapid manufacturing of Inconel-625 using laser assisted and plasma transferred arc depositions [J]. Advances in Manufacturing, 2013, 1: 305-313.

[46] XU Xiang, MI Gao-yang, LUO Yuan-qing, JIANG Ping, SHAO Xin-yu, WANG Chun-ming. Morphologies, microstructures, and mechanical properties of samples produced using laser metal deposition with 316L stainless steel wire [J]. Optics and Lasers in Engineering, 2017, 94: 1-11.

[47] YANG Jiao-xi, MIAO Xuan-he, WANG Xi-bing, YANG Feng. Influence of Mn additions on the microstructure and magnetic properties of FeNiCr/60% WC composite coating produced by laser cladding [J]. International Journal of Refractory Metals and Hard Materials, 2014, 46: 58-64.

[48] LIYANAGE T, FISHER G, GERLICH A P. Microstructures and abrasive wear performance of PTAW deposited Ni-WC overlays using different Ni-alloy chemistries [J]. Wear, 2012, 274-275: 345-354.

魏 莹1,魏先顺1,陈 波1,左建勇2,马天才3,沈 军1

1. 同济大学 材料科学与工程学院,上海 201804;

2. 同济大学 铁道与城市轨道交通研究院,上海 201804;

3. 同济大学 汽车学院,上海 201804

摘 要:采用等离子转移弧堆焊技术制备高碳化钨含量的镍基复合材料(Stelcar 65合金),并通过正交试验优化Stelcar 65合金的堆焊参数。堆焊电流、送粉率和堆焊速度等参数均对碳化钨的分解有显著影响。正交试验优化后的最佳堆焊电流、最佳送粉率和最佳堆焊速度分别为100 A、25 g/min 和 40 mm/min,堆焊层无裂纹、无分解。并对优化后的堆焊层显微组织和显微硬度进行分析。

关键词:等离子转移弧堆焊;镍基复合材料;显微组织;堆焊参数优化

(Edited by Bing YANG)

Foundation item: Project (2016YFB0300502) supported by the National Key Research and Development Program of China; Projects (51601129, 51775386) supported by the National Natural Science Foundation of China; Project (16PJ1410000) supported by Shanghai Pujiang Program, China; Project (16ZR1438700) supported by the Natural Science Foundation of Shanghai, China; Project (TPL1706) supported by Traction Power State Key Laboratory of Southwest Jiaotong University, China

Corresponding author: Xian-shun WEI; Tel: +86-21-69581009; E-mail: weixianshun@tongji.edu.cn

DOI: 10.1016/S1003-6326(18)64897-6