网络首发时间: 2018-04-18 17:49

稀有金属 2018,42(08),878-884 DOI:10.13373/j.cnki.cjrm.xy17070007

高强耐蚀5xxx系铝合金的研究现状及发展趋势

郭成 李宝绵 张海涛 崔建忠

摘 要:

5xxx系铝合金由于其密度低、抗拉强度高、耐蚀性好等优点, 广泛应用于汽车及船舶领域。随着5xxx系铝合金使用要求的不断提高, 人们对该系铝合金的强度及耐蚀性提出了更高的要求。介绍了微合金元素Mn, Cr, Zr, Sc及稀土元素Ce, La, Er等对5xxx系铝合金组织及性能的影响;探讨了复合微合金化及Al3 (Sc, Zr) , Al3 (Er, Zr) 等复合粒子对提高5xxx系铝合金力学性能的作用。文章论述了传统的轧制工艺及新型轧制变形工艺对5xxx系铝合金组织及性能的影响, 介绍了等通道转角挤压以及高压扭转等大塑性变形工艺对5xxx系铝合金组织与性能的影响。简介了国内外对5xxx系铝合金耐蚀性的研究现状, 论述了5xxx系铝合金的腐蚀特点, 并简要说明了合金元素及冷喷涂技术等对提高5xxx系铝合金耐蚀性的作用。对高镁铝合金的优点及缺点进行总结, 对5xxx系铝合金的热处理强化手段进行概述, 并对高强耐蚀5xxx系铝合金的发展趋势做出展望。

关键词:

5xxx系铝合金;高强度;微合金化;加工工艺;耐蚀性;

中图分类号: TG146.21

作者简介:郭成 (1992-) , 男, 山东枣庄人, 硕士研究生, 研究方向:铝合金的开发与应用, 电话:13234040860;E-mail:13234040860@163.com;;*李宝绵, 教授;电话:13019339108;E-mail:bmlee@epm.neu.edu.cn;

收稿日期:2017-07-05

基金:广东省科技攻关项目 (2015B090926013) 资助;

Research Status and Development Trend of High-Strength and Corrosion-Resistant 5xxx Series Aluminum Alloy

Guo Cheng Li Baomian Zhang Haitao Cui Jianzhong

Key Laboratory of Electromagnetic Processing of Materials, Ministry of Education, Northeastern University

Abstract:

5 xxx series aluminum alloy is widely used in automobile and ship fields because of its low density, high tensile strength and good corrosion resistance. With the increasing requirement for the application of 5 xxx series aluminum alloy, it has been proposed higher demand for the strength and corrosion resistance of the alloy. In this article, the effect of microalloying elements Mn, Cr, Zr, Sc and rare earth addition of Ce, La, Er on the microstructure and properties of 5 xxx series aluminum alloy was introduced. The effects of composite microalloying and composite particles Al3 (Sc, Zr) , Al3 (Er, Zr) on improving the mechanical properties of alloy were discussed. The influence of traditional rolling process and new rolling deformation technology on microstructure and properties. The effects of equal channel angular pressing and high pressure torsion on the microstructure and properties of 5 xxx series aluminum alloy and the research status of corrosion resistance of 5 xxx aluminum alloy at home and abroad were discussed. The corrosion characteristics of 5 xxx series aluminum alloy were introduced, and the effects of alloy elements and cold spraying technology on improving corrosion resistance of 5 xxx series aluminum alloy were briefly explained. Besides, the advantages and disadvantages of high magnesium-containing 5 xxx series aluminum alloy, the heat treatment strengthening methods of 5 xxx aluminum alloy were discussed. The development trend of highstrength corrosion-resistant 5 xxx series aluminum alloy was prospected.

Keyword:

5xxx series aluminium alloy; high-strength; micro-alloying; processing technology; corrosion resistance;

Received: 2017-07-05

5xxx系铝合金属于Al-Mg系合金, 该系合金密度小、抗拉强度高, 且耐蚀性较好, 在汽车、船舶等领域具有广泛的应用前景[1]。Mg在α-Al基体中的溶解度较大, Mg与Al形成的化合物结构与基体不共格, 合金的时效强化效果不明显[2]。Mg在Al-Mg合金中起到固溶强化的作用, 固溶强化的作用可通过公式△σSS=HCα (C是Mg含量, α和H是常数) 表示[3]。随着Mg含量增加, 合金强度提高[4], 但是合金的耐蚀性也会相应降低。因此往往通过采用牺牲一定强度的方法来提高其耐蚀性, 这样一来就极大地限制了合金中Mg的添加范围。

1 研究现状

1.1 微合金化的研究

目前关于微量合金元素对5xxx系铝合金的影响的研究已经比较成熟。相关文献[5-8]表明, 在Al-Mg合金中加入Mn, Cr, Zr, Sc等合金元素能够有效地对位错产生钉扎作用, 提高合金的再结晶温度, 抑制合金再结晶, 从而使合金的强度提高。其中Al-Mg合金中加入Sc元素对合金强度的提升最为明显。但是由于Sc元素价格昂贵, 因此大大限制了该元素的使用。近年, 许多工作者开始致力于研究稀土元素对Al-Mg合金组织及性能的影响, 目前效果较好的稀土元素主要有Ce[9], La[10], Er[11]等元素。Al-Mg合金中加入适量的Ce和La元素对提高合金的强度效果明显。Er元素不仅可以提高5xxx系铝合金的强度, 还可以改善合金的耐腐蚀和抗氧化能力。

单一元素的微合金化作用存在一定的局限性, 研究发现, 复合添加两种或两种以上的微合金化元素可以更好地发挥合金元素的作用[12,13], 其中Zr, Sc元素的复合添加对改善5xxx系铝合金性能效果良好[14]。Du等[15]发现Al3 (Sc, Zr) 粒子在铸态合金稳定存在, 热轧后易沿位错分布, 对提高合金的再结晶温度有显著效果。贵州大学高红远等[16]在Al-10Mg铸造合金中添加0.40% (质量分数) 的钪或0.35%的锆均可显著提高材料的抗拉强度和延伸率, 当同时加入0.4%的钪和0.2%的锆时, 合金具有更好的综合性能。由于Sc元素价格较高, 已有研究表明通过Er代替Sc元素与Zr组成Al3 (Er, Zr) , 对细化晶粒和提高合金性能也产生重要影响[17,18]。Shen等[19]研究发现5xxx系铝合金中加入0.3%的复合稀土元素能够提高合金的抗拉强度, 同时使合金具有较好的塑性。此外Sr和Mn, Zn和Cu在5xxx系铝合金中均会相互作用形成复合粒子而抑制β (Al3Mg2) 相的析出, 对合金的耐腐蚀性产生影响[18]。复合粒子与基体作用机制的探讨, 复合原子之间相互作用的研究, 最大程度地发挥微合金化元素的作用, 对5xxx系铝合金的微合金化有明显帮助。

1.2 加工工艺的研究

轧制工艺是5xxx系铝合金主要的变形工艺。轧制温度、轧制道次及道次压下量对合金的组织及性能产生重要的影响。传统的轧制工艺主要是对均匀化处理后的合金铸锭经热轧及冷轧变形后得到所需的铝合金板材, 而许多研究者在此基础上对轧制工艺进行创新。王军等[20]对均匀化处理后的5083铝合金铸锭进行两次热轧, 得到最终的铝合金板材, 其抗拉强度超过320 MPa, 并具有较好的耐腐蚀性能。北京科技大学的马鹏程等[21]研究了一次冷轧和二次冷轧以及第二次冷轧压下量对合金性能的影响。采用二次冷轧工艺并且增大第二次冷轧的压下率, 不仅可以提高合金的强度, 而且可以改善板材的成形性能。近期北京科技大学孟春艳[22]研究了控温轧制对Al-Mg合金性能的影响, 其工艺流程如图1所示。研究表明, Al-Mg合金经控温轧制后的力学性能明显高于传统的轧制工艺, 但控温轧制后的合金在敏化处理后的抗晶间腐蚀能力降低。轧制工艺直接影响着5xxx系铝合金的使用性能, 适当的轧制工艺与退火工艺相配合, 不仅可以使合金具有较高的强度, 同时还可以保证合金具有较好的成形性及耐蚀性能。

近年来, 大塑性变形成为获得高强5xxx系铝合金的重要加工手段。通过大塑性变形获得的纳米晶金属材料由于层错、纳米孪晶和非平衡晶界使得此类合金具有高强度[23,24,25]。并且由于晶粒尺寸小、缺陷密度高等组织结构上的特殊性, 使得这种材料具有很多传统粗晶金属材料所无法比拟的优异性能[25,26,27]。国外关于5xxx系铝合金的大塑性变形研究主要集中在等通道转角挤压对5xxx系铝合金的影响。Haghayeghi Kapranos[28]研究了等通道转角挤压对Al-6Mg合金力学性能的影响, 结果表明, 等通道转角挤压工艺可使合金抗拉强度达550MPa。Zha等[29]在室温下对Al-7Mg合金经过3道次的转角挤压, 得到的合金抗拉强度为509 MPa。Nikulin等[30]研究了等通道转角挤压Al-Mg合金中的纳米级第二相, 第二相粒子在再结晶过程中起到了钉扎和驱动力的作用, 使合金强度显著提高。国内关于5xxx系铝合金的大塑性变形研究较少, 江苏大学的蒋婷慧[31]通过高压扭转得到平均晶粒尺寸小于100 nm的Al-Mg合金, 合金强度提高了3~6倍。谢学锋[32]用高压扭转技术获得了超高强度纳米晶AA5182铝合金, 平均晶粒尺寸为71 nm, 屈服强度达到了690 MPa。虽然5 xxx系铝合金经大塑性变形后强度较高, 但其塑性却难以满足工程上的需求。研究者通过在纳米晶区内引入 (掺入) 亚微晶区, 即形成所谓的“多尺度”微观组织来改善材料的塑性[33]。目前对大塑性变形超细晶纳米晶Al-Mg合金韧化机制研究的深入程度远不如对强化机制的研究[34]。因此如何研制出具有高的强度和良好塑性的超细晶纳米晶Al-Mg合金是超塑性成型技术应用于此合金的主要研究方向。

图1 控温轧制流程图Fig.1 Temperature controlled rolling flow chart[22]

1.3 耐蚀性研究

5xxx系铝合金多应用在汽车、船舶等领域, 因此对材料的耐腐蚀性能要求较高。应用在船舶领域的5xxx系铝合金在海水中电化学腐蚀较为普遍。海水作为电解质溶液, 合金元素作为阳极易发生氧化反应, 使合金溶解。在5xxx系铝合金中, 随着Mg含量的升高, β相析出增多且沿晶界分布。α-Al基体的自腐蚀电位为-0.812 V, β相的自腐蚀电位为-1.085 V, β相的电位较基体更负, 所以会先于基体发生腐蚀, β相越多, 腐蚀越严重, 因此合金在晶界处产生点蚀和晶间腐蚀[35]。

很多学者致力于研究5xxx铝合金的腐蚀机制, 通过各种方法提高合金的耐腐蚀性能。Meng等[36]研究发现向Al-Mg合金中添加一定含量的Zn使得合金析出相为Al-Mg-Zn三元相, 且Zn含量的增加使得晶界析出相减少, 合金的耐晶间腐蚀和应力腐蚀性能提高。Meng等[37]也发现Zn能够抑制Al-Mg合金析出相沿晶界分布, 改善合金的应力腐蚀开裂。国外也有相关研究表明, Zn, Cu元素对提高合金耐蚀性具有一定效果。Unocic等[38]研究发现, Cu和Zn能够改变Al-Mg合金析出相的类型和位置, 提高合金腐蚀抗力。而Sc能够降低合金的电极电位, 降低合金的耐蚀性能[39]。Zhang等[40]发现, 在Al-3%Mg铝合金中加入Nd-Fe-B永磁体产生的磁场能够增加合金的腐蚀电位, 提高合金的耐蚀性能, 并且合金中加入适量的稀土元素对改善合金耐蚀性也有一定的帮助。除了合金元素外, 加工工艺对合金的耐蚀性也会产生较大的影响。Huang等[41]发现均匀化处理使5xxx铝合金的耐蚀性降低。Oguocha等[42]研究了敏化处理温度及时间对AA5083-H116合金耐蚀性的影响, 结果发现随着敏化温度及时间的增加, 沿晶界析出的富Mg相增加, 合金的耐蚀性下降。Zhang等对AA5083铝合金的腐蚀敏感性做了研究, 合金在临界温度区域110~160℃耐蚀性较差, 且Mg含量增加, 敏化程度增加[43]。Engler等[44]研究了AA5182铝合金的晶粒尺寸和织构对晶间腐蚀的影响, 结果表明合金抗晶间腐蚀能力随晶粒的增大而提高, 再结晶织构与轧制方向保留的织构的混合作用对耐腐蚀性产生有利效果。Sridharan等[45]研究冷喷涂工艺对5xxx系铝合金的腐蚀保护, 从研究中得出, 涂层的硬度较高, 基体和涂层的电位相近, 并通过硝酸质量损失试验验证冷喷涂涂层不易致敏, 对5xxx铝合金的腐蚀具有保护作用。

对于5xxx系铝合金来说, 合金强度的提高大多会造成合金耐蚀性的下降。材料的腐蚀问题已经成为提高铝镁合金材料性能研究中的瓶颈, 尤其是材料的剥落腐蚀和晶间腐蚀, 会引起材料强度和塑性的大幅下降[46]。根据上述研究表明, 在Al-Mg合金中加入Zn, Cu或适量稀土元素对改善合金的耐蚀性能效果显著。此外, 通过在铸造过程中加入磁场以及对合金表面进行冷喷涂保护等手段都可以一定程度上改善合金的耐蚀性。如何在改善合金耐蚀性能的同时, 保证合金具有较高的强度, 是目前高强耐蚀5xxx系铝合金主要的研究方向。

2 发展前景

虽然国内外关于5xxx系铝合金的研究已经比较成熟, 但是该系合金仍存在许多问题有待解决。目前, 国内研究的5xxx系铝合金的Mg含量范围基本在4%~8%, 合金的最高抗拉强度在490 MPa左右, 但是当合金抗拉强度超过450 MPa时, 其延伸率会低于10%。近年来, 随着使用要求的不断提高, 人们对Al-Mg合金的强度也提出了更高的要求。5xxx系铝合金的主要强化机制来源于Mg的固溶强化和加工硬化, 高镁铝合金逐渐成为5xxx系铝合金的发展趋势, Mg含量的提高能够提升合金的强度, 但会使沿晶界析出的β相增多, 降低合金的耐蚀性能。因此如何保证高镁铝合金的耐蚀性还有待进一步研究。

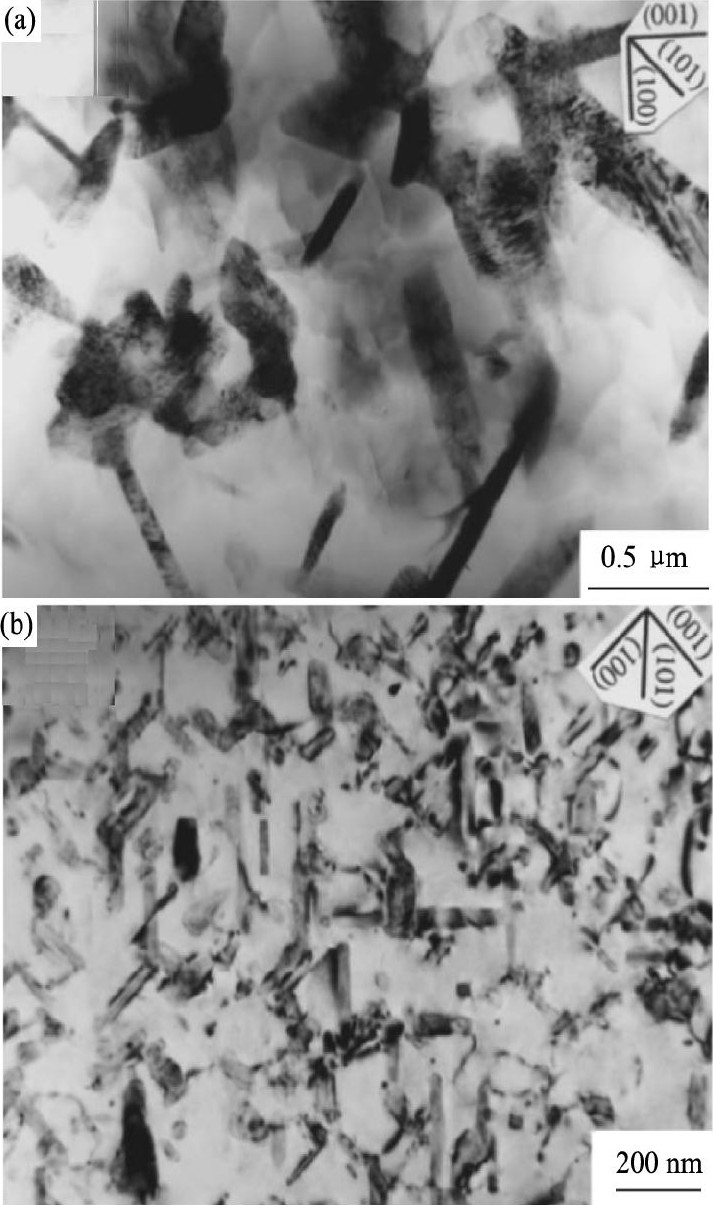

此外, 由于5xxx系铝合金热处理强化效果差, 提高合金强度的手段受到限制。如果能够通过添加适当的合金元素使5xxx系铝合金具有时效析出强化的效果, 则合金的强度会大幅提升, 5xxx系铝合金的应用前景也会更加广泛。国外早有相关研究表明[47,48,49,50,51,52,53,54], 添加适量的Ag元素能够改变Al-Mg合金的时效析出相, 析出相形貌如图2所示[44]。Al-Mg合金中加入Ag元素使合金具有时效析出强化的效果, 但是由于Ag价格较高, 该研究还未应用到实际生产中。近几年, 国内已有研究表明[55], 在Al-Mg合金中加入Zn元素可以使合金热处理强化, 并且合金时效后的强度高于加工态, 同时合金具有较高的塑性, 此研究对提高5xxx铝合金的强度具有重要意义, 目前该研究还未投入到实际生产中。

图2 峰值时效强化态合金的透射电镜显微组织照片Fig.2 TEM images of Al-Mg alloys in peak aging state

(a) Al-10%Mg alloy; (b) Al-10%Mg-0.5%Ag alloy[44]

3 结语

讨论了微合金元素、加工工艺对5xxx系铝合金组织及性能的影响, 讨论了5xxx系铝合金耐蚀性的研究现状, 展望了高镁铝合金及5xxx系铝合金热处理强化的前景, 为开发新型高强耐蚀5xxx系铝合金提供依据。

参考文献

[1] Burger G B, Gupta A K, Jeffrey P W, Lloyd D J.Microstructural control of aluminum sheet used in automotive applications[J].Materials Characterization, 1995, 35 (1) :23.

[2] Zhan G.Effect of Stabilizing Annealing Temperature and Processing on Microstructure and Properties of 5383Aluminum Alloy[D].Changsha:Central South University, 2013.1. (占戈.稳定化退火温度及加工工艺对5383铝合金的组织及性能的影响[D].长沙:中南大学, 2013.1.)

[3] Huskins E L, Cao B, Ramesh K T.Strengthening mechanisms in an Al-Mg alloy[J].Materials Science&Engineering A, 2010, 527 (6) :1292.

[4] Lee B H, Kim S H, Park J H, Kim H W, Lee J C.Role of Mg in simultaneously improving the strength and ductility of Al-Mg alloys[J].Materials Science and Engineering A, 2016, 657:115.

[5] Zhou S, Zhang Z, Li M, Pan D J, Su H L, Du X D, Li P, Wu Y C.Effect of Sc on microstructure and mechanical properties of as-cast Al-Mg alloys[J].Materials&Design, 2015, 90 (6) :1077.

[6] Luo B H, Liu C, Yang L.Effect of Mn and Mg contents on microstructure and properties of 5A01 high magnesium aluminum alloy[J].Materials for Mechanical Engineering, 2011, 35 (6) :30. (罗兵辉, 刘成, 杨磊.锰和镁元素含量对5A01高镁铝合金组织及性能的影响[J].机械工程材料, 2011, 35 (6) :30.)

[7] Shuaib A N.Mechanical properties of Al-2.5Mg-0.1Mn-Si-Cr-Fe alloys[J].Materials and Design, 2002, 23 (2) :181.

[8] Jiang F, Zhou J, Huang H, Qu J.Characterisation of microstructure and mechanical properties in Al-Mg alloy with addition of Sc and Zr[J].Material Research Innovations, 2015, 18 (54) :228.

[9] Gao H Y, Wei G Z, Fan L, Huang X, Gong X P.Effect of Ce on microstructure and mechanical properties of as-cast Al-Mg alloys[J].Nonferroous Metals Engineering, 2014, 4 (3) :15. (高红选, 卫广智, 樊磊, 黄鑫, 巩向鹏.稀土元素铈对铸态Al-Mg合金组织和力学性能的影响[J].有色金属工程, 2014, 4 (3) :15.)

[10] Yi R X, Xie S K, Zheng X Q, Pan X L, Guo X Y.Effect of rare earth larium on solidification curve and microstructure of Al-Mg alloy[J].Casting Forging Welding, 2012, 41 (17) :6. (易荣喜, 谢世坤, 郑小秋, 潘晓亮, 郭秀艳.稀土La对铝镁合金凝固曲线和微观组织的影响[J].金属铸锻焊技术, 2012, 41 (17) :6.)

[11] Rosalbino F, Angelini E, De Negri S, Saccone A, Delfino S.Influence of the rare earth content on the electrochemical behaviour of Al-Mg-Er alloys[J].Intermetallics, 2003, (11) :435.

[12] Karnesky R A, Dalen M E V, Dunand D C, Seidman D N.Effects of substituting rare-earth elements for scandium in a precipitation-strengthened Al-0.08at.%Sc alloy[J].Scripta Materialia, 2006, (55) :437.

[13] Zhang F B, Xu X J, Luo Y, Song T, Zhang Y K, Zhang Z Q.Research progress of microalloyed 6xxx series aluminum alloys[J].Materials Review, 2012, (1) :384. (张福豹, 许晓静, 罗勇, 宋涛, 张允康, 张振强.6XXX系铝合金微合金化的研究进展[J].材料导报, 2012, (1) :384.)

[14] Huang H, Jiang F, Zhou J, Wei L, Qu J, Liu L.Effects of Al3 (Sc, Zr) and shear band formation on the tensile properties and fracture behavior of Al-Mg-Sc-Zr alloy[J].Journal of Materials Engineering&Performance, 2015, 24 (11) :4244.

[15] Du G, Sheng J W, Yan D S, Zhao M J, Rong L J.Coarsening behavior of Al3 (Sc, Zr) precipitates and its influence on recrystallization temperature of Al-Mg-Sc-Zr alloy[J].Journal of Materials Science&Technology, 2009, 25 (6) :749.

[16] Gao H X, Wei G Z, Wu J, Zhang X Y.Effects of zirconium and scandium on microstructure and mechanical properties of Al-Mg casting alloy[J].Nonferrous Metals (Extractive Metallurgy) , 2014, (5) :64. (高红选, 卫广智, 吴健, 张晓燕.锆和钪对AlMg铸造合金组织和力学性能的影响[J].有色金属, 2014, (5) :64.)

[17] Zhao W, Wen S, Wang W, Huang H, Nie Z.Effects of Er and Zr additions on precipitation and recrystallization of Al-Mg alloy[A].International Conference on Computer Science and Electronic Technology[C].Taiyuan, 2015.132.

[18] Che H, Jiang X, Qiao N, Liu X.Effects of Er/Sr/Cu additions on the microstructure and mechanical properties of Al-Mg alloy during hot extrusion[J].Journal of Alloys and Compounds, 2017, 708:662.

[19] Shen H, Liang H, Yao G C, Yang W D, Ren X D.Effect of cerium-rich mischmetal content on the mechanical properties and fracture morphology of new 5xxx series aluminum alloys[J].Applied Mechanics&Materials, 2012, 152-154:239.

[20] Wang J, Li W, Wu B.5 series aluminium alloy plate production method[P].China:CN 104404411A, 2015. (王军, 李伟, 伍彬.一种5系铝合金板材的生产方[P].中国:CN 104404411A, 2015.)

[21] Ma P C, Zhang D, Zhuang L Z, Zhang J S.Effect of cold rolling process and annealing temperature on the microstructure and properties of Al-Mg alloy[J].Journal of Materials Science&Engineering, 2014, 32 (6) :792. (马鹏程, 张迪, 庄林忠, 张济山.冷轧工艺及退火温度对Al-Mg合金组织和性能的影响[J].材料科学与工程学报, 2014, 32 (6) :792.)

[22] Meng C Y.Corrosion Mechanism and Development of the Zn-Containing 5xxx Series A1 Alloy for Ship Building Industry[D].Beijing:University of Science and Technology Beijing, 2016.44. (孟春艳.舰船用含Zn 5xxx系铝合金的抗腐蚀机理及板材开发[D].北京:北京科技大学, 2016.44.)

[23] Liu M P, Roven H J, Murashkin M Y, Valiev R Z, Kilmametov A, Zhang Z, Yu Y D.Structure and mechanical properties of nanostructured Al-Mg alloys processed by severe plastic deformation[J].Journal of Materials Science, 2013, 48 (13) :4681.

[24] Valiev R Z, Enikeev N A, Langdon T G.Towards su-perstrength of nanostructured metals and alloys, produced by SPD[J].Kovove Materialy, 2011, 49 (1) :1.

[25] Xu C, Xu X J, Ma W H, Dong X F, Lu Y D, Guo Y F.Microstructure and strengthening mechanism of Al-1.5%Mg single-phase alloy by recovery annealing[J].Chinese Journal of Rare Metals, 2017, 41 (3) :239. (徐驰, 许晓静, 马文海, 董小飞, 卢予东, 郭云飞.回复态Al-1.5%Mg单相合金大变形组织与强化机制[J].稀有金属, 2017, 41 (3) :239.)

[26] Tang F, Hagiwara M, Schoenung J M.Microstructure and tensile properties of bulk nanostructured Al-5083/Si Cp, composites prepared by cryomilling[J].Materials Science&Engineering A, 2005, 407 (1-2) :306.

[27] Li J L, Li S S, Fan Z Z, Wei L, Xiong Y C.Preparation of super high strength bulk nanocrystalline Al by cryomilling[J].Chinese Journal of Nonferrous Metals, 2013, 23 (5) :1182.

[28] Haghayeghi R, Kapranos P.Microstructure evolution and mechanical properties of Al-6%Mg alloys processed by equal channel angular pressing[J].Materials Science&Engineering A, 2015, 642:84.

[29] Zha M, Li Y, Mathiesen R H, Bjrge R, Roven H J.Microstructure evolution and mechanical behavior of a binary Al-7Mg alloy processed by equal-channel angular pressing[J].Acta Materialia, 2014, 84:42.

[30] Nikulin I, Kipelova A, Malopheyev S, Kaibyshev R.Effect of second phase particles on grain refinement during equal-channel angular pressing of an Al-Mg-Mn alloy[J].Journal of Materials Science, 2012, 60 (2) :487.

[31] Jiang T H.Microstructure and Mechanical Properties of Nanostructured Al-Mg Alloys Processed by High Pressure Torsion[D].Zhenjiang:Jiangsu University, 2014.29. (蒋婷慧.高压扭转大塑性变形纳米晶Al-Mg合金的微观结构及力学性能[D].镇江:江苏大学, 2014.29.)

[32] Xie X F.Study on Amorphization and Nanoindentation of Al-Mg Alloys Processed by High Pressure Torsion[D].Zhenjiang:Jiangsu University, 2015.31. (谢学锋.高压扭转Al-Mg合金的非晶化及纳米压痕研究[D].镇江:江苏大学, 2015.31.)

[33] Li J L, Zhang K, Xiong Y C.Advances in research on nanocrystlline Al-Mg alloys with high performance[J].Journal of Materials Engineering, 2013, (11) :75. (李炯利, 张坤, 熊艳才.高性能纳米晶Al-Mg合金的研究进展[J].材料工程, 2013, (11) :75.)

[34] Wang H, Liu M P, Tang K, Li Y C, Wei J T, Jiang K, Jiang J W.Advances in ultrafine-grained and nanocrystalline Al-Mg aluminum alloys processed by severe plastic deformation[J].Materials Review, 2016, 30 (15) :119. (王辉, 刘满平, 唐恺, 李毅超, 韦江涛, 姜奎, 江家威.大塑性变形制备超细晶/纳米晶Al-Mg铝合金的研究进展[J].材料导报, 2016, 30 (15) :119.)

[35] Yi G, Cullen D A, Littrell K C, Golumbfskie W, Sundberg E, Free M L.Characterization of Al-Mg alloy aged at low temperatures[J].Metallurgical and Materials Transactions A, 2017, 48 (4) :2040.

[36] Meng C Y, Zhang D, Cui H, Zhuang L, Zhang J.Mechanical properties, intergranular corrosion behavior and microstructure of Zn modified Al-Mg alloys[J].Journal of Alloys and Compounds, 2014, 617:925.

[37] Meng C Y, Zhang D, Zhuang L, Zhang J.Correlations between stress corrosion cracking, grain boundary precipitates and Zn content of Al-Mg-Zn alloys[J].Journal of Alloys and Compounds, 2016, 655:178.

[38] Unocic K, Mills M, Daehn G, Kobe P.Microstructural analysis of 5xxx series aluminum alloys for optimal strength and corrosion resistance[J].Microscopy and Microanalysis, 2005, 11 (502) :700.

[39] Tuan N Q, Alves A C, Toptan F, Lopes A B, Pinto A M P.The effect of Sc and Yb microalloying additions and aged-hardening heat treatment on corrosion behavior of Al-Mg alloys[J].Materials and Corrosion, 2016, 67 (1) :60.

[40] Zhang X, Wang Z, Zhou Z, Xu J.Effects of magnetic field and rare earth addition on corrosion behavior of Al-3.0 wt.%Mg alloy[J].Journal of Alloys and Compounds, 2017, 698:241.

[41] Huang Y, Li Y, Xiao Z, Liu Y, Huang Y T, Ren X W.Effect of homogenization on the corrosion behavior of5083-H321 aluminum alloy[J].Journal of Alloys and Compounds, 2016, 673:73.

[42] Oguocha I N A, Adigun O J, Yannacopoulos S.Effect of sensitization heat treatment on properties of Al-Mg alloy AA5083-H116[J].Journal of Materials Science, 2008, 43 (12) :4208.

[43] Birbilis N, Zhang R, Knight S, Holtz R, Goswami R, Davies C.A survey of sensitization in 5xxx series alu-minum alloys[J].Corrosion-Houston Tx, 2015, 72 (2) :144.

[44] Engler O, Hentschel T, Brinkman H J.Correlation of texture and intergranular corrosion in Al-Mg 5xxx series alloys[A].Iop Conference Series Materials Science&Engineering[C].Bonn, 2015, 12111.

[45] Huang G, Li X, Xing L.Corrosion behavior of low pressure cold sprayed Zn-Ni composites coating[J].Anti-Corrosion Methods and Materials, 2016, 63 (6) :461.

[46] Wang Y, Pan Q L, Peng H, Li C, Chen Q, Yin Z M.Effect of annealing temperature on mechanical and corrosion properties of Al-Mg-Sc alloy[J].Journal of Material Science&Engineering, 2012, 30 (6) :913. (王迎, 潘清林, 彭虹, 李晨, 陈琴, 尹志民.退火温度对铝镁钪合金力学和腐蚀性能的影响[J].材料科学与工程学报, 2012, 30 (6) :913.)

[47] Kubota M, Muddle B C.Effect of trace additions of Ag on precipitation in Al-Mg alloys[J].Materials Transactions, 2005, 46 (12) :2968.

[48] Kubota M.Characterisation of precipitate microstructures of natural and artificial ageing in Al-Mg (-Ag) alloys[J].Materials transactions, 2005, 46 (2) :241.

[49] Polmear I J, Sargant K R.Enhanced age-hardening in aluminium-magnesium alloys[J].Nature, 1963, 200 (4907) :669.

[50] Kubota M, Nie J F, Muddle B C.Identification of quasicrystalline particles in an isothermally aged Al-10Mg-0.5 Ag alloy[A].Materials Science Forum[C].Trans.Tech.Publications, 2006, 561.

[51] Kubota M.Observation of beta phase particles in an isothermally aged Al-10 mass%Mg alloy with and without0.5 mass%Ag[J].Materials Transactions, 2008, 49 (2) :235.

[52] Wheeler M J, Blankenburgs, Amp G, Staddon R W.Evidence for a ternary phase in the aluminium-magnesium-silver system[J].Nature, 1965, 207 (4998) :746.

[53] Kubota M, Nie J F, Muddle B C.Characterisation of quasicrystalline particles in an isothermally aged Al-10Mg-0.5 Ag (mass%) alloy[J].Materials Transactions, 2005, 46 (6) :1278.

[54] Kubota M, Nie J F, Muddle B C.Identification of metastable rod-like particles in an isothermally aged Al-10Mg-0.5 Ag (mass%) alloy[J].Materials Transactions, 2005, 46 (6) :1288.

[55] Zhang D, Hou S L, Zhang J S, Zhuang L Z, Liu J C.Preparation method of Al-Mg-Zn alloy and alloy sheet[P].China:CN 104313413B, 2016. (张迪, 侯胜利, 张济山, 庄林忠, 刘君城.一种Al-Mg-Zn系合金及其合金板材的制备方法[P].中国:CN 104313413B, 2016.)