DOI:10.11817/j.ysxb.1004.0609.2021-37946

新型镁合金管材挤压剪切-弯曲成形的研究与验证

胡红军*1,胡刚1,谢黛薇1,章欧1,张丁非2,戴庆伟3,欧忠文4

(1.重庆理工大学 材料科学与工程学院,重庆 巴南,400050;

2. 重庆大学 材料科学与工程学院,重庆 沙坪坝,400044;

3. 重庆科技学院 冶金与材料学院,重庆 沙坪坝,401331;

4. 陆军勤务学院 化学与材料学院,重庆 沙坪坝,401311)

摘 要: 为了促进镁合金的大塑性变形技术的工业化,本文研究了一种正挤压与等通道挤压相结合的镁合金薄壁管材(Tube)挤压(Extrusion)-剪切(Shearing)-弯曲(Bending)(简写为TESB)连续塑性成形方法;采用有限元法对TESB变形过程进行计算机数值模拟;研究结果发现:随着挤压速度的增大,管坯温度升高越明显;预热温度升高及摩擦系数减小,挤压载荷会减小。在挤压机上安装TESB成形模具,进行挤压成形试验,对挤出的管材进行微观组织观察及硬度测定,并对数据进行处理;结果表明:TESB成形可以细化镁合金晶粒,提高TESB成形的均匀性;随着温度升高硬度值有所降低,但是较普通挤压镁合金管材硬度明显上升,硬度最大值出现在剪切区和弯曲区交界位置;数值模拟和实验表明:TESB成形是一种新型的镁合金管材大塑性变形方法,可以有效的细化晶粒、提高组织的均匀性。

关键词: 镁合金薄壁管材;大塑性变形;数值模拟;微观组织

中图分类号:TG146.2 文献标志码:A

镁被誉为21世纪的绿色材料[1-2],因其具有比强度、比刚度高,导热导电性能好,很好的电磁屏蔽、阻尼性、减振性、切削加工性以及加工成本低和易于回收等优点,因而广泛用于航空航天、导弹、汽车、建筑等行业[3]。

晶粒细化是提高镁合金强韧性的一种重要手段,如何制备微米级、纳米级晶粒的镁合金材料是国内外相关研究人员的一个重要研究方向[4-6]。大塑性变形技术是近年来新发展的材料制备成形工艺,它是通过增加待变形金属材料的变形量,使材料组织中产生大量亚晶粒、位错胞等亚微米级的结构,通过成形过程中的应变累积使材料内部的晶粒组织细化至亚微米级,甚至纳米级,因此,其常被用来制备超细晶材料和调控织构等[7]。目前,较成熟的镁合金大塑性变形工艺主要有:等通道角挤压(Equal Channel Angular Pressing,ECAP)[8-9]、累积叠轧(Accumulative Roll Bonding,ARB)、高压扭转成型(High Pressure Torsion,HPT)、多向锻造(Multi-Axial Forging,MAF)和往复挤压(Cyclic Extrusion and Compression,CEC)、双通道挤压、非对称挤压等[10-19]。[1]

有不少学者将两种或两种以上的大塑性变形工艺相结合,设计出新型复合成形工艺,使得制品的成形效率和合格率均得到有效提高;胡红军[20-23]等将普通正挤压和等通道转角挤

压工艺相结合,设计出了挤压-剪切新型复合成形工艺;卢立伟[24]等结合普通正挤压工艺和扭转变形工艺,设计了挤压-扭转新型复合变形工艺,可细化晶粒并提高组织的均匀性。

本文提出了一种正挤压与等通道挤压相结合的镁合金薄壁管材(Tube)挤压(Extrusion)-剪切(Shearing)-弯曲(Bending)(简写TESB)成形方法,提出的TESB工艺是在现有的SPD工艺基础上特别是ECAP工艺改进后而设计的新工艺。本文利用DEFORM-3D 弹塑性有限元分析模拟软件, 进行TESB成形过程模拟, 设计并制造出立式挤压机上使用的模具,并进行了试验验证,对镁合金TESB变形后的微观组织演化进行了分析, 为高性能镁合金管材的生产及试验提供了实验和理论依据。

1 实验方法

实验所采用的的材料为商业镁合金AZ31B,管材挤压成形的方法有很多种,其中正向挤压应用最为广泛。TESB工艺是在管材普通正向挤压的基础上调整模具结构,使得管材在成形过程中再受到两次剪切作用和一次弯曲作用,从而细化晶粒,改善内部晶粒取向。TESB挤压镁合金管材的模具(如图1所示),主要包括挤压杆1、挤压筒2、凹模3、底座4、挤压针5和支撑板6等。

图1 TESB管材挤压工艺模具图

Fig.1 Die diagram of TESB process

(如图2)为模拟所采用的TESB模具结构三维图及成形部分详图,主要由四部分构成:推杆、挤压针、凹模、挤压筒。(图2a)为成形模具装配图,(图2b)为成形区的局部放大,整个成形过程主要包含了五个阶段,管材在挤压成形的过程中依次经过定径区—一次剪切—弯曲—二次剪切—成形管材。因此,该工艺的最大特点就是集挤压剪切-弯曲工艺为一体,在细化晶粒的同时减少了工序,从而节约了大量的时间。

图2 TESB模具结构三维图及成形部分详图

Fig.2 3D drawing of TESB die structure and detailed drawing of forming part

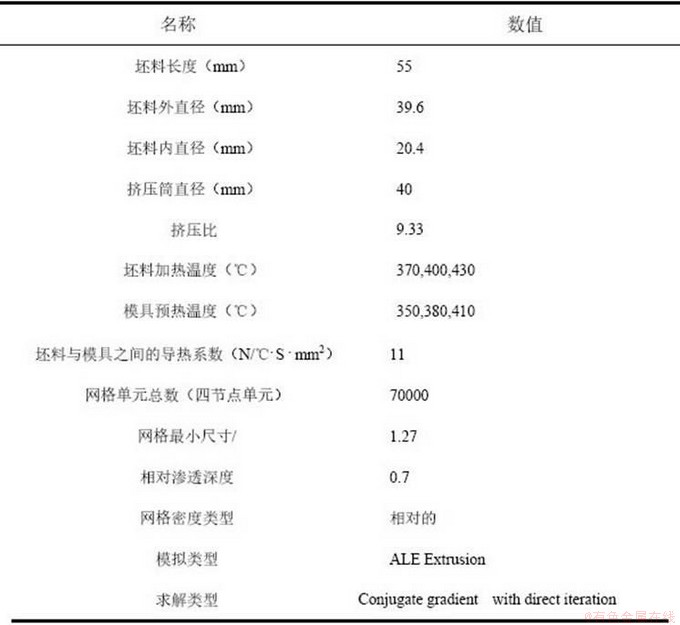

表1 数值计算和实验所采用的参数

Table 1 parameters used in numerical calculations and experiments

挤压实验过程中,存在诸多的影响因素,这些因素都会给实验结果带来不同的影响,其中包括了实验过程中的挤压温度、挤压速度、挤压载荷、润滑、模具结构等都会对实验产生影响。TESB模具相对普通挤压模具而言其结构更为复杂,因此影响因素更多,数值计算和实验所采用的参数见(表1)。

2 结果与讨论

2.1数值模拟结果

(1)不同挤压温度下坯料内部温度场分布

(如图3)所示为挤压速度10mm/s、摩擦因子为0.2时坯料在不同初始挤压温度下温度场的分布。由温度分布云图可知,在整个挤压成型过程中最大温升约为10℃,且最高温度区域都集中分布在弯曲成形部位,一方面是由于该区域在成形过程中所受的应力较大,另一方面是由于摩擦与模具结构的影响导致该处的温升较大,散热慢。

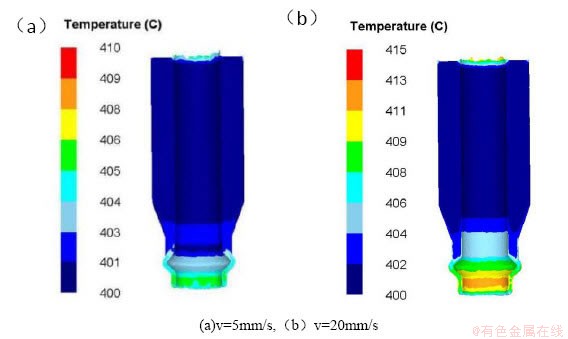

(2)不同挤压速度下的温度场分布情况

通常情况下,当其他参数条件相同时,挤压速度越快,在挤压过程中热量越不容易散失,再加上模具结构的复杂性,因此在成形部分的温度会存在较明显的差异。(如图4)所示为其他工艺参数相同时,挤压速度为5mm/s与20mm/s时的管材成形时温度的分布情况,由图可知,不同挤压速度下管材在成形过程中最大温升不同,速度越快温升越大,且各部分温度也均不相同。这是由于当速度增大时,坯料来不及与外界进行热传递,导致内部温度不能及时向外传递而滞留在坯料内部,使其内部温度升高[25]。

图3 不同初始挤压温度下的坯料温度场分布示意图

Fig. 3 distribution of billet temperature field under different initial extrusion temperatures

图4 挤压速度为5mm/s、20mm/s时管材成形温度分布示意图

Fig. 4 temperature distribution of tube forming at extrusion speeds of 5mm/s and 20mm/s

(3)工艺参数对挤压载荷的影响

通常情况下,挤压载荷随着温度的升高会不断降低,这是由于当温度升高,试样的变形抗力会降低,从而所需要的载荷也随着降低,(如图5)所示为不同初始挤压温度条件下的TESB成形试验的载荷-行程变化曲线;由图可知,其他条件相同时,当初始挤压温度为370℃时对应的载荷最大值约为8.9×104N;当初始挤压温度为430℃时,挤压载荷最大值约为7.5×104N,明显低于较低温度下的挤压载荷;且当行程到达11mm~14mm时,载荷曲线趋于平稳,这是由于该部分为一个定径区,该处坯料前端所受应力均匀,所以载荷大小也趋于水平;当前端经过该区域后,载荷呈明显上升趋势,这是由于该部分坯料发生了剪切与弯曲的变化,该部分由于模具结构的复杂性与摩擦力的存在导致该区间的坯料受到较大的应力产生了较大应变,所以此区域的载荷急剧上升;当顺利挤出成形管材后,载荷曲线趋于稳定。

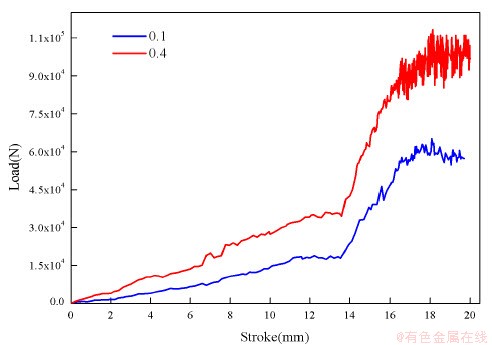

实验中是否采用润滑剂直接影响挤压过程中载荷的大小以及挤压过程中温度场的分布及变化,通常情况下,在添加润滑剂的情况下所需挤压载荷会相对降低,挤压过程中温度的变化也相对较小,更加有利于实验的进行以及加工出外观及性能较好的管材。(如图6)为初始挤压温度为400℃时,摩擦因子为0.4以及摩擦因子为0.1时,挤压载荷与行程的曲线关系示意图。

图5 不同温度条件对TESB挤压的载荷-行程变化曲线

Fig.5 Load-stroke curves of TESB process with different temperatures conditions

由(图6)可以看出,在普通挤压阶段,两不同摩擦因子下的载荷行程曲线均呈线性趋势上升,且相同行程下的载荷差值较小,这是由于在定径前端主要是模具结构的影响,摩擦因子影响较小;当经过定径区之后,摩擦因子为0.4时载荷曲线呈明显的上升,载荷值不断增大,而较小摩擦因子的载荷曲线上升相对较小;这是由于在此过程中由于模具结构的复杂性导致不同摩擦因子对载荷曲线的影响更加明显,当有润滑的条件下,挤压载荷明显小于较大摩擦因子下的载荷。在整个挤压成形过程中,当添加润滑剂时,最大载荷为6.3×104N,而当无润滑时的最大载荷为1.12×105N,约为前者的1.7倍。

图6 不同摩擦因子下的载荷-行程关系示意图

Fig. 6 Schematic diagram of load stroke relationship under different friction factors

2.2.实验结果

(1)金相组织观察与分析

对不同挤压温度下TESB成形的管材进行金相组织观察,利用Nano measure软件对金相尺寸进行测量与计算,通过origin软件绘制出晶粒尺寸的分布柱状图,(如图7)为挤压温度为400℃时的管材金相组织以及晶粒尺寸分布柱状图。

(图7(a))为普通挤压条件下镁合金微观组织以及晶粒尺寸的分布情况,在普通挤压成形阶段的平均晶粒尺寸为62.30μm,晶粒分布较为分散;(图7(b))为经过挤压剪切-弯曲成形工艺后的成形管材部分。由图可知,成形管材的平均晶粒尺寸为17.11μm,且晶粒分布较均匀,大部分晶粒集中分布于13~20μm之间。从图中可以看出,经过TESB成形后,管材的晶粒尺寸发生了明显的变化,即挤压剪切-弯曲成形对镁合金管材细化晶粒具有较好的作用[26-29]。

图7 挤压温度为400℃时管材的微观组织

Fig.7 the microstructures evolution of the tube with extrusion temperature of 400 ℃

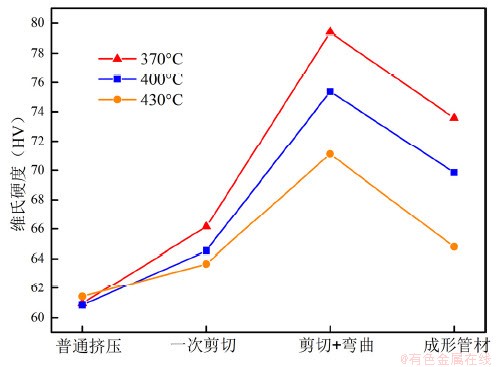

(2)显微硬度测试与分析

(如图8)所示为不同挤压温度下镁合金管材不同区域的硬度分布情况,误差±5HV。由图可知,不同挤压温度下的硬度值各不相同,且硬度的最大值均出现在剪切+弯曲成形区域,依次为80HV、75HV、71HV,这是由于在成形过程中由于模具结构的复杂性与摩擦,导致管坯中形成应力集中,所以此处硬度明显上升。随着温度的升高硬度值越低,最终成形管材的硬度值依次为74HV、70HV、65HV,这是因为随着挤压温度的升高,发生动态再结晶现象,晶粒连续长大,从而导致了硬度值下降。但较普通挤压状态下镁合金的硬度值均有明显上升,即TESB成形工艺在提高材料硬度上具有明显效果。

图8 不同挤压温度下不同成形区的硬度分布图

Fig.8 hardness diagram of different forming areas with different extrusion temperatures

3.结论

本文以挤压剪切成形技术为基础,加入弯曲变形工序,形成新型TESB成形技术,通过数值模拟计算与实验相结合,得到了如下的结论:

在TESB成形过程中,温度场的高温区主要分布于成形管材处,且相同条件下,随着挤压速度的增大温度升高越明显;随着温度升高(其他条件相同)挤压载荷随之减小;当减小摩擦力(模具内壁涂润滑剂)时,在不改变其他因素的情况下,挤压载荷也会随之减小;

TESB成形技术工艺对于管材的细化具有明显的效果,经此工艺成形的管材平均晶粒尺寸由原来的62.30μm细化至17.11μm,且细化后的晶粒尺寸大小分布较为均匀;

通过对实验过程中不同区域的硬度测试发现,随着温度升高硬度值有所降低,但是较初始普通挤压条件下明显上升;由于受实验条件及模具结构的影响硬度最大值均出现在剪切+弯曲区,不同挤压温度下最终管材的硬度值也较普通挤压区分别增加了14HV、10HV、5HV。

REFERENCES

[1] 宋广胜,牛嘉维,张士宏,等.镁合金棒材扭转变形的孪晶机制[J].中国有色金属学报,2020,30(7):1574-1583.

SONG Guang-sheng,NIU Jia-wei,ZHANG Shi-hong,et al.Twinning mechanism of magnesium alloy rod torsion[J]. The Chinese Journal of Nonferrous Metals,2020, 30(7): 1574-1583.

[2] 张玉, 李明, 杨文龙, 等.T4和T6热处理参数对Mg-12Zn-2Al镁合金组织和性能的影响[J].中国有色金属学报, 2020, 30(10): 2322-2330.

ZHANG Yu, LI Ming, YANG Wen-long, et al. Effects of T4 and T6 heat treatment parameters on microstructure and mechanical properties of Mg-12Zn-2Al magnesium alloy[J].The Chinese Journal of Nonferrous Metals,2020,30(10): 2322-2330.

[3] 汪建强,郭丽丽,王长峰.AZ31镁合金位错密度模型及热压缩的微观组织预测[J].中国有色金属学报,2020,30(1):48-58.

WANG Jian-qiang, GUO Li-li, WANG Chang-feng. Dislocation density model of AZ31 magnesium alloy and microstructure prediction of thermal compression[J]. The Chinese Journal of Nonferrous Metals,2020,30(1):48-58.

[4] DU Yu-zhou, LIU Dong-jie, GE Yan-feng, et al. Effects of deformation parameters on microstructure and texture of Mg-Zn-Ce alloy[J].Transactions of Nonferrous Metals Society of China,2020,30:2658-2668.

[5] 宋祥, 王忠卫, 曾荣昌.镁合金: 成分、组织与阻燃[J].中国有色金属学报, 2021, 31(3): 598-622.

SONG Xiang, WANG Zhon-gwei, ZENG Rong-chang. Magnesium alloy: composition, structure and flame

retardancy[J]. The Chinese Journal of Nonferrous Metals, 2021,31(3): 598-622.

[6] Abdolhamid AZIZI,Hossein ALIMARDAN. Effect of welding temperature and duration on properties of 7075 Al to AZ31B Mg diffusion bonded join[J].Transactions of Nonferrous Metals Society of China,

2016,26(01):85-92.

[7] Y.L.Ding,J.G.Wang,M.Zhao,D.Y.Ju.Effect of annealing temperature on joints of diffusion bonded Mg/Al alloy[J].Transactions of Nonferrous Metals Society of China,2018,28(02):251-258.

[8] MABUCHI M, IWASAKI H, YANASE K, et al. Low temperature superplasticity in an AZ91 magnesium alloy processed by ECAE[J].Scripta Materialia, 1997,36(6):681-686.

[9] Straska J, Janecek M, Cizek J, et al.Microstructure stability of ultra-fine grained magnesium alloy AZ31 processed by extrusion and equal-channel angular pressing (EX-ECAP)[J]. Materials Characterization,2014, 94(08): 69-79.

[10] AKBARIPANAH F, FERESHTEH-SANIEE F, MAHMUDI R, et al. The influences of extrusion and equal channel angular pressing (ECAP) processes on the fatigue behavior of AM60 magnesium alloy[J]. Materials Science & Engineering A, 2013,565(5):308-316.

[11] JAHADI, RAMIN, SEDIGHI, et al.ECAP effect on the micro-structure and mechanical properties of AM30 magnesium alloy[J]. Materials Science & Engineering A, 2014,593(2):178-184.

[12] HE Y B, PAN Q L, QIN Y J, et al. Microstructure and mechanical properties of ZK60 alloy processed by two-step equal channel angular pressing[J]. Journal of Alloys & Compounds, 2010,492(1):605-610.

[13] SUH J, VICTORIA-HERNANDEZ J, LETZIG D, et al.Improvement in cold formability of AZ31 magnesium alloy sheets processed by equal channel angular pressing[J].Journal of Materials Processing Technology, 2015,217:286-293.

[14] 宋广胜,牛嘉维,张士宏,等.镁合金棒材扭转变形的孪晶机制[J].中国有色金属学报,2021,30(7):1574-1583.

SONG Guang-sheng,NIU Jia-wei,ZHANG Shi-hong,et al.Twinning mechanism of magnesium alloy rod torsion[J].Transactions of Nonferrous Metals Society of China,2021,30(7):1574-1583.

[15] WANG Q, CHEN Y, LIU M, et al. Microstructure evolution of AZ series magnesium alloys during cyclic extrusion compression[J]. Materials Science & Engineering A, 2010,527(9):2265-2273.

[16] LIN J, WANG Q, PENG L, et al. Microstructure and high tensile ductility of ZK60 magnesium alloy processed by cyclic extrusion and compression[J]. Journal of Alloys & Compounds, 2009,476(1):441-445.

[17] WANG Q, CHEN Y, LIU M, et al. Microstructure evolution of AZ series magnesium alloys during cyclic extrusion compression[J]. Materials Science & Engineering A, 2010,527(9):2265-2273.

[18] HUA H, TANG Z, YUAN T, et al. Effects of cyclic extrusion and compression parameters on microstructure and mechanical properties of Mg-1.50Zn-0.25Gd alloy[J]. Materials & Design, 2015,86:788-796.

[19] 夏显明,薛克敏, 李萍,等.高压扭转对挤压态ZK60镁合金微观组织和力学性能的影响[J].锻压技术, 2018,43(5):130-136.

XIA Xian-ming, XUE Ke-min, LI Ping, et al. Effect of high pressure torsion on Microstructure and mechanical

properties of as extruded ZK60 magnesium alloy [J]. Forging technology, 2018,43 (5):130-136

[20] 张丁非, 胡红军, 戴庆伟, 等. 高性能镁合金晶粒细化新技术[M]. 北京: 冶金工业出版社, 2016: 23-28.

ZHANG Ding-fei, HU Hong-jun, DAI Qing-wei, et al. New technology for grain refinement of high-performance magnesium alloys[M]. Beijing: Metallurgical Industry Press, 2016: 23-28.

[21] HU H J, LI Y Y, WANG X, et al. Effects of Extrusion-Shear Process Conditions on the Microstructures and Mechanical Properties of AZ31 Magnesium Alloy[J]. High Temperature Materials & Processes, 2016,35(10):

967-972.

[22] HU H,YANG L,ZHANG D,et al.The influences of extrusion-shear process on microstructures evolution and mechanical properties of AZ31 magnesium alloy[J].Journal of Alloys & Compounds, 2017,695:1088-1095.

[23] 胡红军. 挤压剪切与正挤压对AZ31镁合金塑性变形的影响[J]. 材料热处理学报, 2014,35(4):202-207.

HU Hong-jun. The effect of extrusion shear and forward extrusion on plastic deformation of AZ31 magnesium alloy[J]. Journal of Materials and Heat Treatment, 2014, 35(4): 202-207.

[24] 卢立伟, 陈胜泉, 刘楚明, 等.正挤压-扭转剪切变形对镁合金组织与性能的影响[J]. 金属热处理, 2016,41(7):25-29.

LU Li-wei, CHEN Sheng-quan, LIU Chu-ming, et al. The effect of forward extrusion-torsion shear deformation on the microstructure and properties of magnesium alloys[J]. Heat Treatment of Metals, 2016,41(7):25-29.

[25] X. D. Lin,C. M. Liu,X. J.,et al.Structures and properties of aluminum matrix composite reinforced by primary Si and Si/Mg2Si particles fabricated by centrifugal casting[J].The Chinese Journal of Nonferrous Metals,2013,23(03):695-702.

[26] 黄晓锋, 杨剑桥, 魏浪浪,等.Mg-7zn-0.3mn-xcu镁合金半固态组织演变[J].中国有色金属学报,2021,30(6):1238-1248.

HUANG Xiao-feng,YANG Jian-qiao,WEI Lang-lang,ZHANG,et al.Semi-solid microstructure evolution of Mg-7Zn-0.3Mn-xCu alloy [J]. The Chinese Journal of Nonferrous Metals,2021,30(6):1238-1248.

[27] 刘笑霖, 毛萍莉, 王瑞峰, 等.预制孪晶对az31镁合金板材高速变形行为的影响[J].中国有色金属学报,2021,31(3): 649-658.

LIU Xiao-lin, MAO Ping-li, WANG Rui-feng, et al.Influence of pre-twinning on high strain rate compressive behavior of AZ31 Mg alloy rolling sheet [J]. The Chinese Journal of Nonferrous Metals,2021,31(3): 649-658.

[28] Kumar, S. D. , & Kumar, S. S.. Effect of heat treatment conditions on ballistic behaviour of various zones of friction stir welded magnesium alloy joints [J]. Transactions of Nonferrous Metals Society of China, 2021, 31(1): 156-166.

[29] 陈洪胜, 张媛琦, 王文先,等.异步错距旋压镁合金管材成形性能[J].中国有色金属学报,2020,30(12): 2821-2831.

CHEN Hong-sheng, ZHANG Yuan-qi, WANG Wen-xian,et al.Forming properties of magnesium alloy tubes by asynchronous stagger spinning[J].Transactions of Nonferrous Metals Society of China, 2020,30(12):2821-2831.

Researches and verification on a new type forming for extrusion-shear-bending of magnesium alloy thin-walled tube

Hu Hongjun*1, Hu Gang1, Xie Daiwei1, Zhang Ou1,Zhang Dingfei2, Dai Qingwei3, Ou Zhongwen4

(1.School of materials science and engineering, Chongqing University of technology, Banan, Chongqing, 400050;

2.School of materials science and engineering, Chongqing University, Shapingba, Chongqing, 400044;

3. School of metallurgy and materials, Chongqing University of science and technology, Shapingba, Chongqing, 401331;

4. School of chemistry and materials, army service college, Shapingba, Chongqing, 401311)

Abstract: In order to promote the industrialization of large plastic deformation technology of magnesium alloy, an extrusion-shearing-bending (TESB) forming method of magnesium alloy thin-walled tube has been studied by combining forward extrusion and equal channel angle extrusion. The deformation process of has been simulated by finite element method. Preheated temperature of tube increase with the rising of extrusion speeds obviously,and the extrusion loads decrease with the rising of preheated temperatures and the dropping of friction factors. The TESB forming die is installed on the extruder and TESB experiments have been done.To observe the microstructures of the extruded tube the testing data have been processed. The experiments results show that TESB forming can refine the microstructures of magnesium alloy tube and improve the forming efficiency. The research results show that TESB is a new method of large plastic deformation of magnesium alloy tube, which can effectively refine the grains and improve the uniformity of microstructures.[2]

Key Word:Magnesium alloy thin-walled tube; Large plastic deformation ; Numerical simulation; Microstructure

Fund projects: General project of National Natural Science Foundation of China (5207104251771038), Chongqing Talent Project (cqyc202003047), Chongqing Natural Science Foundation Project (cstc2018jcyjax0249 and cstc2018jcyjax0653)

Date of receipt: March 18, 2021; date of revision: May 8,2021

Corresponding Author: Hu Hongjun, Professor, Ph.D.; Tel: 18996100916; E-mail: hhj@cqut.edu.cn

基金项目:国家自然基金面上项目 (52071042,51771038), 重庆英才项目 (CQYC202003047),重庆市自然科学基金项目(cstc2018jcyjAX0249 and cstc2018jcyjAX0653 ).

收稿日期:2021-3-18;修订日期:2021-5-8

通信作者:胡红军,教授,博士;电话:18996100916;E-mail:hhj@cqut.edu.cn